Sponge brick produced from aluminum ash and preparation process thereof

A preparation process, sponge brick technology, applied in the field of building materials, to achieve efficient utilization, solve the problem of fluorine pollution, and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

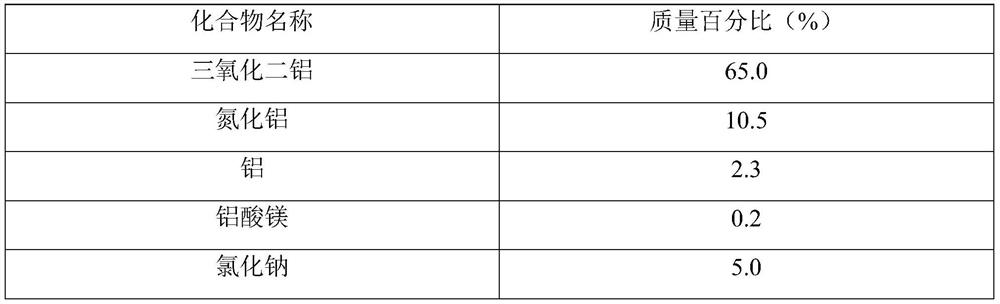

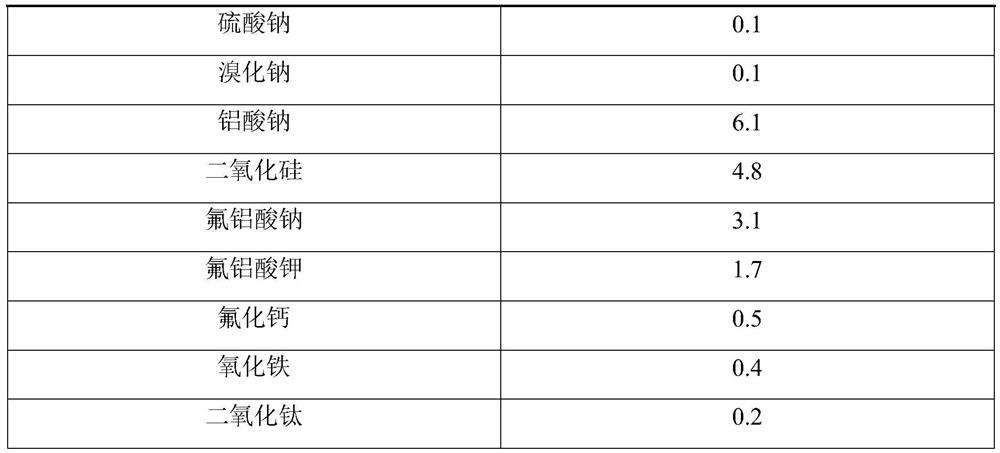

Method used

Image

Examples

Embodiment 1

[0031] The preparation technology of the sponge brick that described aluminum ash is produced comprises the following steps:

[0032] (1) 55% of aluminum ash, 15% of 200 mesh potassium albite tailings fine powder, 12% coal gangue particles, 15% high temperature clay and 3% mass concentration of 28% water glass solution are mixed uniformly to obtain a sponge. Mixture;

[0033] (2) Fill the sponge to the mixture in the metal brick mold of the press, and pressurize it once at 35MPa;

[0034] (3) The adobe after pressing is dried at 110°C for 9 hours, then fired at 1100°C for 50 minutes, and cooled to obtain the product.

Embodiment 2

[0036] The preparation technology of the sponge brick that described aluminum ash is produced comprises the following steps:

[0037] (1) Mix 65% aluminum ash, 10% 200 mesh potassium albite tailings fine powder, 10% coal gangue particles, 10% high temperature clay and 5% mass concentration of 30% water glass solution to obtain a sponge and mix material;

[0038] (2) Fill the sponge to the mixture in the metal brick mold of the press, and pressurize it once at 40MPa;

[0039] (3) The adobe after pressing is dried at 110°C for 9 hours, then fired at 1100°C for 50 minutes, and cooled to obtain the product.

Embodiment 3

[0041] The preparation technology of the sponge brick that described aluminum ash is produced comprises the following steps:

[0042] (1) 70% aluminum ash, 10% 200 mesh potassium albite tailings fine powder, 6% coal gangue particles, 7% high temperature clay and 7% mass concentration of 25% water glass solution are mixed evenly to obtain a sponge and mix material;

[0043] (2) Fill the sponge to the mixture in the metal brick mold of the press, and pressurize it once at 50MPa;

[0044] (3) The adobe after pressing is dried at 110°C for 9 hours, then fired at 1100°C for 50 minutes, and cooled to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com