Method for preparing high-coulombic-efficiency lithium ion battery negative pole material chrysanthemum-shaped nanometer titania

A nano-titanium dioxide, lithium-ion battery technology, applied in the direction of titanium dioxide, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problem of lithium-ion batteries not obtaining satisfactory capacity and stable cycle performance, limiting large-scale production and Application and other issues, to achieve good electrochemical performance, excellent electrochemical performance, enrich the effect of mesoporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Dissolve 2.3g of tetrabutyl titanate in a certain volume of isopropanol solvent, stir magnetically for 15 minutes to form a clear solution, and then add a certain amount of of the glycerol reagent and continued stirring for 20 minutes to form a clear solution.

[0022] (2) The above solution was transferred to a high-pressure reactor, and hydrothermal reaction was carried out at 180° C. for 14 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifugally washed, separated and dried to obtain titanium dioxide precursor nanomaterials.

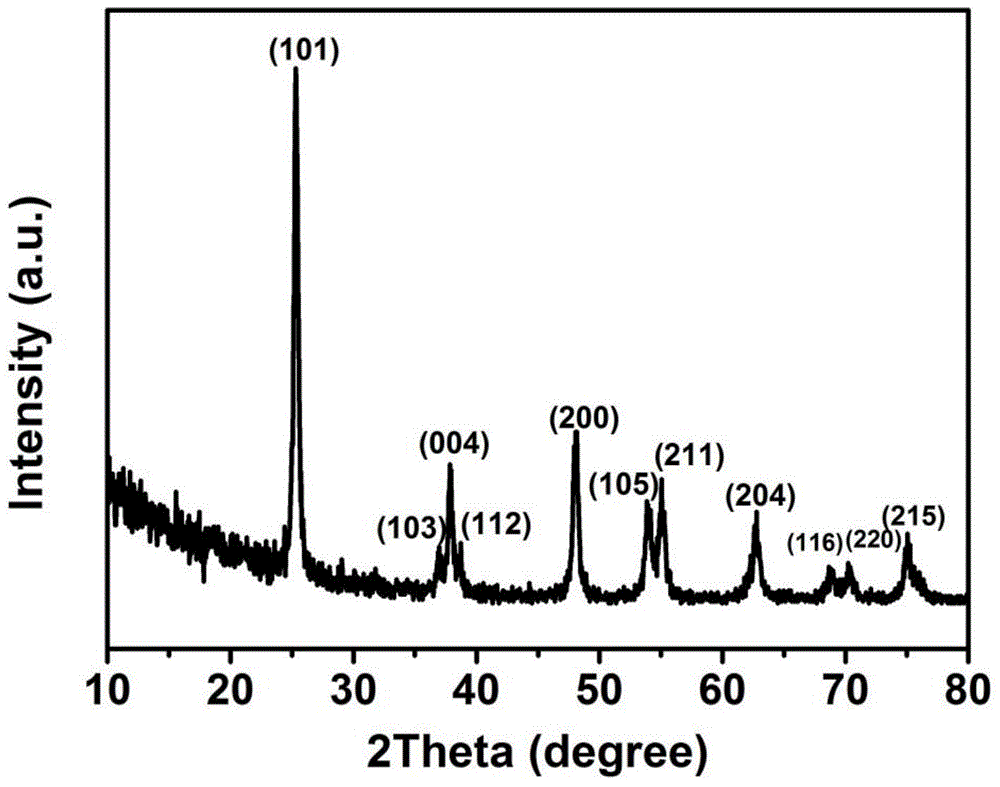

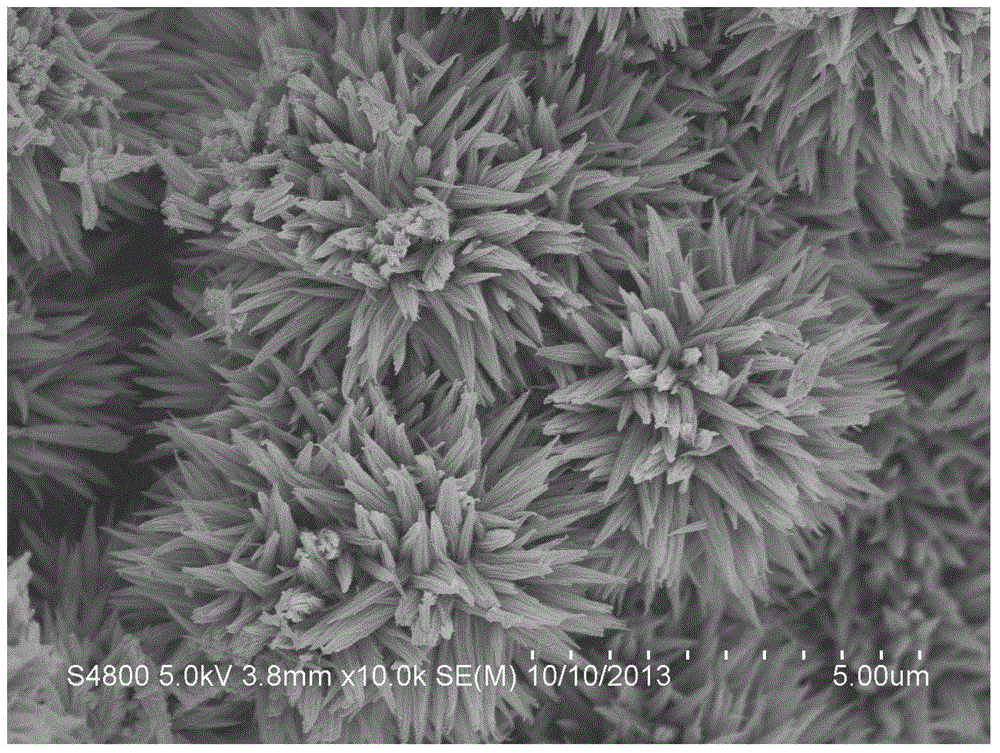

[0023] (3) Put the titanium dioxide precursor nanomaterial obtained in the previous step into a high-temperature furnace for heat treatment at 500° C. for 5 hours, and then naturally cool to room temperature to obtain chrysanthemum-shaped nano-titanium dioxide.

[0024] (4) Use the material synthesized in the previous step for the negative electrode material of lithium ion battery, use conductive c...

Embodiment 2

[0027] (1) Dissolve 1.2 g of isopropyl titanate in a certain volume of n-propanol solvent, stir magnetically for 10 minutes to form a clear solution, and then add a certain amount of amount of glycerol reagent and continue to stir for 15 minutes to form a clear solution.

[0028] (2) The above solution was transferred to a high-pressure reactor, and hydrothermal reaction was carried out at 120°C for 36 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed, separated and dried to obtain titanium dioxide precursor nanomaterials.

[0029] (3) Put the titanium dioxide precursor nanomaterial obtained in the previous step into a high-temperature furnace for heat treatment at 450° C. for 8 hours, and then naturally cool to room temperature to obtain chrysanthemum-shaped nano-titanium dioxide.

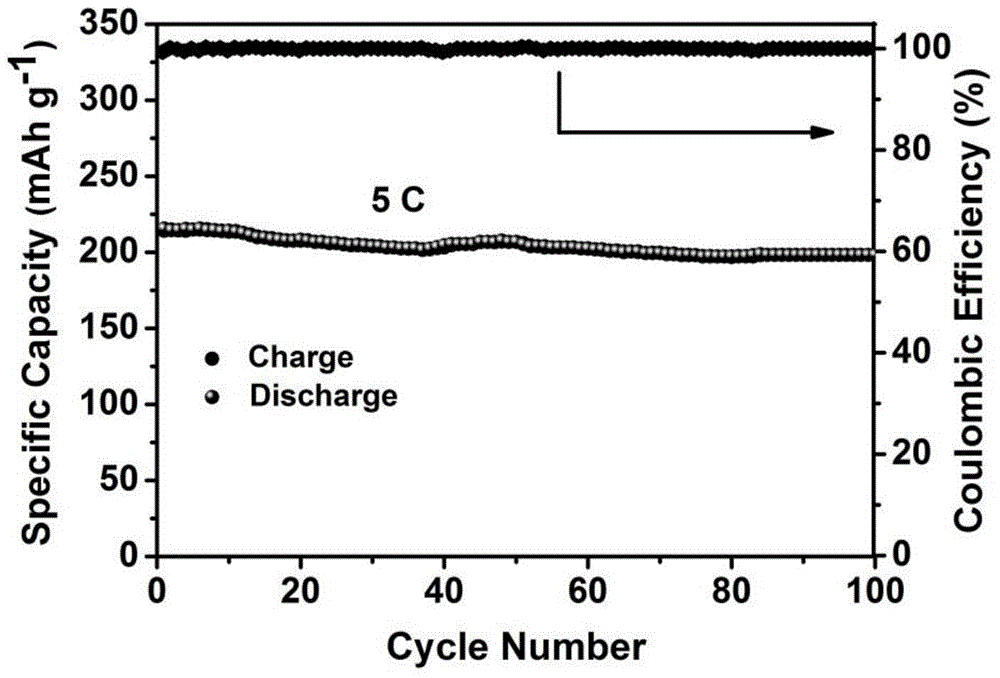

[0030] (4) After the battery is assembled according to the method of Example 1, at 5C (850mA g -1 ) under the current density test, the fir...

Embodiment 3

[0032] (1) Dissolve 3.5g of titanium tetrachloride in a certain volume of n-butanol solvent, form a clear solution after magnetic stirring for 15 minutes, then be 7 according to the volume ratio of n-butanol, ethylene glycol and glycerol mixed solvent: 1 Add a certain amount of ethylene glycol and glycerol mixed reagent, and continue to stir for 20 minutes to form a clear solution.

[0033](2) The above solution was transferred to a high-pressure reactor, and hydrothermal reaction was carried out at 230°C for 10 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifugally washed, separated and dried to obtain titanium dioxide precursor nanomaterials.

[0034] (3) Put the titanium dioxide precursor nanomaterial obtained in the previous step into a high-temperature furnace for heat treatment at 600° C. for 5 hours, and then naturally cool to room temperature to obtain chrysanthemum-shaped nano-titanium dioxide.

[0035] (4) After the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com