Preparation method of modified zirconium silica sol ceramic polishing liquid

A technology of ceramic polishing and silica sol, which is applied in the field of ceramic material manufacturing, can solve problems such as easy condensation, expensive cerium oxide, and unfavorable marketization, so as to increase water resistance and wear resistance, reduce production costs, and increase polishing brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

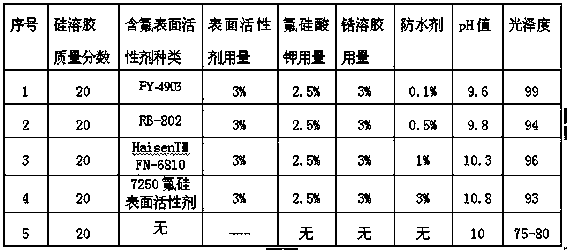

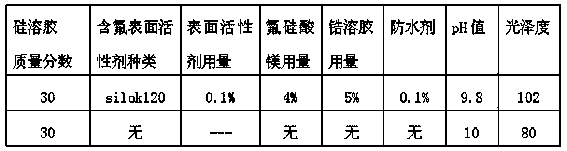

Examples

Embodiment 1

[0022] A method for preparing a modified zirconium silica sol ceramic polishing liquid, which is carried out according to the following steps:

[0023] 1): Add fluorine-containing surfactant dropwise to silica sol with a particle size of 5-20nm to form system A; the mass fraction of silica in the silica sol is 10-30%, and the pH of the silica sol is 9.5-10.5;

[0024] Calculated by weight, the content of silica sol is 95-99.9% of system A, and the content of fluorine-containing surfactant is 0.1-5% of system A;

[0025] Among them, the fluorosurfactant is preferably a water-soluble fluorosurfactant, more preferably an anionic fluorosurfactant or a nonionic fluorosurfactant, such as anionic fluorosurfactant AC-703, silok100, zonyl-1033D , RB-802, non-ionic fluorosurfactant HaisenTM FN-6810, RB-5100, FY-4902, FY-4903, silok120, AKS / 4046, 7250 fluorosilicone surfactant;

[0026] The addition of fluorine-containing surfactant is beneficial to improve the dispersion of silica sol....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com