Catalyst for preparing anisole from phenol and dimethyl carbonate

A dimethyl carbonate and catalyst technology, applied in the chemical field, can solve the problems of limiting the conversion rate of raw materials and production and processing capacity, and achieve good industrial application prospects, expand the spacing between laminates, and have the effect of no equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In beaker A, make 100ml solution A with 0.12mol magnesium nitrate hexahydrate and 0.03mol aluminum nitrate nonahydrate with deionized water, and make 100ml solution with 0.255mol sodium hydroxide and 0.0648mol anhydrous sodium carbonate with deionized water B, add 100ml deionized water to beaker C. After stirring and dissolving, use a peristaltic pump to pump solution A and solution B into beaker C at a certain rate. After the end, continue to stir the solution in beaker C at room temperature for 10 h, and maintain the pH between 9-11. After the stirring, the slurry in the beaker C was filtered and washed with deionized ion until neutral. Dry the obtained precipitate in an oven at 110°C for 12 hours, and the product is a hydrotalcite-like material, which is denoted as Mg4Al-LDH. Reserved for subsequent experiments.

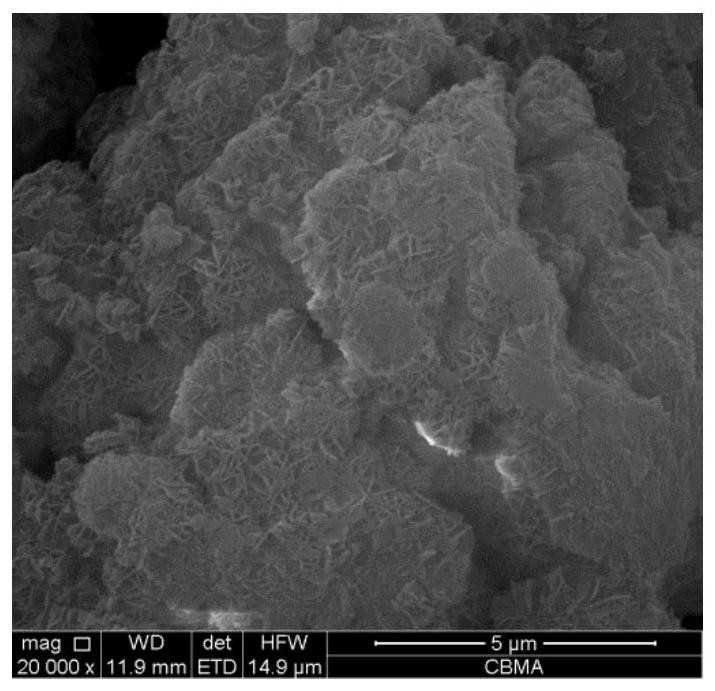

[0030] Put the Mg4Al-LDH into the muffle furnace for calcination at a heating rate of 3°C / min, from room temperature to 450°C and then calcine for 5h. ...

Embodiment 2

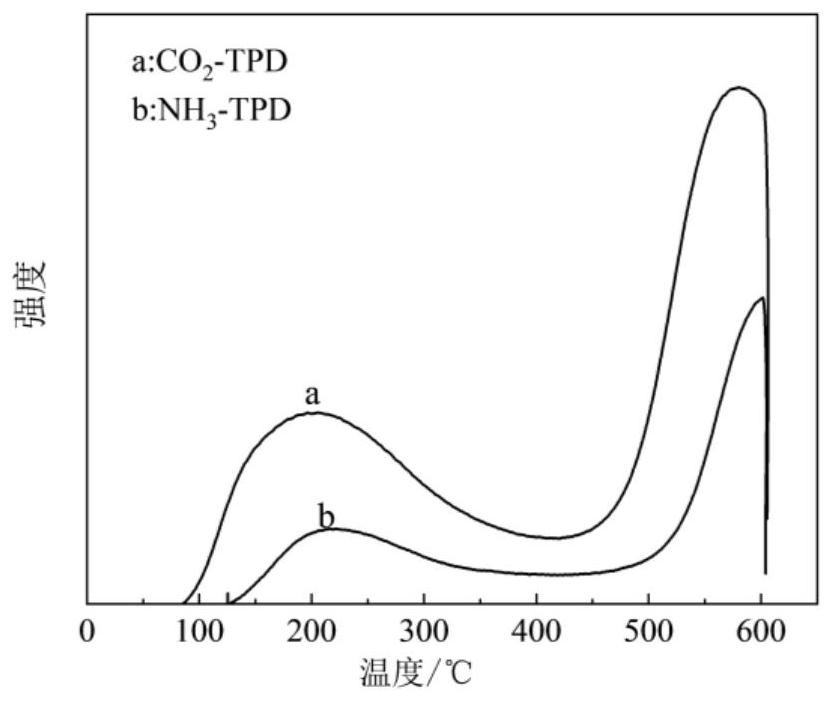

[0033] Take 1g of Mg4Al-LDH and add 50ml of 0.1mol / L ammonium fluoroaluminate solution. Stirring was carried out at room temperature for 6h. After the stirring is finished, filter with suction, wash, dry, and roast, and the product is marked as Mg4Al-LDO-0.1FAl. A 0.1 g sample was taken for gas-phase alkylation of phenol and dimethyl carbonate under the same reaction conditions as in Example 1. The product was analyzed by gas chromatography, and the conversion rate was 99.22%, and the selectivity was 69.98%. The acid-base TPD of the obtained catalyst is shown in figure 2 , the amount of weak base is 0.21mmol / g, the amount of strong base is 0.408mmol / g, the amount of weak acid is 0.084mmol / g, and the amount of strong acid is 0.305mmol / g.

Embodiment 3

[0035]Take 1g of Mg4Al-LDH, add 50ml of 0.025mol / L ammonium fluoroaluminate solution, stir at room temperature for 6h, then suction filter, wash, dry, and roast. The product is marked as Mg4Al-LDO-0.025FAl. A 0.1 g sample was taken for the gas-phase alkylation reaction of phenol and dimethyl carbonate. The reaction conditions were the same as in Example 1. The product was analyzed by gas chromatography, and the conversion rate was 99.04%, and the selectivity was 83.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com