Refining agent for aluminum alloy containing high proportion of returned materials and its application method

A refining agent, aluminum alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of deterioration of casting performance, poor purification effect of melt, etc., to improve yield, easy to use, degassing and degassing Excellent effect of cleaning slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Preparation of refining agent:

[0061] The step of preparing refining agent of the present invention has:

[0062] Step A, according to the target composition of refining agent, NaCl, Na 3 AlF 6 , Al-10Nb and Al 2 Mix Cu, stir evenly, put it into a melting furnace, heat up at a rate of 20°C / min, when the temperature rises to 800-820°C, keep it warm for 10 minutes, turn off the power, cool the mixture to room temperature, take it out and break it into 1-5mm granules to make a premix;

[0063] Step B, according to the target composition of refining agent, the premix that step A obtains is mixed with MnCl 2 , MgCl 2 , CaF 2 , Zn, RE and binder are mixed evenly, and pressed to a density greater than 3g / cm by using a hydraulic press under a pressure parameter of 20-30KN 3 And a round ingot with a mass of 0.25 kg is obtained to obtain a round ingot-shaped refining agent.

[0064] The target composition of described refining agent is:

[0065]

[0066] How to use ...

Embodiment 1

[0074] The preparation steps of embodiment 1 refining agent have:

[0075] Step A, according to the target composition of the refining agent, the weighed NaCl, Na 3 AlF 6 , Al10Nb and Al 2 Mix Cu, stir evenly, put it into a melting furnace, heat up at a rate of 20°C / min, when the temperature rises to 810°C, keep it warm for 10 minutes, turn off the power, cool the mixture to room temperature, take it out and break it into 1-5mm particles , to prepare the premix;

[0076] Step B, according to the target composition of refining agent, the premix that step A obtains is mixed with MnCl 2 , MgCl 2 , CaF 2 , Zn, RE (that is, La, Ce and Nd) and the binder are mixed evenly, and the YL41 hydraulic press is used to compress the density to 3.2g / cm2 under the pressure parameter of 25KN. 3 And a round ingot with a mass of 0.25 kg is obtained to obtain a round ingot-shaped refining agent.

[0077] The target composition of the refining agent of embodiment 1 is:

[0078]

[0079] ...

Embodiment 2

[0098] The preparation steps of embodiment 2 refining agent have:

[0099] Step A, according to the target composition of the refining agent, the weighed NaCl, Na 3 AlF 6 , Al10Nb and Al 2 Mix Cu, stir evenly, put it into a melting furnace, heat up at a rate of 20°C / min, when the temperature rises to 800°C, keep it warm for 10 minutes, turn off the power, cool the mixture to room temperature, take it out and break it into 1-5mm particles , to prepare the premix;

[0100] Step B, according to the target composition of refining agent, the premix that step A obtains is mixed with MnCl 2 , MgCl 2 , CaF 2 , Zn, RE (that is, La, Ce and Er) and the binder are mixed evenly, and the YL41 hydraulic press is used to compress the density to 3.1g / cm under the pressure parameter of 24KN. 3 And a round ingot with a mass of 0.25 kg is obtained to obtain a round ingot-shaped refining agent.

[0101] The target composition of the refining agent of embodiment 2 is:

[0102]

[0103] E...

PUM

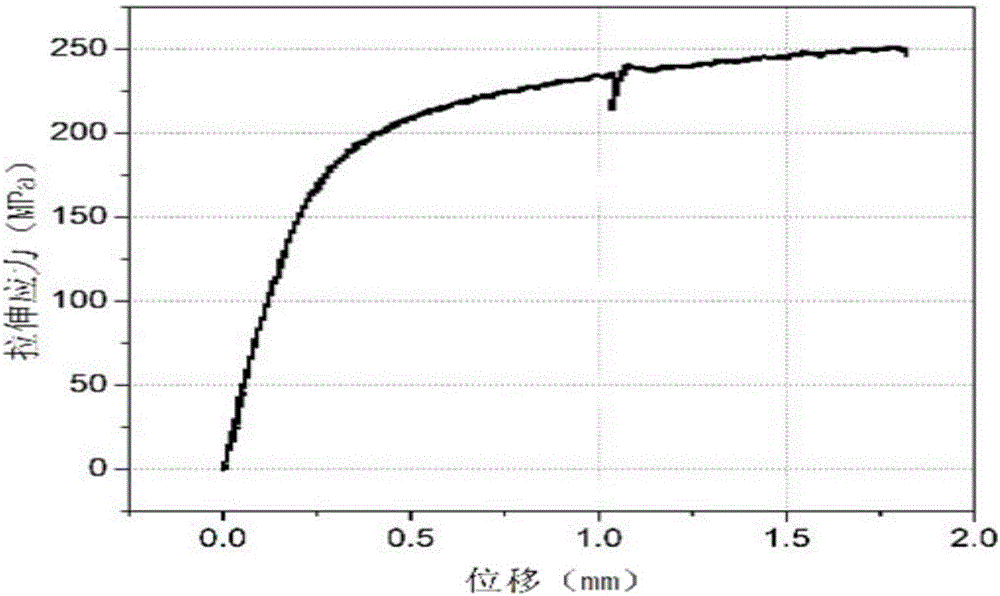

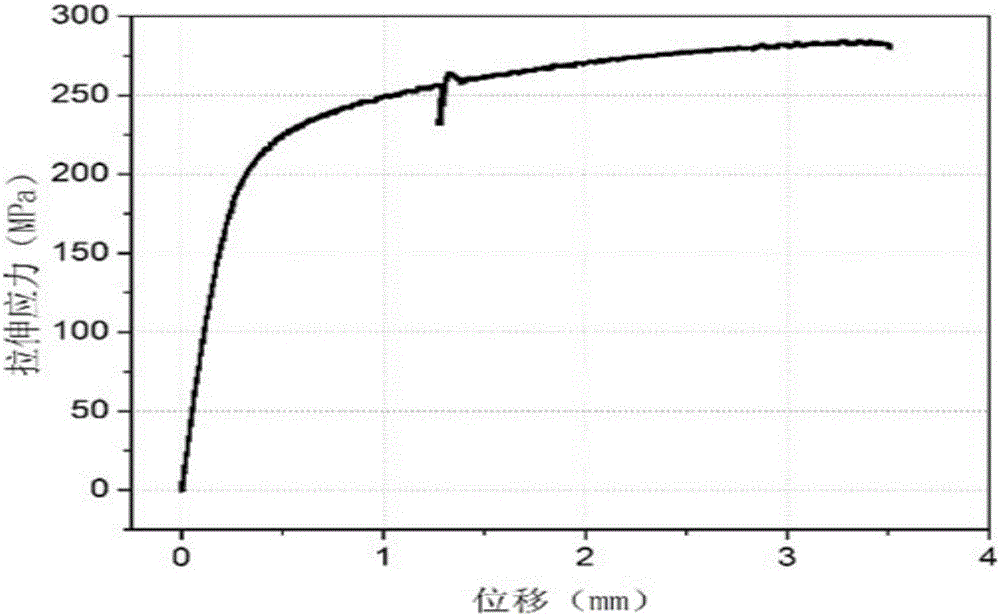

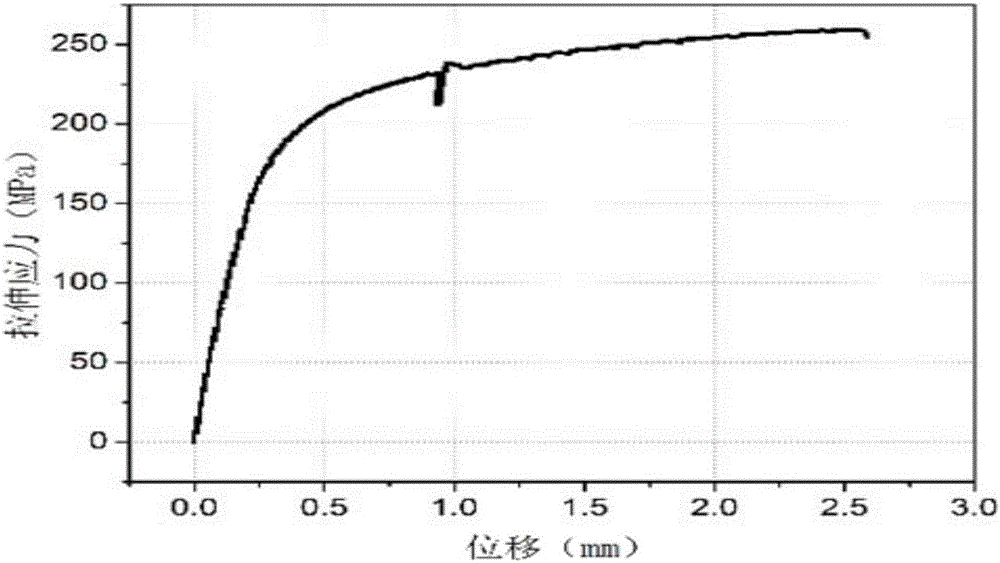

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com