Fluorosilicate red fluorescent powder and preparation method thereof

A red phosphor, fluorosilicate technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of high equipment requirements, harsh preparation conditions, high energy consumption, and achieve stable physical and chemical properties, luminous Stable performance and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

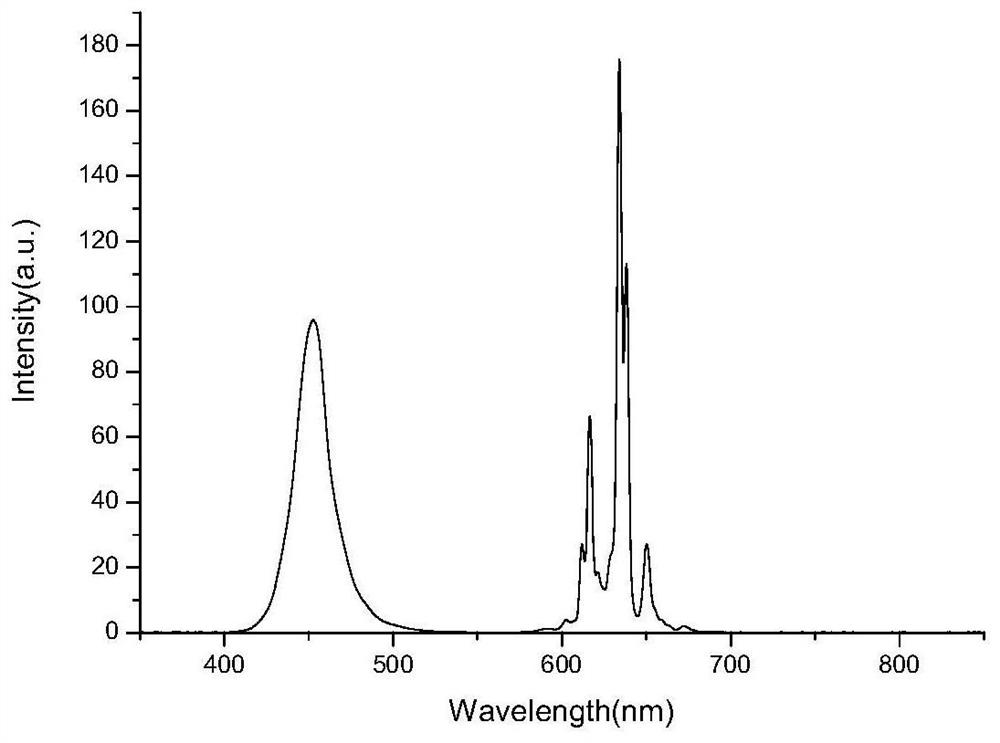

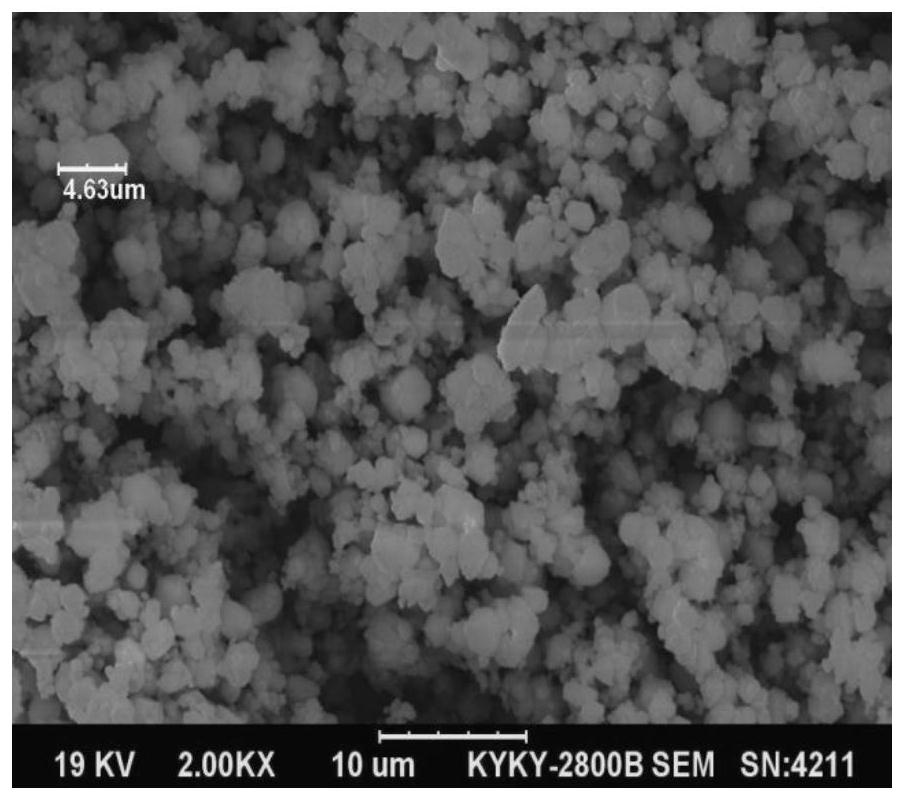

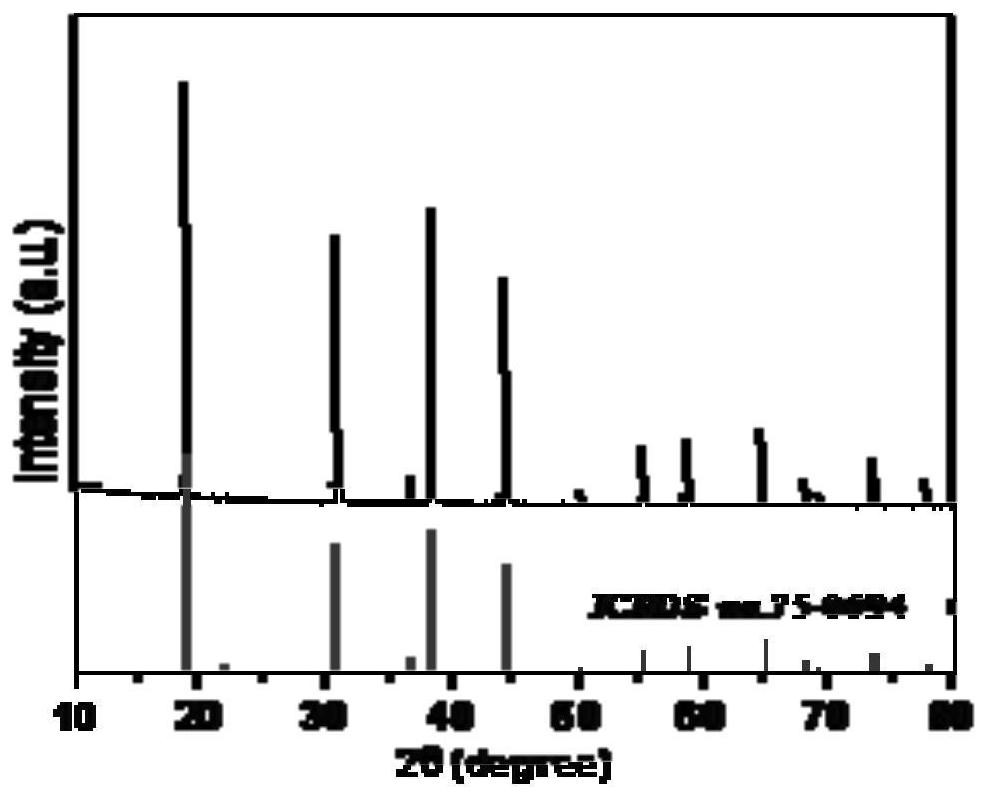

[0024] The chemical formula of fluorosilicate red phosphor is Ca 0.6 SiO 2 f 2 :0.4Mn 2+ , prepared by the following steps:

[0025] (1) According to the chemical formula Ca 0.6 SiO 2 f 2 :0.4Mn 2+ The stoichiometric ratio of raw materials was weighed and mixed with calcium fluoride, potassium fluoride, silicon dioxide, oxalic acid, and manganese dioxide, stirred in ethanol, filtered, dried at 100°C, and sieved;

[0026] (2) adding 0.3% of the raw material weight of ammonium fluoride and ammonium chloride for grinding, grinding, mixing and sieving to obtain a mixture, wherein the weight ratio of ammonium fluoride and ammonium chloride is 4:1;

[0027] (3) The mixture obtained in step (2) is packed into a crucible, and heated in a high-temperature furnace under H 2 and N 2 Sintering in reducing atmosphere and 850°C for 5 hours, cooling to obtain manganese-doped fluorosilicate red phosphor Ca 0.6 SiO 2 f 2 :0.4Mn 2+ .

Embodiment 2

[0029] The chemical formula of fluorosilicate red phosphor is Ca 0.83 SiO 2 f 2 :0.17Mn 2+ , prepared by the following steps:

[0030] (1) According to the chemical formula Ca 0.83 SiO 2 f 2 :0.17Mn 2+ The stoichiometric ratio of raw materials was weighed and mixed with calcium fluoride, potassium fluoride, silicon dioxide, oxalic acid, and manganese dioxide, stirred in ethanol, filtered, dried at 100°C, and sieved;

[0031] (2) adding 0.4% of the weight of the raw material to ammonium fluoride and ammonium chloride for grinding, grinding, mixing and sieving to obtain a mixture, wherein the weight ratio of ammonium fluoride and ammonium chloride is 6:1;

[0032] (3) The mixture obtained in step (2) is packed into a crucible, and heated in a high-temperature furnace under H 2 and N 2 Sintering under reducing atmosphere and 950°C for 4 hours, cooling to obtain manganese-doped fluorosilicate red phosphor Ca 0.83 SiO 2 f 2 :0.17Mn 2+ .

Embodiment 3

[0034] The chemical formula of fluorosilicate red phosphor is Ca 0.44 SiO 2 f 2 :0.56Mn 2+ , prepared by the following steps:

[0035] (1) According to the chemical formula Ca 0.44 SiO 2 f 2 :0.56Mn 2+ The stoichiometric ratio of raw materials was weighed and mixed with calcium fluoride, potassium fluoride, silicon dioxide, oxalic acid, and manganese dioxide, stirred in ethanol, filtered, dried at 100°C, and sieved;

[0036] (2) adding 0.2% of the weight of the raw material to ammonium fluoride and ammonium chloride for grinding, grinding, mixing and sieving to obtain a mixture, wherein the weight ratio of ammonium fluoride and ammonium chloride is 8.4:1;

[0037] (3) The mixture obtained in step (2) is packed into a crucible, and heated in a high-temperature furnace under H 2 and N 2 Sintering under reducing atmosphere and 1000°C for 6 hours, cooling to obtain manganese-doped fluorosilicate red phosphor Ca 0.44 SiO 2 f 2 :0.56Mn 2+ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com