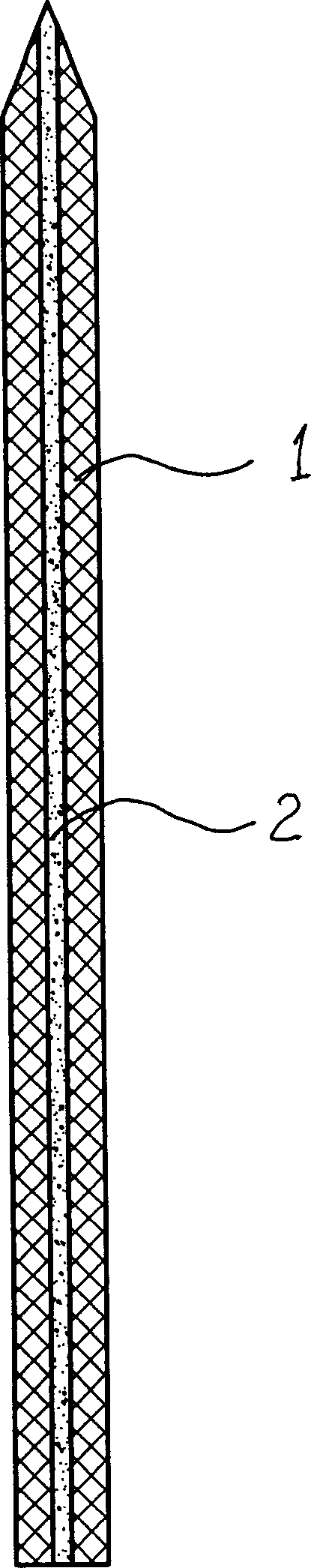

Medical carbon rod and its prepn. method

A carbon rod and rod body technology, applied in the field of medical carbon rod and its preparation, can solve the problems of inconvenient use and small therapeutic dose, and achieve the effects of convenient use and replacement and high therapeutic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of hollow rod

[0035] Get 100 kilograms of carbon black and 20 kilograms of coal tar pitch and mix, and make stick;

[0036] Put the rod-shaped body into a roasting tank filled with roasting powder, and then put the roasting tank into a roasting kiln for roasting—that is, it takes 3 days to burn to 650°C, and then burns to 800°C in 3 days. The roasting tank with rods is taken out from the kiln, buried in sand and air-isolated and lowered to normal temperature (20-30°C); open the roasting tank, take out the rods, and place them in a rotating drum to remove the roasting on the rods. powder gravel;

[0037] Take out the rod-shaped body from which the baked powder and gravel have been removed, use a crusher to crush the rod-shaped body into particles with a diameter not greater than 5 mm, and add 20 kg of graphite to the rod-shaped body particles, and grind them together to form a 200-mesh mixed fine powder;

[0038] Add the above-mentioned mixed micropow...

Embodiment 2

[0047] (1) Preparation of hollow rod

[0048] Get 100 kilograms of carbon black and 50 kilograms of coal tar pitch and mix, and make flake;

[0049] Put the flakes into a roasting tank filled with roasting powder, put the roasting tank into a roasting kiln and bake it—that is, burn it to 550°C in 24 hours, and then burn it to 1050°C in 96 hours. The roasting tank with flakes is taken out from the roasting kiln, buried in sand and isolated from the air, and lowered to normal temperature (20-30°C); open the roasting tank, take out the flakes, and place them in a rotating drum to remove the flakes. baking powder grit;

[0050] Take out the flakes from which the baked powder has been removed, use a crusher to crush the flakes into particles with a diameter not greater than 5 mm, add 10 kg of graphite to the flake particles, and grind them together to form a 100-mesh mixed fine powder ;

[0051] Add the above-mentioned mixed fine powder into a kneader with a temperature of 200°C...

Embodiment 3

[0060] (1) Preparation of hollow rod

[0061] Get 100 kilograms of carbon black and 40 kilograms of coal tar pitch and mix, and make stick;

[0062] Put the rod-shaped body into a roasting pot with roasting powder, put the roasting pot into a roasting kiln and roast it—that is, burn it to 600°C in 48 hours, and then burn it to 1100°C in 48 hours. The rod-shaped roasting tank is taken out of the roasting kiln, buried in sand and isolated from the air, and lowered to normal temperature (20-30°C); open the roasting tank, take out the slice, and place it in a rotating drum to remove the roasted powder and gravel on the rod-shaped body ;

[0063] Take out the rod-shaped body from which the baked powder and gravel have been removed, use a crusher to crush the rod-shaped body into particles with a diameter not greater than 5 mm, add 30 kg of graphite to the rod-shaped body particles, and grind them together to form a 150-mesh mixed fine powder;

[0064] Add the above-mentioned mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com