A kind of solid catalyst for acetone self-condensation reaction and its preparation method and application

A solid catalyst and self-condensation technology, which is applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve the problems of harsh preparation conditions, poor catalyst repeatability, and poor catalyst strength of the co-precipitation method, and achieve the goal of promoting Bonding, enhanced activity and selectivity, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

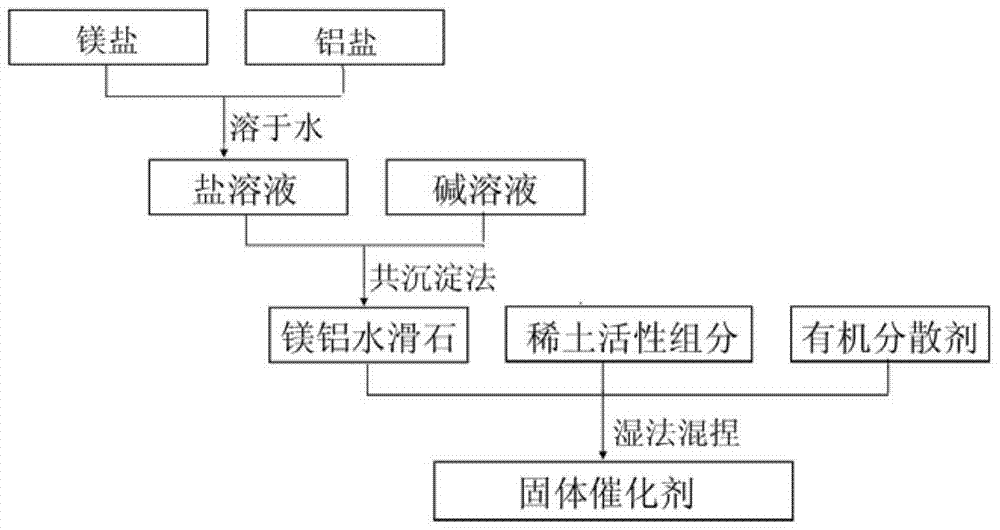

[0034] In this example, the catalyst precursor is prepared by co-precipitation method, and then the solid catalyst is prepared by wet kneading, such as figure 1 As shown, the specific process of the preparation method is as follows:

[0035] 1. Preparation of mixed salt solution:

[0036] Weigh 666.7g Mg(NO 3 ) 2 ·6H 2 O and 322.2g Al(NO 3 ) 3 9H 2 O crystals, add deionized water, stir to dissolve the salt completely, and prepare a 1000ml mixed salt solution;

[0037] 2. Preparation of alkaline solution:

[0038] Take a certain amount of sodium hydroxide, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 3.8mol / L, then weigh a certain amount of sodium carbonate, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 1.0mol / L. 2 CO 3 solution.

[0039] 3. Preparation of magnesium aluminum hydrotalcite:

[0040] Add 500ml deionized water into the reaction kettle, after heating to 60°C, mix salt solution an...

Embodiment 2

[0048] In this example, the catalyst precursor is prepared by the co-precipitation method, and then the solid catalyst is prepared by wet kneading. The specific process is as follows:

[0049] 1. Preparation of mixed salt solution:

[0050] Weigh 650.5g Mg(NO 3 ) 2 ·6H 2 O and 310.2g Al(NO 3 ) 3 9H 2 O crystals, add deionized water, stir to dissolve the salt completely, and prepare a 1000ml mixed salt solution;

[0051] 2. Preparation of alkaline solution:

[0052] Take a certain amount of sodium hydroxide, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 3.8mol / L, then weigh a certain amount of sodium carbonate, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 1.0mol / L. 2 CO 3 solution.

[0053] 3. Preparation of magnesium aluminum hydrotalcite:

[0054] Add 500ml deionized water into the reaction kettle, after heating to 65°C, mix salt solution and alkali solution (NaOH solution and NaOH solution...

Embodiment 3

[0060] In this example, the catalyst precursor is prepared by the co-precipitation method, and then the solid catalyst is prepared by wet kneading. The specific process is as follows:

[0061] 1. Preparation of mixed salt solution:

[0062] Weigh 700.4g Mg(NO 3 ) 2 ·6H 2 O and 352.1g Al(NO 3 ) 3 9H 2 O crystals, add deionized water, stir to dissolve the salt completely, and prepare a 1000ml mixed salt solution;

[0063] 2. Preparation of alkaline solution:

[0064] Take a certain amount of sodium hydroxide, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 3.8mol / L, then weigh a certain amount of sodium carbonate, dissolve it in deionized water, and prepare a NaOH solution with a concentration of 1.0mol / L. 2 CO 3 solution.

[0065] 3. Preparation of magnesium aluminum hydrotalcite:

[0066] Add 500ml deionized water into the reaction kettle, after heating to 50°C, mix salt solution and alkali solution (NaOH solution and NaOH solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com