Patents

Literature

65results about How to "Control the rate of hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antifouling coating composition, antifouling coating film formed from the composition, coated object having the coating film on surface, and method of antifouling by forming the coating film

ActiveCN102171293AInhibit or prevent attachmentLittle temperature dependenceAntifouling/underwater paintsRosin coatingsMethacrylateDissolution

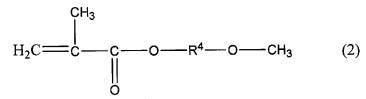

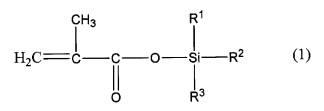

Provided is a composition for forming an antifouling coating film which, in seawater, can effectively have antifouling performance over long and has a small temperature dependence of coating film dissolution rate and which is highly safe for the environment. The antifouling coating composition is characterized by comprising (A) a triorganosilyl-ester-containing copolymer obtained from a mixture of (a) a triorganosilyl methacrylate monomer represented by general formula (1) (wherein R<1>, R<2>, and R<3> are the same or different and each represents an alpha-branched C3-6 alkyl or phenyl) and (b) a methoxyalkyl methacrylate monomer represented by general formula (2) (wherein R<4> represents a C2-4 alkylene), the content of the monomer (a) in the mixture being 45 to 65 wt.% and the total content of the monomer (a) and the monomer (b) in the mixture being 80 wt.% or higher, and (B) at least one copper salt selected from the copper salt of rosin and the copper salts of rosin derivatives.

Owner:NITTO KASEI CO LTD

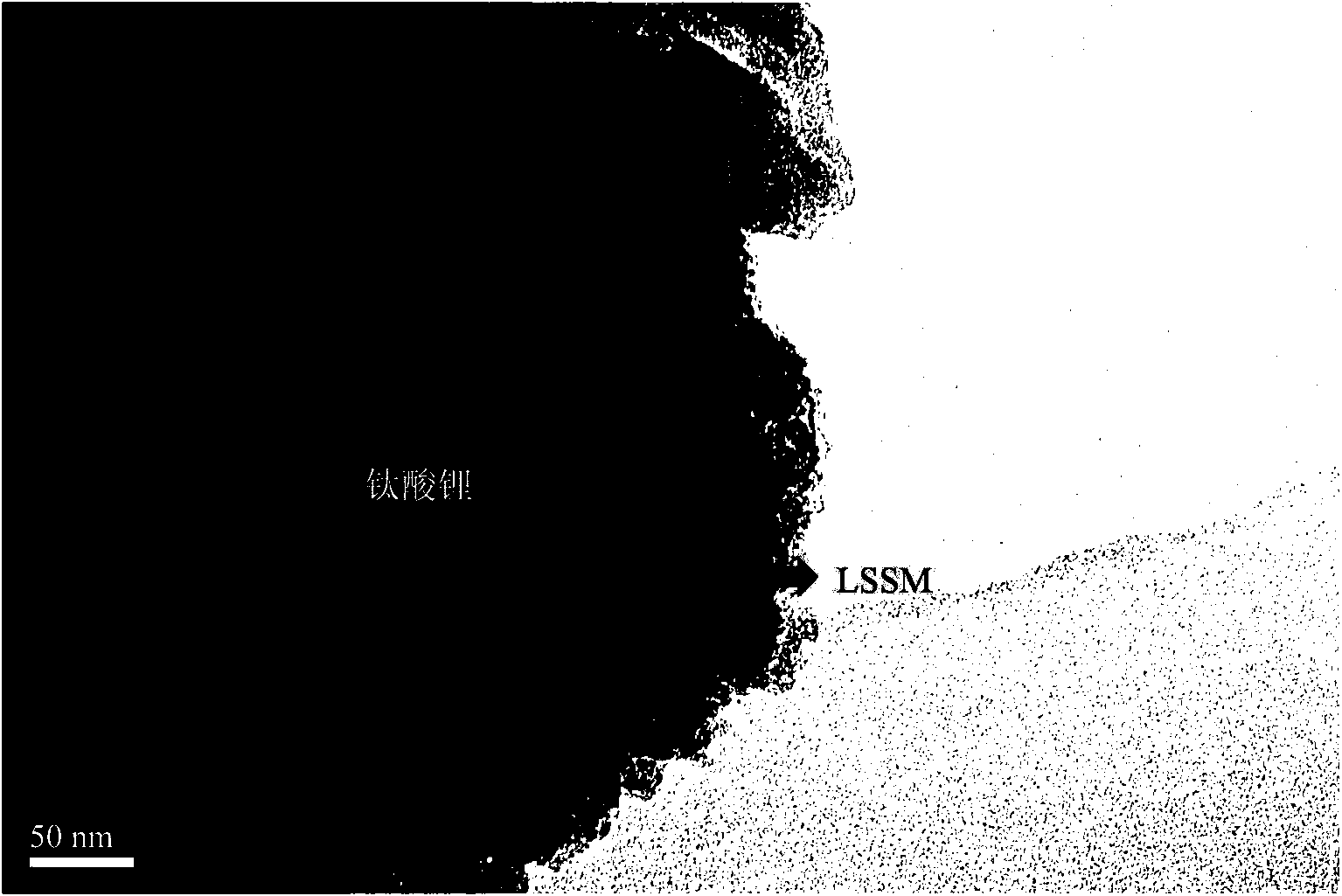

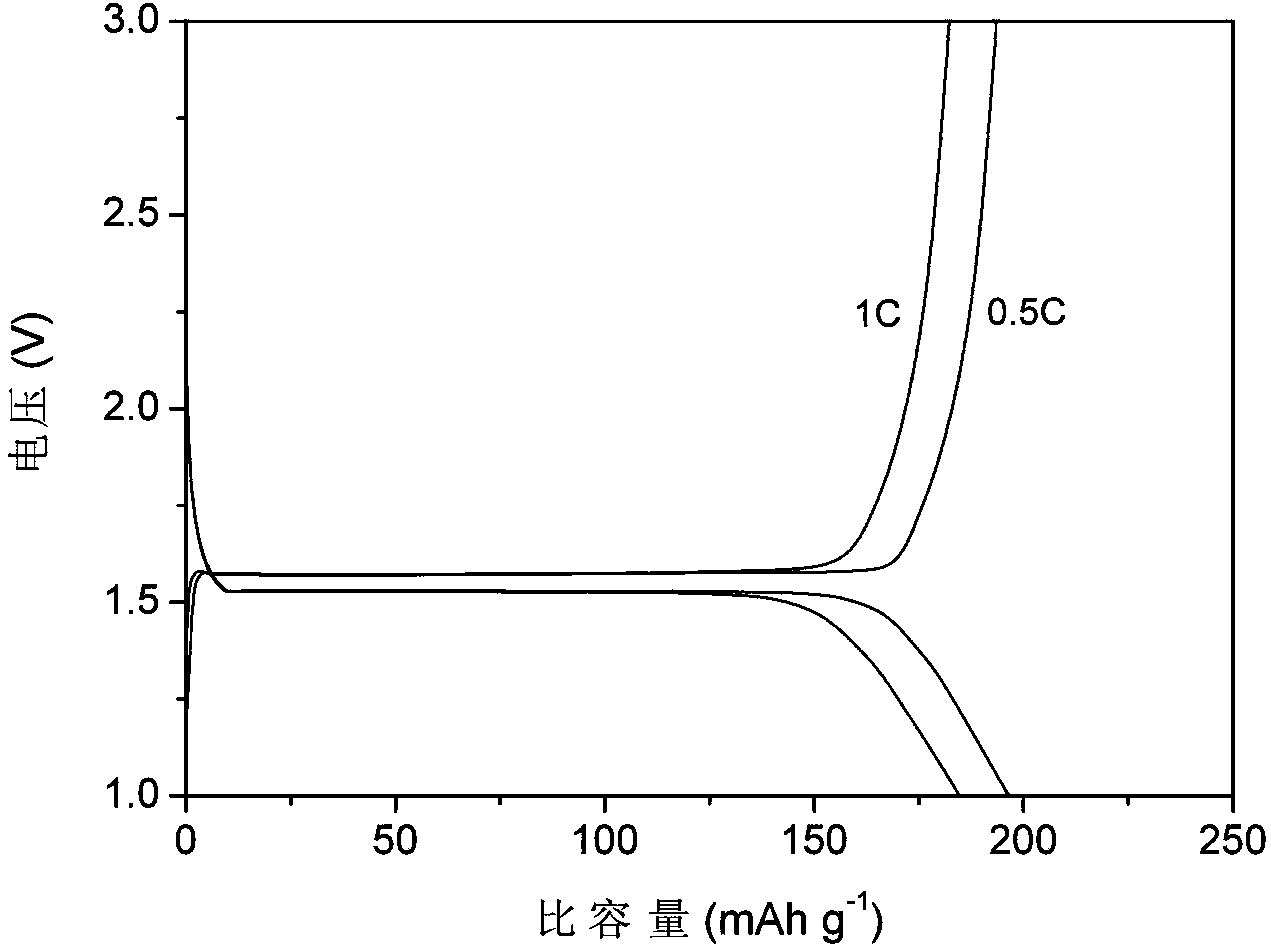

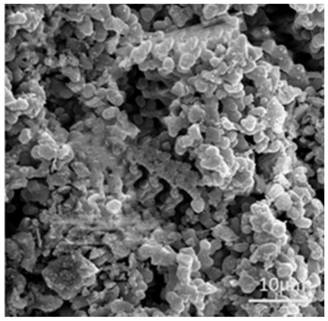

Preparation method of nanometer lithium titanate covered with double highly-conductive materials

InactiveCN103682301AImprove uniformityImprove particle agglomerationCell electrodesSecondary cellsAlcoholConductive materials

The invention provides a preparation method of nanometer lithium titanate covered with double highly-conductive materials. Through a sol-gel method, a La[0.5]Sr[0.5]Sc[0.1]Mn[0.9]O3 / C-Li4Ti5O12 anode material is prepared by a step of blending a soluble Li compound and a soluble Ti compound according to a molar ratio of Li / Ti=0.8-1.0, adding into an alcohol-water mixed solvent containing a hydrolysis inhibitor, adding a bi-component chelating agent, subjecting the bi-component chelating agent and metal ions to chelation under alkaline conditions, and stirring and heating to form gel; a step of dissolving a La compound, a Sr compound, a Sc compound and a Mn compound into an alcohol-water mixed solvent according to a molar ratio of La: Sr: Sc: Mn=0.5:0.5:0.1:0.9, adding the bi-component chelating agent, subjecting the bi-component chelating agent and metal ions to chelation under alkaline conditions, and stirring to form sol; a step of mixing the gel and the sol and stirring to form co-gel to obtain a sintering precursor; and a step of ball milling and calcining at 900-1150 DEG C for 5-15 h. The lithium titanate prepared by the method has good dispersion effects and excellent electrochemical performance, and the agglomeration phenomenon of nano-powder is improved significantly.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

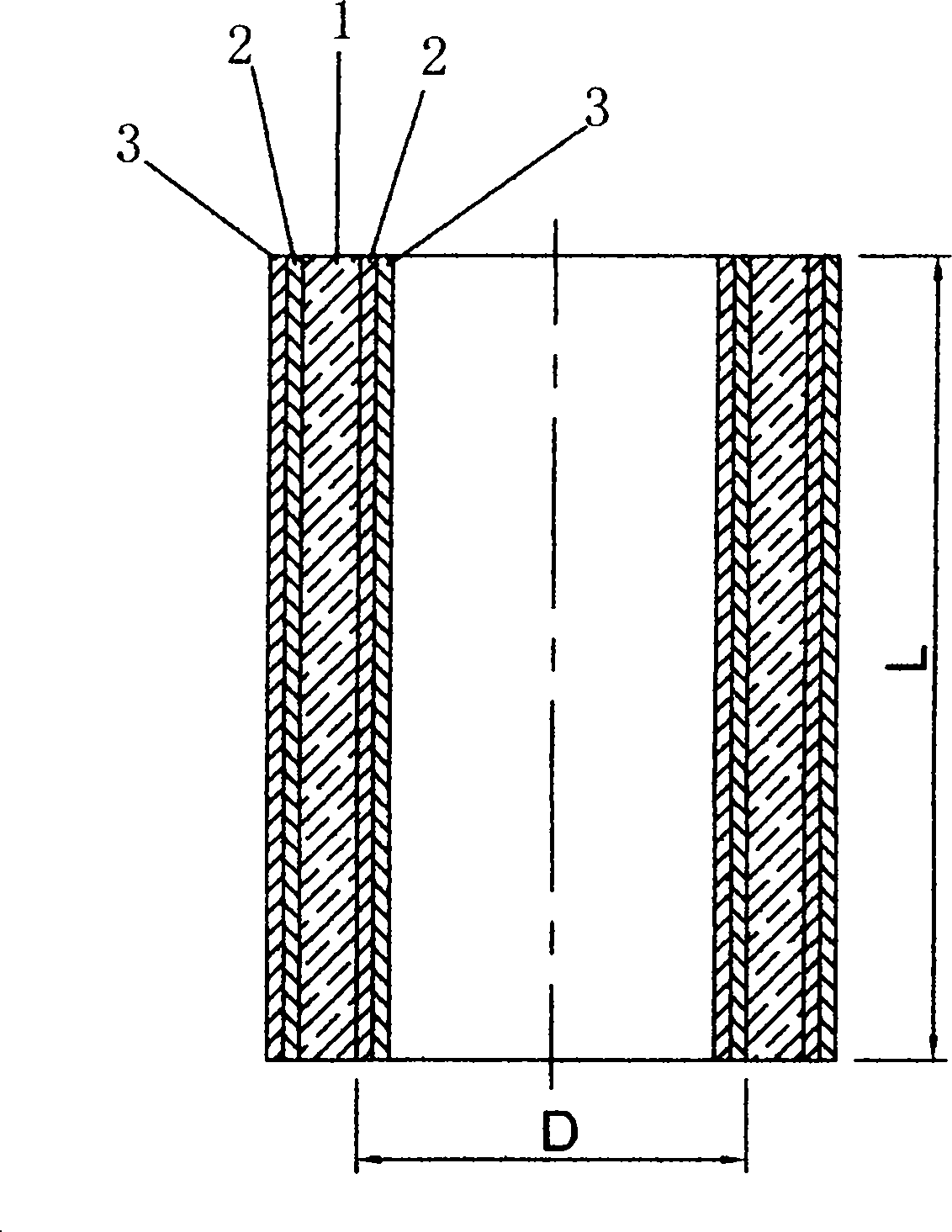

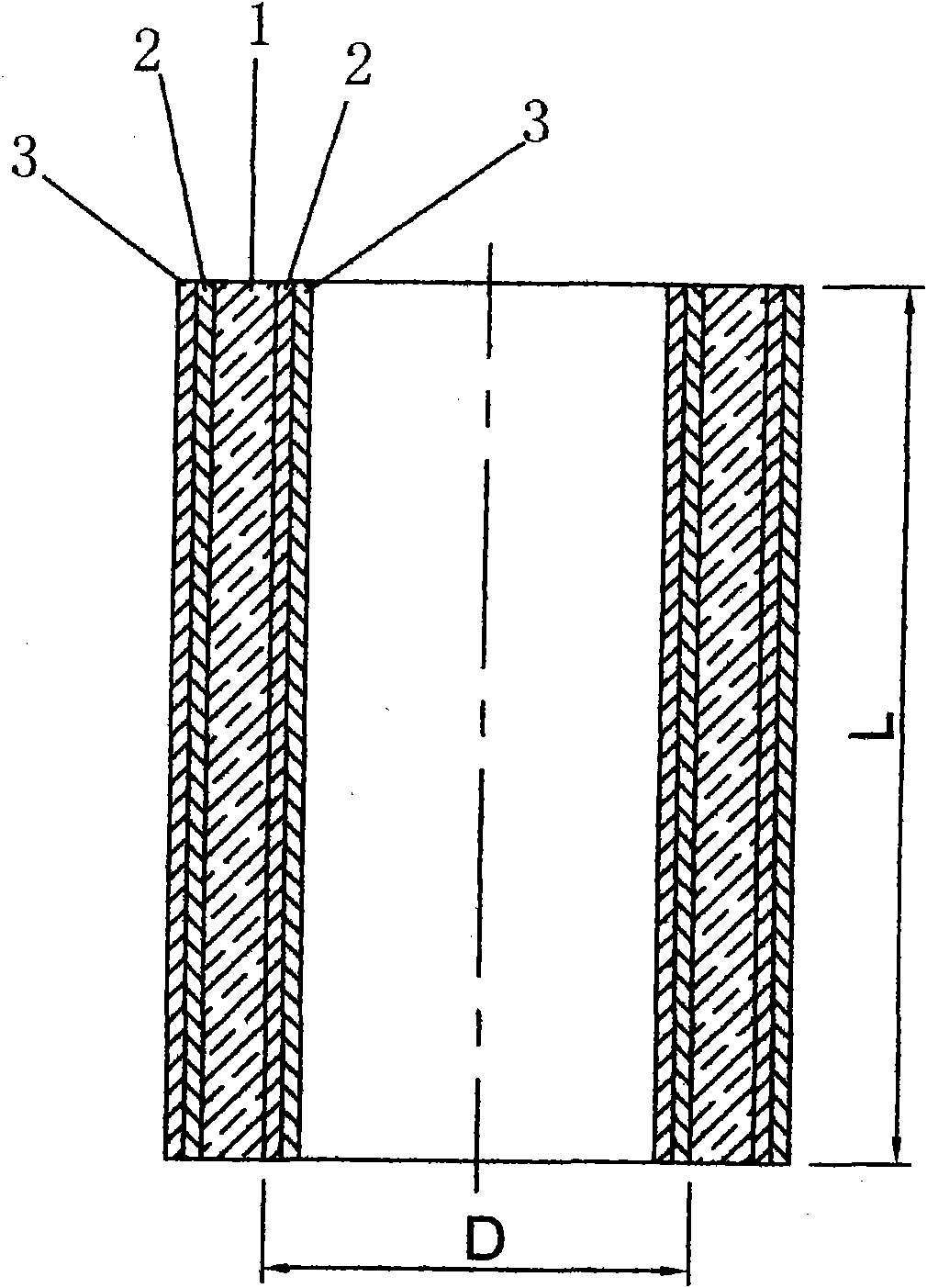

Method for coating multiple compound high anti-reflection films on inner surface and outer surface of glass tube with length/aperture ratio greater than 30

The invention discloses a method for coating multiple compound high anti-reflection films on the inner surface and the outer surface of a glass tube with a length / aperture ratio greater than 30. In a compound high anti-reflection glass tube prepared by the method, at least one TiO2 film and at least one SiO2 film are respectively formed. The film coating method comprises the steps of sol preparation by a hydrolysis method, film preparation by a pulling method and low-temperature hot drying coating aftertreatment. The invention has the characteristics of simple and convenient method, good film coating quality, energy consumption saving, long service life of finished products, and the like, and provides technical supports for channel type solar thermal generating equipment.

Owner:常州龙腾光热科技股份有限公司

Collosol gel production method of nano NiO material

InactiveCN1493526AControl the rate of hydrolysisSmall particle sizeNickel oxides/hydroxidesColloidal chemistry detailsPolyethylene glycolEthanol

A process for preparing NiO nanoparticles in the form of tetragonal crystal by sol-gel method includes dissolving polyethanediol in deionized water, adding less ammonia water to regulate pH=7.5-8, dissolving nickel acetate in absolute alcohol, slowly adding the solution to said aqueous solution of polyethanediol, high-speed stirring, holding temp at 70 deg.c for 4 hr while stirring to obtain sol, filtering, drying and calcining at 500 deg.C for 2 hr.

Owner:SHANGHAI UNIV

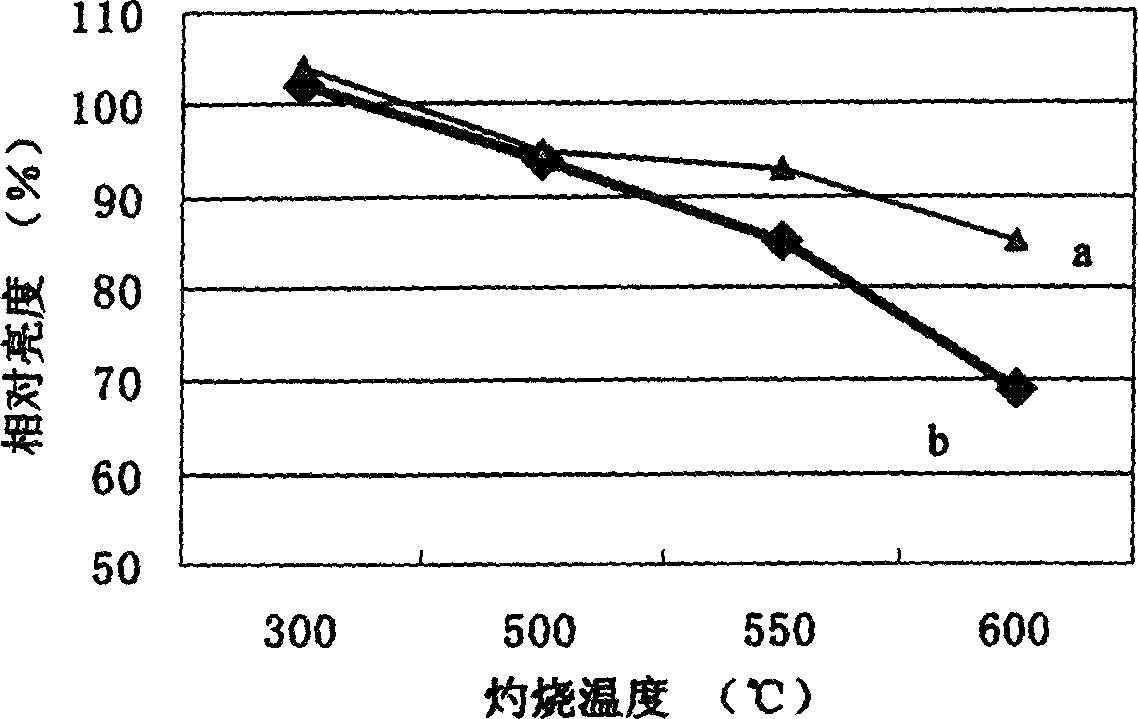

Silicon oxide coated fluorescent powder and its coating method

InactiveCN1664052AControl the rate of hydrolysisControl formLuminescent compositionsPhosphorSupersonic waves

Disclosed is the silicon oxide integument phosphor powder covered with silicon oxide on the surface of the phosphor powder. The method of integument comprising: preparing suspension at the concentration 0.2~5% with color plasma panel display phosphor powder and water, weighing relevant quantity of sodium silicate with nine water according to the proportion between silicon oxide and phosphor powder by weight (0.5~20): 100, adding to the phosphor powder suspension, dispersing with supersonic wave and stirring to make it dissolved and the phosphor powder suspension stable, employing strong acid as precipitator and preparing solution with concentration 0.01~2M; heating the phosphor powder suspension to 20~120 DEG C, stirring and dispersing with supersonic wave at the same time, stirring with speed 100r / m~ 300r / m and dropping the precipitator into the phosphor powder suspension at the speed of 5~500ml / min to make the pH value 3~11, then keeping the temperature and stirring for 30~180 minutes; getting the integument phosphor powder after centrifugalizating the phosphor powder suspension, washing, dewatering and drying at 60-120DEG C to make the integument phosphor powder moisture percentage below 0.25%,incandescing at 200~400 DEG C for 1~3hours and air cooling in the furnace.

Owner:SOUTHEAST UNIV

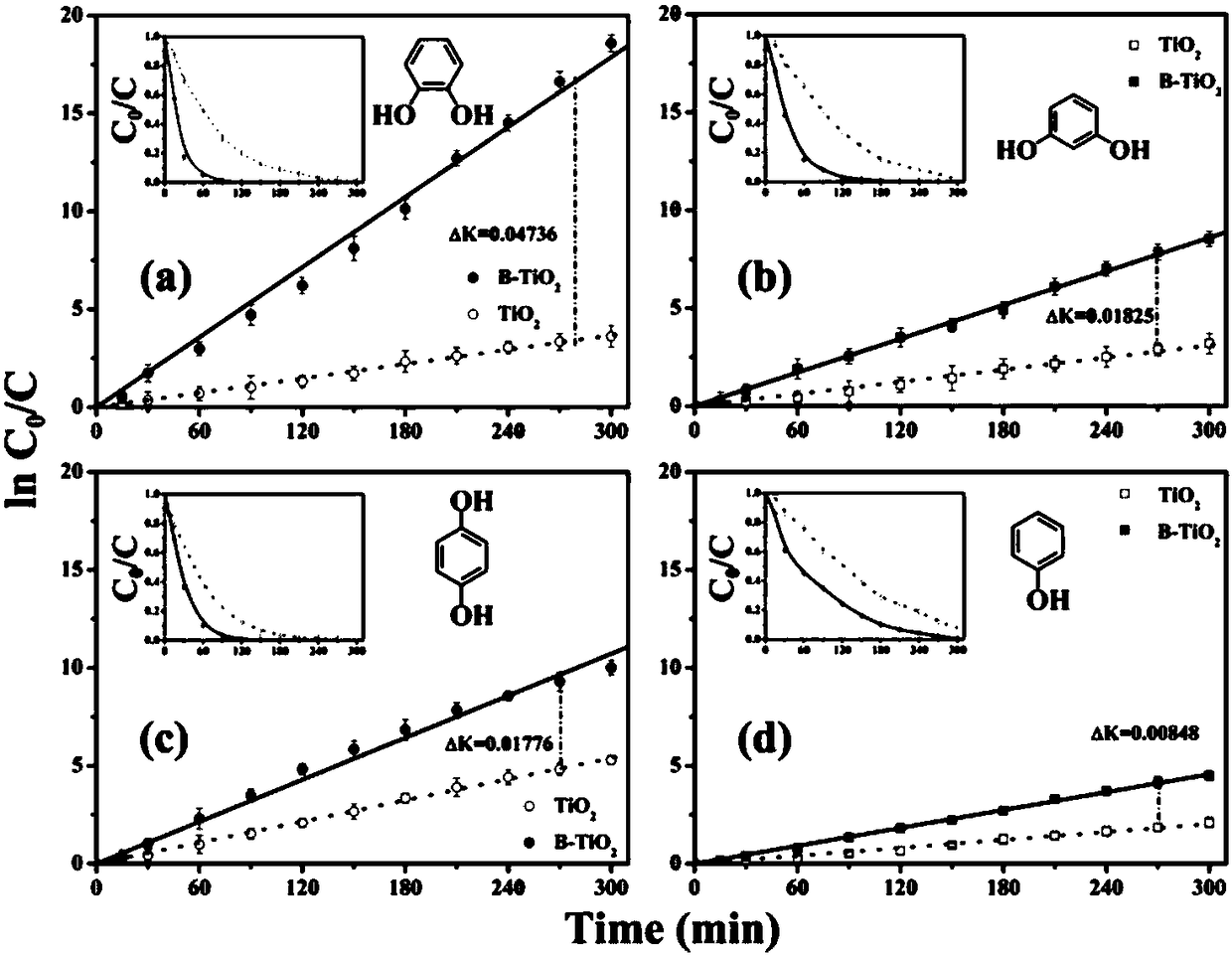

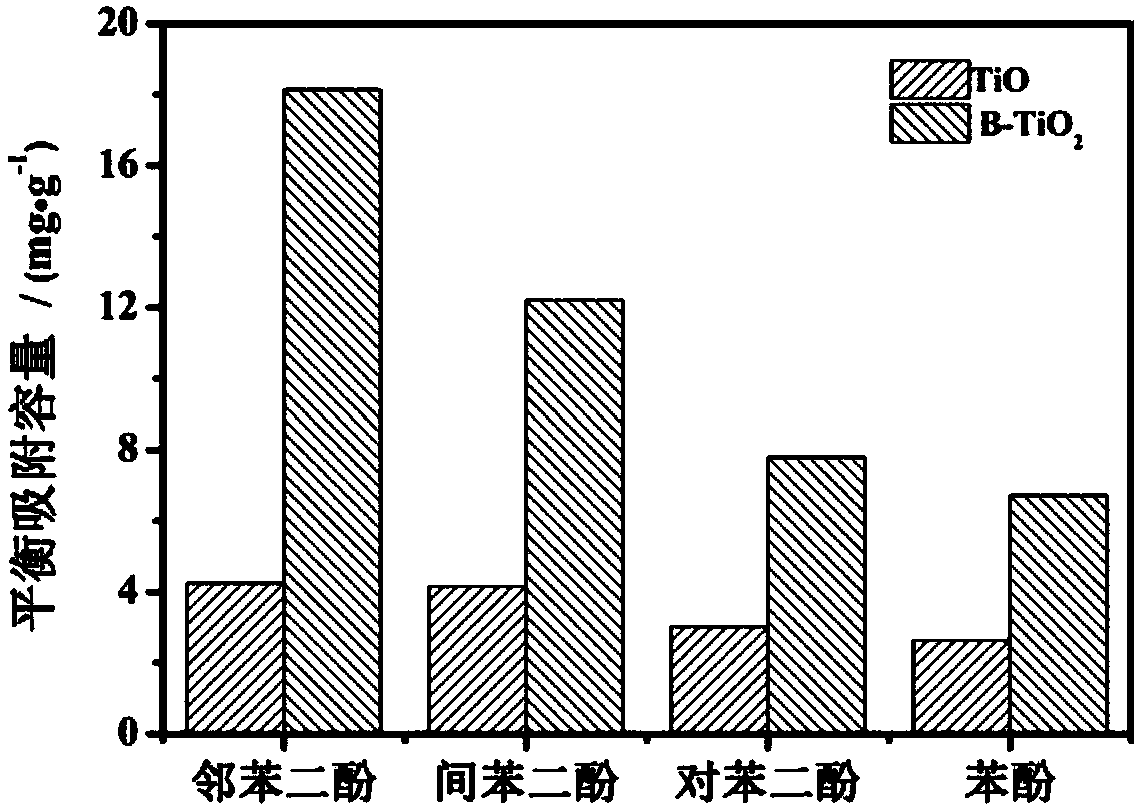

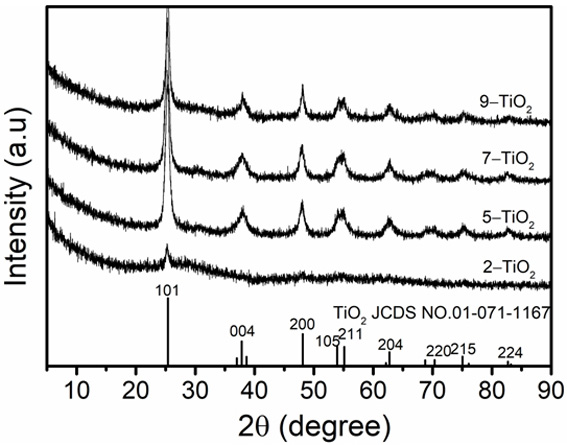

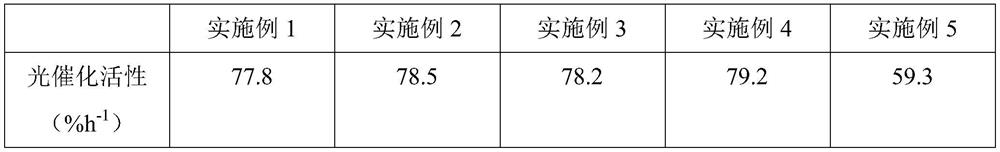

Preparation method of interstitial boron doping titanium dioxide photocatalytic material and application

InactiveCN108452788AEfficient enrichmentRapid oxidation kineticsMaterial nanotechnologyPhysical/chemical process catalystsPhenolAdsorption effect

The invention relates to a preparation method of an interstitial boron doping titanium dioxide photocatalytic material and application. An interstitial boron doping TiO2 nanometer photocatalyst can beprepared by a low-temperature sol-gel method, wherein the interstitial boron ions have an effect of serving as Lewis acid sites on the catalyst surface, and the adsorption effect on Lewis alkaline phenol is greatly enhanced. Compared with the prior art, the preparation method disclosed by the invention has the advantages that adsorption of phenol in water can be effectively enhanced, the selective adsorption aim can be achieved by virtue of different chemical configuration adsorption effects, and finally the aim of rapidly oxidizing targeted pollutants is achieved by virtue of a photocatalytic oxidation technology. The method is simple, feasible, obvious in enhanced adsorption effect, high in selectivity and high in catalytic efficiency.

Owner:TONGJI UNIV

Preparation method of high heat conductivity coating

The invention discloses a preparation method of high heat conductivity coating. The preparation method comprises the following steps: firstly preparing a boron nitride nanosheet by adopting a solventstripping method, preparing composite powder, finally performing the high-temperature treatment, obtaining a boron nitride nanosheet / nano titanium oxide composite material, modifying the boron nitridenanosheet / nano titanium oxide composite material by adopting a prepared modification solution, finally mixing and stirring styrene-acrylic emulsion, acrylic resin and deionized water, then adding theprepared modified boron nitride nanosheet / nano titanium oxide composite material, basalt fibers and a cross-linking agent, stirring and mixing, finally adding a defoaming agent and a thickening agent, uniformly stirring and mixing, and obtaining high heat conductivity coating. The high heat conductivity coating prepared in the invention is good in stability, good in heat conductivity and excellent in mechanical performance.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

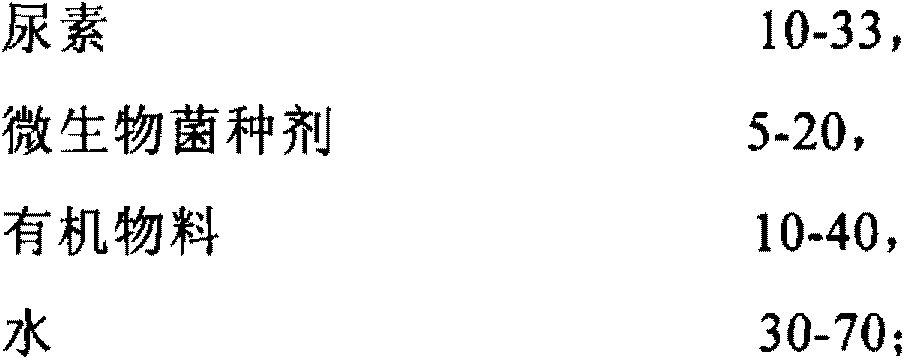

High-nitrogen-concentration composite microbial fertilizer and preparation method thereof

ActiveCN103193541AEffectively control the hydrolysis rateControl the rate of hydrolysisFertilizer mixturesMonopotassium phosphateFermentation

The invention relates to a high-nitrogen-concentration composite microbial fertilizer and a preparation method thereof, wherein the raw materials of the high-nitrogen-concentration composite microbial fertilizer comprise the following components in percentage by weight (wt%): 10-33% of urea, 5-20% of microbial strain agent, 10-40% of organic materials and 30-70% of water. The preparation method comprises the following steps of: adding the materials to a fermentation container, stirring evenly, fermenting for 15-25 days, adding appropriate monopotassium phosphate when lots of gas gives off and after detecting that the weight percentage concentration of ammonium nitrogen of the materials fermented completely is lower than 2%, thereby obtaining the composite microbial fertilizer in liquid or solid form, and finally, weighing and packaging. According to the invention, active small molecular amide nitrogen is transformed and fixed into slow-release macromolecular organic nitrogen through biochemical reaction of microorganisms; therefore, the content of nitrogen nutrient in the composite microbial fertilizer is improved and the activity and amount of microorganisms also are guaranteed; besides, the utilization rate of urea is improved and pollution on the natural environment caused by easy loss of nitrogen is reduced. As a result, a novel, long-acting, environmentally-friendly composite microbial fertilizer is developed.

Owner:江西良田上品实业有限公司

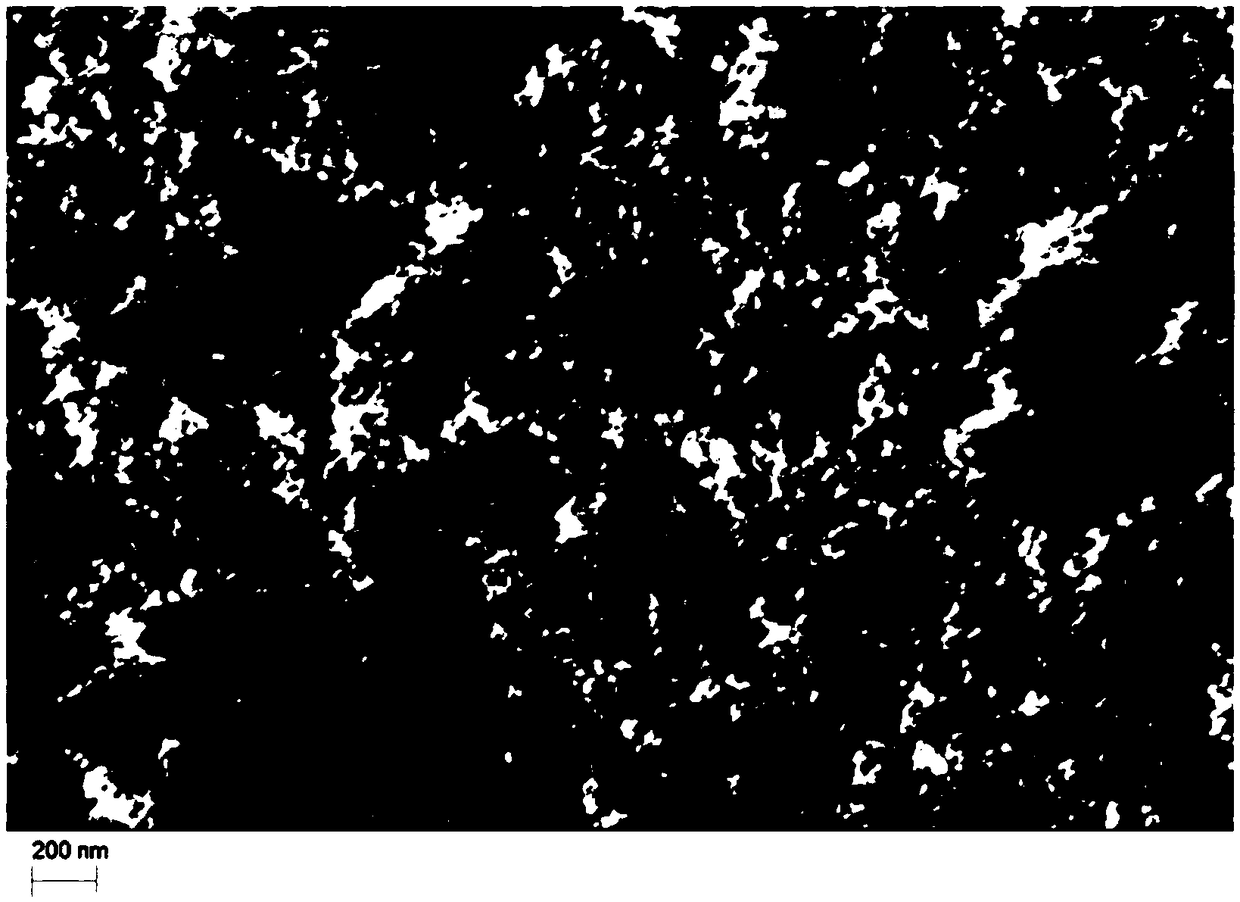

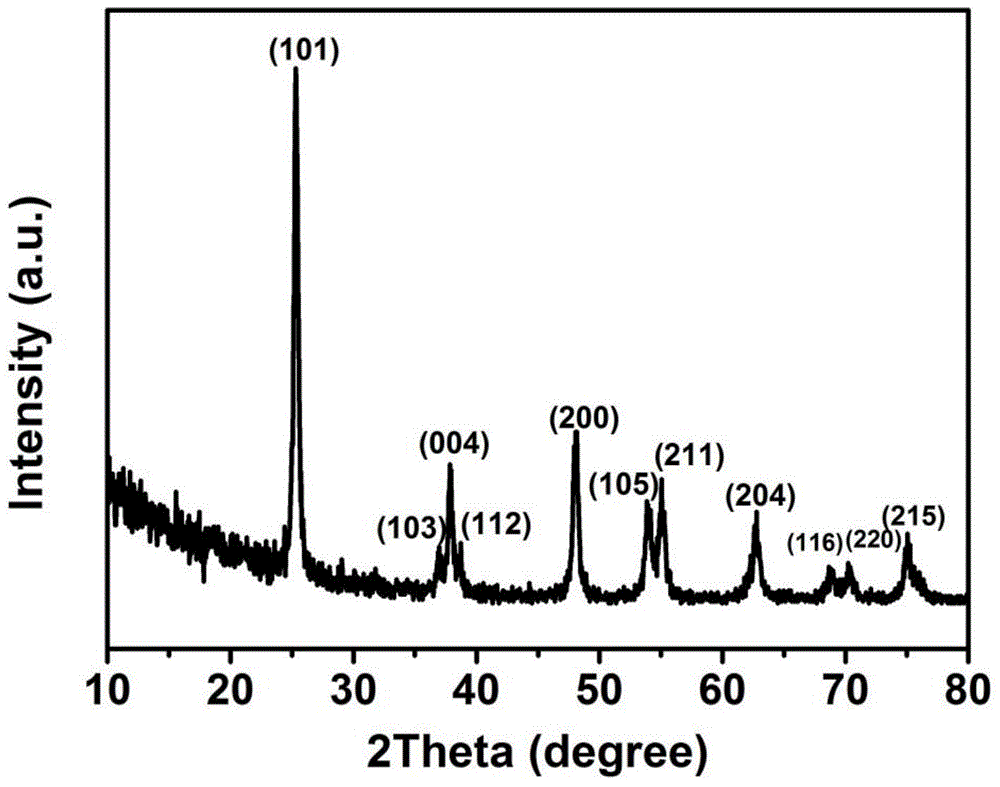

Titanium dioxide/silicon dioxide photocatalyst and preparation method thereof

InactiveCN109499562AInhibition of phase transitionControl the rate of hydrolysisPhysical/chemical process catalystsSilica particleAcetic acid

The invention relates to a titanium dioxide / silicon dioxide photocatalyst and a preparation method thereof. The preparation method comprises the steps: firstly, dropwise adding water into a titanate,ethyl alcohol and glacial acetic acid mixed system and controlling the titanate hydrolyzing speed to obtain amorphous titanium dioxide particles with a smaller particle size; then dropwise adding strong oxidizing acid to react to obtain titanium dioxide sol; converting the amorphous titanium dioxide into anatase titanium dioxide. The prepared titanium dioxide particles have the advantages of smallparticle size, high anatase phase purity and favorability for improving photocatalytic activity. The titanium dioxide sol particles are ultrasonically stirred and dispersed into silicon dioxide sol,and the titanium dioxide particles can be loaded on silicon dioxide particles after being dried; as the silicon dioxide particles have a larger specific surface area and the silicon dioxide can inhibit phase change of titanium dioxide, photocatalytic activity is further improved. According to the method, the preparation conditions are moderate, roasting treatment is avoided, energy is saved, and meanwhile, good photocatalytic activity can be obtained.

Owner:HUAIHUA UNIV

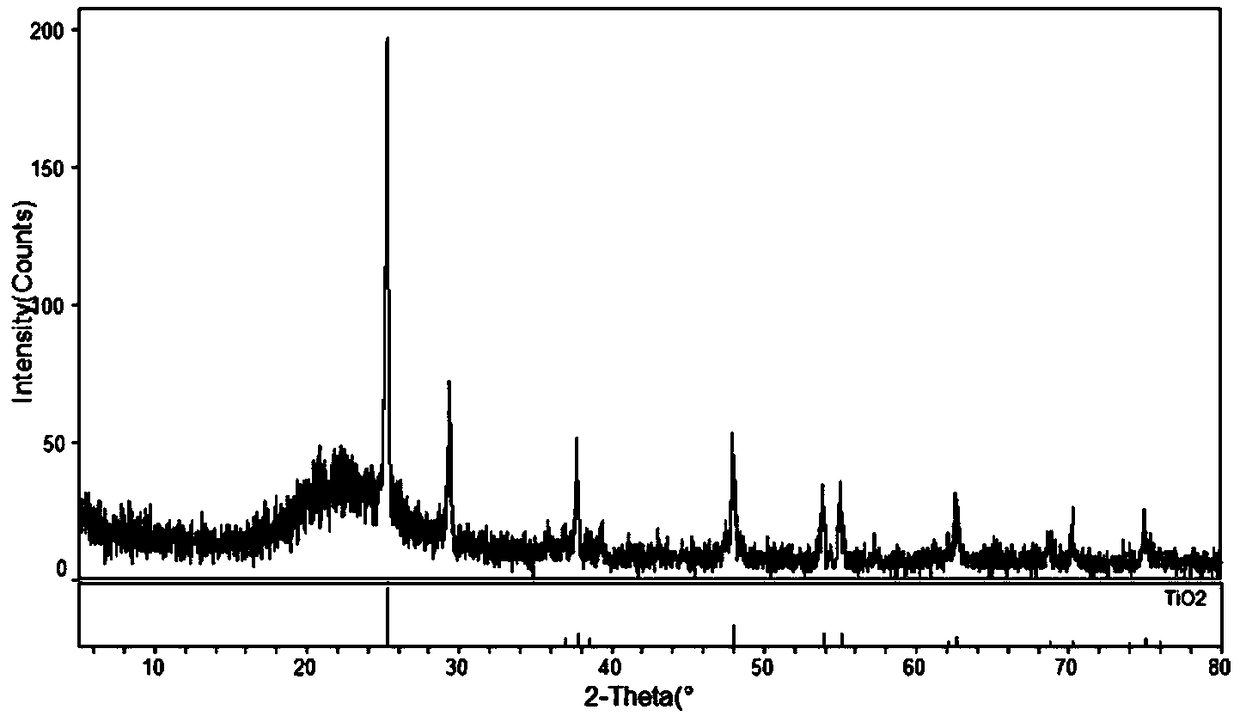

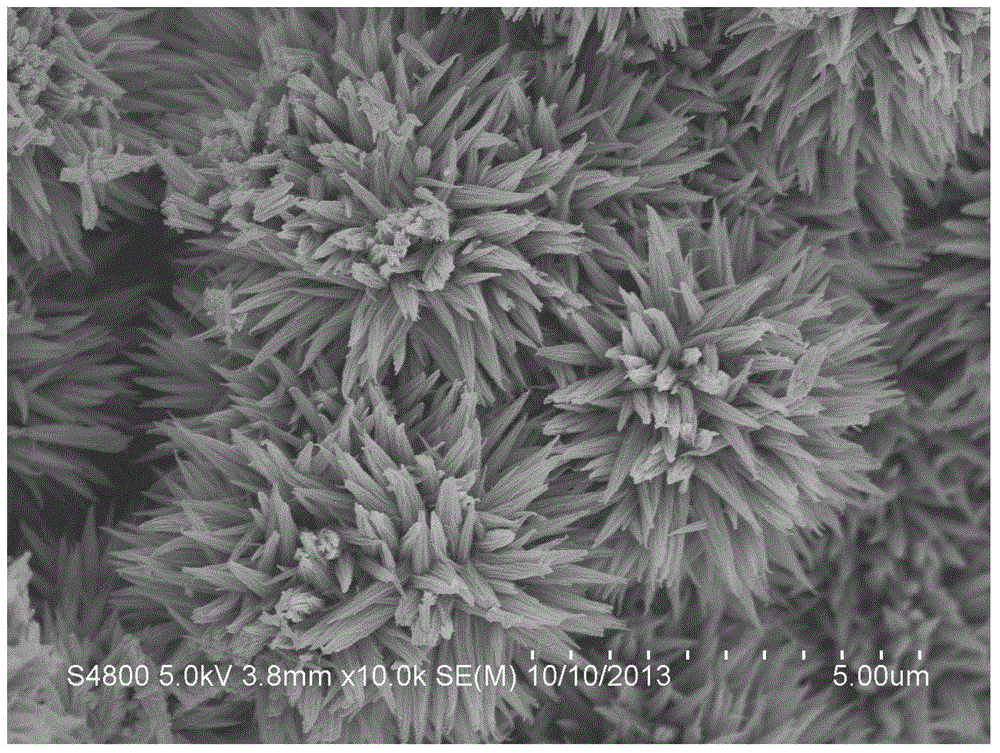

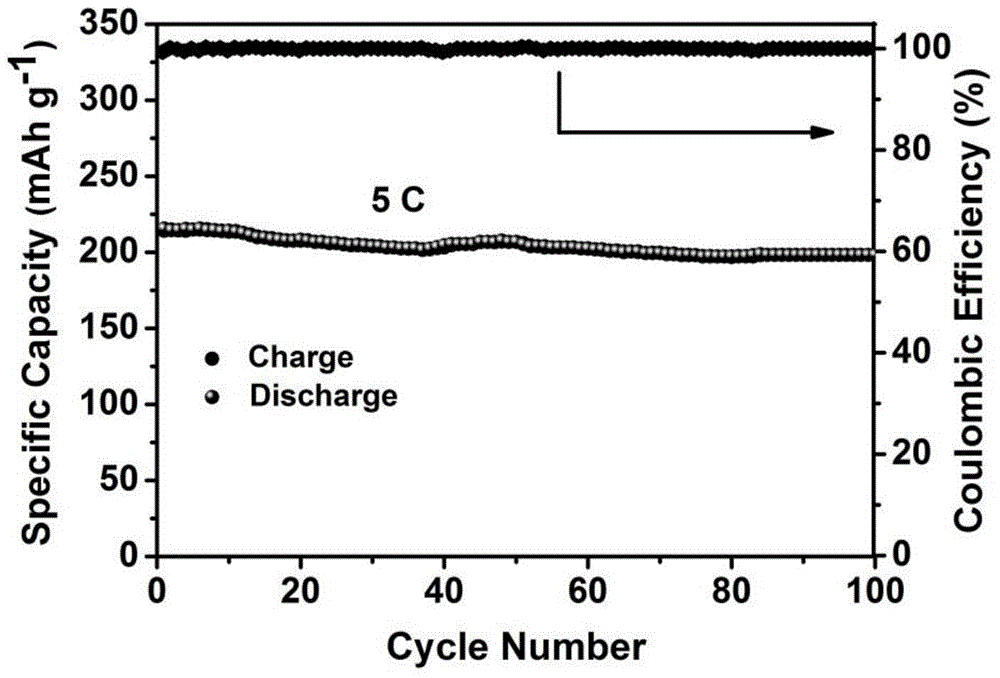

Method for preparing high-coulombic-efficiency lithium ion battery negative pole material chrysanthemum-shaped nanometer titania

InactiveCN104466155AUniform shapeGood dispersionMaterial nanotechnologyCell electrodesHydrolysisHeat treated

The invention discloses a method for preparing high-coulombic efficiency lithium ion battery negative pole material chrysanthemum-shaped nanometer titania. The method comprises the following steps: dissolving a titanium source compound in short-chain monohydric alcohol, stirring to form a clarified solution, adding polyhydric alcohols, further stirring to form a clarified solution, carrying out a hydrothermal reaction, forming a complex with the titanium source compound by utilizing the polyhydric alcohols as guide agents and inducers, controlling hydrolysis of the titanium source compound by taking the short-chain monohydric alcohol as a dispersing agent so at to generate a titania precursor, and performing low-temperature heat treatment, thereby obtaining the lithium ion battery negative pole material chrysanthemum-shaped nanometer titania. The preparation method disclosed by the invention is simple in process and easy to operate, and raw materials are readily available; the high-coulombic efficiency lithium ion battery negative pole material chrysanthemum-shaped nanometer titania is low in cost and environmentally friendly, special equipment is not needed in the whole reaction process, the industrial production is promoted, the final product is high in quality, and according to the prepared nanometer / micron grading structure, the aims of shortening the ion transport distance and improving the conductivity and ion diffusion rate of the material can be simultaneously achieved, so that the material has excellent rate capability, stable cycle performance and high coulombic efficiency. The material prepared by the invention is an ideal lithium ion negative pole material with wide commercial application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

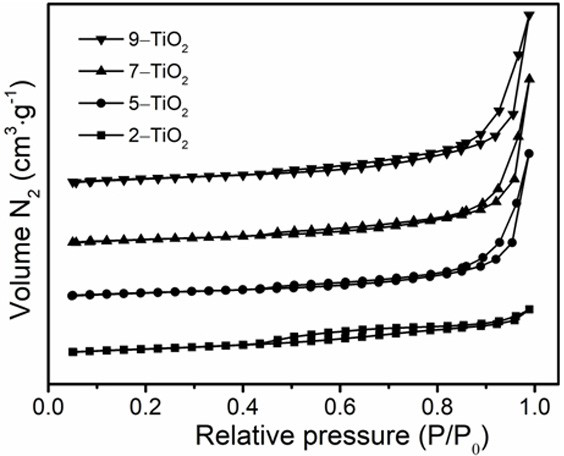

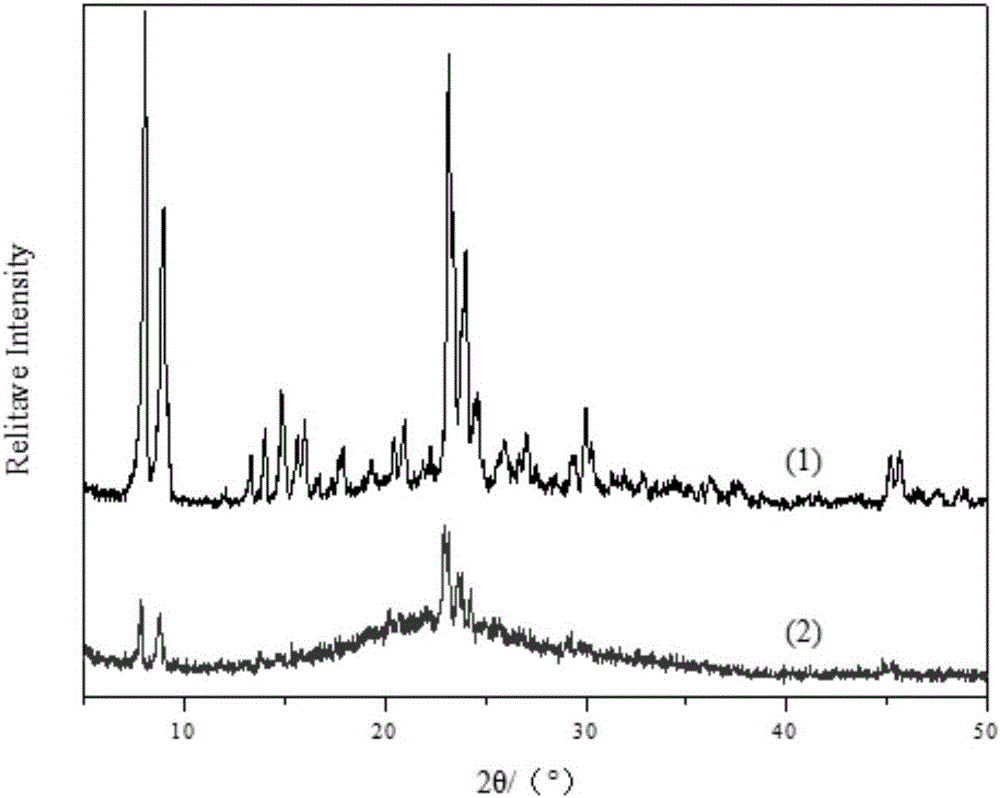

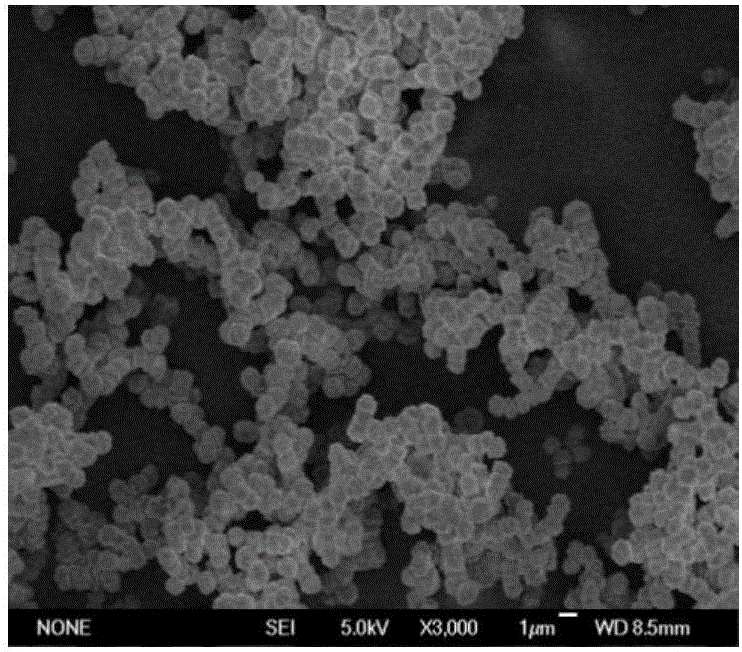

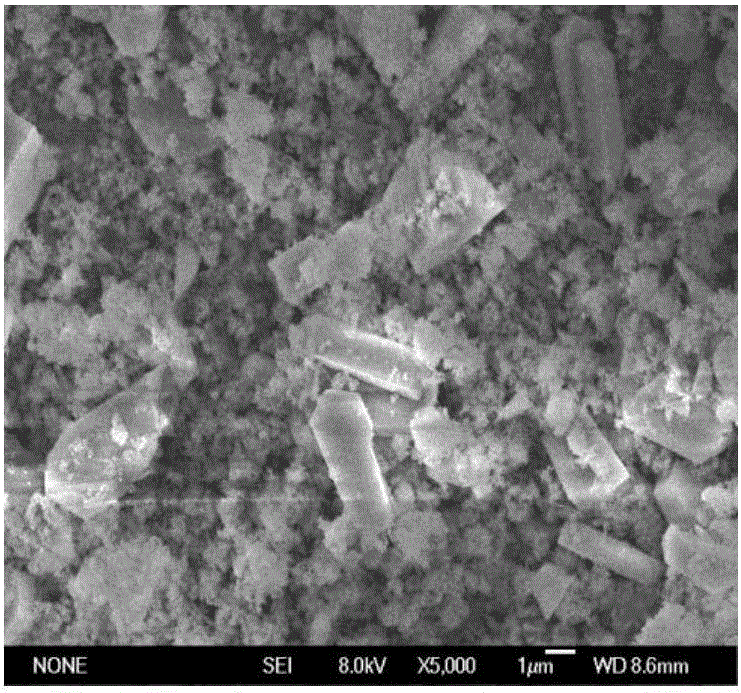

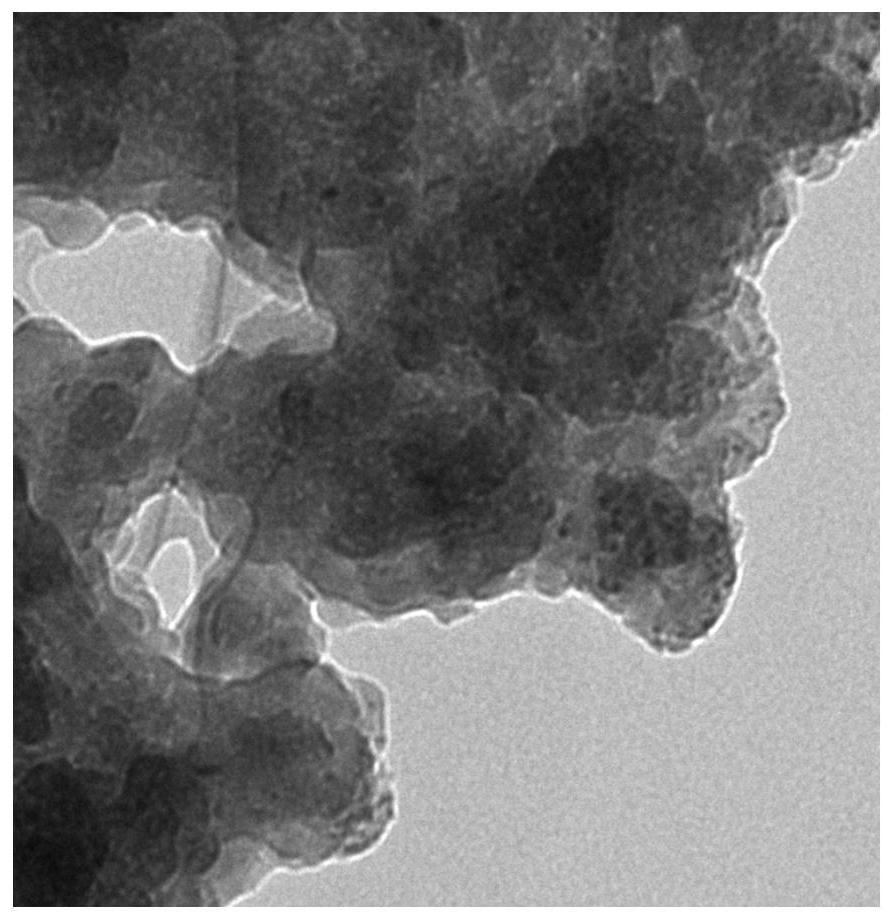

Preparation method of two-dimensional porous titanium dioxide nano sheet

ActiveCN112516980AFavorable for selective catalytic oxidationImprove mass transfer efficiencyMaterial nanotechnologySulfur preparation/purificationActive siteSelective catalytic oxidation

The invention discloses a preparation method of a two-dimensional porous TiO2 nano sheet, which comprises the following steps: preparing a porous TiO2 precursor by using a sol-gel method, carrying outhydrothermal synthesis to obtain TiO2, and roasting to remove a pore-forming agent, thereby obtaining the two-dimensional porous TiO2 nano sheet. The method is high in repeatability and mild in hydrothermal condition, the prepared TiO2 nano sheet is regular in morphology, rich active sites are exposed through the porous structure of the TiO2 nano sheet, the mass transfer efficiency can be improved, and the TiO2 nano sheet has good catalytic activity in a selective catalytic oxidation H2S reaction.

Owner:FUZHOU UNIV

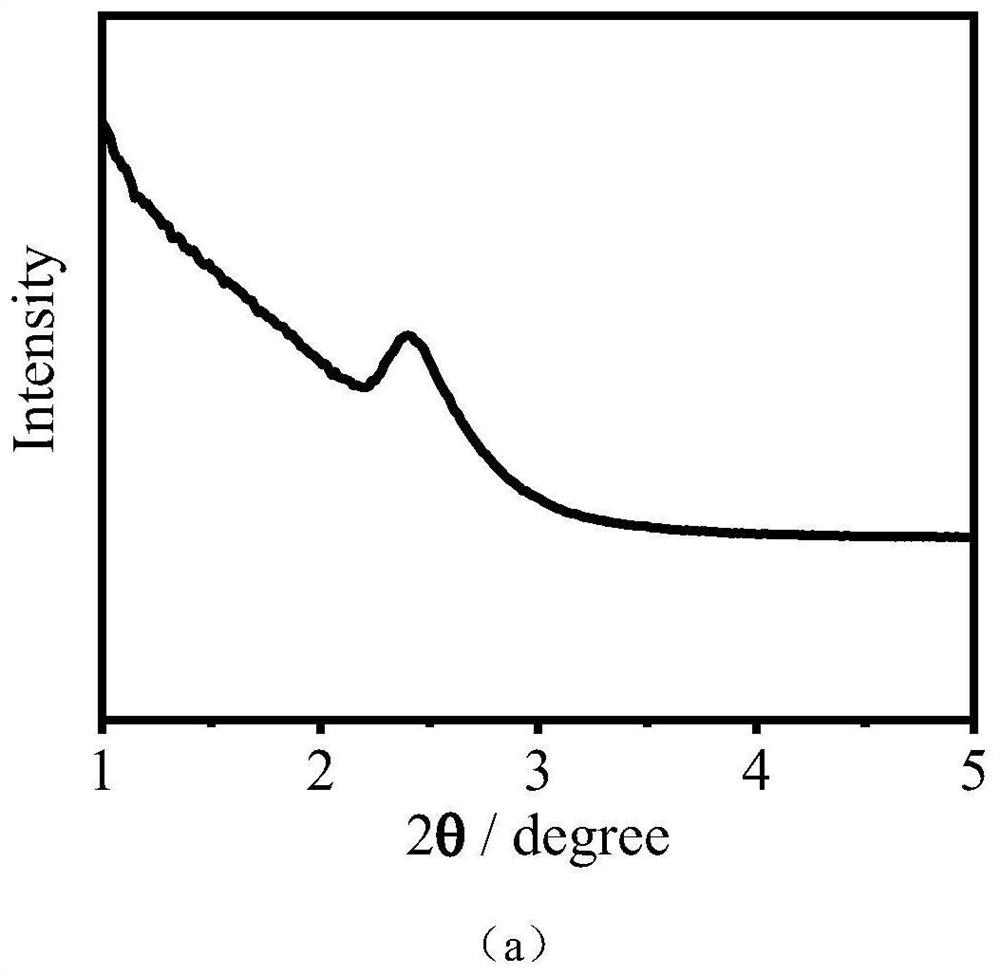

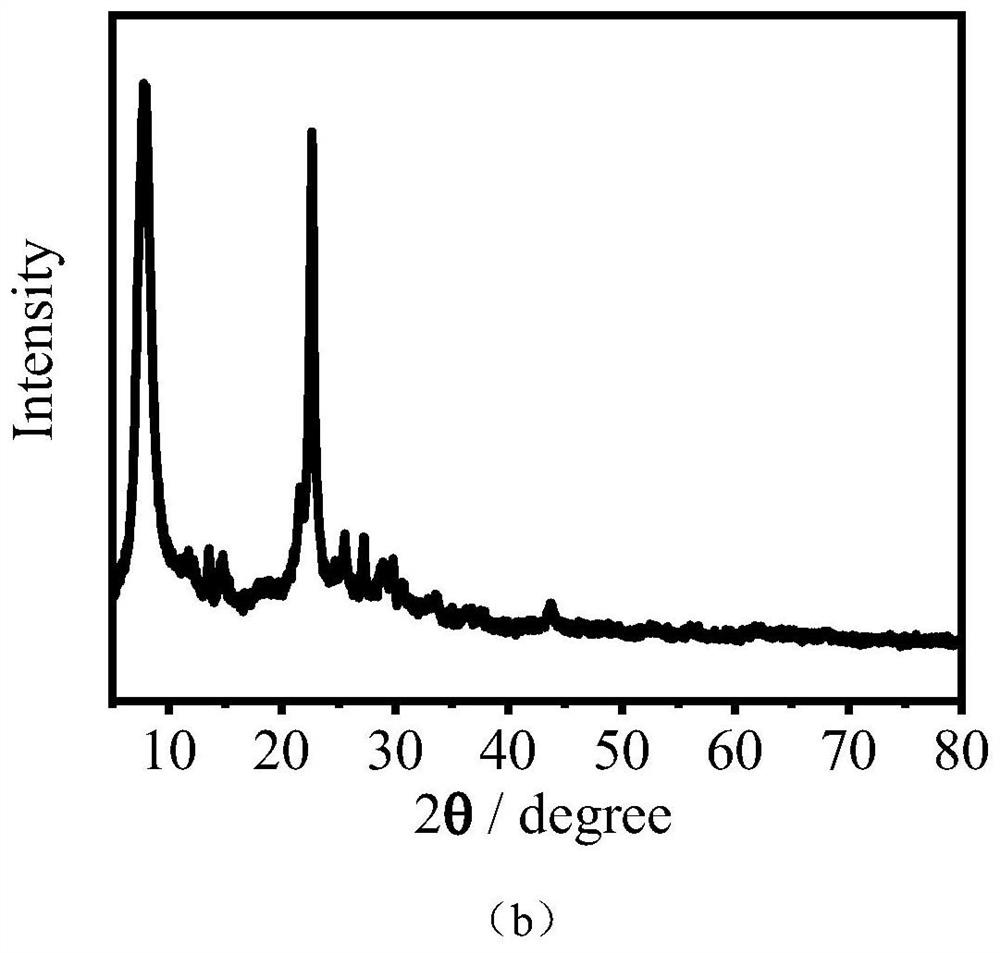

Method for preparing mesoporous TS-1 titanium silicalite molecular sieves through hydrothermal crystallization method

ActiveCN106082260AReduce the impact of entering the skeletonIncrease contentCrystalline aluminosilicate zeolitesMolecular sieveEmulsion

The invention relates to a method for preparing mesoporous TS-1 titanium silicalite molecular sieves through a hydrothermal crystallization method. The method includes the following main steps of firstly, mixing a template agent, water and a silicon source at a temperature of 5-50 DEG C to form a solution A; secondly, mixing a pore-enlarging agent and water to form a solution B; thirdly, adding an emulsifying agent to a titanium source to form an emulsion C; fourthly, introducing inert gas into the emulsion C to conduct demulsification on the emulsion and release the titanium source, mixing the solution A and the solution B according to the volume ratio of 1:1, dropwise adding the mixture into the emulsion C to form D, adjusting pH to be 8-13 in the dropwise adding process, and conducting hydrothermal crystallization, washing and dry-roasting on the D after titration is completed to obtain the product. The method reduces production cost, the preparation method is simple, TS-1 aperture is large, framework titanium content is high, and repeatability is good.

Owner:QINGDAO UNIV OF SCI & TECH

Application of volcanic used as titanium dioxide loaded photocatalyst

ActiveCN104549355AImprove carrier strengthGood for recyclingMetal/metal-oxides/metal-hydroxide catalystsUreaChemistry

The invention relates to application of a volcanic used as a titanium dioxide loaded photocatalyst. The application comprises the following steps: (1) removing impurities on the surface of the volcanic to prepare a volcanic carrier; (2) dissolving Ti(SO4)2 and urea into water according to proportions to prepare load solutions; (3) soaking the volcanic carrier into the load solutions for reacting, adding urea solutions or ammonia water in a reaction process; aging, filtering, drying and baking to prepare the volcanic loaded titanium dioxide photocatalyst. The volcanic is used as a carrier of the titanium dioxide photocatalyst, so that the intensity of the carrier is high, and the performance of the loaded photocatalyst can be improved to a certain extent; in addition, the carrier has a rich honeycomb porous structure, and is high in specific surface area and high in adsorption performance; because of the carrier of the photocatalyst, the load firmness and the photocatalytic performance of the loaded catalyst can be improved.

Owner:山东默锐环境产业股份有限公司

HMS@NiPt@Beta core-shell structure catalytic material and preparation method and application thereof

ActiveCN113457720AImprove stabilityOptimize electronic structureOrganic chemistryMolecular sieve catalystsDehydrogenationPetrochemical

The invention discloses an HMS@NiPt@Beta core-shell structure catalytic material and a preparation method and application thereof. According to the catalytic material, a microporous Beta molecular sieve serves as a core, a mesoporous HMS molecular sieve serves as a shell, NiPt bimetallic nanoparticles are evenly distributed on the surface of the microporous Beta molecular sieve, the core of the microporous Beta molecular sieve is prepared through a hydrothermal synthesis method, niPt bimetallic nanoparticles are loaded on the surface of the microporous Beta molecular sieve through a low-temperature oxygen plasma treatment technology, the mesoporous HMS molecular sieve shell is prepared through a vapor phase crystal transformation method, and based on the total mass of the catalytic material, nickel accounts for 10-30 wt%, platinum accounts for 0.01-5 wt%, the microporous Beta molecular sieve core accounts for 40-60 wt%, and the balance is the mesoporous HMS molecular sieve shell. The catalytic material is applied to a reaction for catalyzing dehydrogenation coupling of pyridine to synthesize 2, 2'-dipyridyl, has the advantages of low dosage, few side reactions, short process and the like, and has a good application prospect in the fields of adsorption separation, petrochemical engineering, fine chemical production and the like.

Owner:SOUTHEAST UNIV

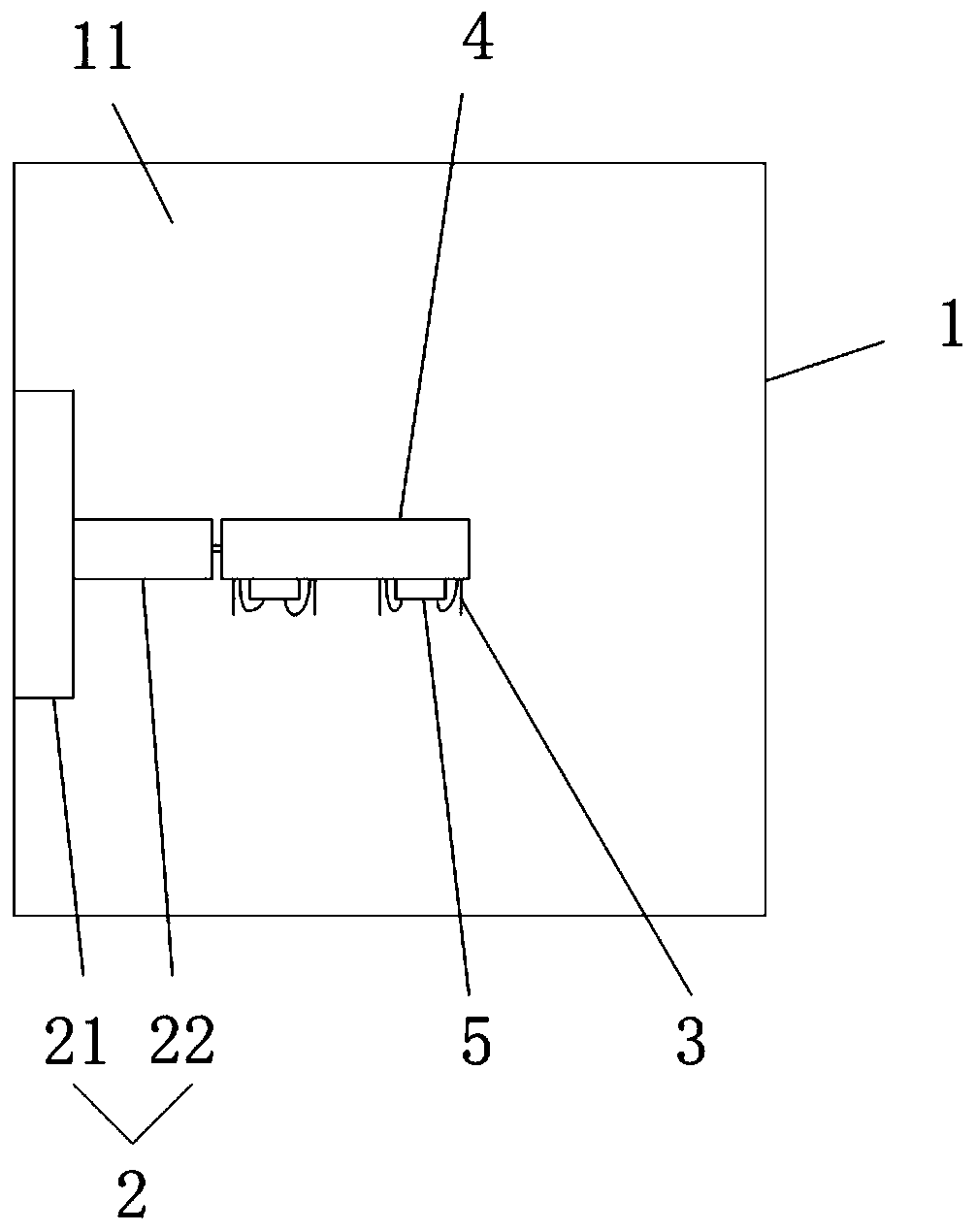

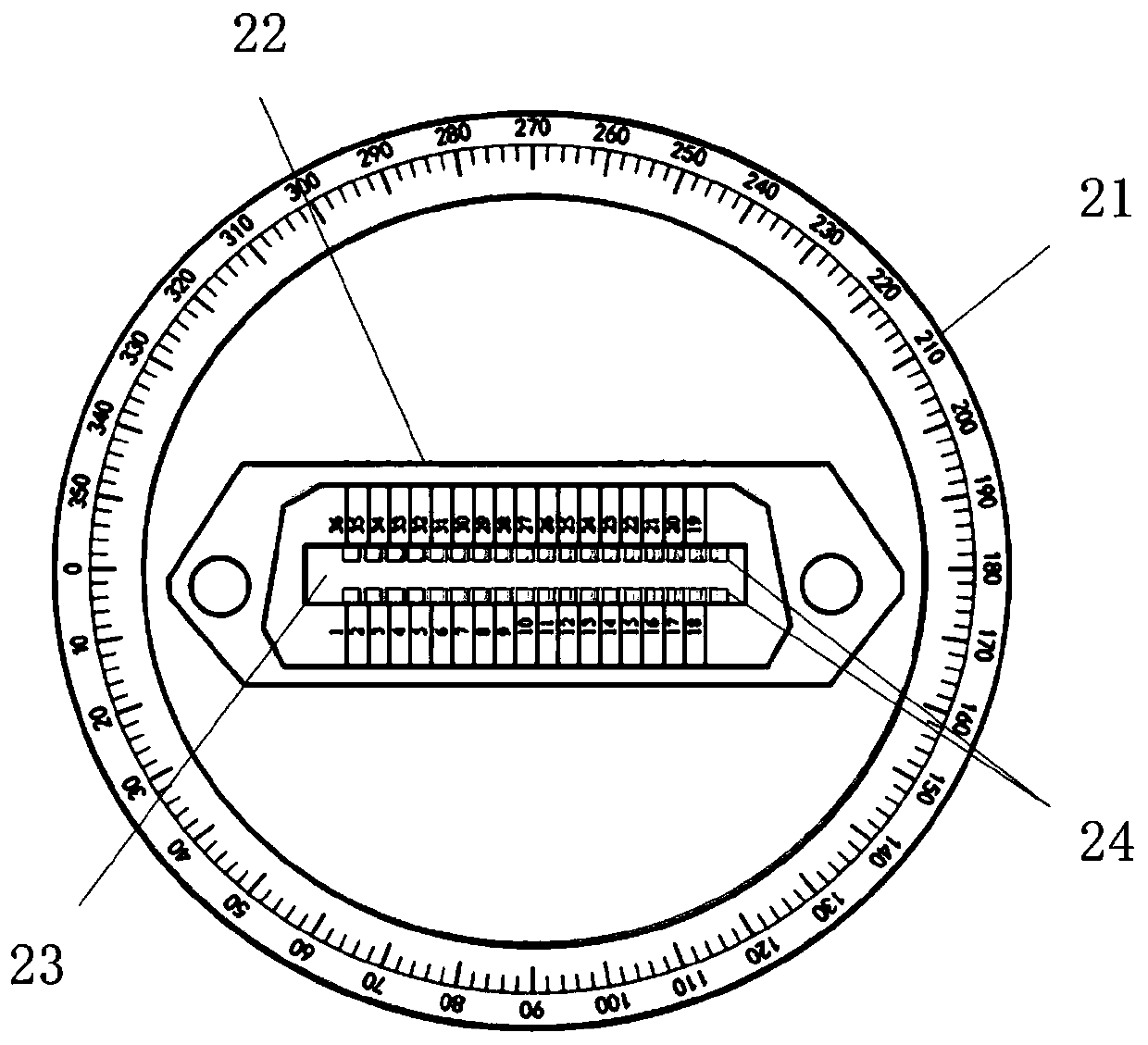

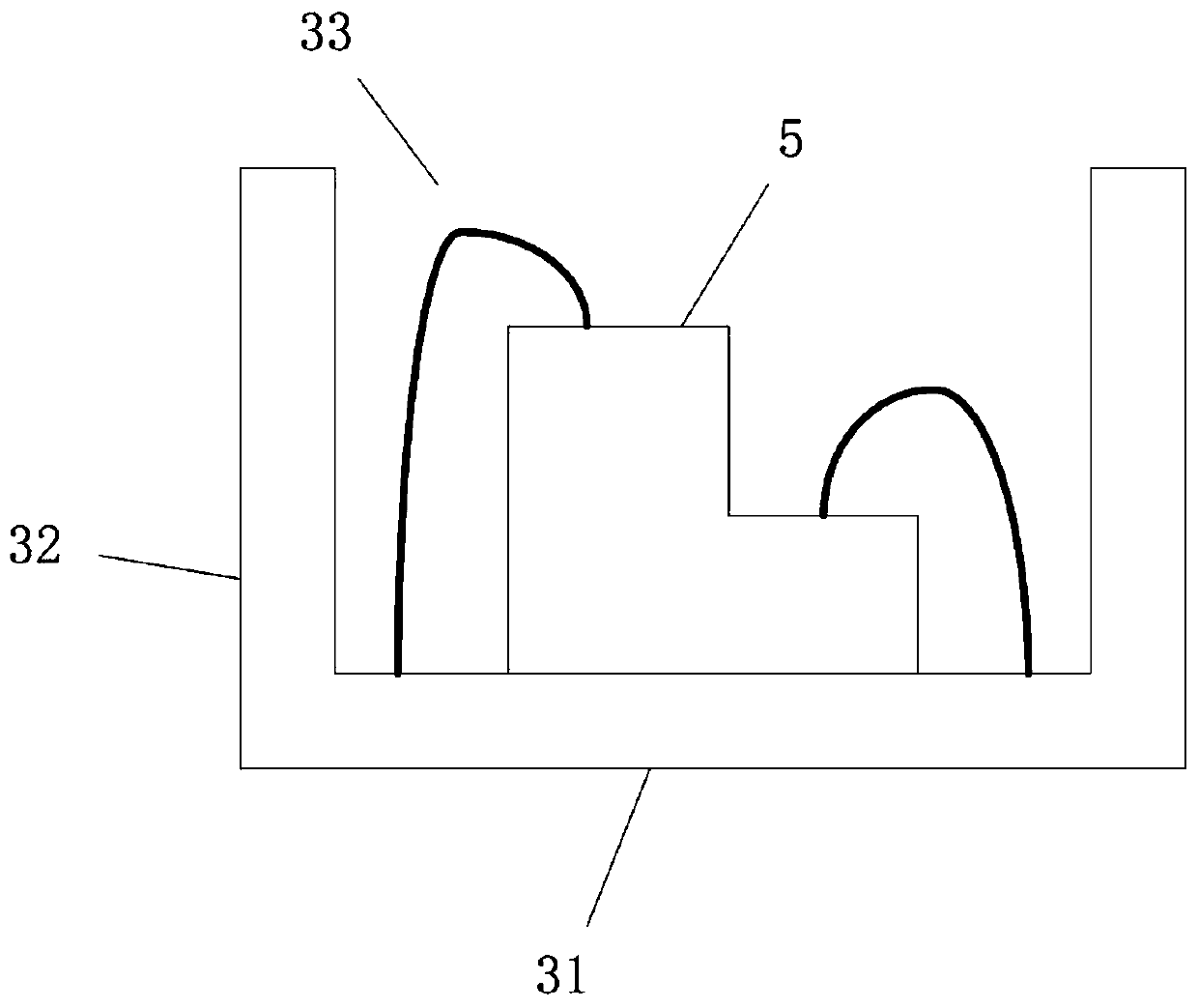

System and method for quickly testing hydrolysis resistance of LED chip

PendingCN111190095AImprove reliabilityFast hydrolysisElectronic circuit testingSemiconductor operation lifetime testingElectrically conductiveEngineering

The invention discloses a system and method for quickly testing hydrolysis resistance of an LED chip, and the system comprises a temperature and humidity regulator which is provided with a cavity; a rotating device which is connected to the inner wall of the cavity and can rotate along the inner wall of the cavity; a support of a cup-shaped structure, and a test substrate. The LED chip is installed on the support and is in conductive connection with the support; the support is fixed on the test substrate and electrically connected with the test substrate, and the test substrate is connected tothe rotating device; the direction of the LED chip is adjusted through the rotating device, reverse voltage is introduced into the test substrate, and the temperature and humidity in the cavity are adjusted, so that an impact test is carried out on the LED chip. The direction of the LED chip is adjusted through the rotating device, the hydrolysis speed of the LED chip is effectively increased, and therefore the detection time is shortened.

Owner:FOSHAN NATIONSTAR SEMICON

Production process of mold mattress

PendingCN111690183AIncreased mechanical and chemical stabilityReduce surface shrinkageChemistryComposite material

The invention discloses a production process of a mold mattress. The invention relates to the field of latex industry, in particular to a production process for high-temperature production of mold mattresses. The invention provides a mold mattress production process, which is convenient to process, improves the product stability and reduces the cost. According to the invention, the phenomena of surface shrinkage, insufficient die punching and the like can be reduced during high-temperature production, a curing agent can be smoothly hydrolyzed in foamed latex due to high die temperature and guarantee of certain latex temperature, the gelling effect is ensured, and the phenomena of layering or poor structural tension and the like caused by poor gelling effect are avoided. According to the invention, the yield is improved, and the production efficiency is also improved.

Owner:江苏金世缘乳胶制品股份有限公司

Preparation method of metal oxide/hollow microsphere composite filler

ActiveCN111995883AAvoid uneven crystallizationUniform hydrolysisPigment treatment with organosilicon compoundsReflecting/signal paintsMicrospherePhysical chemistry

The invention discloses a preparation method of a composite filler. According to the method, a metal oxide precursor is formed at first, hollow microspheres are introduced in the growth process of metal oxide crystal nucleuses, a silane coupling agent is added, metal oxide crystals and the hollow microspheres are combined in order through hydrolysis of the silane coupling agent, and agglomerationof metal oxide on the surfaces of the hollow microspheres is avoided; and metal oxide crystals in an ordered array are formed and then are rapidly hydrolyzed and crosslinked together with a metal oxide precursor, so rapid accumulation and growth of a metal oxide layer are realized, a tightly combined metal oxide wrapping layer is obtained by means of calcination and the like, and a flat reflectinglayer on the surface of the formed filler is effectively controlled. According to the method, the density and reflectance ratio of a surface reflection layer can be improved, and the heat insulationeffect of the obtained composite filler is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

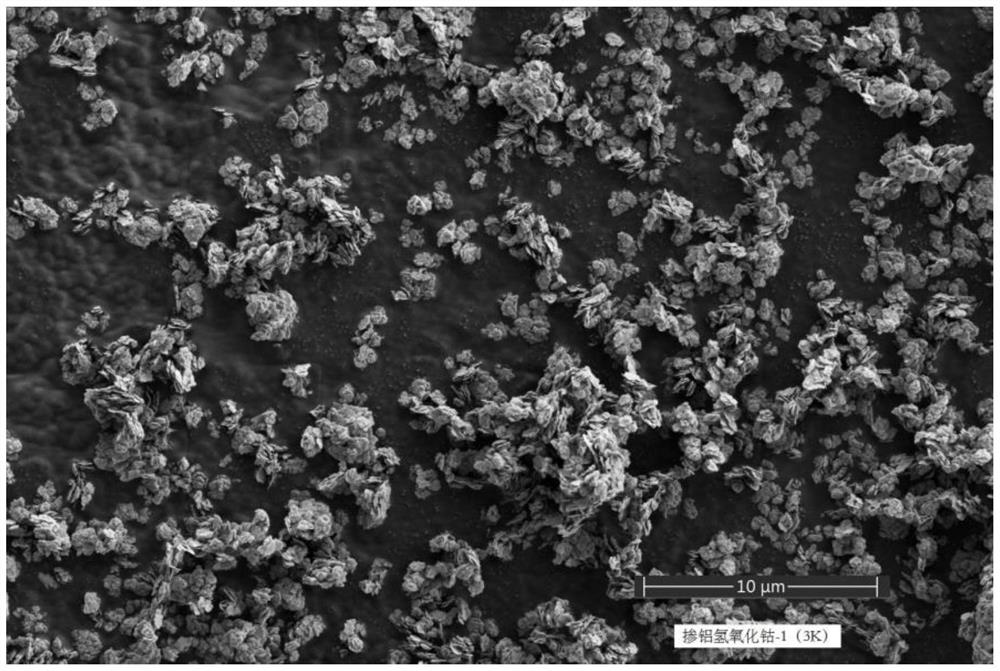

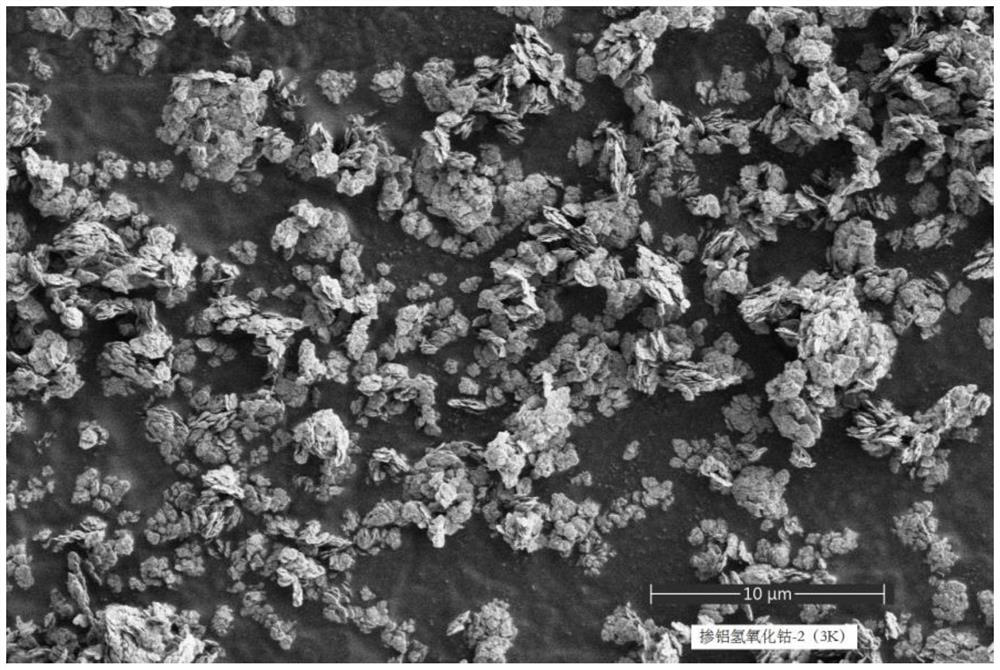

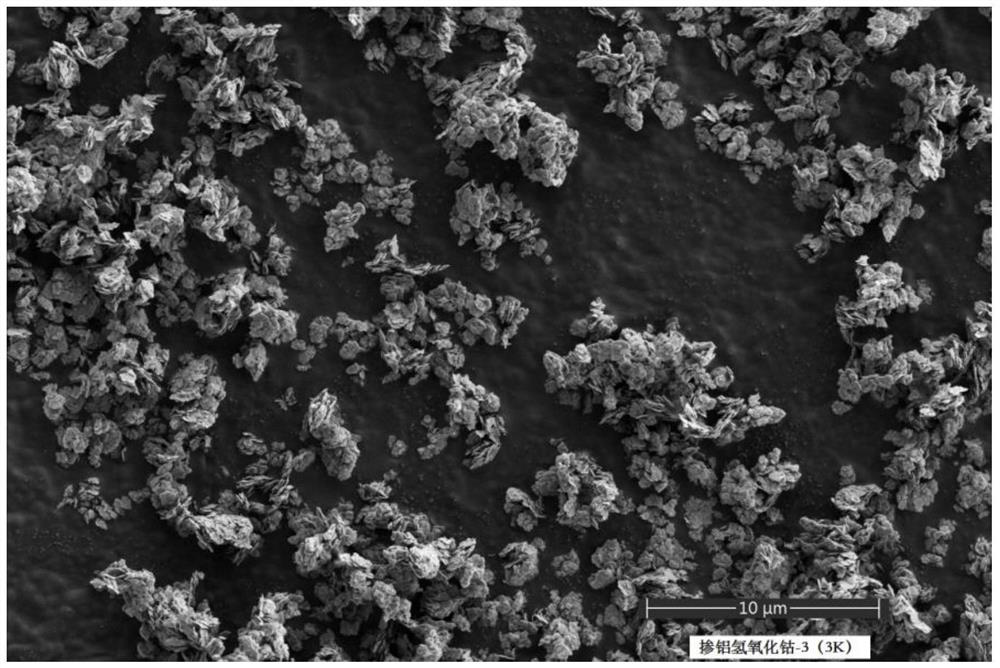

High-voltage lithium cobalt oxide coated material aluminum-doped cobalt hydroxide and preparation method thereof

InactiveCN113501553AAvoid stickingSolving Dispersion ProblemsCell electrodesCobalt oxides/hydroxidesSodium aluminateMaterials science

The invention provides a high-voltage lithium cobalt oxide coated material aluminum-doped cobalt hydroxide and a preparation method thereof, and is mainly used in the technical field of preparation of lithium battery positive electrode materials. The method comprises the following steps: 1, preparing a cobalt salt solution, a sodium metaaluminate solution and a sodium hydroxide solution; 2, adding pure water into a reaction kettle, adjusting the pH value to be 11.0-12.0 by using sodium hydroxide, adjusting the temperature to be 40-70 DEG C, stirring at 80-300rpm, adding the three solutions at the same time, controlling the pH value to be 11.0-12.0 in the process, controlling the feeding reaction time to be 4-8 hours, and stirring and dispersing for 0.2-0.4 hour after the feeding is finished; and 3, carrying out filter pressing, washing and drying on the synthesized aluminum-doped cobalt hydroxide, and crushing the aluminum-doped cobalt hydroxide by adopting a jet mill to finally obtain the agglomeration-free submicron aluminum-doped cobalt hydroxide. According to the invention, the problem of adhesion between submicron particles is effectively solved, and the prepared aluminum-doped cobalt hydroxide has a very good coating effect.

Owner:CENT SOUTH UNIV

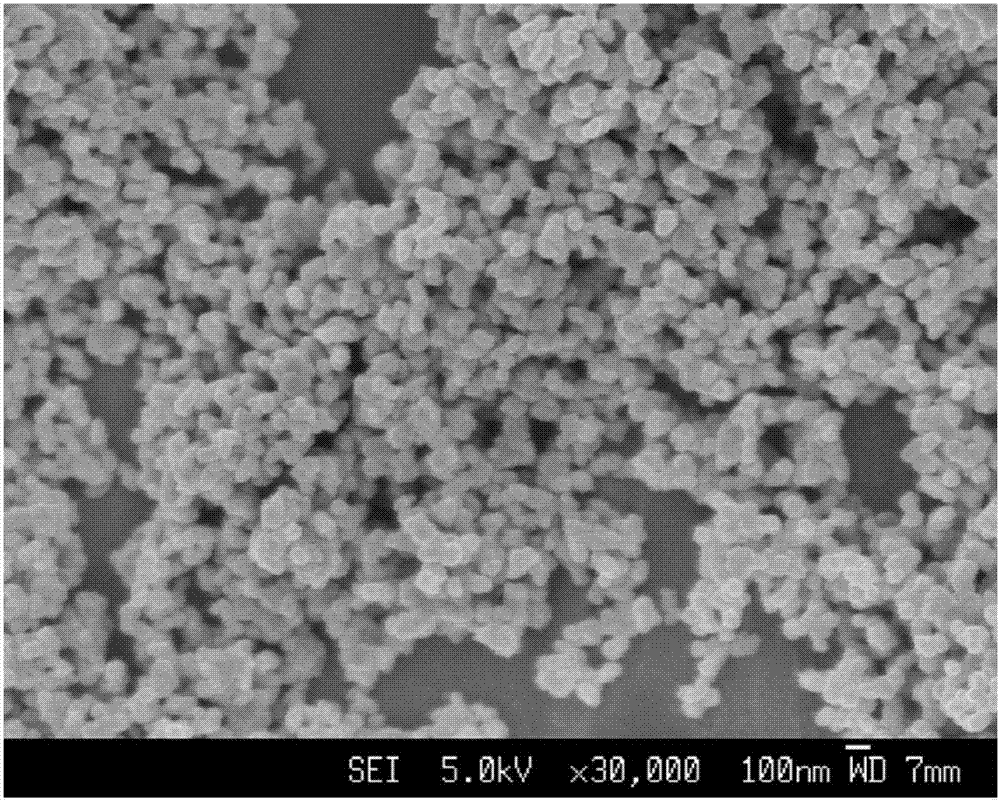

High-purity high-sintering active indium tin oxide mixed powder preparation method

ActiveCN107140949APrevent coagulationReduce severe reunionMaterial nanotechnologyVacuum evaporation coatingAmmonium hydroxideIndium

The invention discloses a high-sintering active indium tin oxide mixed powder preparation method. The method particularly comprises the steps that high-activity nano SnO2 powder is prepared, wherein a compound dispersing agent is dissolved into water, an appropriate amount of SnCl4 is added, stirring is conducted till the mixture is completely transparent, and clarification is conducted; stirring is kept, an appropriate amount of ammonium hydroxide is added, a tin-containing precursor is obtained, after the precursor is placed in a high pressure reaction kettle to be subjected to hydrothermal treatment, sediment is taken out to be washed repeatedly, dried and subjected to low temperature thermal treatment, and nano SnO2 powder is obtained; metal indium is dissolved into hydrochloric acid, a InCl3 aqueous solution is generated, and a method similar to the method for synthesizing SnO2 powder is used for preparing nano In2O3 powder; the prepared InCl3 is mixed with SnO2 in proportion, PVA is added, by means of a spray drying technology, mixed indium tin oxide granulation powder which is less in aggregation, good in liquidity and prone to pressure molding is obtained, and the preparation method can be suitable for preparing high-end ITO target materials.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

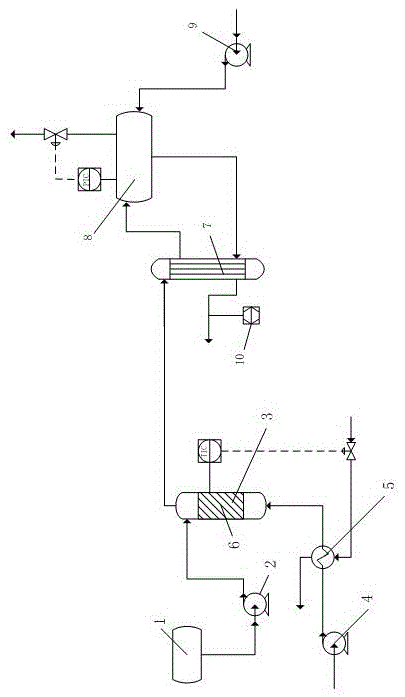

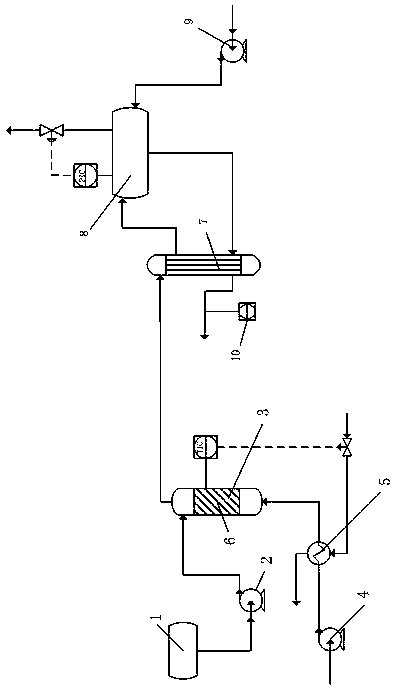

Low carbon olefin oligomerization process control method

ActiveCN105669340AControl the rate of hydrolysisReal-time monitoring of acidityHydrocarbonsHydrocarbon preparationAcid waterPotential difference

The invention relates to a low carbon olefin oligomerization process control method. The method comprises the following steps: (1) enabling a sodium dihydrogen phosphate water solution in an acid water tank to enter from the upper part of a neutralization sedimentation tank through an acid water pump; (2) inputting low carbon olefin and low pressure steam into a heater, and heating to respectively obtain low carbon olefin and low pressure steam condensate; discharging the low pressure steam condensate; enabling the low carbon olefin to enter from the bottom of the neutralization sedimentation tank; (3) enabling the low carbon olefin to contact with the sodium dihydrogen phosphate water solution reversely, and regulating and controlling the water content of the low carbon olefin according to a mode; (4) when the water content of the low carbon olefin is 200ppm-3000ppm, performing oligomerization on the low carbon olefin and a solid phosphoric acid catalyst, thus obtaining a reaction product; (5) enabling steam and water in a balanced state in a steam pocket to flow inside from the lower part of a reactor under potential difference action, and reacting with the reaction product obtained in the step (4), thus respectively obtaining C5-C16 olefin products and steam; enabling the steam to return to the steam pocket; detecting the C5-C16 olefin products by an online acidity analyzer, and then discharging. The low carbon olefin oligomerization process control method can achieve the aim of real-time monitoring.

Owner:北京凯美诺科技有限公司

Preparation method of quartz sand/titanium dioxide composite catalyst

InactiveCN112705185AReduce loadLow costGas treatmentDispersed particle separationPtru catalystPhoto catalytic

The invention discloses a preparation method of a quartz sand / titanium dioxide composite catalyst. The invention aims to solve the problem of low photocatalytic degradation efficiency of a composite catalyst prepared in the prior art. The preparation method comprises the following steps: 1, weighing tetrabutyl titanate, adding tetrabutyl titanate into deionized water according to a set mass ratio, and adding nitric acid to obtain a suspension; 2, stirring the suspension in a water bath for 1 h to obtain sol; 3, diluting the titanium dioxide sol with water, and adding quartz sand into the titanium dioxide sol according to a set mass ratio; 4, drying a mixture obtained in the previous step in a drying oven to constant weight so as to obtain solid particles; and 5, putting the solid particles into a hydrothermal reaction kettle, naturally cooling the solid particles to room temperature after a reaction, and then conducting filtering and drying to obtain the catalyst, wherein the addition amount of the quartz sand is 2.0%-10.0% of the mass of the titanium dioxide and the mass of the composite catalyst, and the temperature of hydrothermal treatment is 100 DEG C to 200 DEG C. The method has the advantages of improving photocatalytic degradation efficiency and the like.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Polypyrrole-graphene/polyurethane antifouling coating, its preparation method and application

ActiveCN113913100BAvoid stickingReduce penetrationAntifouling/underwater paintsPaints with biocidesCrack resistancePolypyrrole

The invention discloses a polypyrrole-graphene / polyurethane antifouling paint, a preparation method and application thereof, wherein the polypyrrole-graphene / polyurethane antifouling paint is composed of component A and component B; in parts by weight, A The components are mainly composed of the following raw materials: 500 parts of group-hydrolyzed polyurethane prepolymer, 25-50 parts of bentonite, 25-50 parts of titanium dioxide, 60-120 parts of zinc oxide, 15-30 parts of talc, polypyrrole-graphene 15-30 parts of nanofillers; by weight, component B is mainly composed of the following raw materials: 5-7 parts of leveling agent, 5-7 parts of defoamer, 6-15 parts of chain extender, 10 parts of silane coupling agent ‑25 parts, 1-2 parts of catalyst. The present invention is a two-component polyurethane coating, which has good adhesion, anti-collision and crack resistance, and can also improve antifouling performance and antifouling durability.

Owner:HARBIN ENG UNIV

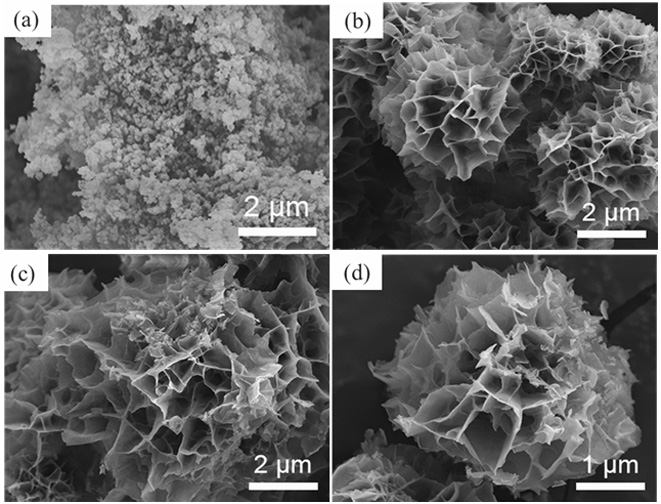

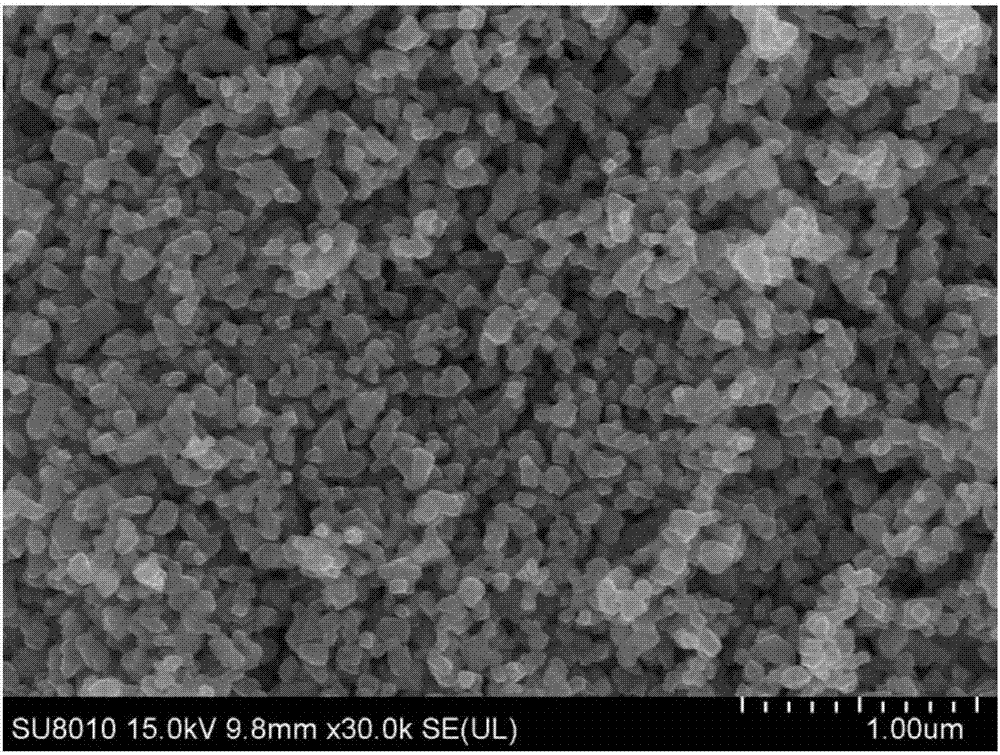

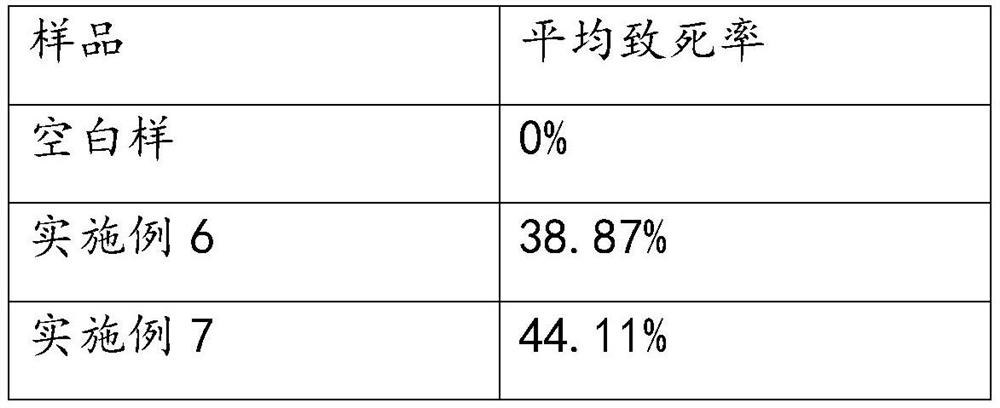

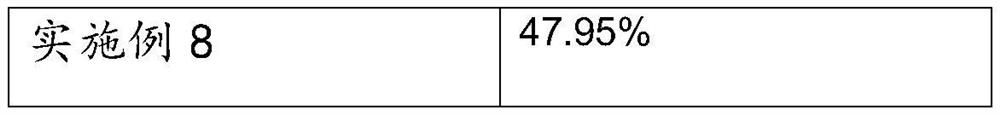

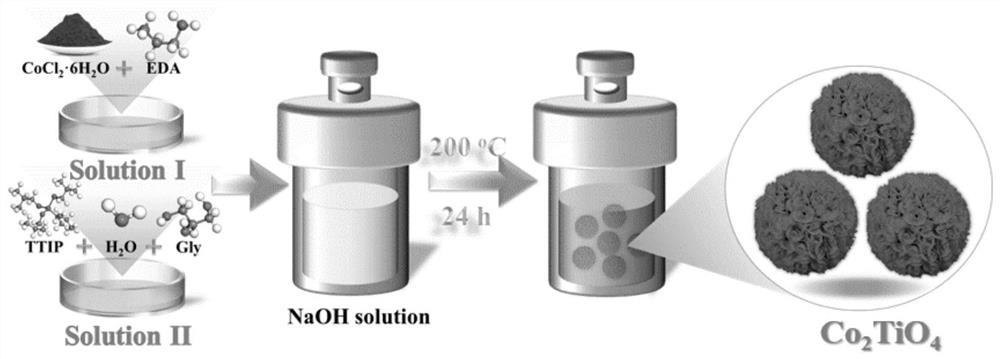

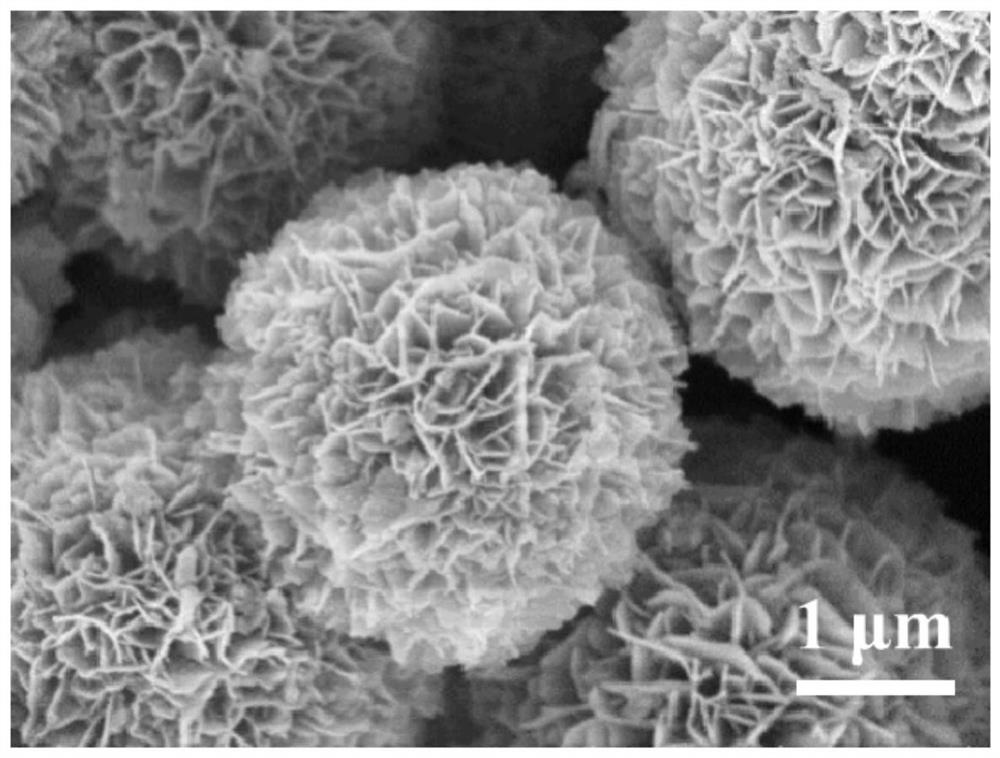

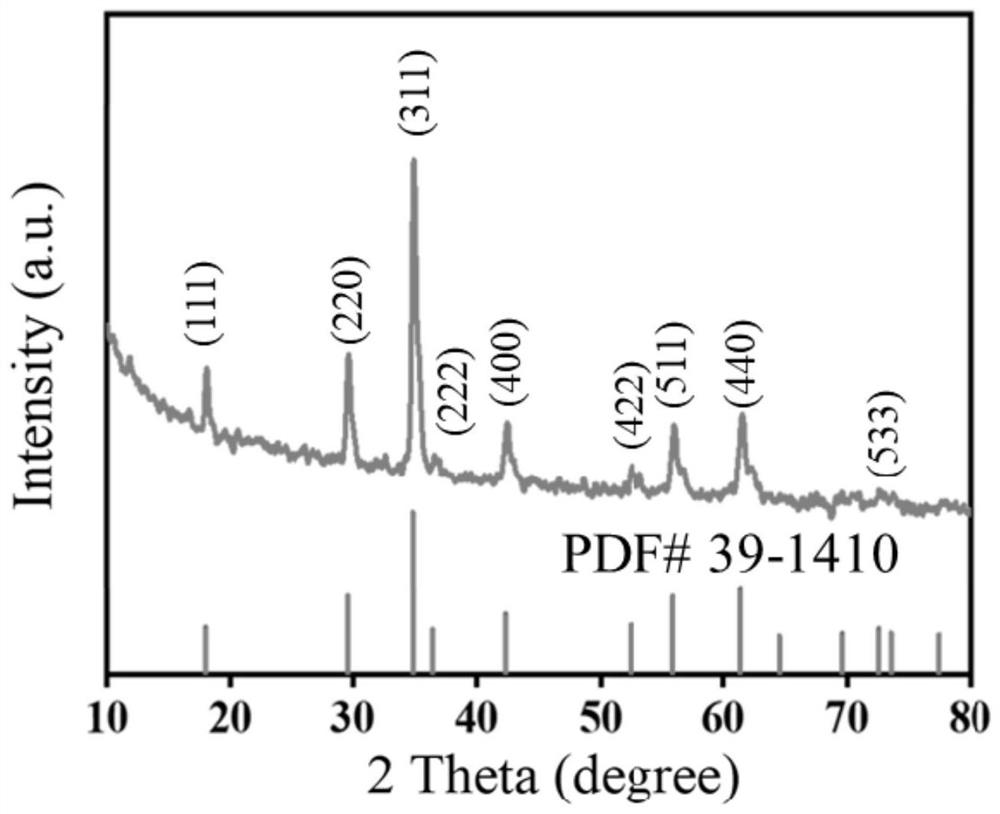

Preparation method and application of three-dimensional multistage flower-like cobalt-titanium spinel nano material

InactiveCN111620385ASimple processLow costWater contaminantsCatalyst activation/preparationPhysical chemistryEthylenediamines

The invention provides a preparation method of a three-dimensional multistage flower-like cobalt-titanium spinel nano material, which comprises the following steps: dissolving a cobalt source in an ethylenediamine solution to obtain a cobalt source-ethylenediamine precursor; dissolving a titanium source in an aqueous solution of glycerol to obtain a titanium source-glycerol precursor; adding the cobalt source-ethylenediamine precursor and the titanium source-glycerol precursor into an alkaline solution, uniformly mixing, reacting at 180-220 DEG C for 12-48 hours, and carrying out centrifuging,washing and drying after the reaction is finished, thereby obtaining the three-dimensional multi-stage flower-like cobalt-titanium spinel nano material. The cobalt-titanium spinel nano material prepared by the method has a spherical flower-like microstructure, and has the characteristics of monodispersity, pure phase crystal form, developed pore structure (about 10.8nm), large specific surface area (113.6m<2>.G<-1>) and the like. The preparation method disclosed by the invention has the advantages of simple process, low cost, convenience and quickness, high yield and easiness in large-scale production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

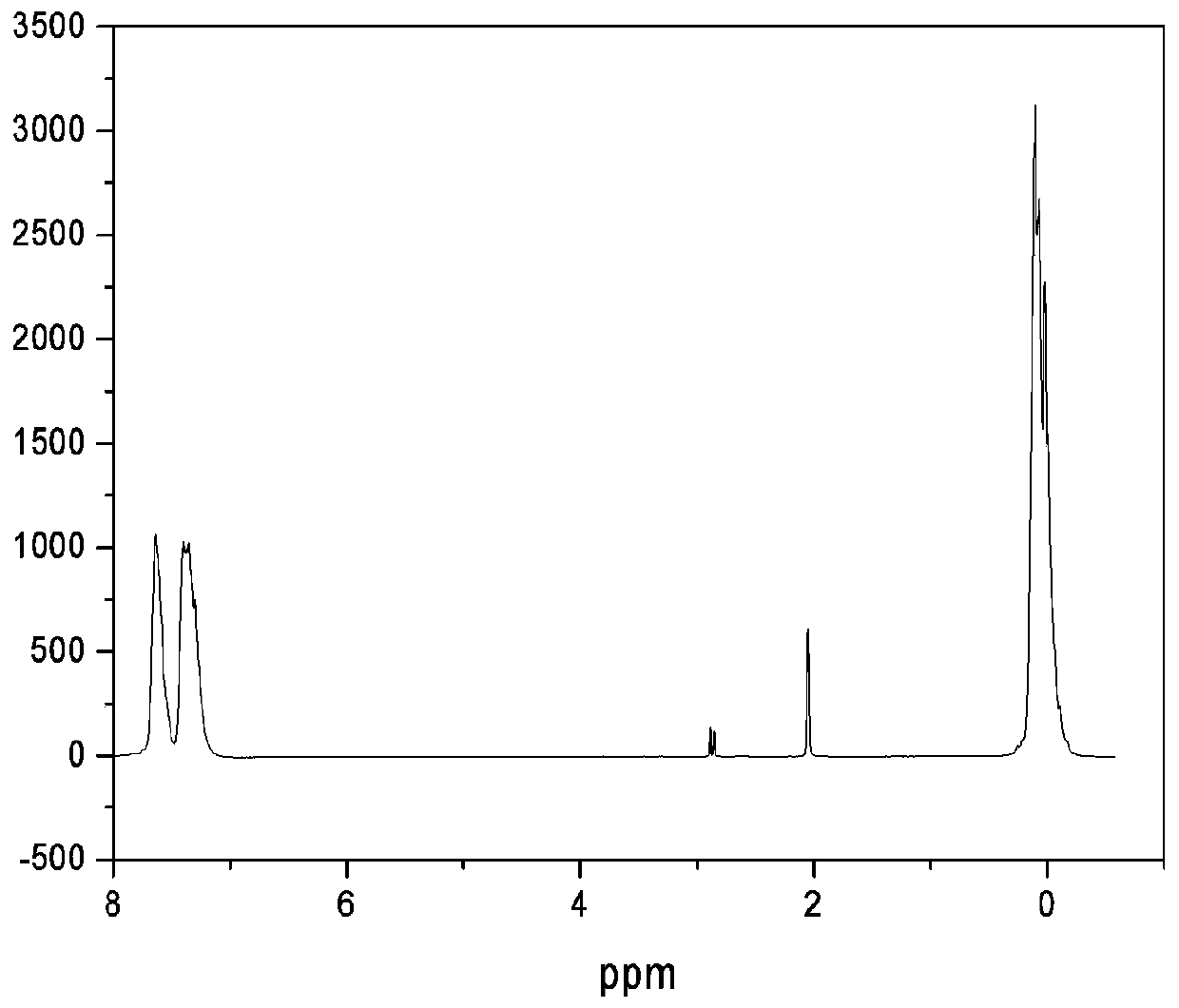

Preparation method of phenyl silicone oil

The invention discloses a preparation method of phenyl silicone oil, the preparation method comprises the following steps: (1) adding a hydrolysis mixed solution and dimethyl alkoxy silane into diphenyl alkoxy silane to have a hydrolysis reaction to obtain a hydrolysate, wherein the speed ratio of the dimethyl alkoxy silane to the hydrolysis mixed solution is (3-10):1, the hydrolysis mixed solution comprises a hydrolysis catalyst, a hydrolysis accelerator and water; (2) adding an end capping agent and a polymerization catalyst into the hydrolysate to have a polymerization reaction, adding a hydroxyl remover in the process of the polymerization reaction, and finishing the reaction to obtain a finished product. The dimethyl alkoxy silane and the hydrolysis mixed solution are added into the diphenyl alkoxy silane at certain speed ratio, the hydrolysis speed is effectively controlled, the phenyl in the hydrolysate is more evenly distributed, the prepared hydrolysate is clear and transparent, the hydrolysate with the evenly distributed phenyl is obtained without rearranging at the high temperature, and the quality of a final product, the phenyl silicone oil, is improved.

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

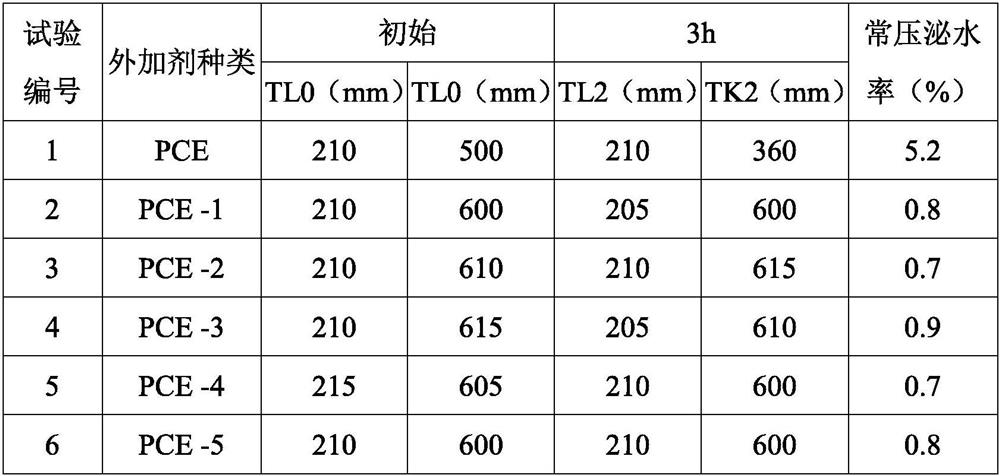

A kind of preparation method of ether high water retention type polycarboxylate water reducer

The invention discloses a preparation method of an ether-based high water-retaining polycarboxylate water-reducer, which comprises the following steps: (1) esterification reaction; (2) monomer blending; (3) copolymerization reaction; (4) and react. The preparation method of the present invention grafts glucose, the esterification product of the first compound, and the unsaturated fluorine-containing monomer into the polycarboxylic acid molecular chain by copolymerization, and introduces glucose into the molecular structure of the prepared polycarboxylate water reducer. Ester structure, fluorophenyl structure, phosphoric acid group structure, amino structure, etc., under the mutual synergy of these structures, the polycarboxylate superplasticizer of the present invention has high water retention and can effectively lock the water in concrete , control the hydrolysis rate of the ester group, will not lag behind bleeding, and the concrete fluidity is stable.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

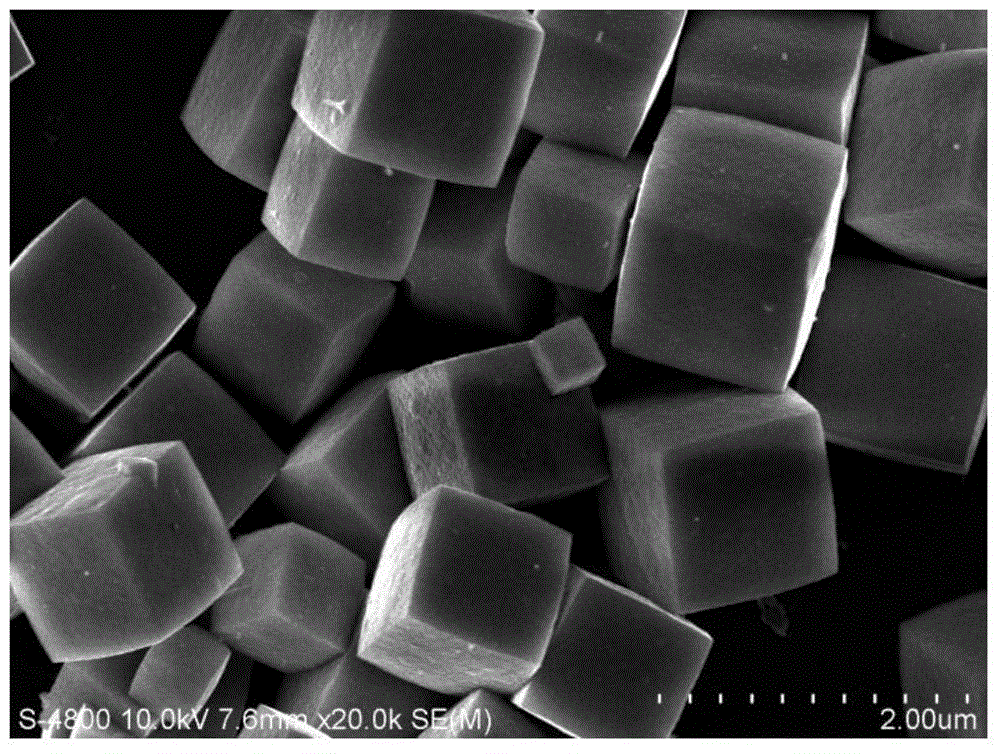

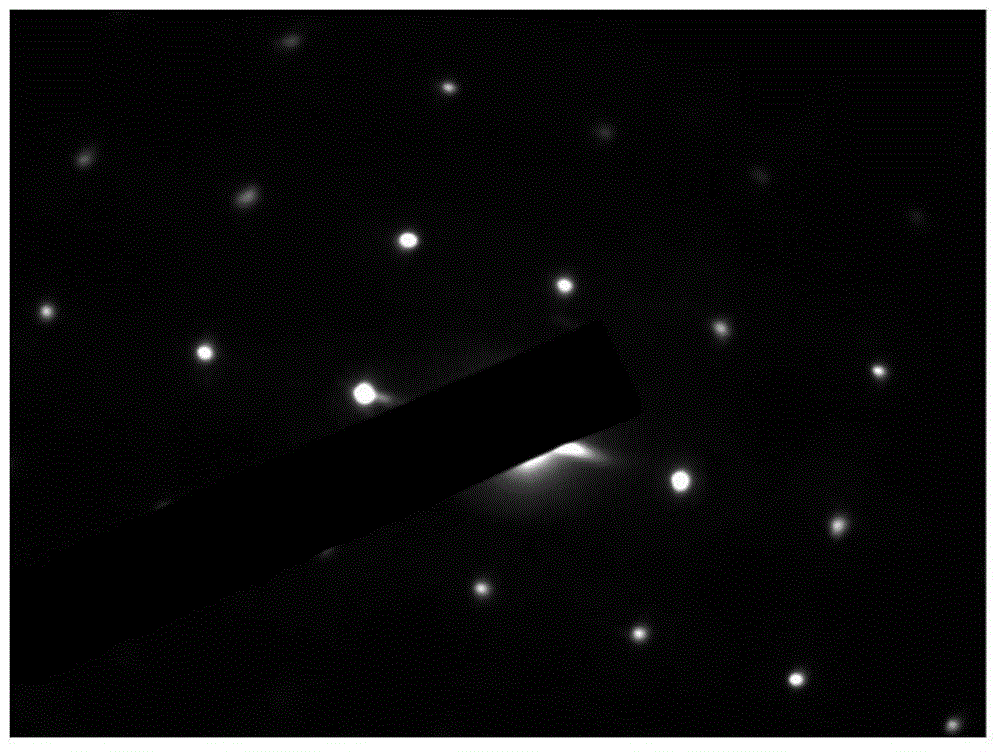

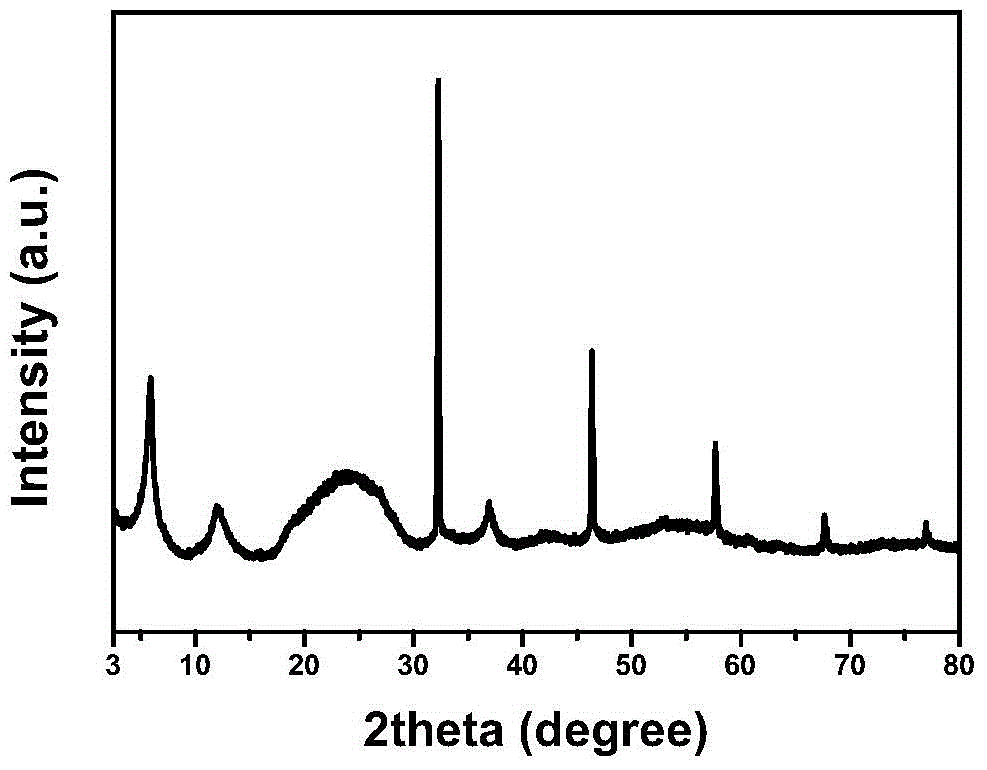

A kind of tantalum oxychloride micron cubic crystal photocatalyst and its preparation method and application

InactiveCN104874410BFine control of acidityFine control of hydrolysis ratePhysical/chemical process catalystsTantalum compoundsCarboxylic acidSingle crystal

The invention discloses a tantalum oxide chlorine micron cubic crystal photocatalyst as well as a preparation method and application thereof. The preparation process comprises the following steps: dissolving Ta5+ tantalate in a mixed solution of concentrated hydrochloric acid and carboxylic acid, wherein the molar ratio of HCL to carboxylic acid is 1:(1.4-5.6); performing hydrolysis reaction on the mixed solution containing tantalate at a temperature of 100-240 C degree for 3-18 hours; cooling naturally, filtering and collecting precipitate and drying to obtain the tantalum oxide chlorine micron cubic crystal. The preparation method is simple, moderate in reaction and good in repeatability and can be widely applied to preparation of a single crystal structure of metal oxide of which the precursor is hydrolyzed rapidly; the micron cubic crystal is high in crystallization degree, strong in light absorption ability, high in charge migration efficiency and has a relatively strong photocatalytic hydrogen generation ability and a wide application prospect in the field of solar energy utilization and photochemistry conversion.

Owner:WUHAN UNIV OF TECH

A kind of sulfonated zirconium phosphonate solid strong acid porous material and its preparation method

ActiveCN104549379BHigh surface areaHas a multi-level pore structurePhysical/chemical process catalystsStrong acidsPore diameter

The invention discloses a sulfated zirconium phosphonate solid strong acid porous material. The granule diameter of the material is from tens of microns to hundreds of microns, the material is in a mesoporous-macropore structure, the pore diameter of a macropore is 300-500nm, a pore wall of which the diameter is 1.6-2.2nm between macropores is in a mesoporous structure, the specific surface area is 400-650m<2> / g, and the exchange capacity of a hydrogen ion is 5.4-6.6mmol / g. The porous material has the advantages that the acidity is strong, and the porous material has a higher actual industrial production value.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of control method of low carbon olefin oligomerization reaction process

ActiveCN105669340BControl the rate of hydrolysisReal-time monitoring of acidityHydrocarbonsHydrocarbon preparationAcid waterPotential difference

The invention relates to a low carbon olefin oligomerization process control method. The method comprises the following steps: (1) enabling a sodium dihydrogen phosphate water solution in an acid water tank to enter from the upper part of a neutralization sedimentation tank through an acid water pump; (2) inputting low carbon olefin and low pressure steam into a heater, and heating to respectively obtain low carbon olefin and low pressure steam condensate; discharging the low pressure steam condensate; enabling the low carbon olefin to enter from the bottom of the neutralization sedimentation tank; (3) enabling the low carbon olefin to contact with the sodium dihydrogen phosphate water solution reversely, and regulating and controlling the water content of the low carbon olefin according to a mode; (4) when the water content of the low carbon olefin is 200ppm-3000ppm, performing oligomerization on the low carbon olefin and a solid phosphoric acid catalyst, thus obtaining a reaction product; (5) enabling steam and water in a balanced state in a steam pocket to flow inside from the lower part of a reactor under potential difference action, and reacting with the reaction product obtained in the step (4), thus respectively obtaining C5-C16 olefin products and steam; enabling the steam to return to the steam pocket; detecting the C5-C16 olefin products by an online acidity analyzer, and then discharging. The low carbon olefin oligomerization process control method can achieve the aim of real-time monitoring.

Owner:北京凯美诺科技有限公司

Organic pollutant photodegradation catalyst and preparation method thereof

InactiveCN111514874AAppropriate amount of dopingHigh catalytic activityWater/sewage treatment by irradiationWater treatment compoundsManganese sulphateAcetic acid

The invention provides an organic pollutant photodegradation catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) slowly dropwise adding a butyl titanate solution into absolute ethyl alcohol, stirring, then adding manganese sulfate and ferric nitrate, stirring, adding anhydrous acetic acid to regulate the pH value to 2.5-3.5, and obtaining a premixedsolution; (2) carrying out ultrasonic treatment while stirring the premixed solution, and then slowly spraying water into the premixed solution through a sprayer; after the water is sprayed, stoppingthe ultrasonic treatment, and continuously stirring; standing the obtained product, drying in vacuum, grinding, heating to 530-560 DEG C, and roasting; and grinding and sieving to obtain the organicpollutant photodegradation catalyst manganese / iron co-doped titanium dioxide. The prepared organic pollutant photodegradation catalyst is good in stability and good in organic pollutant degradation effect, and the preparation process is mild in reaction condition, easy to operate and easy for industrial production.

Owner:ANHUI SCI & TECH UNIV

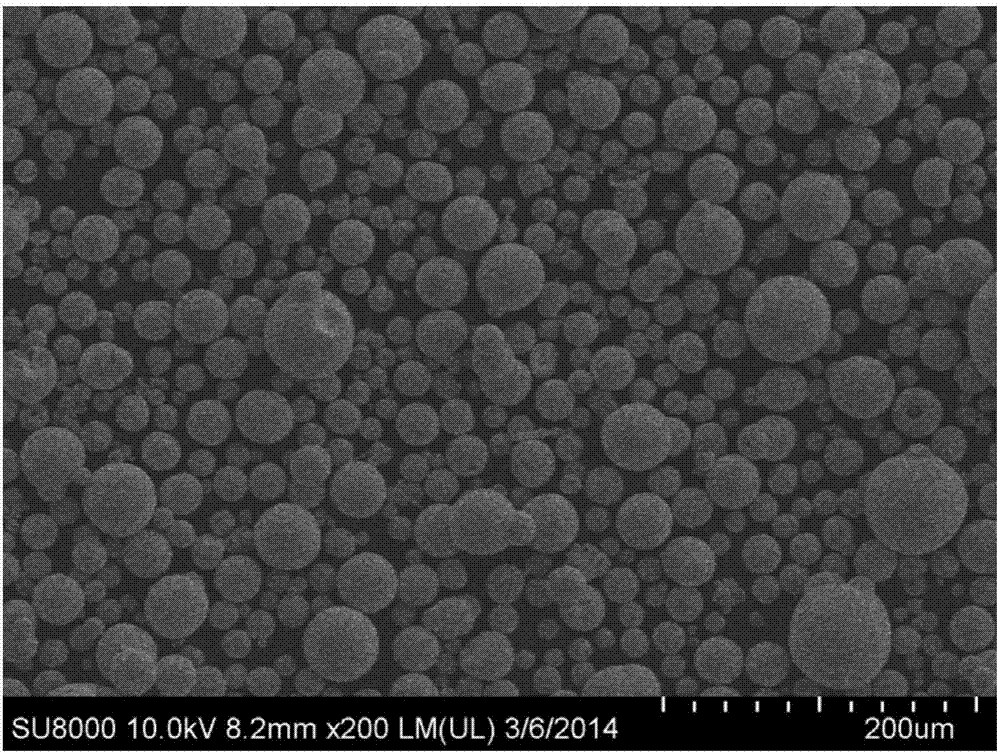

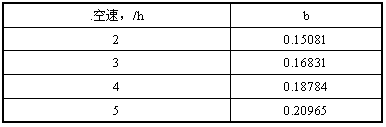

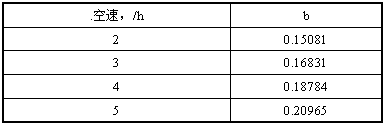

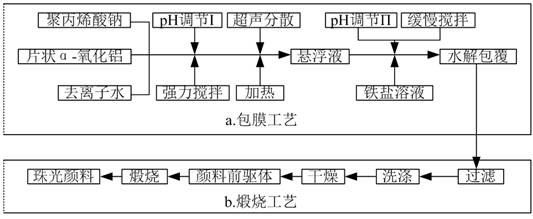

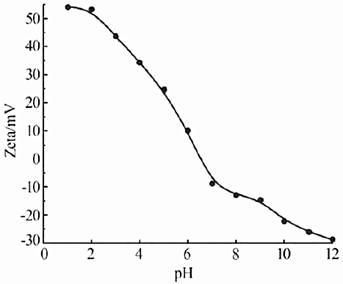

Preparation method of pearlescent pigment taking flaky alpha-aluminum oxide as matrix

ActiveCN114716847APearlescent effect is obviousGood chemical stabilityPigment physical treatmentChemical stabilitySalt solution

The invention discloses a method for preparing pearlescent pigment by taking flaky alpha-aluminum oxide as a matrix, which comprises the following steps: firstly, taking flaky alpha-Al2O3 as a matrix liquid, and adding an adsorbent and an acidic pH regulator I to prepare a water suspension solution with negative charges on the surface of the flaky alpha-Al2O3; adding a metal salt solution and an alkaline pH regulator II into the aqueous suspension solution, and carrying out hydrolysis coating reaction to obtain a pearlescent pigment precursor; and finally, filtering, washing, drying and calcining the pearlescent pigment precursor to obtain the pearlescent pigment. The prepared pearlescent pigment can present a remarkable pearlescent effect, and the pigment has relatively high chemical stability and mechanical stability; and the application range is wide, and the coating can be applied to long-term outdoor service products and high-temperature environments.

Owner:GUIYANG VOCATIONAL & TECHNICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com