Silicon oxide coated fluorescent powder and its coating method

A technology of fluorescent powder and silicon oxide, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult control of coating layer thickness, poor protection effect, uneven coating layer, etc., to improve thermal degradation resistance and Anti-work degradation performance, continuous, uniform and compact coating layer, and shortened process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

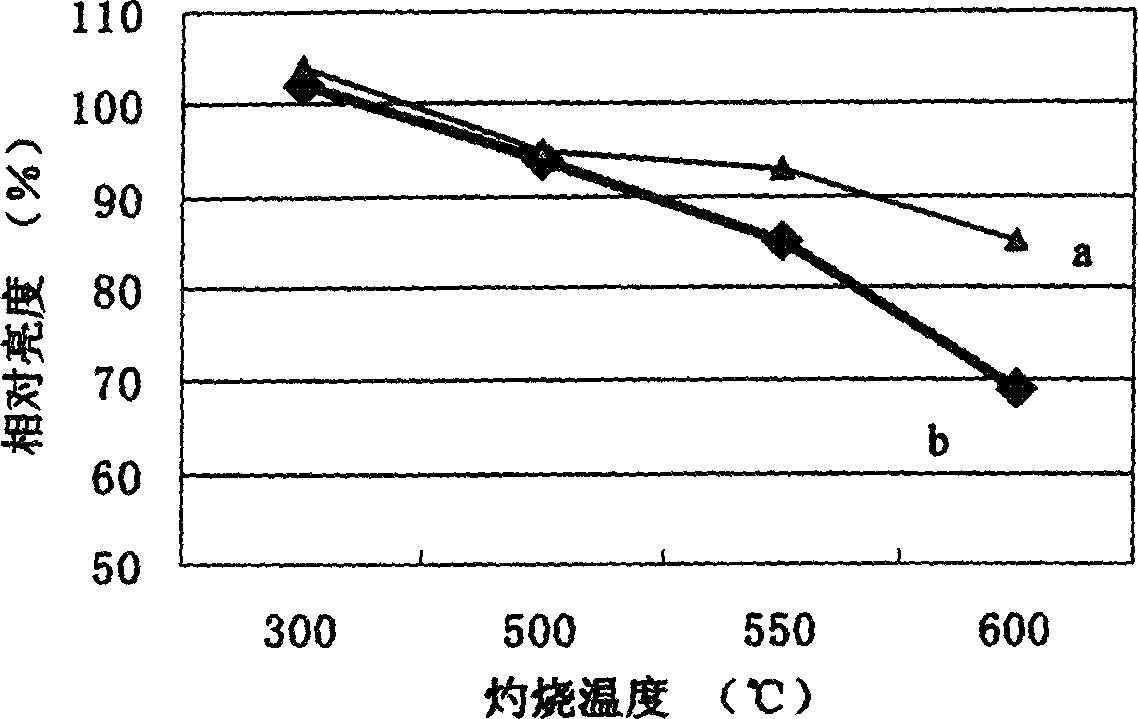

[0024] A silicon oxide-coated phosphor powder for a color plasma flat panel display is coated with SiO on the surface of the phosphor powder 2 The envelope, the SiO 2 The outside of the envelope can also be coated with La 2 o 3 and ZrO 2 , constitute the composite coating, in this example, in SiO 2 The outer coating of the envelope is ZrO 2 Coating, coating the outside of the phosphor coating with La 2 o 3 envelope.

Embodiment 2

[0026] A coating method for preparing the above coated fluorescent powder:

[0027] 1) Use distilled water to make the fluorescent powder of the color plasma flat panel display into a fluorescent powder suspension with a concentration of 0.2% to 5%. 2 Weigh the corresponding amount of Na with a mass ratio of (0.5-20): 100 to the phosphor 2 SiO 3 9H 2 O, and add phosphor suspension, ultrasonically disperse and stir for 10-30min to make Na 2 SiO 3 Dissolve and make the phosphor suspension in a stable state, with HCl, HNO 3 or H 2 SO 4 As a precipitating agent, it is prepared into a solution with a concentration of 0.01-2M, and the above-mentioned SiO 2 The mass ratio to phosphor can be selected as 05:100, 20:100, 1.5:100, 5:100, 6.4:100, 8:100, 10:100, 13:100 or 16:100, and SiO 2 The dosage is preferably 5-10wt% of the total mass of the phosphor, and the concentration of the above-mentioned precipitant can be selected as 0.05, 0.1, 0.5 or 1M; before preparing the phospho...

Embodiment 3

[0031] Weigh 50g of BaMgAl for PDP 10 o 17 :Eu 2+ Phosphor powder (BAM) was put into NaOH solution with a concentration of 0.5M, soaked for 24 hours, then separated and dehydrated with a centrifuge, and washed with distilled water until the supernatant was neutral.

[0032] Weigh the alkaline pretreated PDP phosphor BaMgAl 10 o 17 :Eu 2+ Put 10g of blue powder into a small amount of distilled water, and disperse it ultrasonically for 30 minutes. by SiO 2 / Phosphor powder = 2.5wt% ratio weighs 1.18gNa 2 SiO 3 9H 2 O Add the phosphor suspension, and add 5ml of 0.1% Tween 80 dispersant to the phosphor suspension, and finally add water to dilute to 500ml, stir for 30min to obtain a uniformly dispersed coating mother liquor. Heat the mother liquor water bath to 60°C and keep it warm, vigorously stir the mother liquor pair (stirring speed: 200r / m), slowly drop the HCl solution with a concentration of 0.25M into the mother liquor until the pH value is equal to 6-9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com