Alpha, alpha-dimethyl benzyl alcohol hydrogenolysis catalyst and preparation method thereof

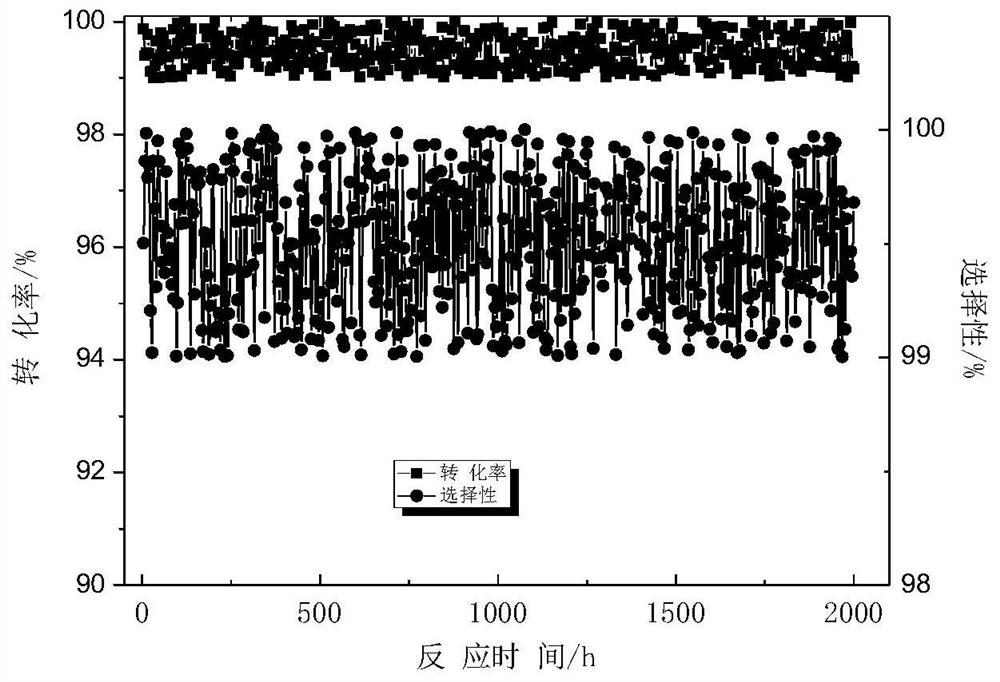

A technology of dimethyl benzyl alcohol and catalyst, which is applied in the field of catalysis, can solve problems such as insufficient stability, and achieve the effects of inhibiting the growth of crystal grains, increasing the degree of dispersion, and strengthening the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Dissolve 10.15g of niobium pentachloride in 11.3g of isopropanol and add it to 120g of aluminum isopropoxide after completely dissolving. At room temperature, use a high-frequency plasma generator with a radio frequency of 15MHz. The discharge parameters are voltage 100V, positive current (100±10) mA, gate current (50±10) mA, and processing vacuum 2Pa. The hydrolysis time is 2h.

[0083] Continue to use the plasma reactor to treat the reaction system, completely decompose the isopropanol, and the COD in the waste water is less than 50ppm. Carrier a was obtained by filtering, drying and calcining at 800°C for 6h.

[0084] Add 0.68L of water into the precipitation kettle, mix 151g of copper nitrate and 20.59g of 50% manganese nitrate aqueous solution, and then add them into the reactor in parallel with 15wt% sodium carbonate solution to obtain precursor b. The precipitation process temperature is controlled at 75°C, the precipitation time is 1h, the precipitation pH is ...

Embodiment 2

[0089] Dissolve 16.24g of niobium pentachloride in 18.0g of isopropanol, add it into 160g of aluminum isopropoxide after complete dissolution, heat to 40°C, and use a high-frequency plasma generator with a radio frequency of 14MHz. The discharge parameters are voltage 100V, positive current (100±10) mA, gate current (50±10) mA, and processing vacuum 50Pa. The hydrolysis time is 1.5h.

[0090] Continue to use the plasma reactor to treat the reaction system, completely decompose the isopropanol, and the COD in the waste water is less than 50ppm. Carrier a was obtained by filtering, drying and calcining at 900°C for 6h.

[0091] Add 0.62L of water into the precipitation kettle, mix 136g of copper nitrate and 20.59g of 50% manganese nitrate aqueous solution, and then add them into the reactor in parallel with 15wt% sodium carbonate solution to obtain precursor b. The precipitation process temperature is controlled at 65°C, the precipitation time is 1.5h, the precipitation pH is ...

Embodiment 3

[0096] Dissolve 16.24g of niobium pentachloride in 18.0g of isopropanol, add it into 160g of aluminum isopropoxide after completely dissolving, heat to 40°C, and use a high-frequency plasma generator with a radio frequency of 14MHz. The discharge parameters are voltage 100V, positive current (100±10) mA, gate current (50±10) mA, and processing vacuum 50Pa. The hydrolysis time is 1.5h.

[0097] Continue to use the plasma reactor to treat the reaction system, completely decompose the isopropanol, and the COD in the waste water is less than 50ppm. Carrier a was obtained by filtering, drying and calcining at 900°C for 6h.

[0098] 0.58L of water was added into the precipitation tank, 136g of copper nitrate and 8.23g of 50% manganese nitrate aqueous solution were mixed evenly, and then added to the reactor in parallel with 15wt% sodium carbonate solution to obtain precursor b. The precipitation process temperature is controlled at 65°C, the precipitation time is 1.5h, the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com