Preparation method of two-dimensional porous titanium dioxide nano sheet

A nanosheet and gel method technology, applied in titanium dioxide, chemical instruments and methods, preparation/purification of sulfur, etc., can solve the problem of not being able to have a sheet-like structure and a pore-like structure at the same time, and achieve the effect of accelerating mass transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

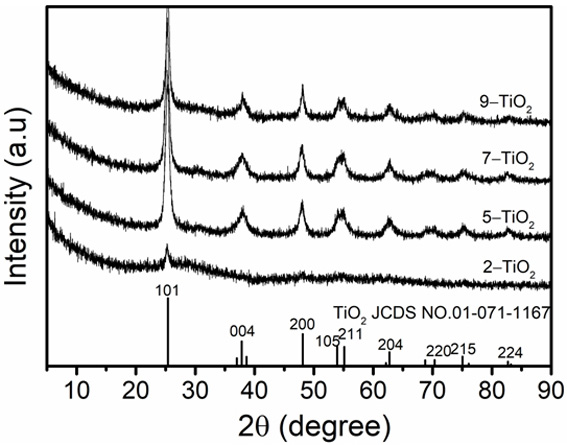

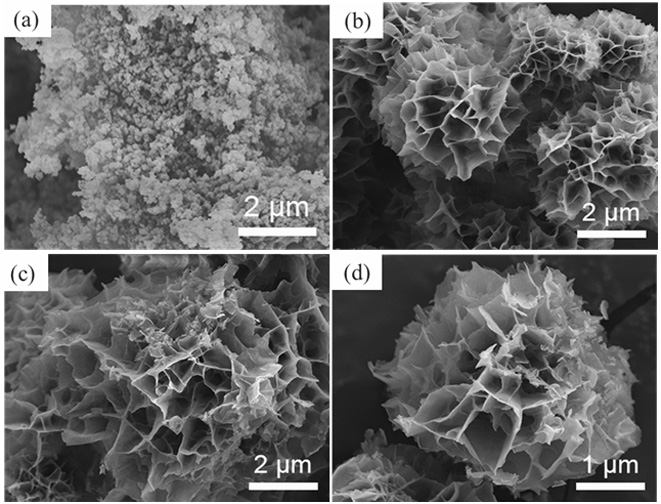

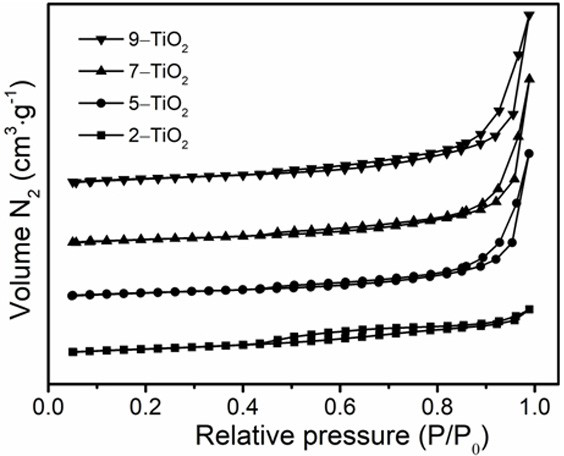

[0029] 0.4968 g polyether F127 (M W ≈12600 mol·g -1 ) and 0.9896g of polyvinylpyrrolidone (PVP) were added to a mixed solution consisting of 15 mL of tetrahydrofuran, 15 mL of dichloromethane, 2.4118 g of glacial acetic acid and 3.5164 g of concentrated hydrochloric acid. After stirring for 10 min, 3.4212 g of tetrachloromethane was added dropwise Titanium chloride, continue to stir for 5 min after the dropwise addition, then add 0.2 g of distilled water dropwise to obtain a red solution, place the obtained red solution in an oven at 40 °C for 24 h to obtain a white gel; weigh 1.0324 g of the obtained gel and add into 30 mL of glycerol / ethanol solvent (the volume ratio of glycerol to ethanol is 1:2), and after vigorously stirring for 10 min, the resulting colorless and clear solution was transferred to the lining of a 50 mL hydrothermal kettle, and heated at 150 °C Hydrothermal treatment for 15 h, after hydrothermal treatment, at 10000 rpm·h -1 The white precipitate was obta...

Embodiment 2

[0031] 0.5016 g polyether F127 (M W ≈12600 mol·g -1 ) and 1.0235 g of polyvinylpyrrolidone (PVP) were added to a mixed solution consisting of 15 mL of tetrahydrofuran, 15 mL of dichloromethane, 2.4243 g of glacial acetic acid and 3.4989 g of concentrated hydrochloric acid. After stirring for 10 min, 3.4169 g of tetrachloromethane was added dropwise Titanium chloride, continue to stir for 5 min after the dropwise addition, then add 0.2 g of distilled water dropwise to obtain a red solution, place the obtained red solution in an oven at 40 °C for 24 h to obtain a white gel; weigh 1.1205 g of the obtained gel and add into 30 mL of glycerol / ethanol solvent (the volume ratio of glycerol to ethanol is 1:5), and after vigorously stirring for 10 min, the resulting colorless and clear solution was transferred to the lining of a 50 mL hydrothermal kettle, and heated at 150 °C Hydrothermal treatment for 15 h, after hydrothermal treatment, at 10000 rpm·h -1 The white precipitate was obt...

Embodiment 3

[0033] 0.4896 g polyether F127 (M W ≈12600 mol·g -1 ) and 1.0358g of polyvinylpyrrolidone (PVP) were added to a mixed solution consisting of 15 mL of tetrahydrofuran, 15 mL of dichloromethane, 2.4268 g of glacial acetic acid and 3.4936 g of concentrated hydrochloric acid. After stirring for 10 min, 3.4023 g of tetrachloromethane was added dropwise Titanium chloride, continue to stir for 5 min after the dropwise addition, then add 0.2 g of distilled water dropwise to obtain a red solution, place the obtained red solution in an oven at 40 °C for 24 h to obtain a white gel; weigh 1.0561 g of the obtained gel and add into 30 mL of glycerol / ethanol solvent (the volume ratio of glycerol to ethanol is 1:7), and after vigorously stirring for 10 min, the resulting colorless and clear solution was transferred to the lining of a 50 mL hydrothermal kettle, and heated at 150 °C Hydrothermal treatment for 15 h, after hydrothermal treatment, at 10000 rpm·h -1 The white precipitate was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com