Patents

Literature

98results about How to "Control form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

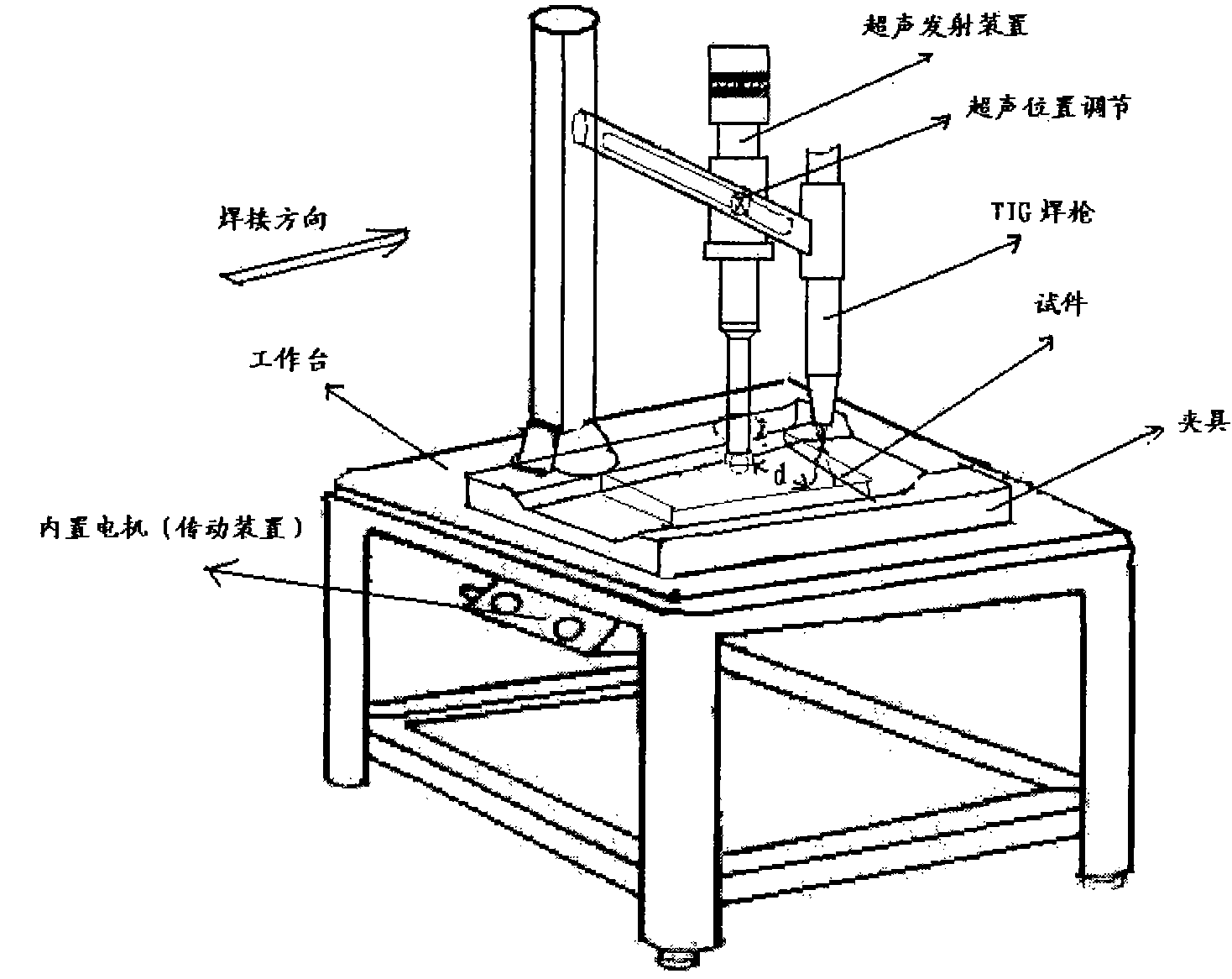

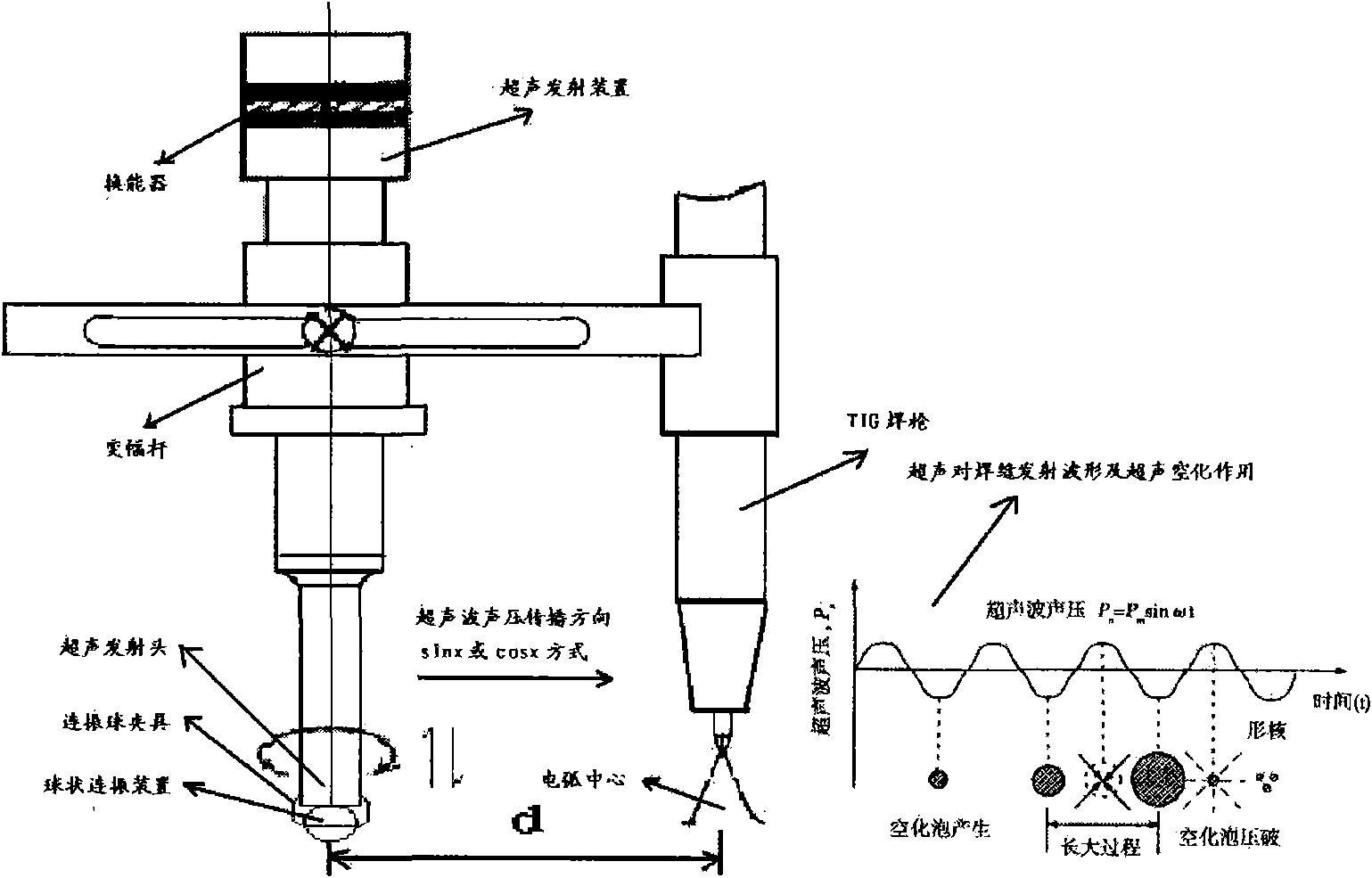

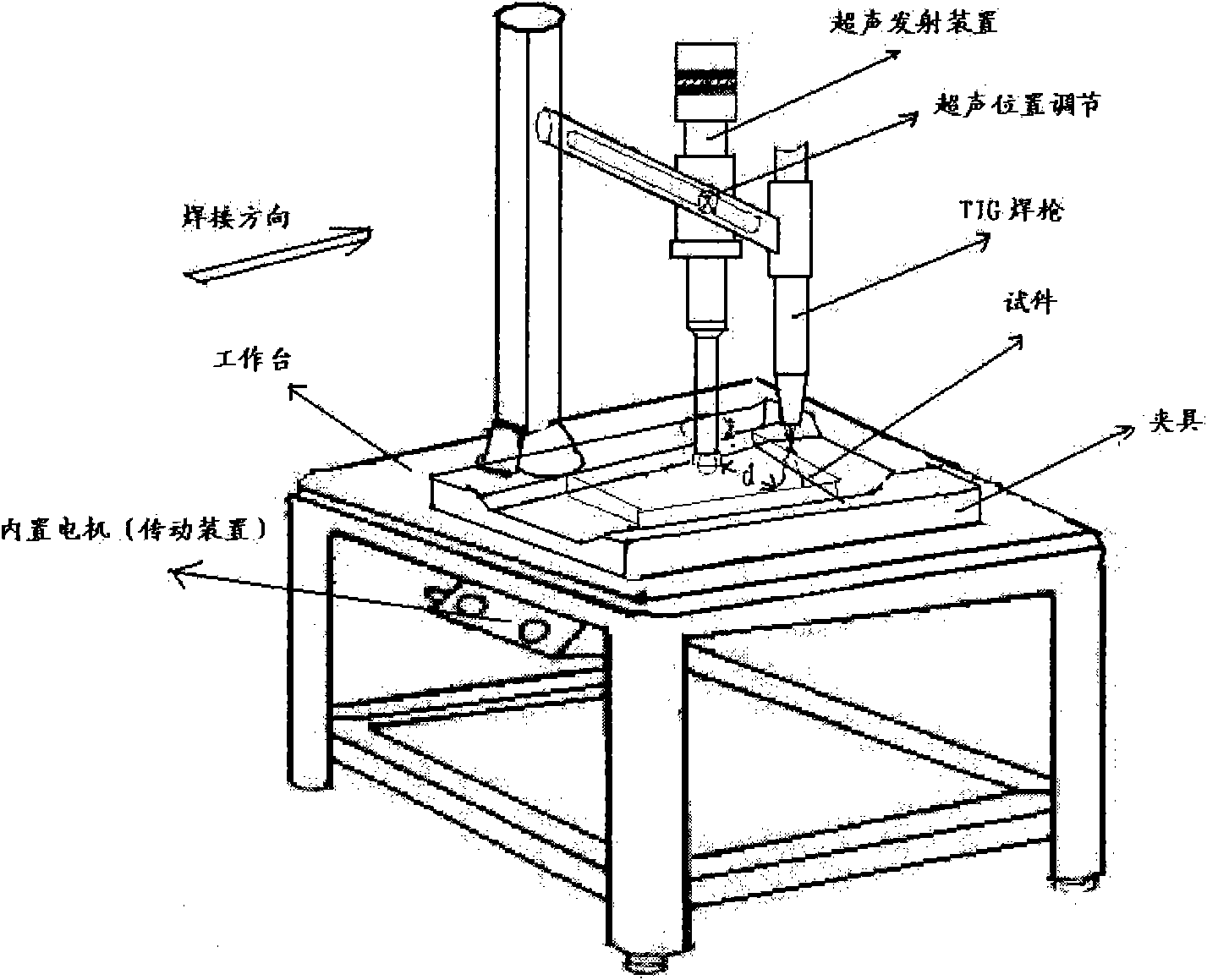

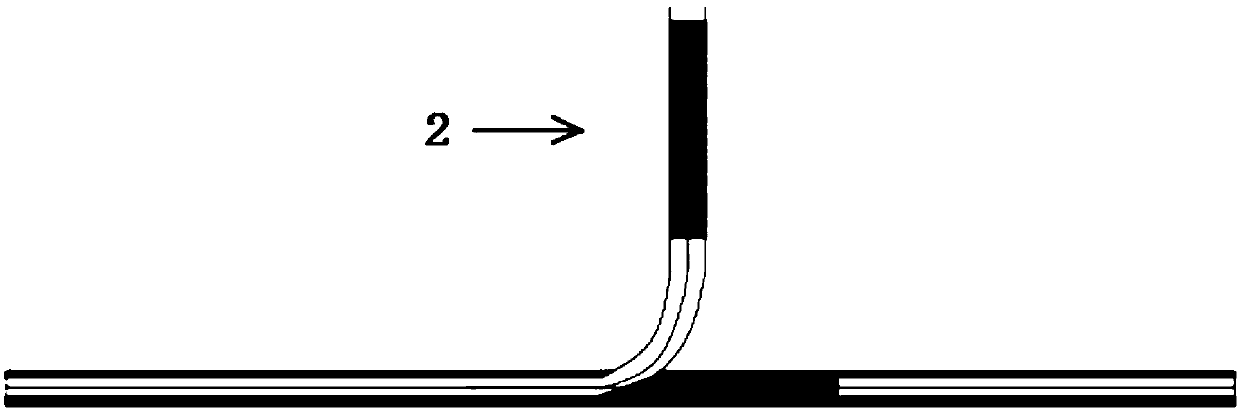

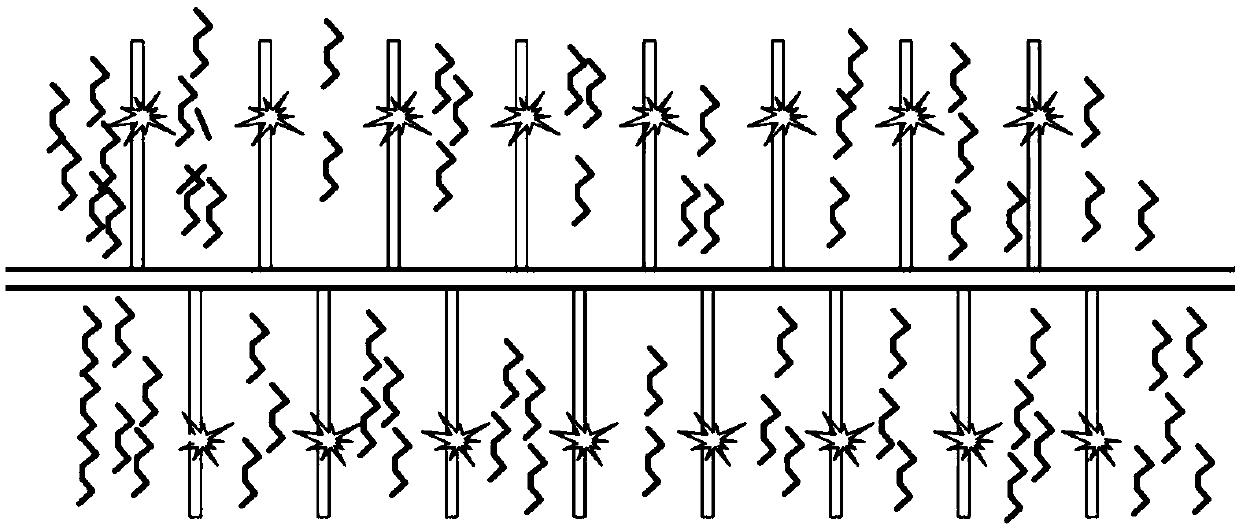

Ultrasonic welding method of Al/Ti dissimilar metal TIG (Tungsten Inert Gas) electrical arc micro-melting brazing and following welding

The invention provides an ultrasonic welding method of Al / Ti dissimilar metal TIG electrical arc micro-melting brazing and following welding, wherein an isochronous and stable ultrasonic vibration system is added in the TIG micro-melting brazing process, and the simultaneous and equi-directional welding of TIG micro-melting brazing and following welding is realized through a spherical interlinking device. The method comprises the following steps of: enabling a welding gun tungsten electrode and a test piece to reach reasonable welding height by vertically adjusting the position of a welding gun; enabling a continuous vibration ball to cling to the surface of the test piece by vertically adjusting an ultrasonic transmitting device; measuring the distance d from the contact point of the continuous vibration ball and the surface of the test piece to a TIG welding gun tungsten electrode by horizontally adjusting an ultrasonic generating device to enable d to satisfy welding requirements; and reasonably matching an ultrasonic vibration device and a TIG welding gun by adjusting d, and adjusting the acting position of ultrasonic vibration by adjusting d. The invention has strong process applicability and good stability, realizes the semi-automatic welding of Al / Ti dissimilar metal connection, and has wider usability and good improving action for the welding joints of TIG micro-melting brazing for various dissimilar metals.

Owner:HARBIN INST OF TECH

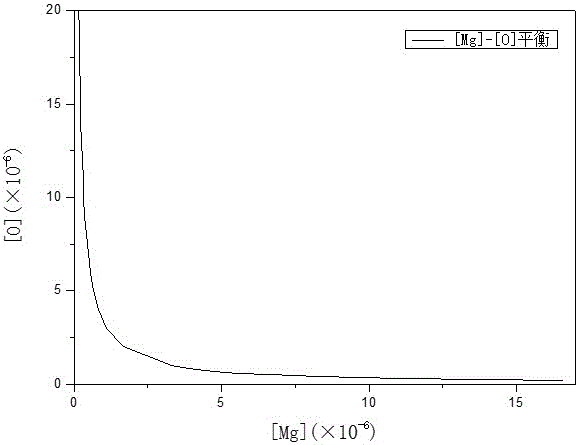

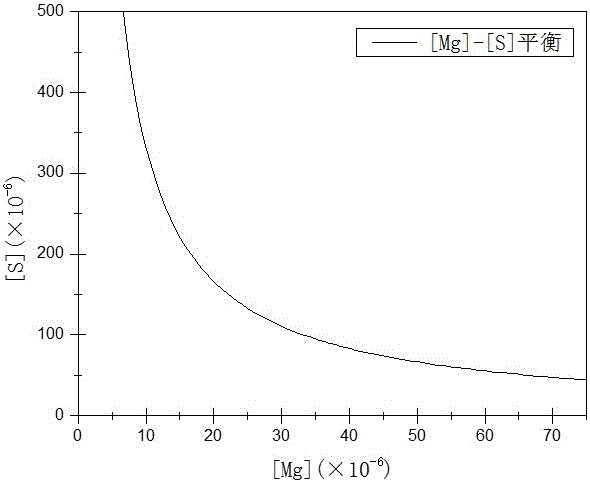

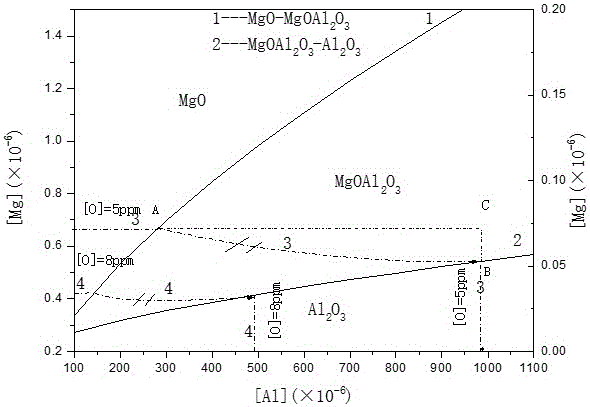

Magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and preparation method thereof

The invention discloses magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and a preparation method thereof. The steel is prepared from, by weight percent, 0.15%-0.25% of C, not larger than 0.12% of Si, 0.80%-1.50% of Mn, not larger than 0.035% of P, 0.02%-0.055% of S, 0.80%-1.30% of Cr, 0.015%-0.055% of Al, 0.004%-0.015% of N, 0.0006%-0.004% of Mg, 0.0006%-0.005% of Ca, not larger than 0.0025% of [O] and the balance iron and inevitable impurities. Composite modification is carried out on inclusion by adding a small quantity of calcium and magnesium elements in the refining process, and the composite inclusion with oxide (including multiple oxide) as a core is formed, wherein the core of the composite inclusion is wrapped by sulfide; splitting of the oxide to a steel substrate can be relieved, the anti-fatigue performance can be improved, and the transverse mechanical property of the steel can be improved; and the magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel both good in mechanical performance and cutting performance is produced, and has large economic benefits.

Owner:SHANGHAI UNIV

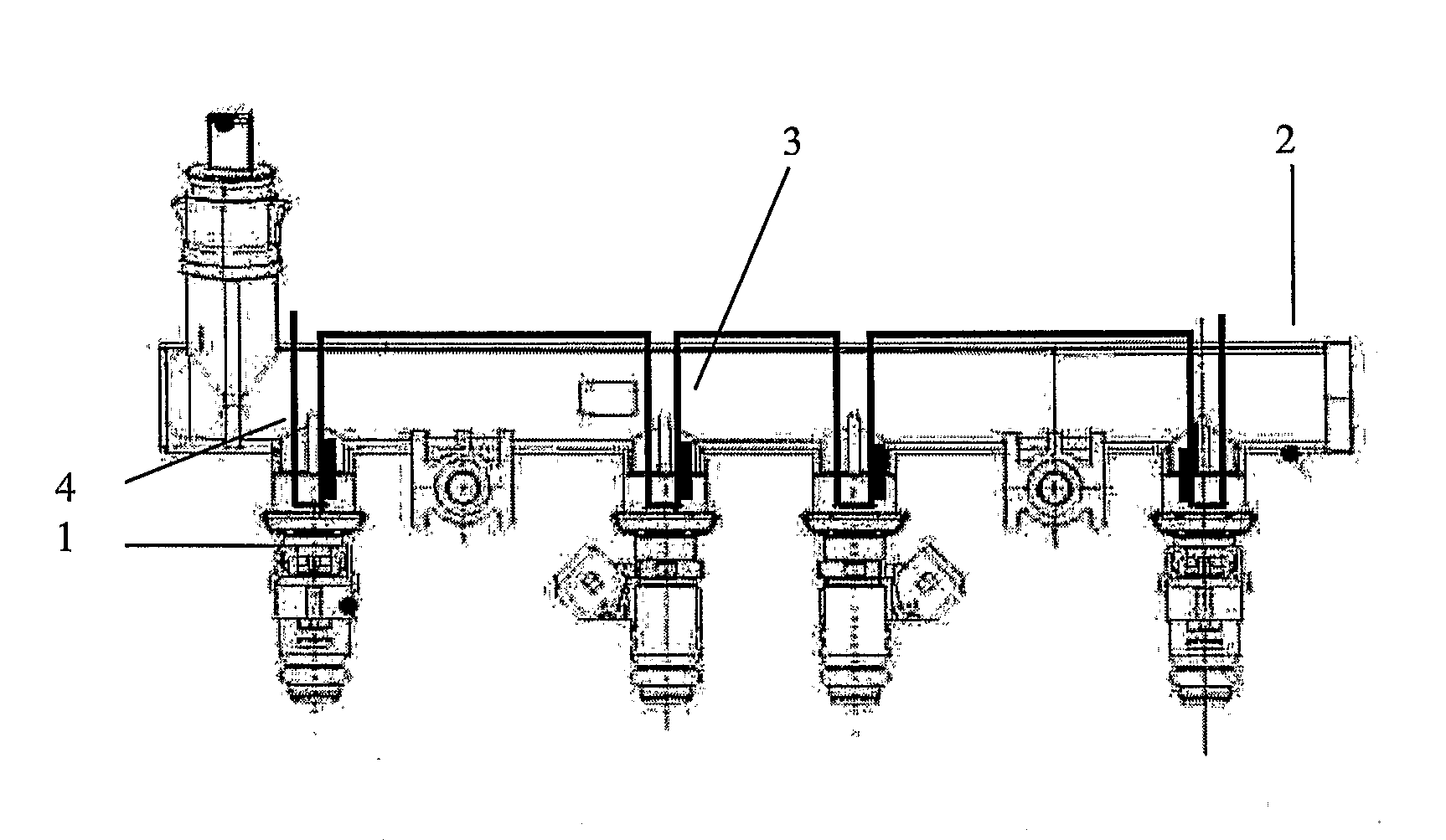

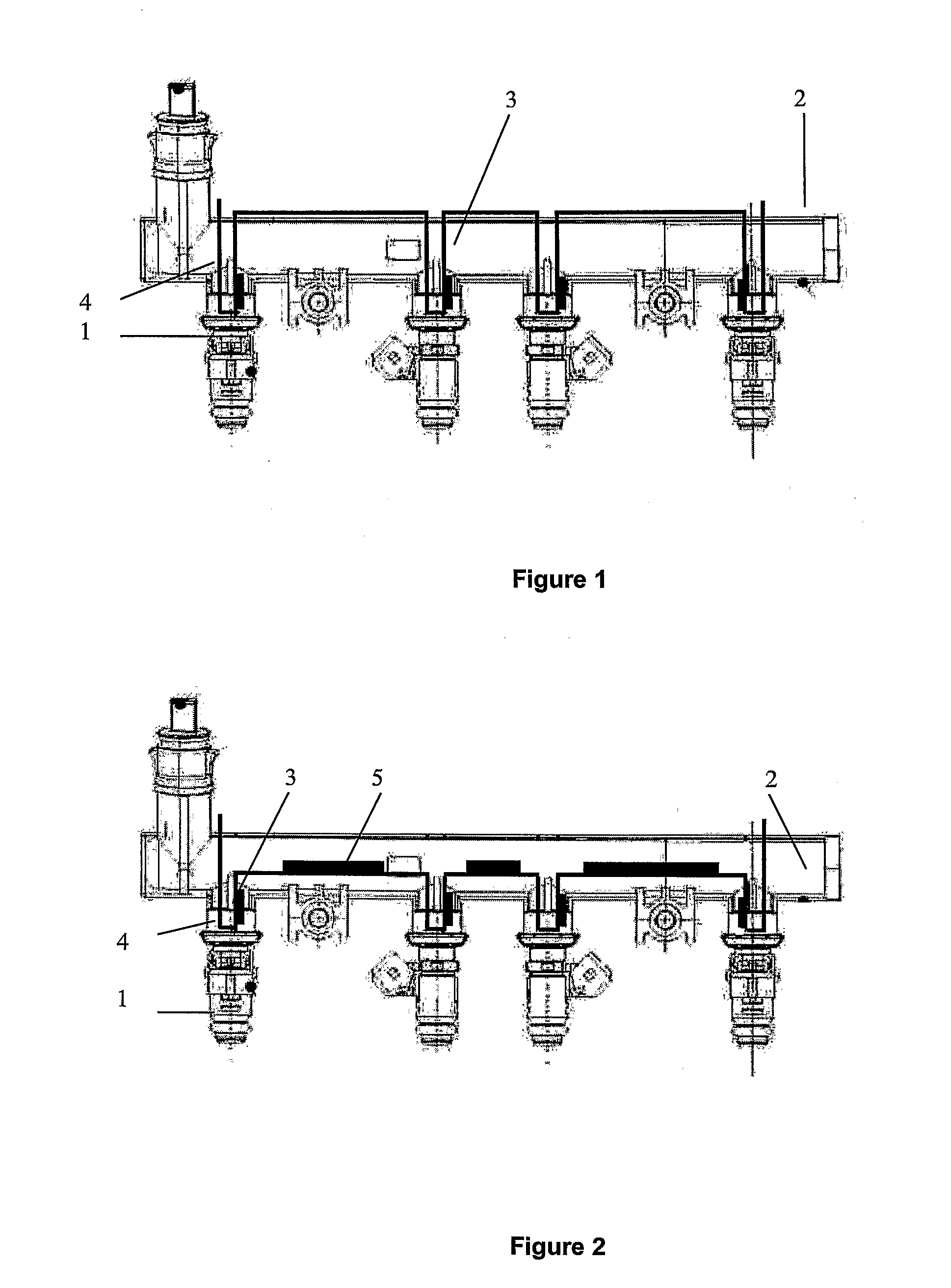

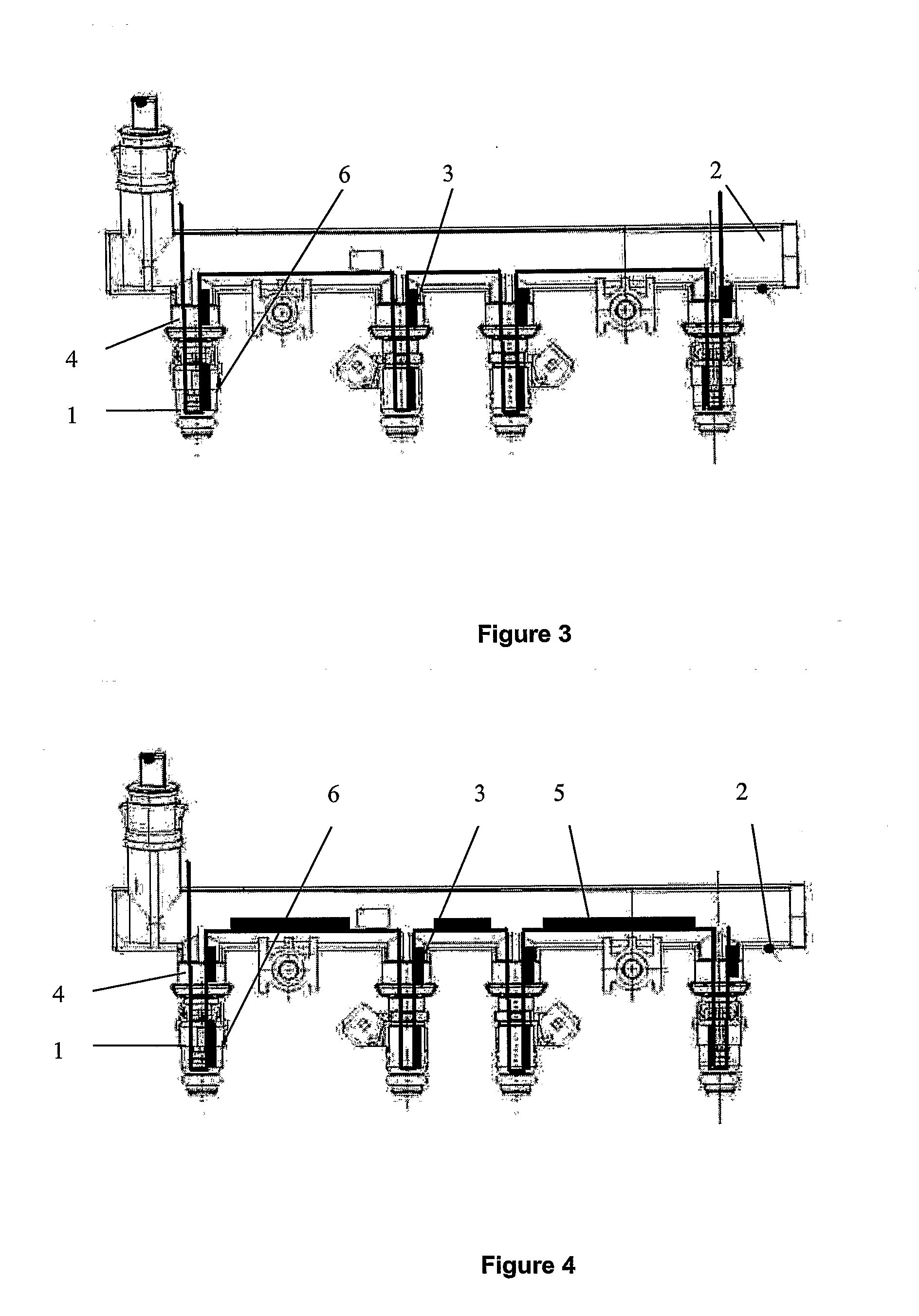

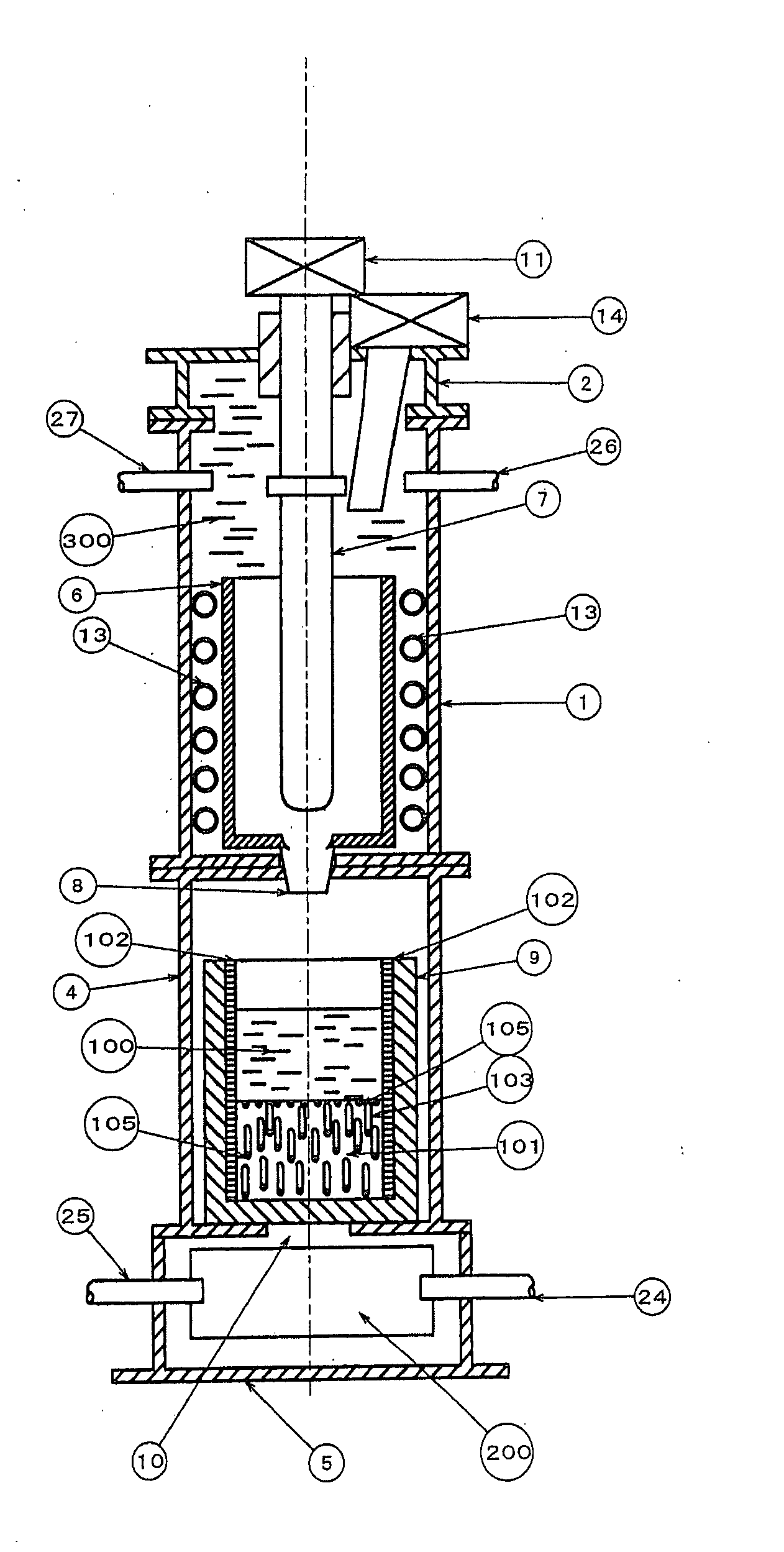

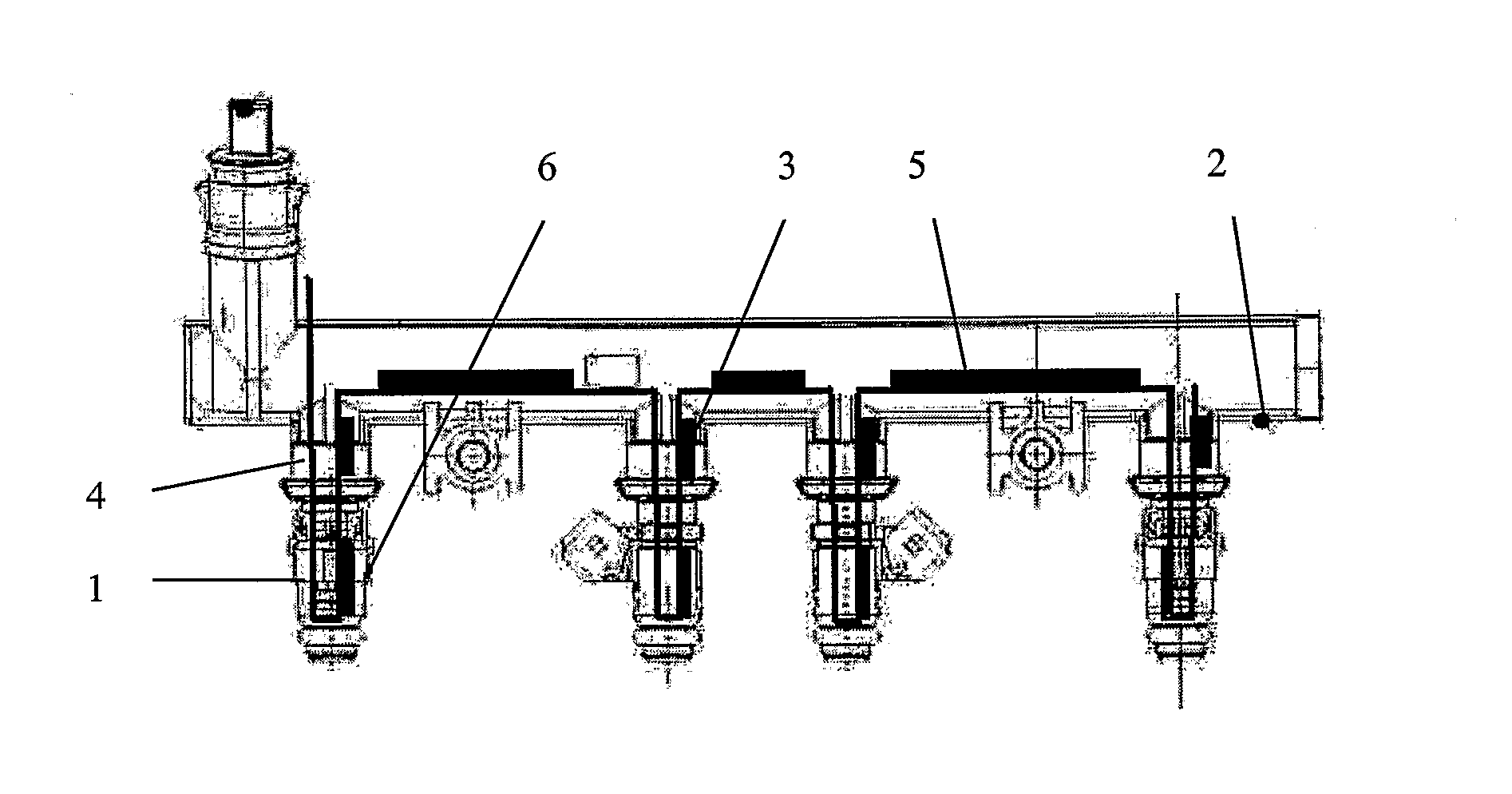

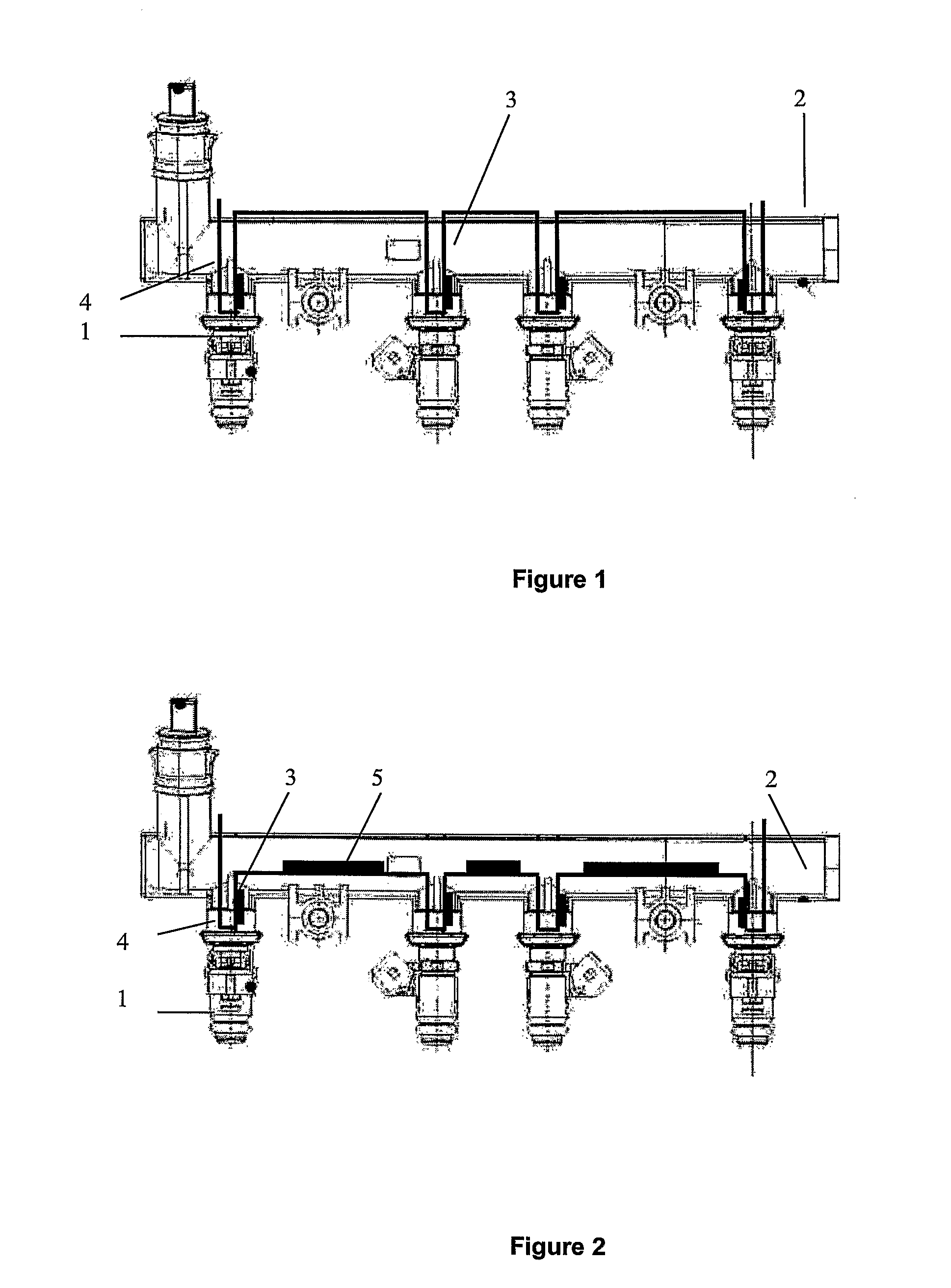

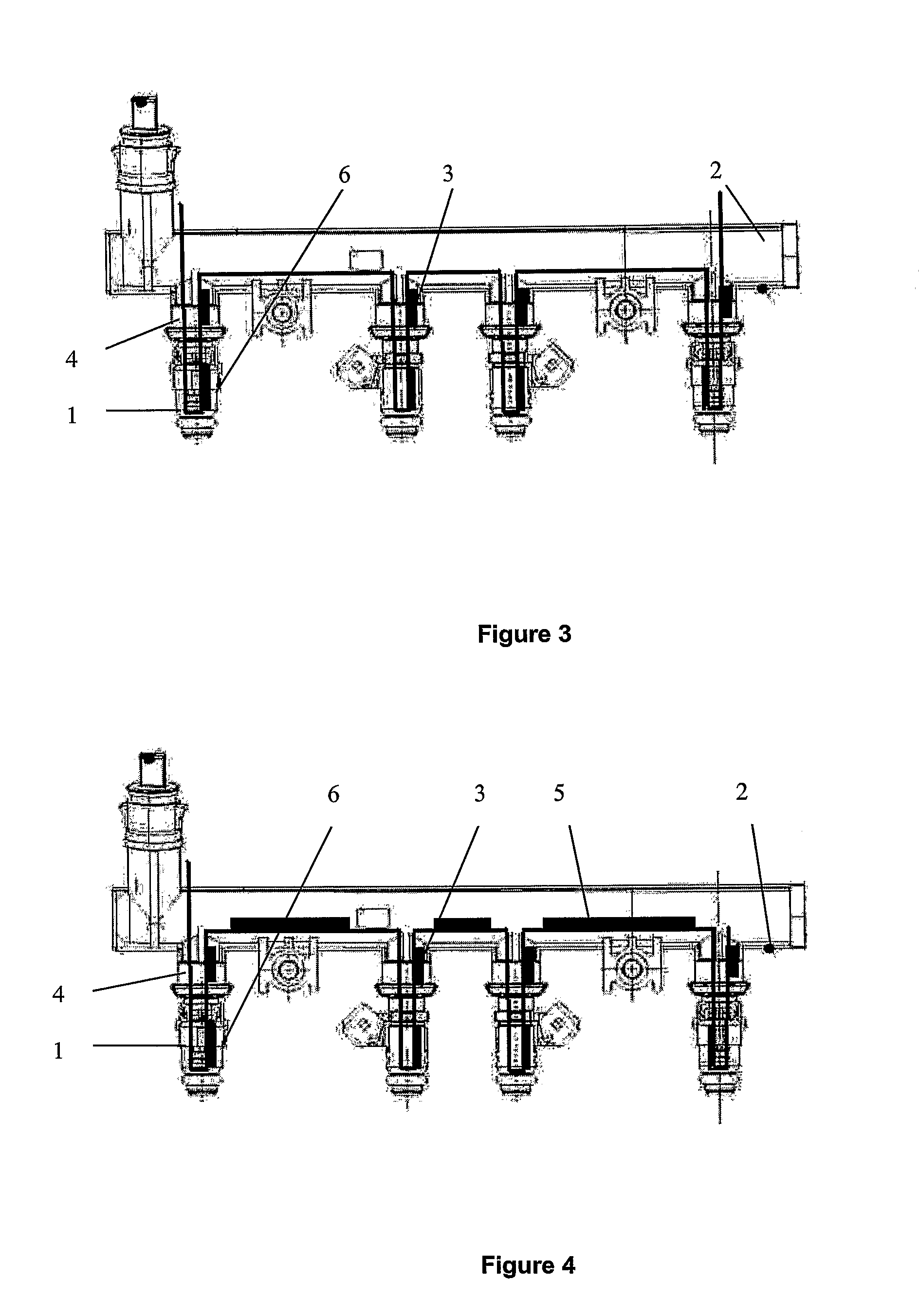

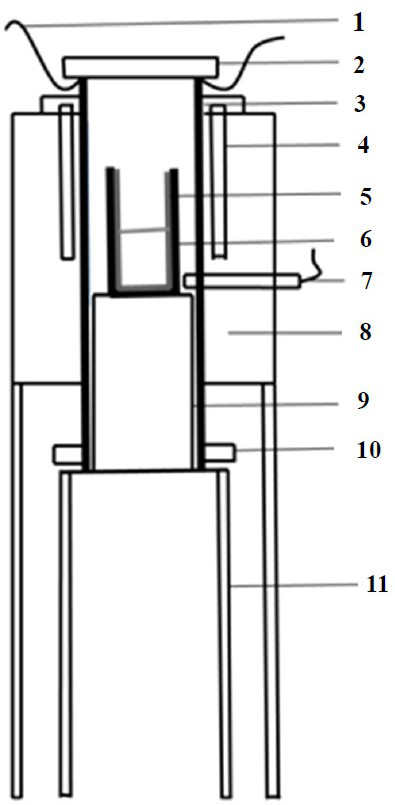

Cold start up auxiliary system for alcohol and flex engines with air-inlet and alcohol warm up

InactiveUS20090241915A1Strong in of in consumptionStrong influenceElectrical controlInternal combustion piston enginesAlcoholGasoline

The present invention relates to a new auxiliary system of cold start, preferably used in the internal combustion engines that use alcohol as fuel. The engines ‘Flex Fuel’ (alcohol / gasoline / GNV) are included in the possibility of the use of this invention. The cold starting system makes use of resistances (3) positioned in the entrance of the injectors (4); resistances (6) inside of each injector (1) or one resistance (5) for every pipe holder of nozzles (2), and the three possibilities can be used simultaneously, combined two by two or separately, depending on the necessity of warm up alcohol flow and the energy consumption. It can also make use of groups of resistances (11, 12, 13) positioned in the intake. Additionally one or two auxiliary injectors can be foreseen (supplementary) in the intake collector with the same alcohol heating system.

Owner:FIAT AUTOMOVEIS

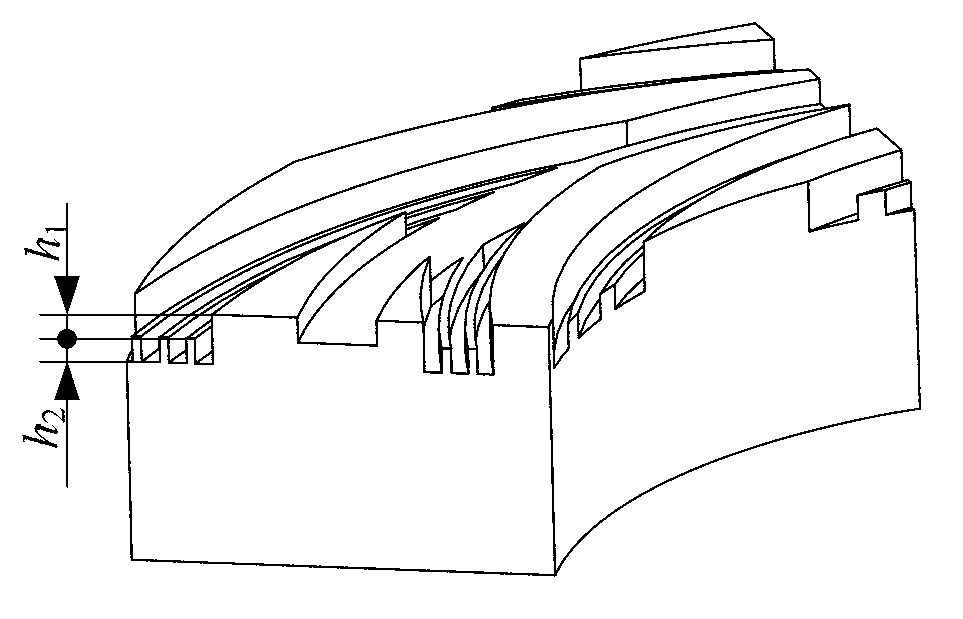

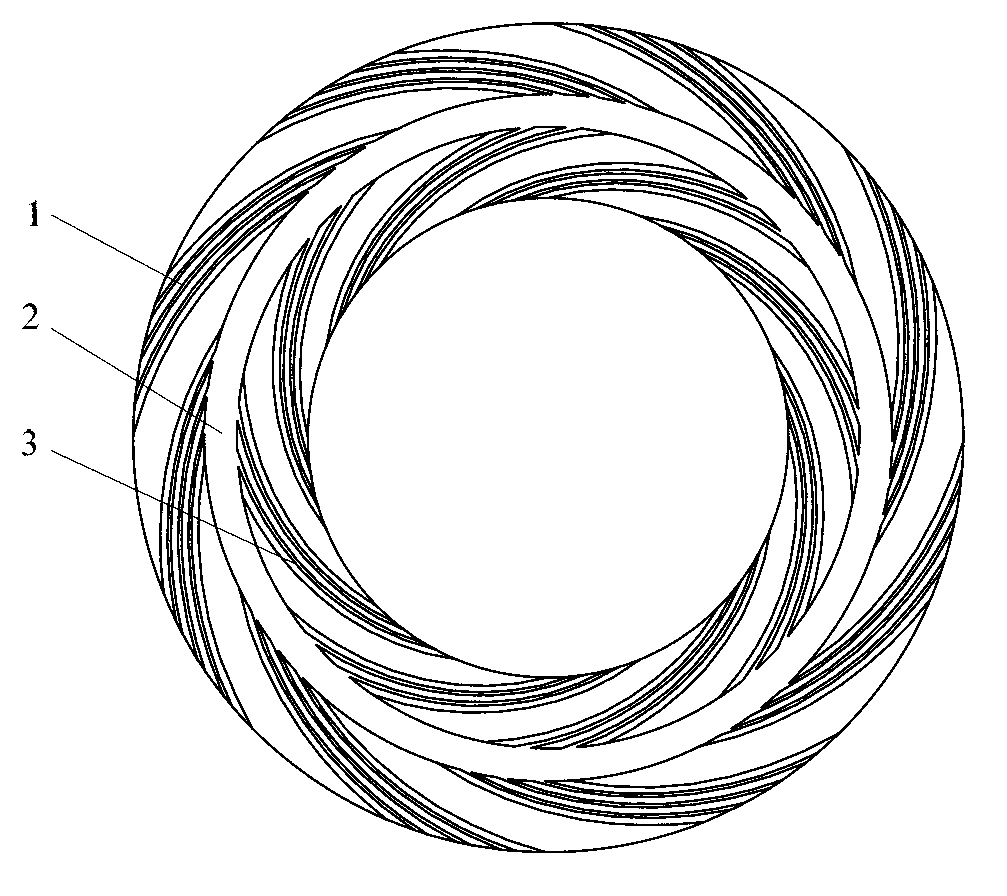

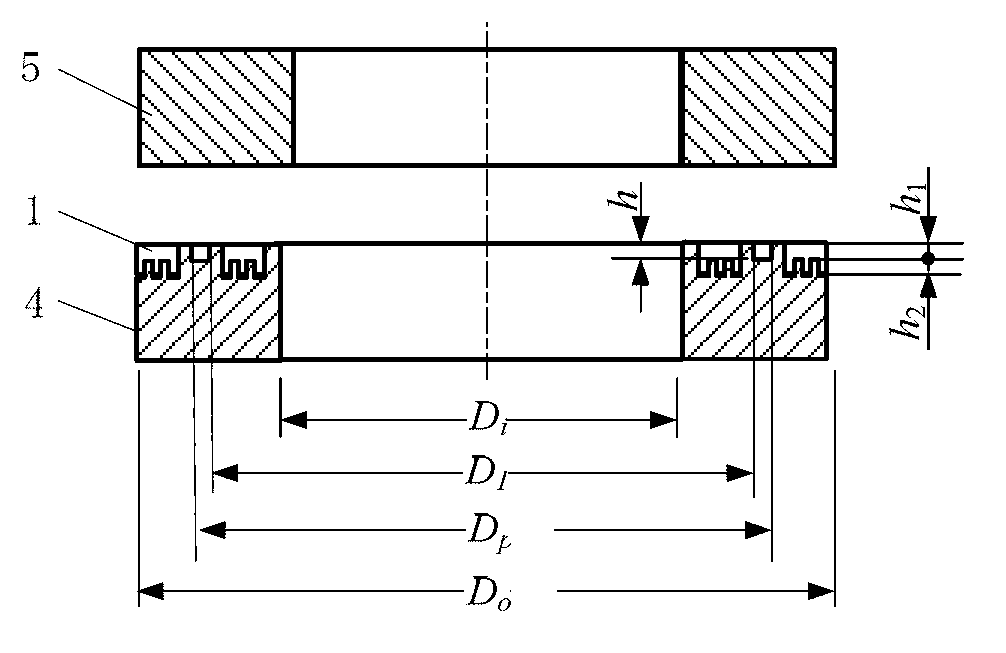

Microgroove double-layer composite groove deep end surface mechanical seal structure

ActiveCN103062411AEnhance the dynamic pressure effectImprove adsorption capacityEngine sealsEngineeringHigh pressure

The invention discloses a microgroove double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a microgroove double-layer composite groove deep dynamical pressure groove, a ring groove and a microgroove double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, the upper layer of the dynamical pressure groove is hollow, and a microgroove shape line on the lower layer of the dynamical pressure groove forms an upstream texture and is same to a dynamical pressure groove shape line on the upper layer; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, the upper layer of the pumping groove is hollow, and a microgroove shape line on the lower layer of the pumping groove forms a downstream texture and is same to a shape line on the upper layer of the pumping groove; the upstream texture and the downstream texture are connected through the ring groove; and the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove.

Owner:山东誉中新材料股份有限公司

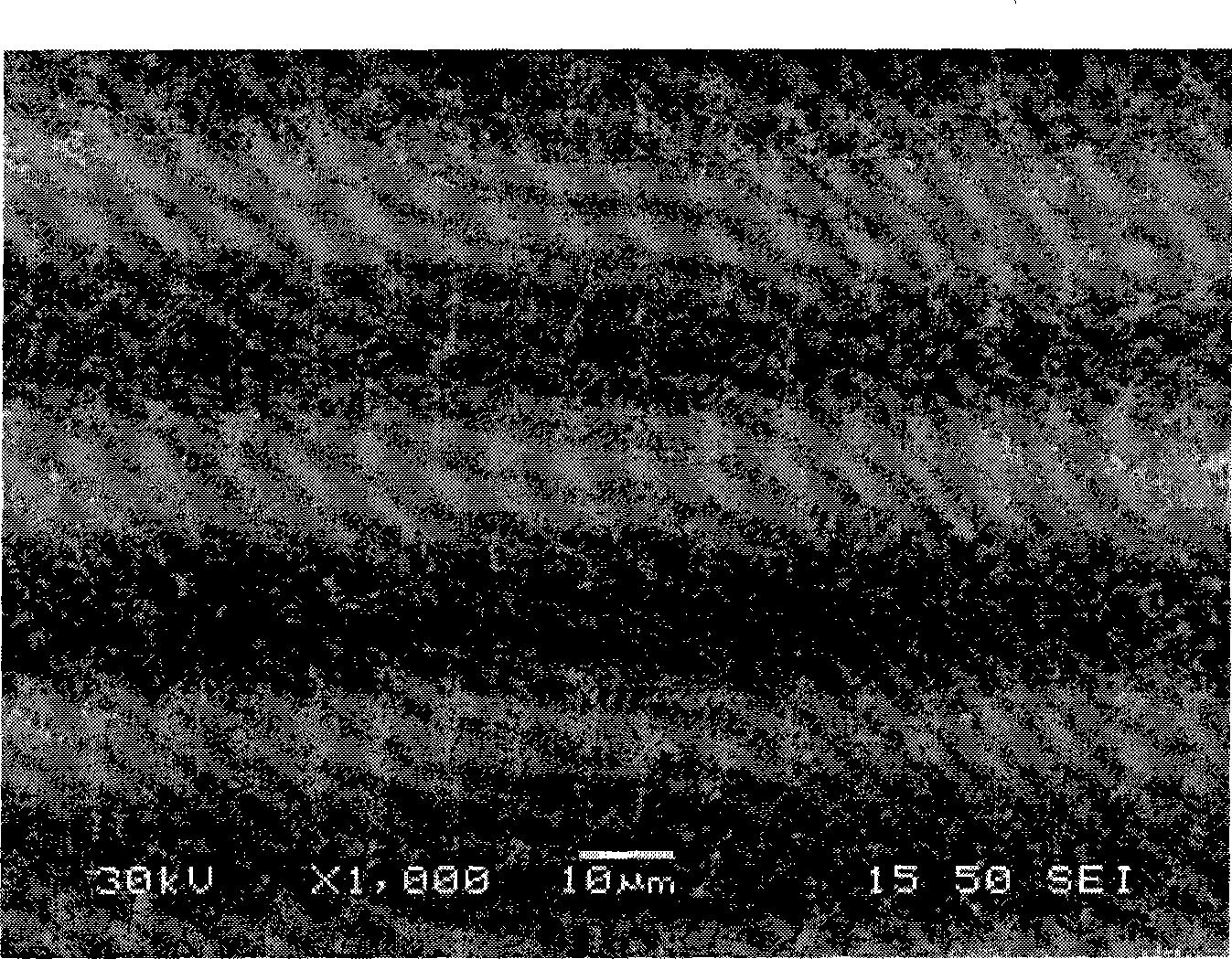

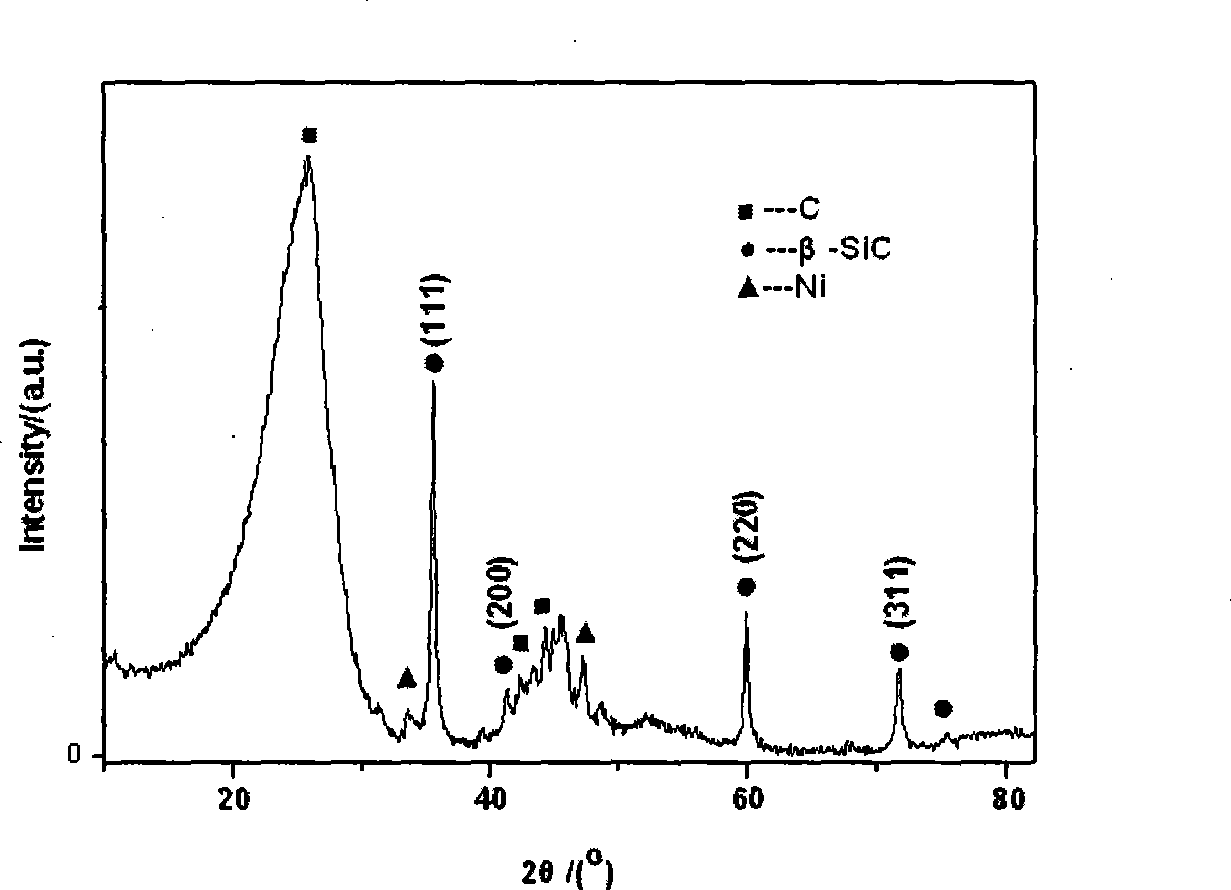

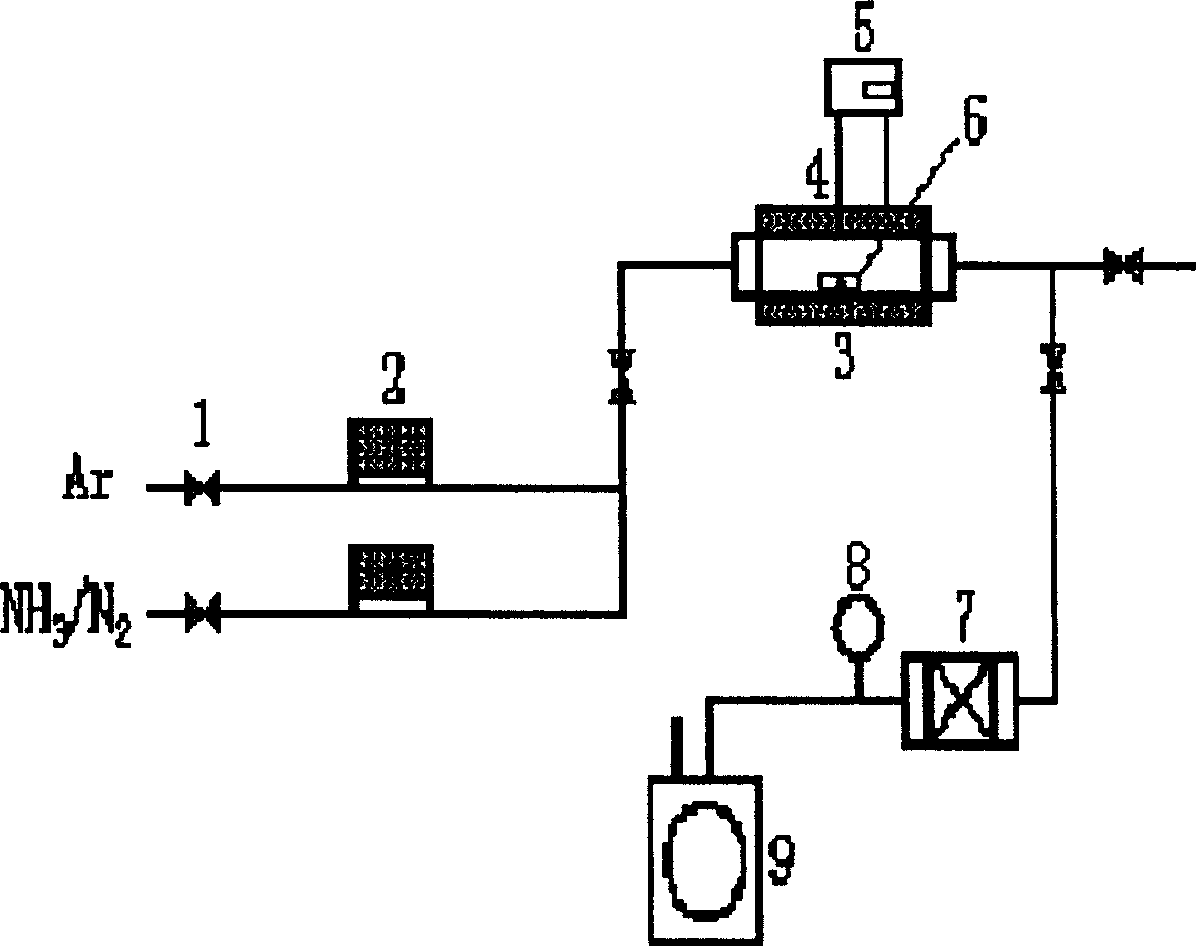

Method for manufacturing silicon carbide nanometer fibre/carbon fibre composite felt body

The invention discloses a method for preparing silicon carbide nano-fiber or carbon fiber composite felt, which comprises following steps: eliminating adhesion of needle integrated carbon felt or not eliminating the adhesion, then, absorbing one of transition group cobalt or nickel on the surface of carbon felt fiber in a mode of fine grained shapes through adopting a method of electroplating or electroless plating, drying, then, depositing silicon carbide in a chemical vapor deposition furnace, controlling the flow capacity of deposition gas source trichloromethylsilanes, carrier gas hydrogen and diluted argon, keeping the furnace pressure to be 20-500Pa when the deposition temperature is 1073-1373K, keeping the depositing time to be 1 to 15 hours, cooling along the furnace, then, taking out of the furnace, and obtaining the composite felt whose carbon felt fiber surface is grown with nanometer silicon carbide fiber. The composite felt which is weaved through adopting the method sufficiently exerts the mechanical and physical properties of each direction in situ growing nano-sic fiber and takes the mechanical and physical properties as an enhanced body of traditional C / C or C / SiC composite materials, the anisotropy of the composite materials is increased, and the using performance is increased.

Owner:CENT SOUTH UNIV +1

Method for preparing nano coating additive emulsion with flame-retarding characteristic

This invention is related to a kind of nano additive emulsion to coatings characteristic of fire retardant and its preparation method. The said method is that using the modified inorganic particles as 'seeds'in the water solution, adding wetting agent, buffering agent and functioned styrene monomer, initiating the polyreaction system, and then obtaining inorganic and organic nano composite emulsion. The said preparation method used in this invention is universal. The said composite has characteristic of fire retardant and can be used as an additive to coatings to improve the function and performance of the coatings and enhance the added value of the products.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for crosslinked gelatin antimicrobial film material

InactiveCN102775624AIncrease added valueLow priceFlexible coversWrappersControlled releaseFood safety

The invention discloses a preparation method for a crosslinked gelatin antimicrobial film material. The method comprises the following steps of: (1) adding glycerol into gelatin aqueous solution; (2) adding an antimicrobial agent into the solution obtained in the step (1) and dissolving with stirring; (3) adding a crosslinking agent and reacting at the temperature of 45 to 55 DEG C for 20 to 40 minutes under the condition of magnetic stirring; and (4) performing vacuum degassing on the material obtained in the step (3) to obtain the film, wherein the antimicrobial agent is nisin or lysozyme. By the method, the release speed of the antimicrobial agent in the film material can be scientifically adjusted and the purpose of controlled release is realized. The crosslinked gelatin antimicrobial film material can be applied to an inner packaging material for food and aims to solve the food safety problem caused by that the microorganisms grow on the surface in the storage process of the food. The protein-lysozyme / nisin composite antimicrobial film material prepared by the method has great application potency of improving food quality and prolonging the shelf life of the food.

Owner:SOUTH CHINA UNIV OF TECH

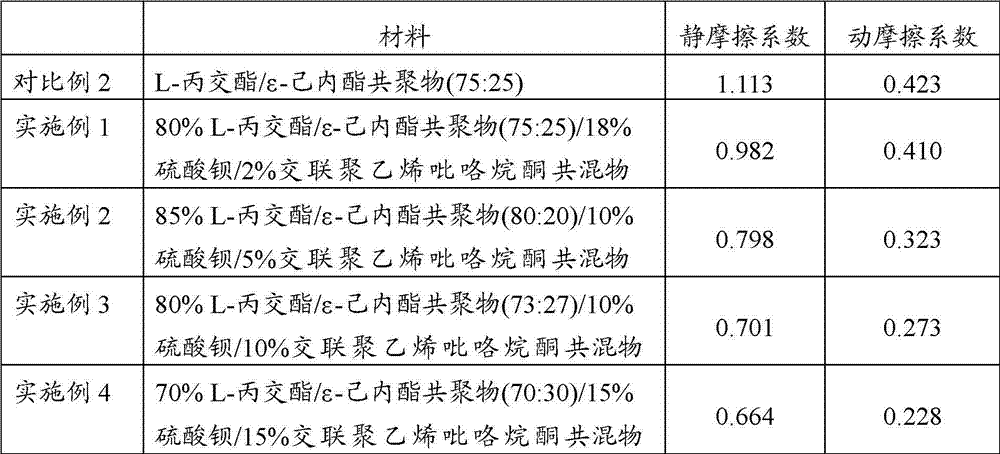

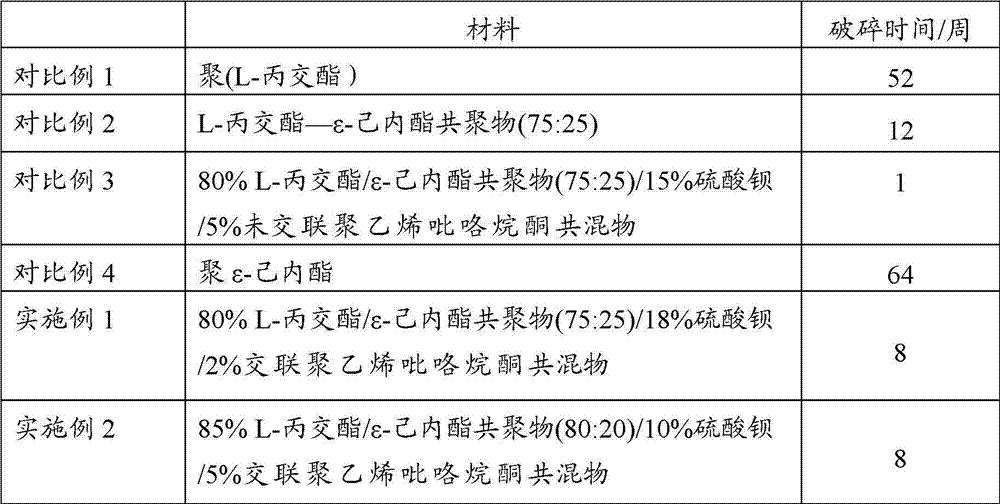

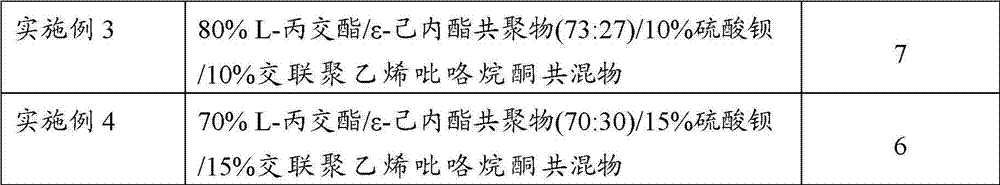

Composite material for making degradable ureteral stent and application thereof

ActiveCN103041454AIncreased degradation rateAvoid cloggingStentsSurgeryBiocompatibility TestingCross-linked polyethylene

The invention provides a kind of composite material for making a degradable ureteral stent, comprising: 60-98% by weight of L-lactide / Epsilon-caprolactone copolymer, and 2-40% by weight of polyvinylpolypyrrolidone. The L-lactide / Epsilon-caprolactone copolymer in the composite material is elastomeric material with good biocompatibility, and the polyvinylpolypyrrolidone can reduce a surface friction coefficient of the prepared degradable ureteral stent, and simultaneously raises the degradation speed of the degradable ureteral stent. The invention also discloses a degradable ureteral stent prepared by the composite material. The degradable ureteral stent has good biocompatibility, is easy to degrade, and can be used in an operation in urinary surgery.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +2

Thermal treatment method used for improving duplex stainless steel welded structure

InactiveCN102560065AImprove pitting resistanceControl volumeFurnace typesHeat treatment furnacesHeat-affected zoneElectrical impulse

The invention discloses a thermal treatment method used for improving a duplex stainless steel welded structure, which comprises the following steps: 1) heating by an electric oven at the temperature lower or close to duplex stainless steel phase transition when a duplex stainless steel weld seam and a heat affected zone are heated by a thermal treatment technology, simultaneously carrying out electric pulse heating; 2) insulating for 10-60 minutes after heating, cooling with three phases, wherein in a first phase, the temperature of the welded structure is 850 DEG C and the cooling speed is controlled at 1-30 DEG C / s, simultaneously providing pulse current; in a second phase: the temperature is decreased to 800-500 DEG C, the cooling speed is controlled at 5-50 DEG C / s, and the cooling speed is greater than that of the first phase; in a third phase: the temperature is decreased below 500 DEG C and the cooling speed is controlled more than 30 DEG C / s. The thermal treatment for duplex stainless steel welded seam and the heat affected zone can control the volume fraction and existence form of ferrite, avoid the precipitation of a brittleness phase in ferrite / austenite, ferrite / ferrite crystal boundary, and enhance the capability of pitting corrosion resistance of the duplex stainless steel.

Owner:WENGFU (GRP) CO LTD

Novel metallic material

The invention discloses a novel metallic material prepared from C, Si, Mn, Ni, Cr, Cu, Al, Ti, Sn, Fe and rare earth. The novel metallic material is characterized by comprising the following components by percentage: 0.2-2.4% of C, 0.3-1.3% of Si, 0.9-2.0% of Mn, 1.0-10% of Ni, 15-25% of Cr, 0.8-2.3% of Cu, 0.1-1.0% of Al, 0.1-0.8% of Ti, 0.8-1.5% of Sn, 0.6-1.7% of at least one of rare earth elements Ce and La and the balance of Fe. The mechanical property, abrasion resistance, corrosion resistance, cold resistance, heat resistance and flowability of the metallic material are improved, so that the metallic material is compact in texture and high in quality.

Owner:无棣向上机械设计服务有限公司

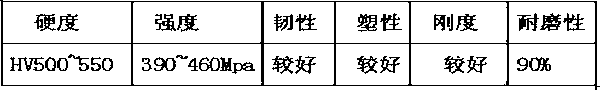

Mesoporous titanium dioxide and preparation method thereof and application thereof

InactiveCN102718254AOptimal Control StructureLow densityInorganic non-active ingredientsNanotechnologyActive agentSurface-active agents

The invention belongs to the field of medicine technology, and relates to a preparation method of mesoporous titanium dioxide with high biological compatibility and a controllable structure and application of the mesoporous titanium dioxide as a hard soluble drug carrier. The method adopts a soft template method, namely, adopts a surfactant as a structure guiding agent, isopropyl titanate as titanium source, and double distilled water as a reaction rate modifier to prepare the mesoporous titanium dioxide having different mesoporous passage structures. The prepared mesoporous titanium dioxide is of large specific surface area, chemical stability, non-toxic effect, no side effect and good biocompatibility, and is suitable for being used as the hard soluble drug carrier. The application of the titanium dioxide as the hard soluble drug carrier can lay a theoretical foundation for uses of multivariant functional carriers. The method adopts a solvent method and a fusion method to perform embedding and adsorption on a drug so as to uniformly disperse the drug inside the mesoporous or on surface of the carrier. The drug carrier system can assist in significantly enhancing water solubility of a hard soluble drug and improving dissolution rate in vitro and oral bioavailability.

Owner:SHENYANG PHARMA UNIVERSITY

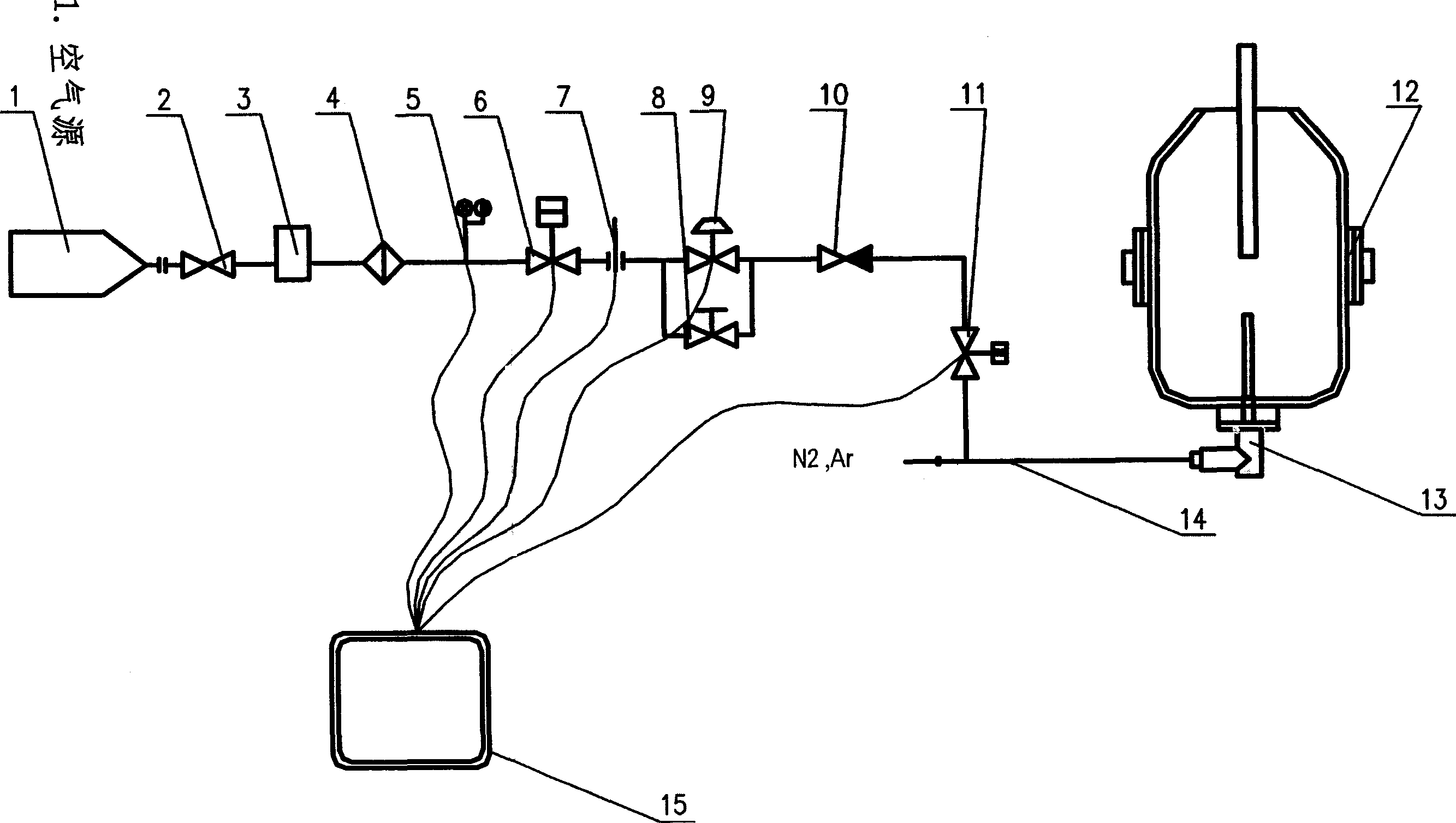

Combined-blowing converter bottom gas supply element blocking-preventing device and method

ActiveCN1743466AGuaranteed metallurgical effectExtend your lifeManufacturing convertersComputer control systemSlag

This invention blow-stop ventilation device of a bottom blow gas supply element of a multi-blow converter is composed of an air dehydrator, a pneumatic fast cut valve, a pneumatic regulation valve, a gas flowmeter, a pressure tester, a computer control system, a blow-step gas source and gas transportation pipe lines interconnected by the gas transportation pipe lines. Said method takes air as the gas supply element and utilizes 20% oxygen in the air to oxidize the blockage-slag-metal mushroom head continuously to keep it at reasonable state to ensure the life time of the supply element the same with the converter lining.

Owner:CENT IRON & STEEL RES INST

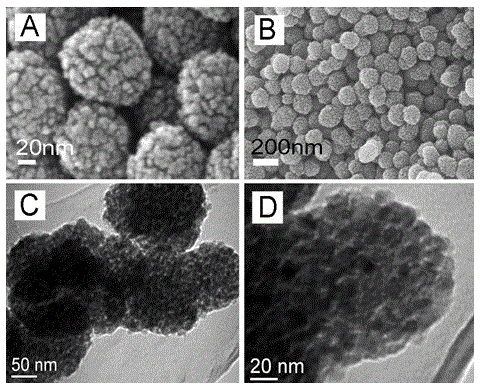

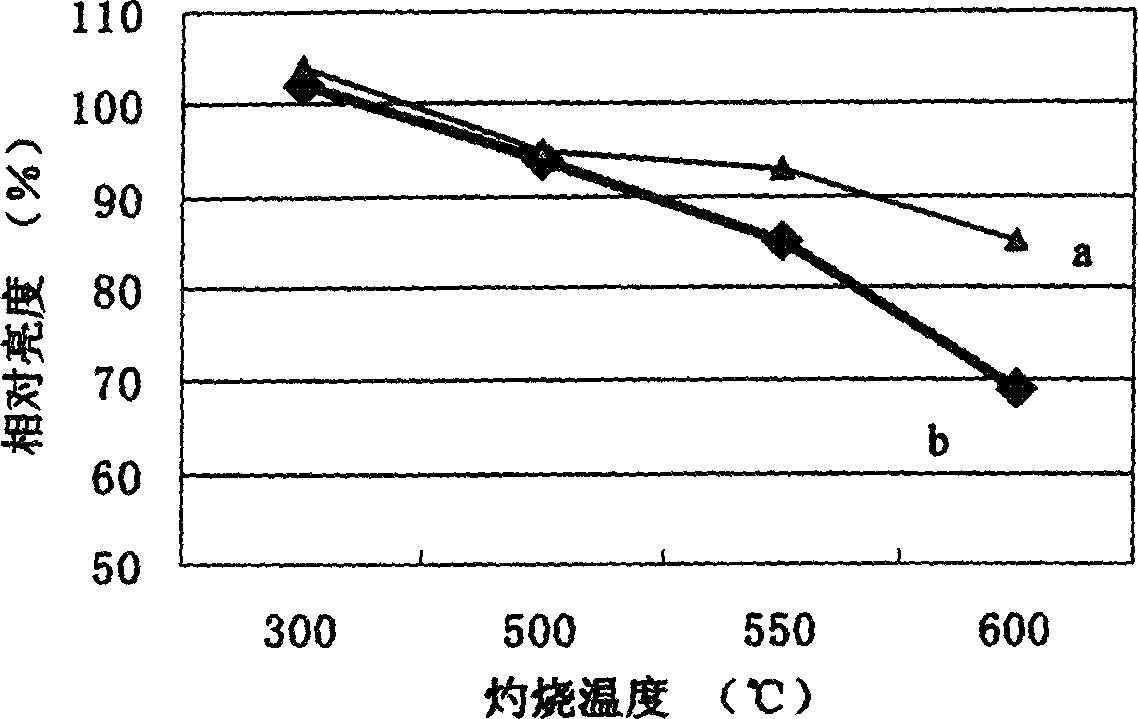

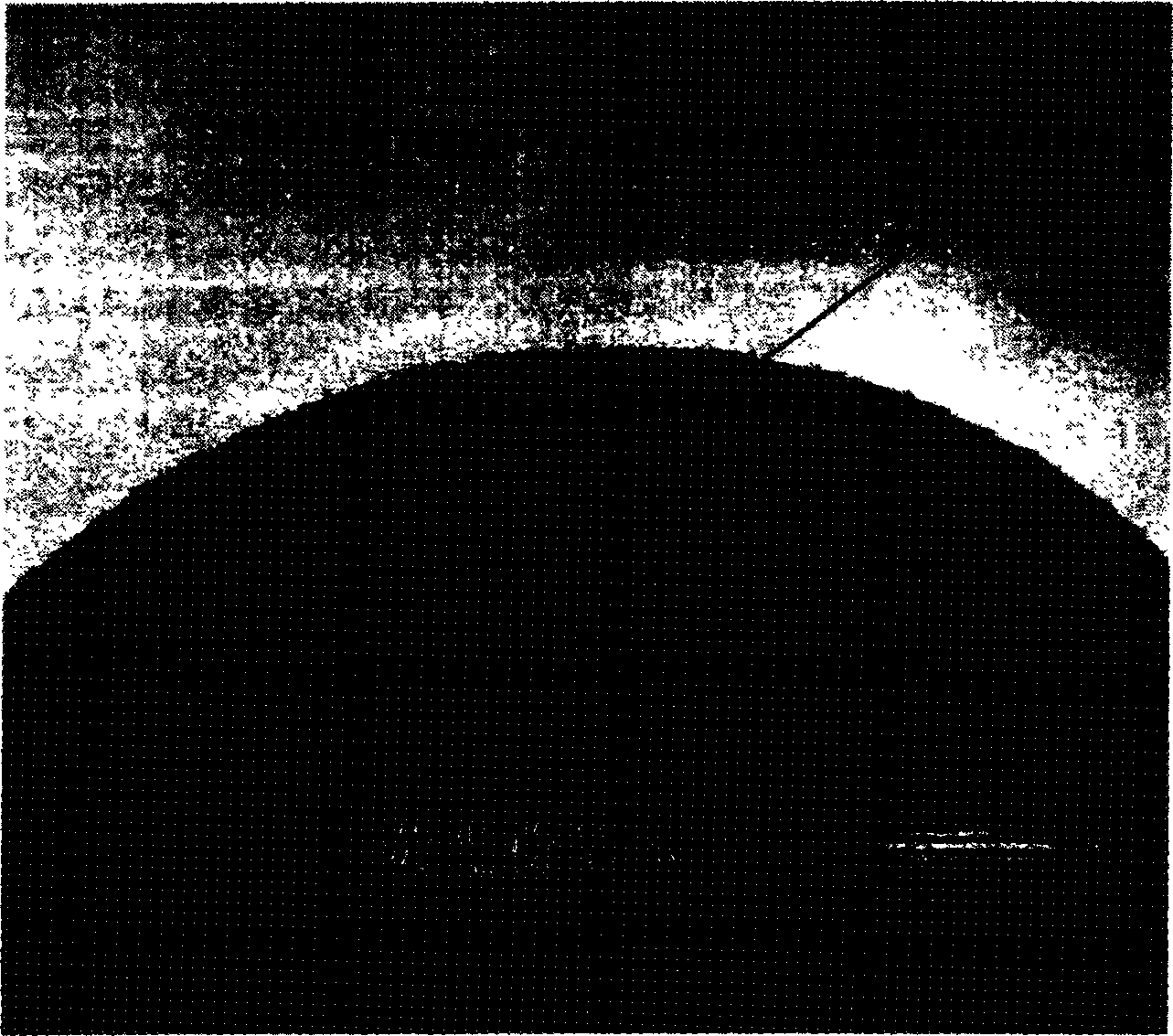

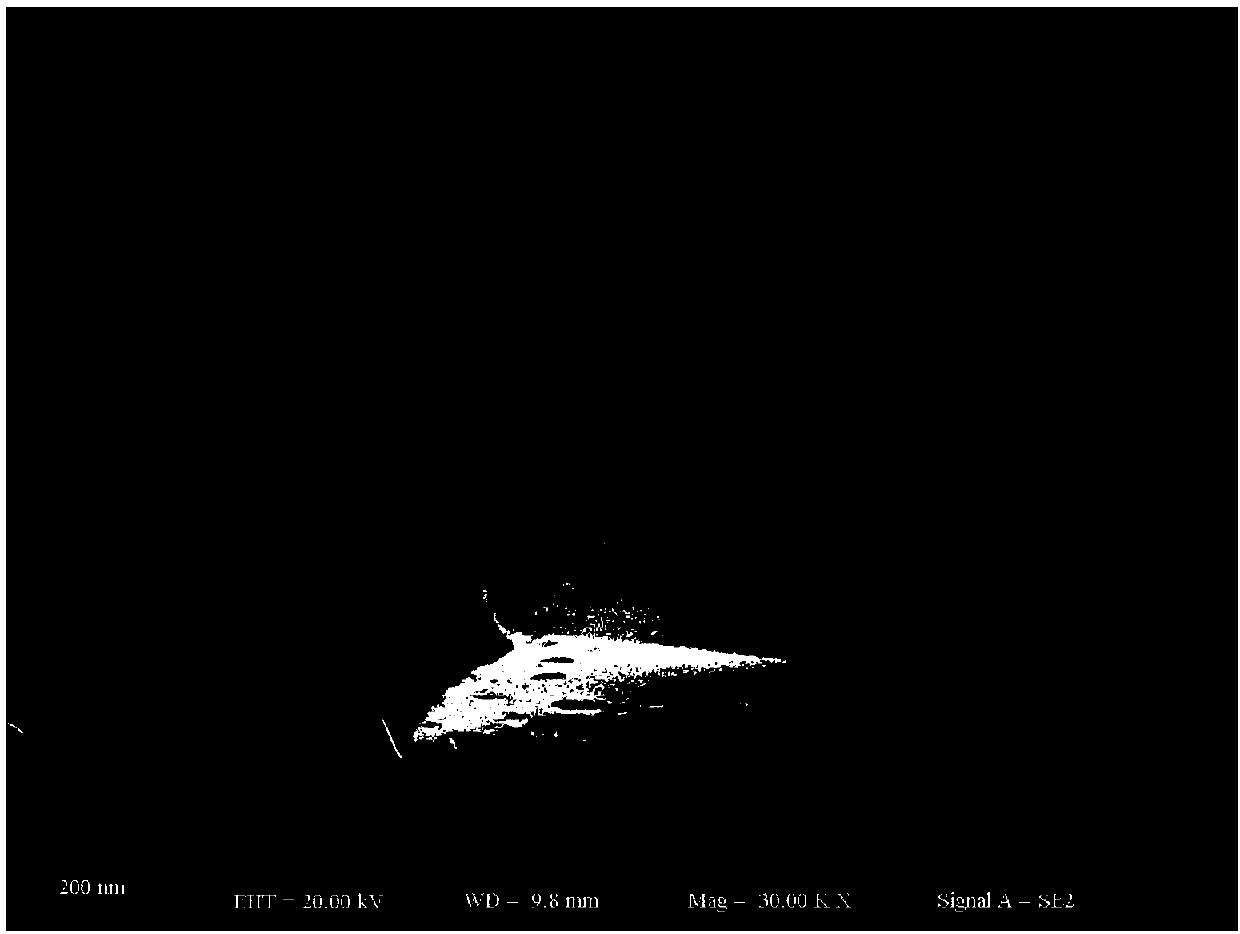

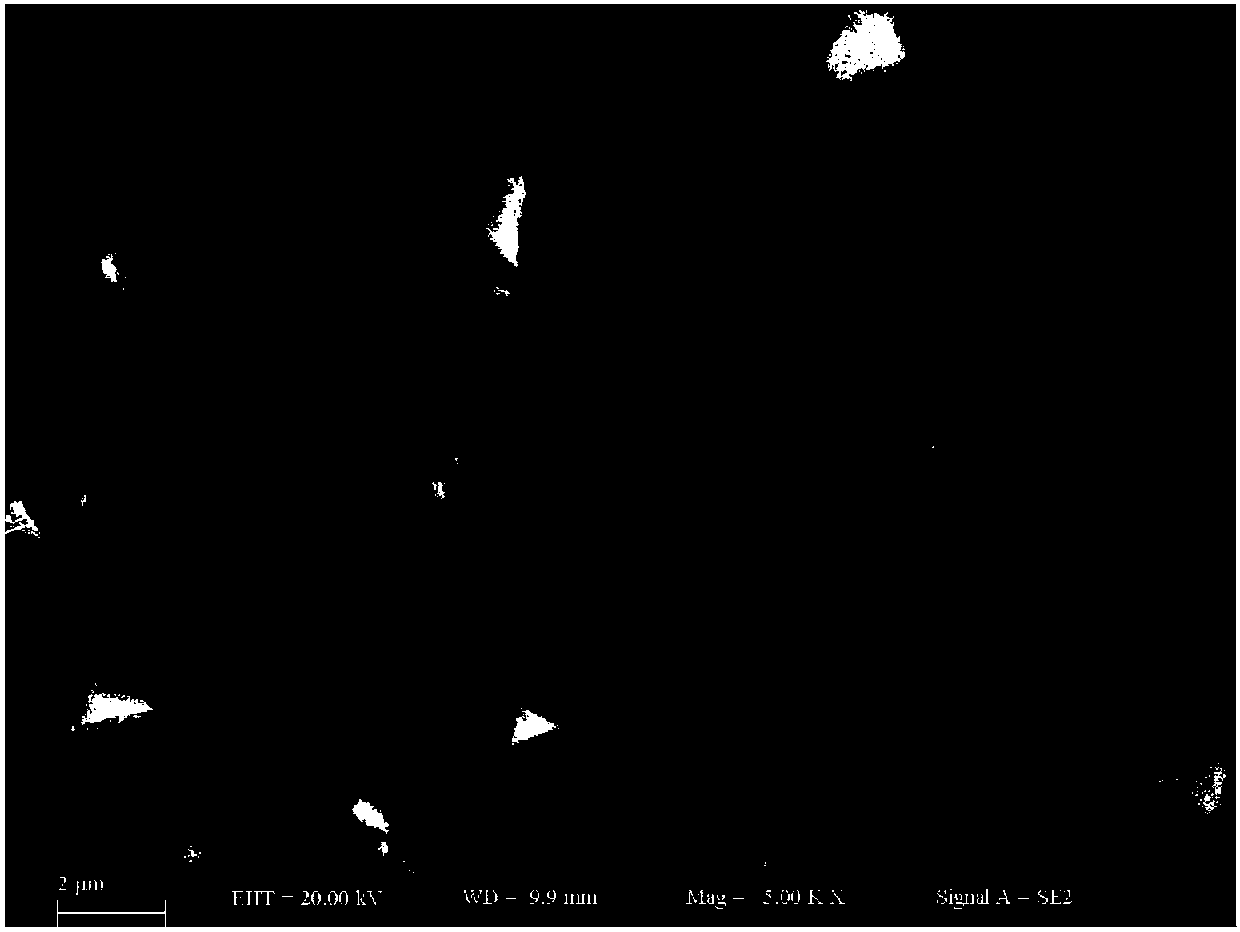

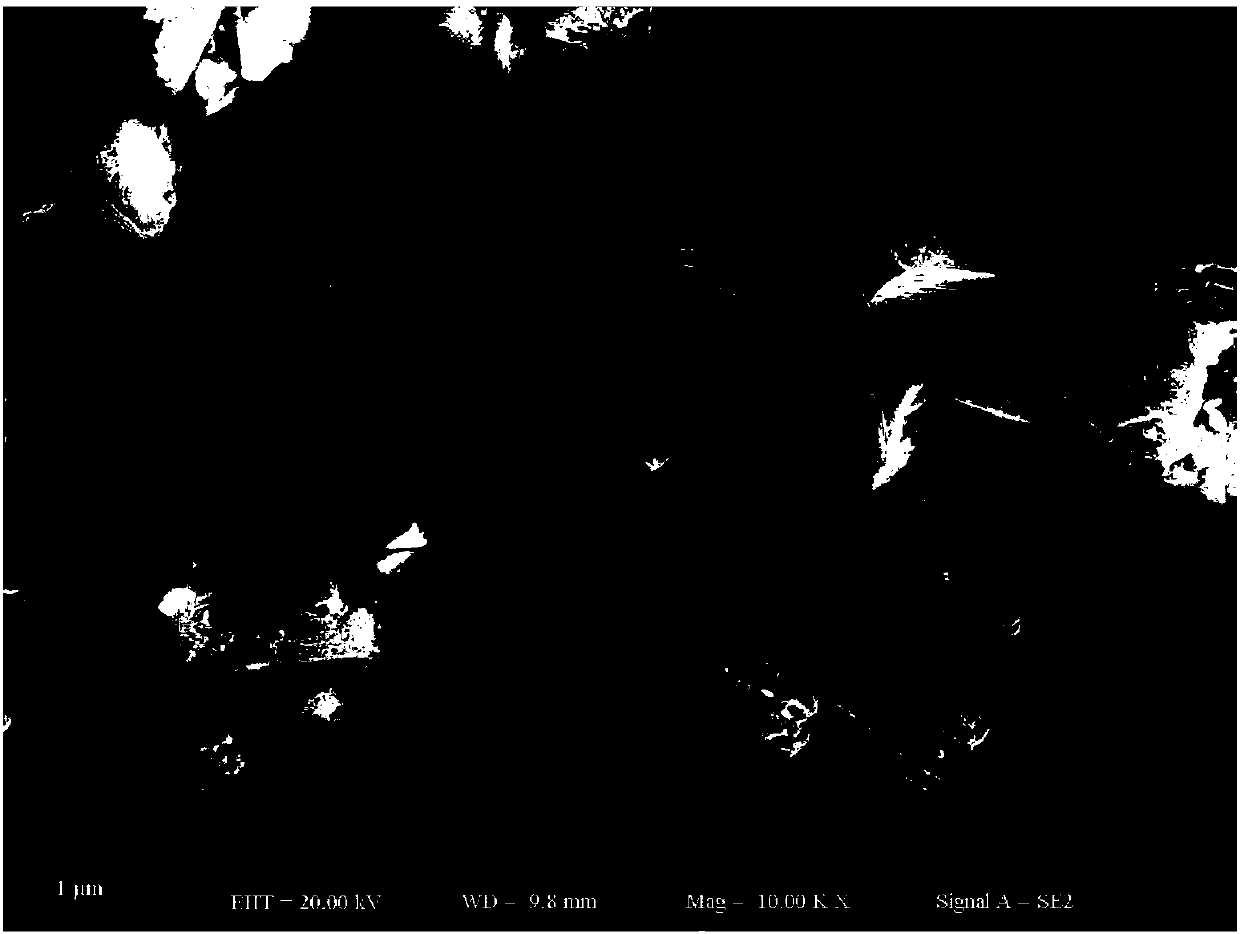

Silicon oxide coated fluorescent powder and its coating method

InactiveCN1664052AControl the rate of hydrolysisControl formLuminescent compositionsPhosphorSupersonic waves

Disclosed is the silicon oxide integument phosphor powder covered with silicon oxide on the surface of the phosphor powder. The method of integument comprising: preparing suspension at the concentration 0.2~5% with color plasma panel display phosphor powder and water, weighing relevant quantity of sodium silicate with nine water according to the proportion between silicon oxide and phosphor powder by weight (0.5~20): 100, adding to the phosphor powder suspension, dispersing with supersonic wave and stirring to make it dissolved and the phosphor powder suspension stable, employing strong acid as precipitator and preparing solution with concentration 0.01~2M; heating the phosphor powder suspension to 20~120 DEG C, stirring and dispersing with supersonic wave at the same time, stirring with speed 100r / m~ 300r / m and dropping the precipitator into the phosphor powder suspension at the speed of 5~500ml / min to make the pH value 3~11, then keeping the temperature and stirring for 30~180 minutes; getting the integument phosphor powder after centrifugalizating the phosphor powder suspension, washing, dewatering and drying at 60-120DEG C to make the integument phosphor powder moisture percentage below 0.25%,incandescing at 200~400 DEG C for 1~3hours and air cooling in the furnace.

Owner:SOUTHEAST UNIV

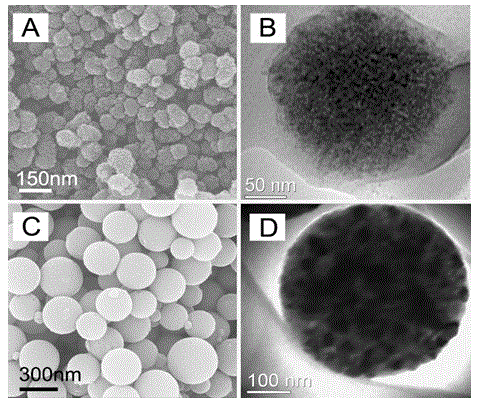

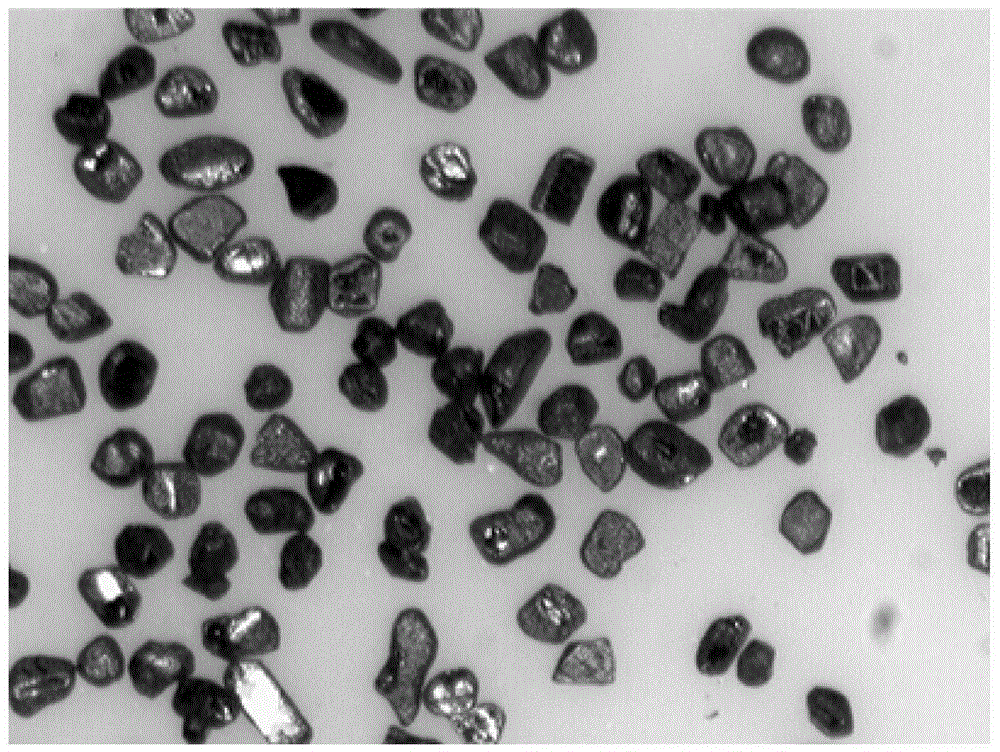

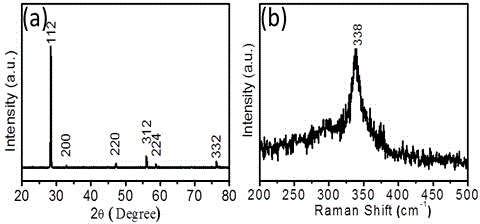

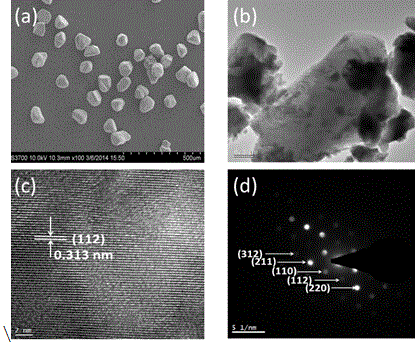

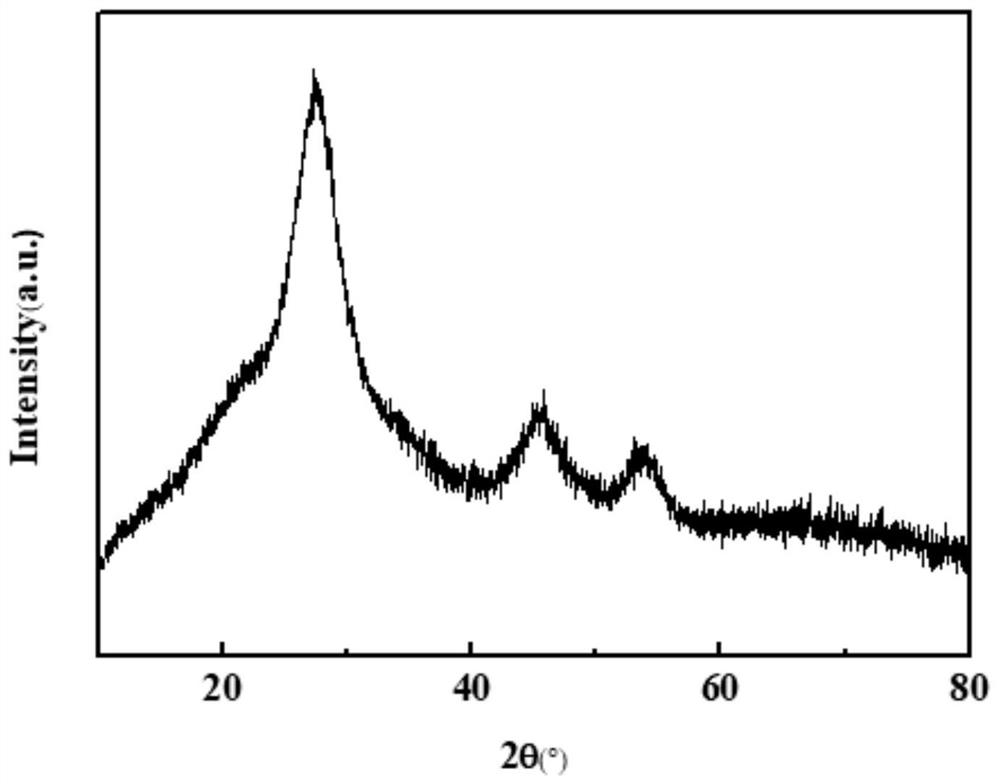

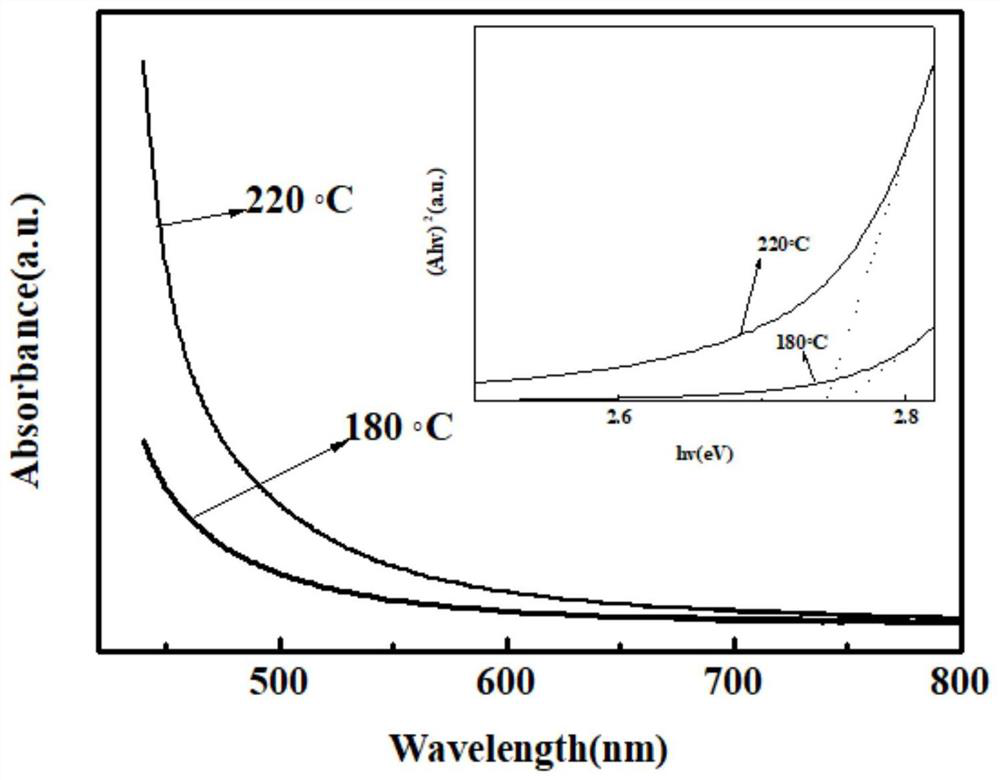

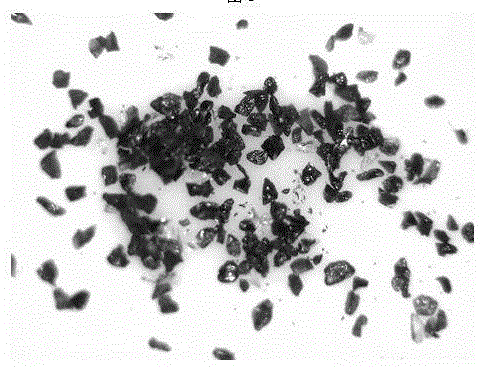

Preparation method for micron-sized spherical CZTSSe monocrystalline particles

ActiveCN104979429AUniform sizeThe size is easy to controlFinal product manufacturePhotovoltaic energy generationPowder mixtureDevice material

The invention relates to the technical field of semiconductor photovoltaic materials and semiconductor devices, and discloses a preparation method for micron-sized spherical CZTSSe monocrystalline particles. Metal simple substance powder, sulfide powder, selenide powder, elemental sulfur powder, elemental selenium powder, flux, Cu2ZnSnS4 nanoparticles and as the like are combined as reaction raw materials, and are ground and mixed according to the designed formula. The powder mixture is vacuum-encapsulated into a quartz reactor; the quartz reactor is kept at the temperature of 750 DEG C to 1000 DEG C for 48-120 hours, and then is quickly cooled to the room temperature; and samples are taken out, cleaned and dried to obtain the CZTSSe monocrystalline particles. The size of the prepared monocrystalline particles can be regulated and controlled by utilizing recrystallization temperature and time, and the components of the particles can be effectively regulated within a certain range through the molar ratio of the elements in a precursor. The prepared monocrystalline particles are uniform and controllable in size, and are better than the monocrystalline particles prepared by the traditional method in performance.

Owner:LINGNAN NORMAL UNIV

Slim hole explosion crack generation assisted hydraulic fracturing method

The invention discloses a slim hole explosion crack generation assisted hydraulic fracturing method. The method includes the following steps: firstly, windowing is carried out to side-drill a horizontal drilling well to form a long open slim hole, an explosive is put, and after the explosive explodes to impact rock, a large number of microcracks and micro-gaps are formed; secondly, perforation operation is carried out on the crack growing gaps formed by the impact of explosion pulse, slick-water is injected into perforation holes to form a main crack, the radial cracks and activated natural cracks are further opened to communicate with the main crack to form a complex crack network of main crack-branch crack, a glue solution or slick-water fracturing fluid mixed with a proppant is pumped for sanding to further extend and expand the main crack and the explosion cracks, the cracks are filled with the proppant, continuous sanding is carried out until designed sand volume is reached and then the operation is stopped. The method of the invention is simple in operation and mature in technology and can effectively improve the transformation efficiency of a deep shale gas reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

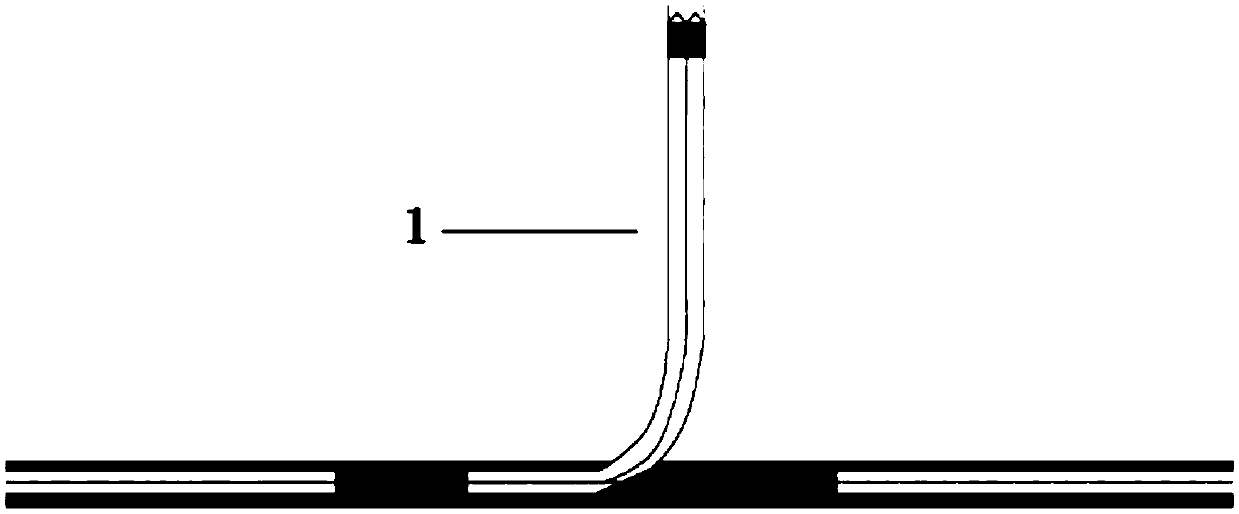

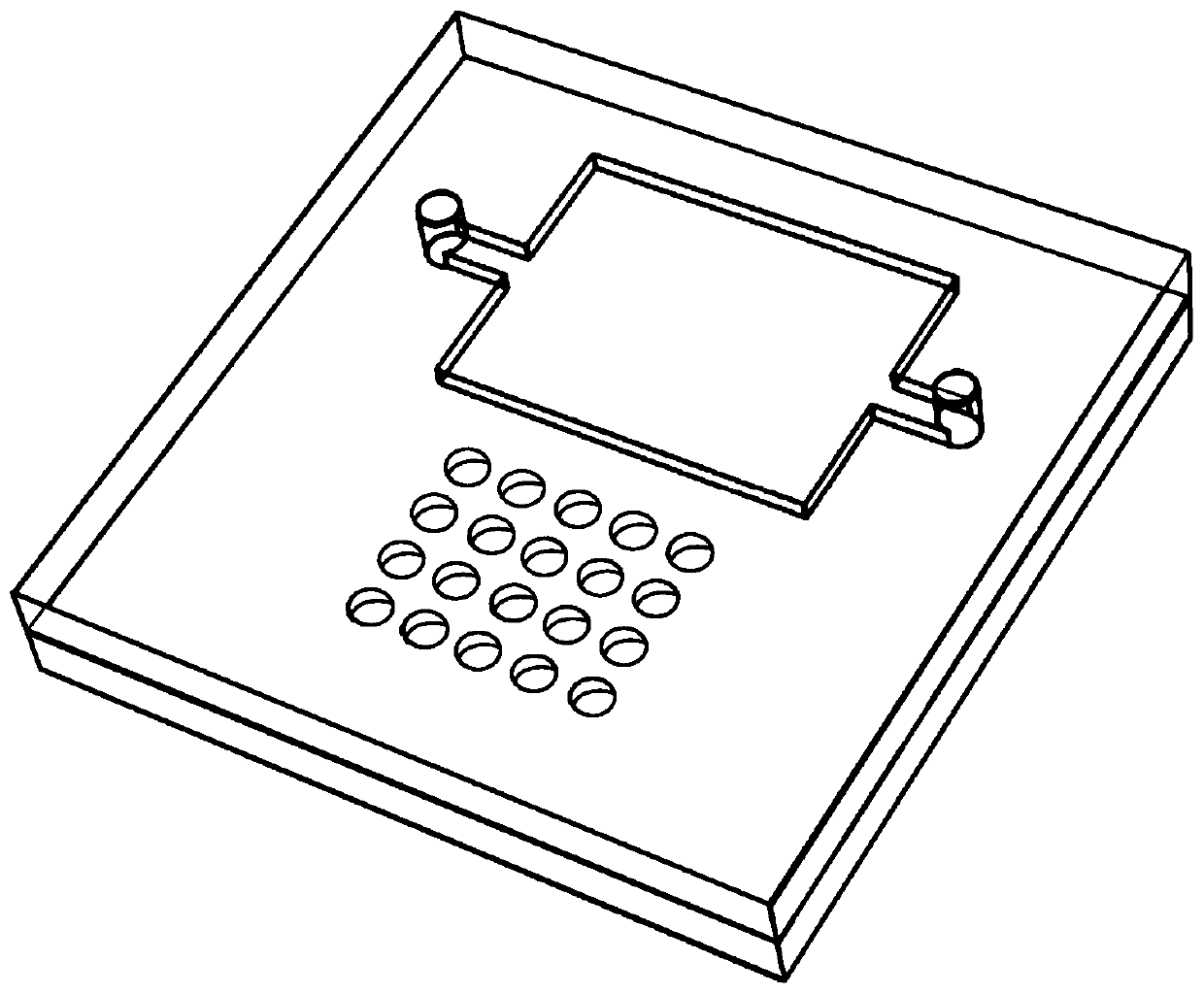

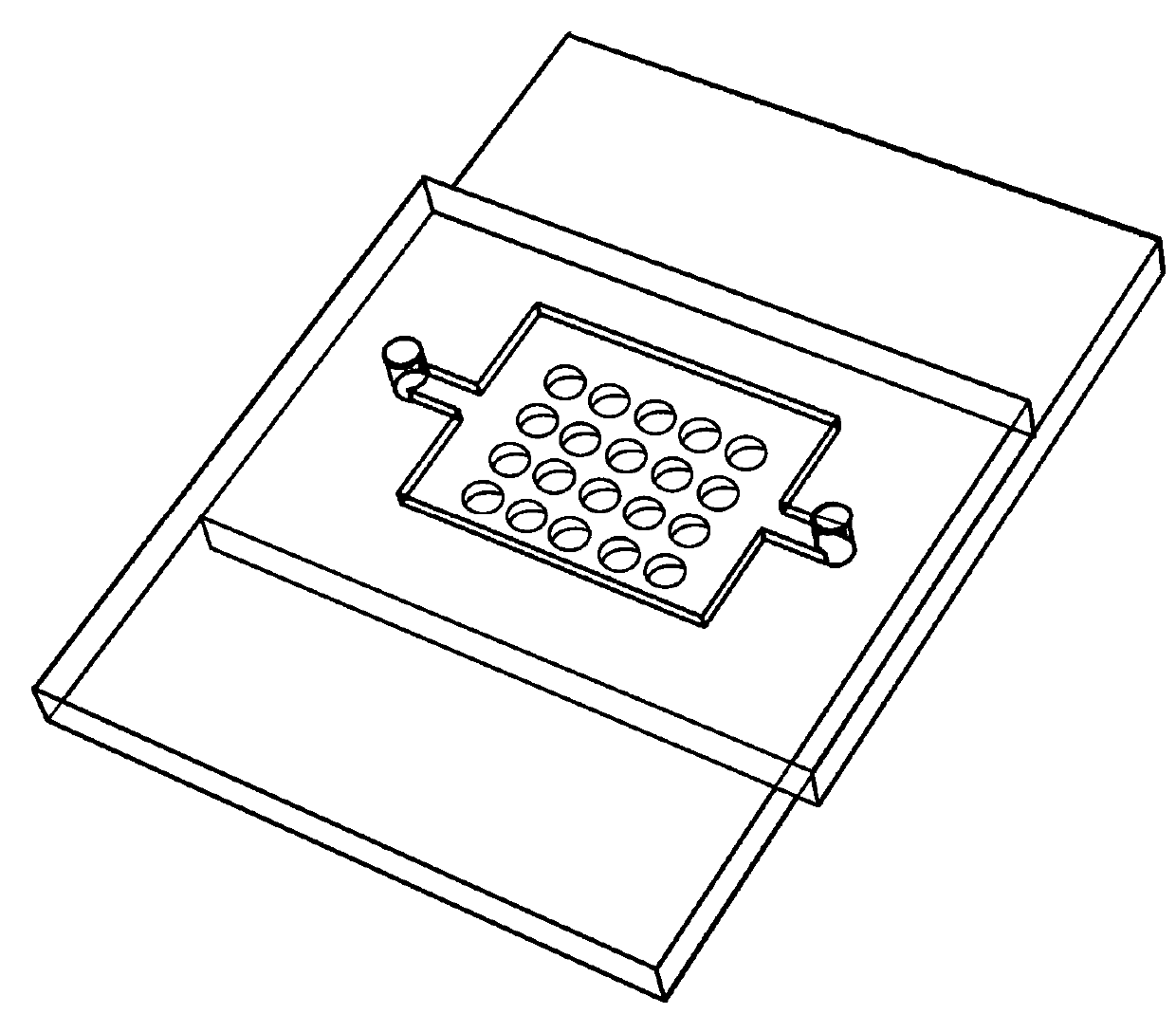

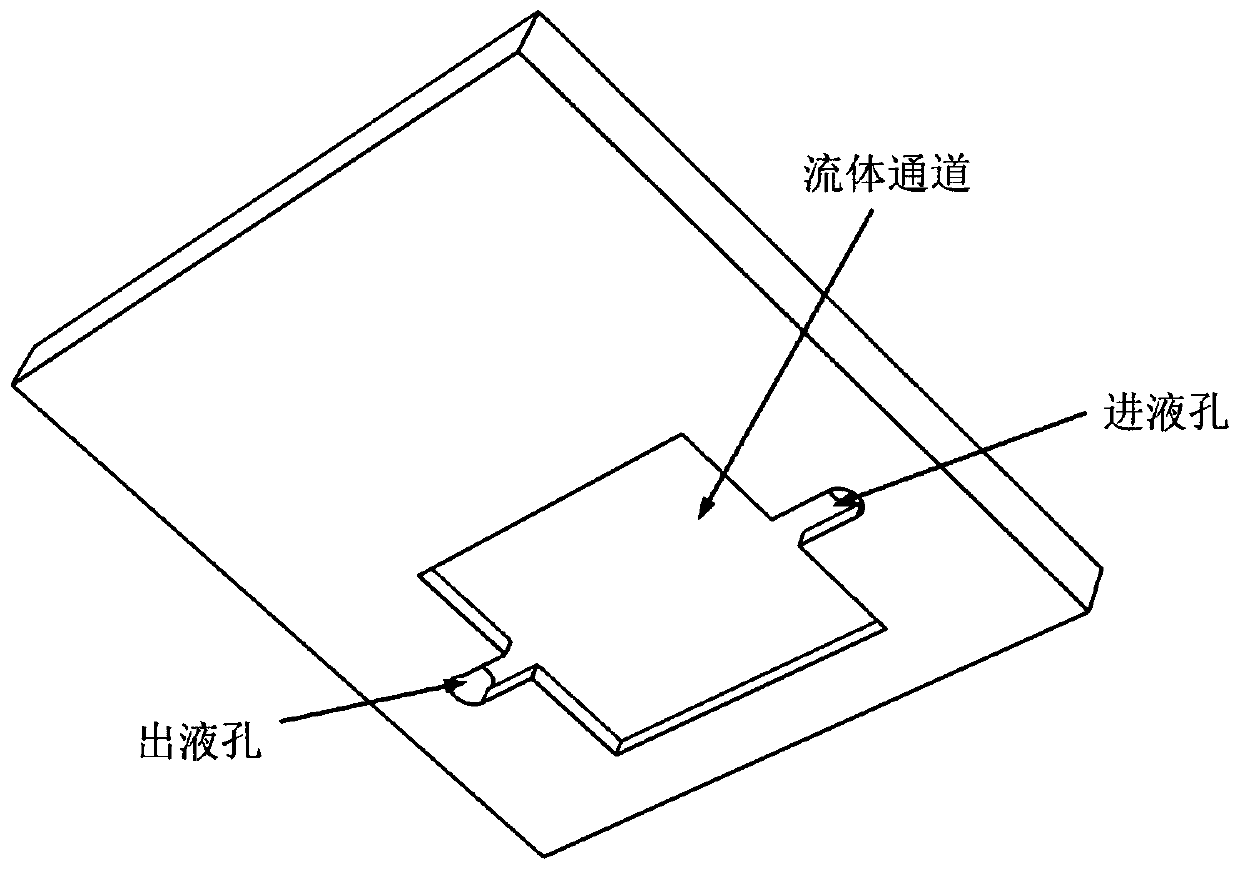

Method for generating liquid droplet array on microfluidic chip

ActiveCN110643483AEasy to processLarge toleranceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringChipset

Owner:SHANGHAI JIAOTONG UNIV

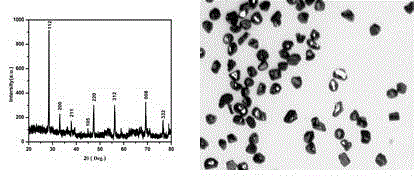

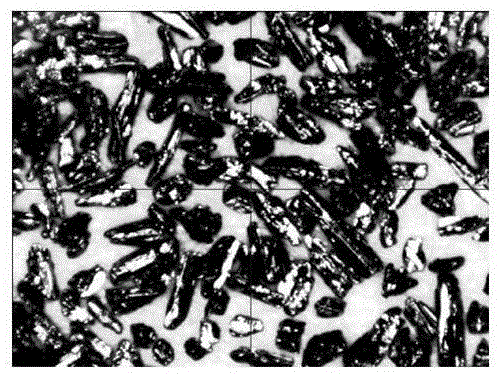

Micron-sized spherical copper-zinc-tin-sulfur monocrystal particle preparation method

ActiveCN104952979AThe size is easy to controlImprove performanceFinal product manufactureSemiconductor devicesPhysical chemistrySingle crystal

The invention relates to the technical field of semiconductor photoelectric materials and devices and discloses a micron-sized spherical copper-zinc-tin-sulfur monocrystal particle preparation method. The method includes: grinding and mixing different combinations of metal powder, sulfides, elemental sulfur powder, fluxing agents, copper-zinc-tin-sulfur nano particles and the like according to designed proportions, packaging mixed powder in a quartz reaction vessel in a vacuum manner, keeping the quartz reaction vessel at the temperature of 750-1000 DEG C for 48-120h, and quickly cooling the quartz reaction vessel to the room temperature; taking out a sample, and washing and drying to obtain copper-zinc-tin-sulfur monocrystal particles; the prepared monocrystal particles are adjustable in size by means of recrystallization temperature and time, and ingredients of the particles can be effectively regulated within a certain range through a molar ratio of elements in a precursor. The prepared monocrystal particles are uniform in ingredient and controllable in size so as to be superior to those prepared according to traditional methods.

Owner:LINGNAN NORMAL UNIV

Preparation method of beta-type bismuth oxide

ActiveCN107857300ASynthesis temperature is lowEffective size controlBismuth compoundsAlcoholPhosphate

The invention relates to a preparation method of beta-type bismuth oxide. The preparation method comprises the following steps of S1, preparing a bismuth nitrate solution; S2, adding polyacrylamide tothe bismuth nitrate solution in the step S1 and stirring evenly; S3, disposing an alkaline solution with a concentration of 2-4 mol / L, adding alcohol ether phosphate ester, stirring and mixing, mixing the alkaline solution and the solution obtained in the step S2 in an equal volume ratio, stirring evenly, and adjusting the pH to 8-13 to obtain a bismuth oxide precursor refluxing liquid; S4, performing boiling reflux on the bismuth oxide precursor refluxing liquid with an oil bath, performing water condensation reflux to obtain the product; S5, washing, drying and grinding the product to obtain beta-type bismuth oxide powders. The preparation method adopts a boiling reflux method to prepare bismuth oxide with a single crystal form, greatly reduces the synthesis temperature of the powders,achieves standardized production, can effectively control the size, composition and morphology of crystal grains, and obtains high-purity beta-type bismuth oxide.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Calcium sulfur magnesium series easy cutting steel

The invention relates to the fast machine steel containing elements of calcium, sulfur and magnesium belonging to the area of metal material. The invented material can be utilized to manufacture important parts such as crankshafts and connecting rods applied in automobiles. Measures are taken such as the neutral covering dregs, diffusion deoxidation, deoxidation by use of feeding wire, deteroprating the encrusting matter by use of the elements of calcium, sulfur and magnesium etc. to produce the steel with both of good mechanical and fast machine properties. The mechanical properties of steels Y45CaSMg, Y45CaSMg are as following: the tensile strength as 800 MPa for sample in hot rolling state, the extensibility as 17.7% and the contraction of area as 47%.

Owner:LAIWU IRON & STEEL GRP +1

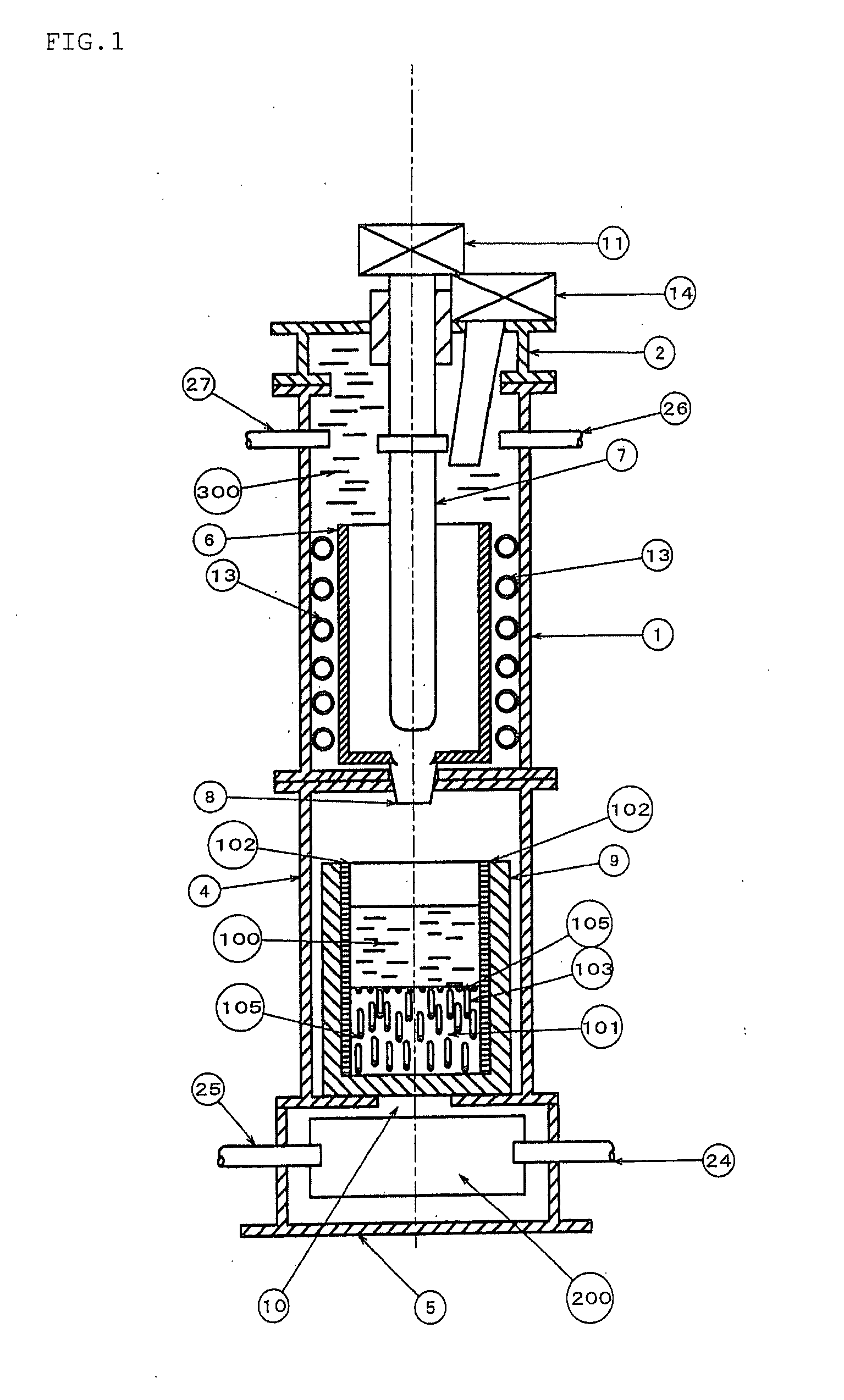

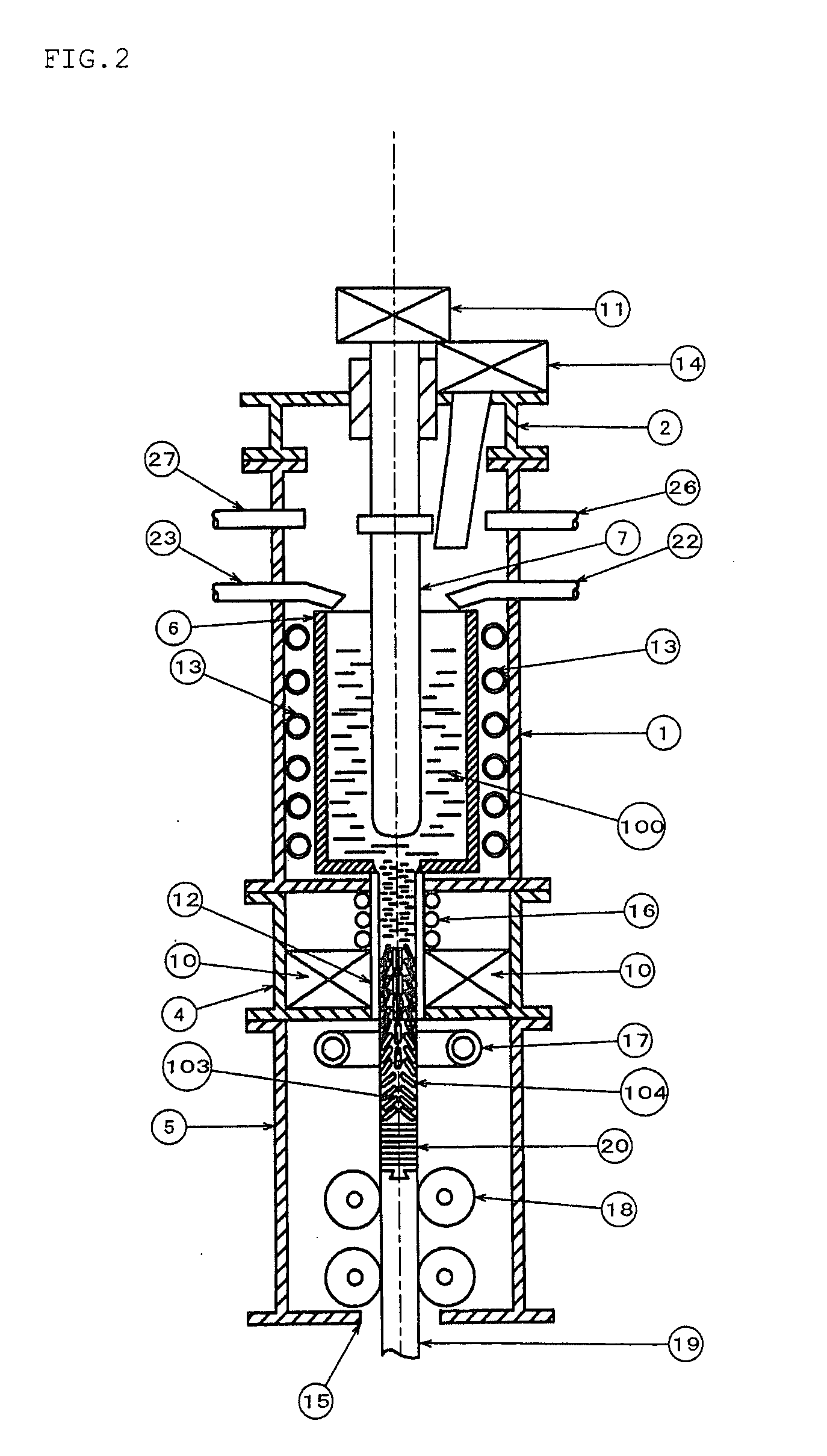

Method for manufacturing porous body

InactiveUS20090317282A1High qualityEnable mass productionMelt-holding vesselsSiliconHigh pressureMolten material

The present invention provides a process for producing a porous body which comprises dispersing a gas-forming compound in a molten porous body-forming material, and then solidifying the molten material. With this process, the present invention enables manufacture of high quality and highly uniform porous bodies even under an atmospheric pressure, without requiring high pressure ambience.

Owner:LOTUS ALLOY

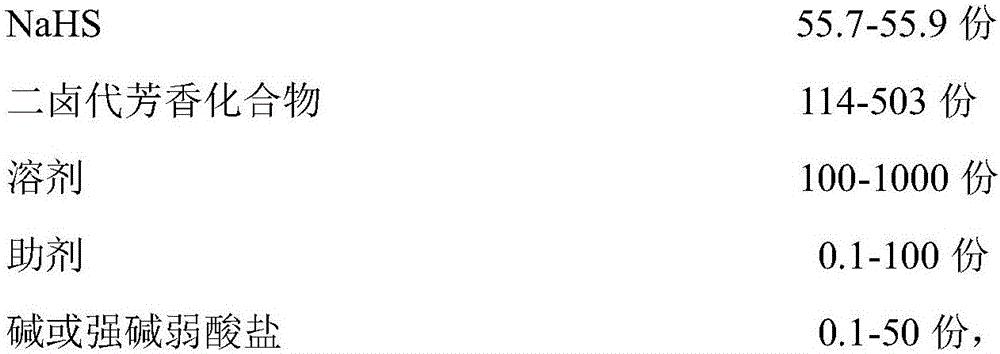

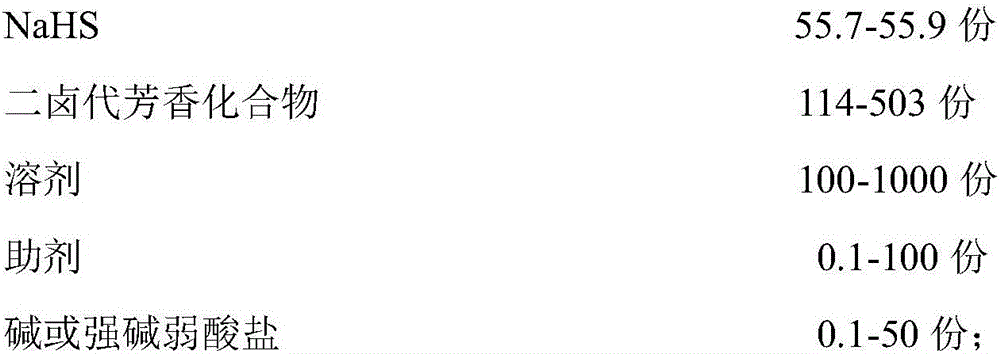

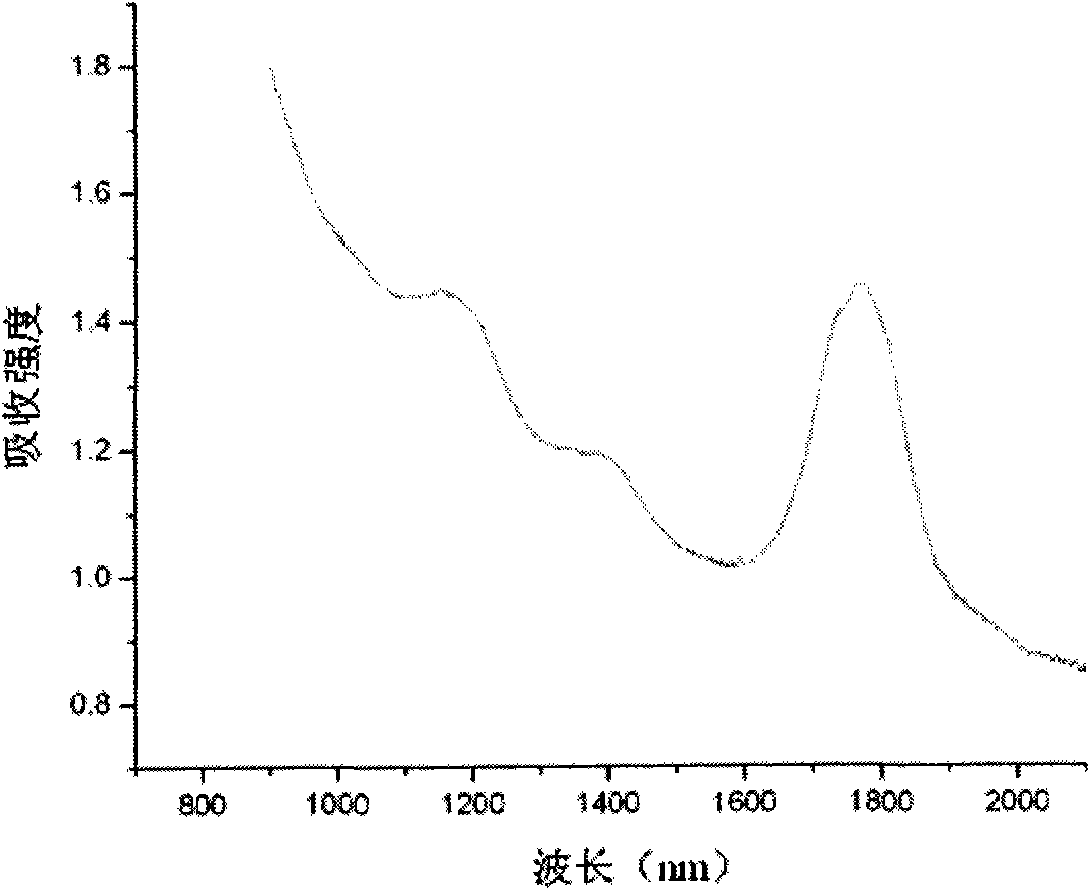

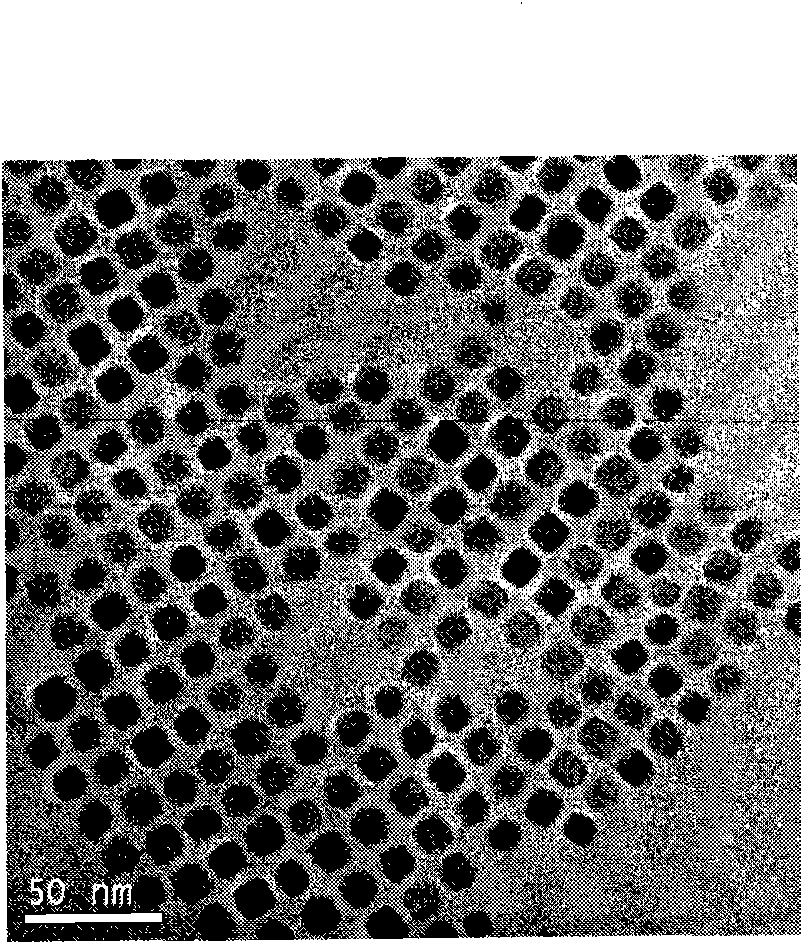

High-brightness polyarylene sulfide with narrow particle size distribution and preparation method of polyarylene sulfide

The invention relates to high-brightness and low-cost polyarylene sulfide with narrow particle size distribution and a preparation method of polyarylene sulfide and belongs to the field of polymer synthesis. The high-brightness polyarylene sulfide with narrow particle size distribution is prepared from components of raw materials in parts by weight as follows: 55.75-55.9 parts of NaHS, 114-503 parts of dihalogenated aromatic compounds, 100-1,000 parts of a solvent, 0.1-100 parts of an aid and 0.1-50 parts of alkali or strong alkali and weak acid salt, wherein the aid is at least two of lithium salt, zinc salt, sodium salt, magnesium salt and calcium salt. The high-brightness polyarylene sulfide having narrow particle size distribution and suitable for industrial production is provided and is characterized in that high-brightness polyarylene sulfide is prepared from the raw materials including sodium hydrosulfide and dihalogenated aromatic compounds under coordination of the specific aid through a solution condensation polymerization reaction and has narrow particle size distribution and high brightness.

Owner:SICHUAN UNIV

Method for preparing lead selenide nanocrystals

InactiveCN101844751AEvenly dispersedGood dispersionNanostructure manufactureBinary selenium/tellurium compoundsBoiling pointNanocrystal

The invention discloses a method for preparing lead selenide nanocrystals. The method comprises the following steps of: putting selenium powder in a container; removing the air from the container and filling the container with inert gas; adding alkylamine which has a long chain with a boiling point of over 180 DEG C into the container; fully stirring and heating the selenium powder and the ammonia to perform full reaction so as to form ligand; adding lead chloride into the alkylamine which has the long chain with the boiling point of over 180 DEG C, fully stirring the mixture, vacuuming the container and then heating the mixture of the lead chloride and ammonia to fully dissolve the lead chloride in the ammonia; and injecting the mixture of selenium powder into the mixture of lead chloride to perform reaction so as to obtain the lead selenide nanocrystalline particles.

Owner:LANZHOU UNIVERSITY

Prepn process of nanometer BN and B-C-N capsule or nanometer fullerene-like particle

InactiveCN1608976AGrowth favors controlRule out the possibility of oxidationNanostructure manufactureNitrogen-metal/silicon/boron binary compoundsMicrowaveAlloy

The preparation process of nanometer BN and B-C-N capsule or nanometer fullerene-like particle adopts nitrogen containing gas or solid as nitrogen source, carbon containing gas or solid as carbon source and nanometer catalyst alloy particle containing in 20-70 % or simple substance B as boron source to produce nanometer BN particle, nanometer BN capsule or the mixture of nanometer BN capsule and nanometer fullerene-like BN particle through reaction at 600-900 deg.c or under the activation of microwave plasma, and the nanometer BN capsule or the mixture of nanometer BN capsule and nanometer fullerene-like BN particle is post-treated to produce corresponding pure nanometer fullerene-like BN particle. The present invention develops one new method of preparing high purity nanometer fullerene-like particle, and several kinds of nanometer hollow BN and B-C-N structure are prepared in the said method.

Owner:NANJING UNIV

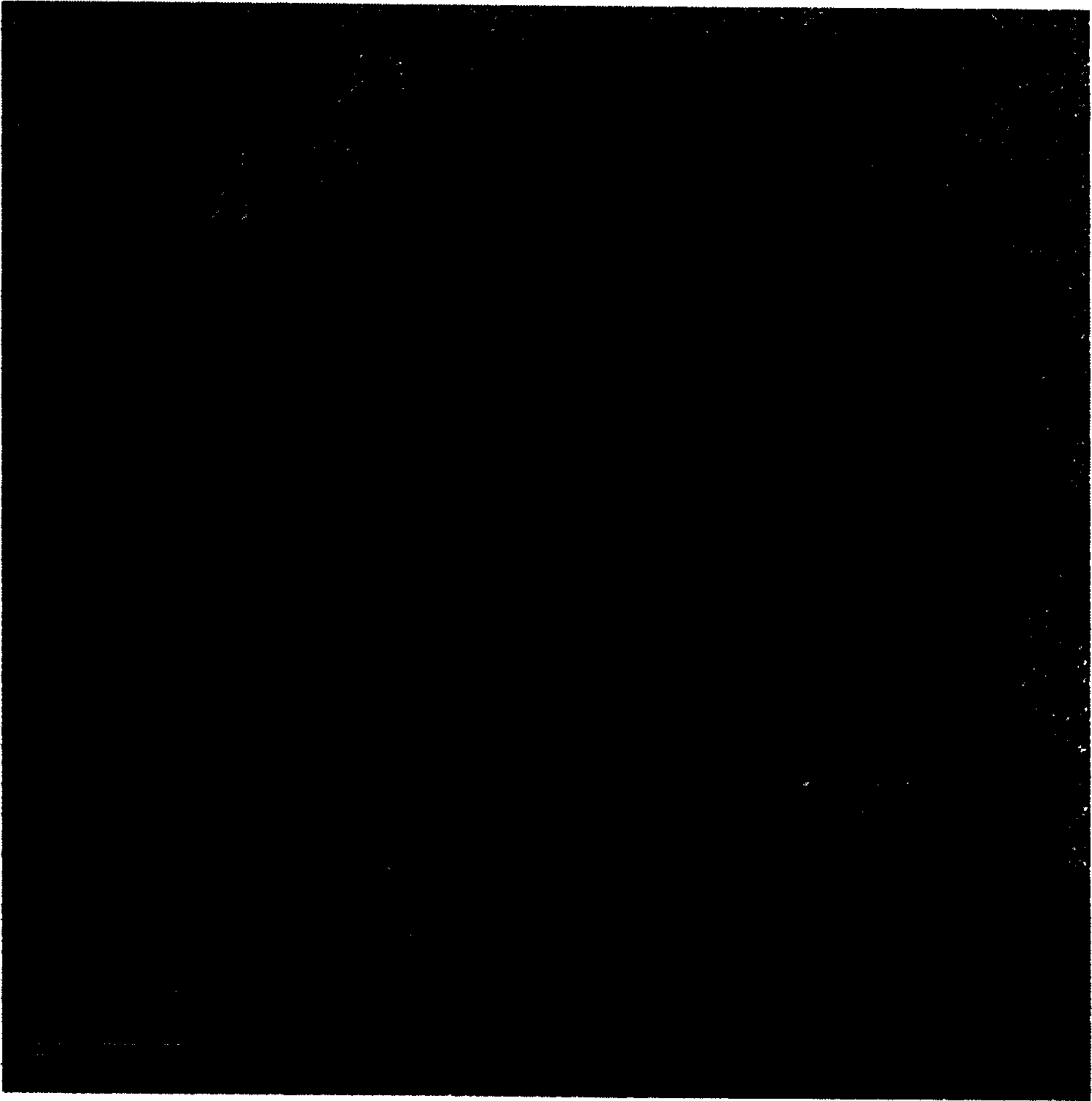

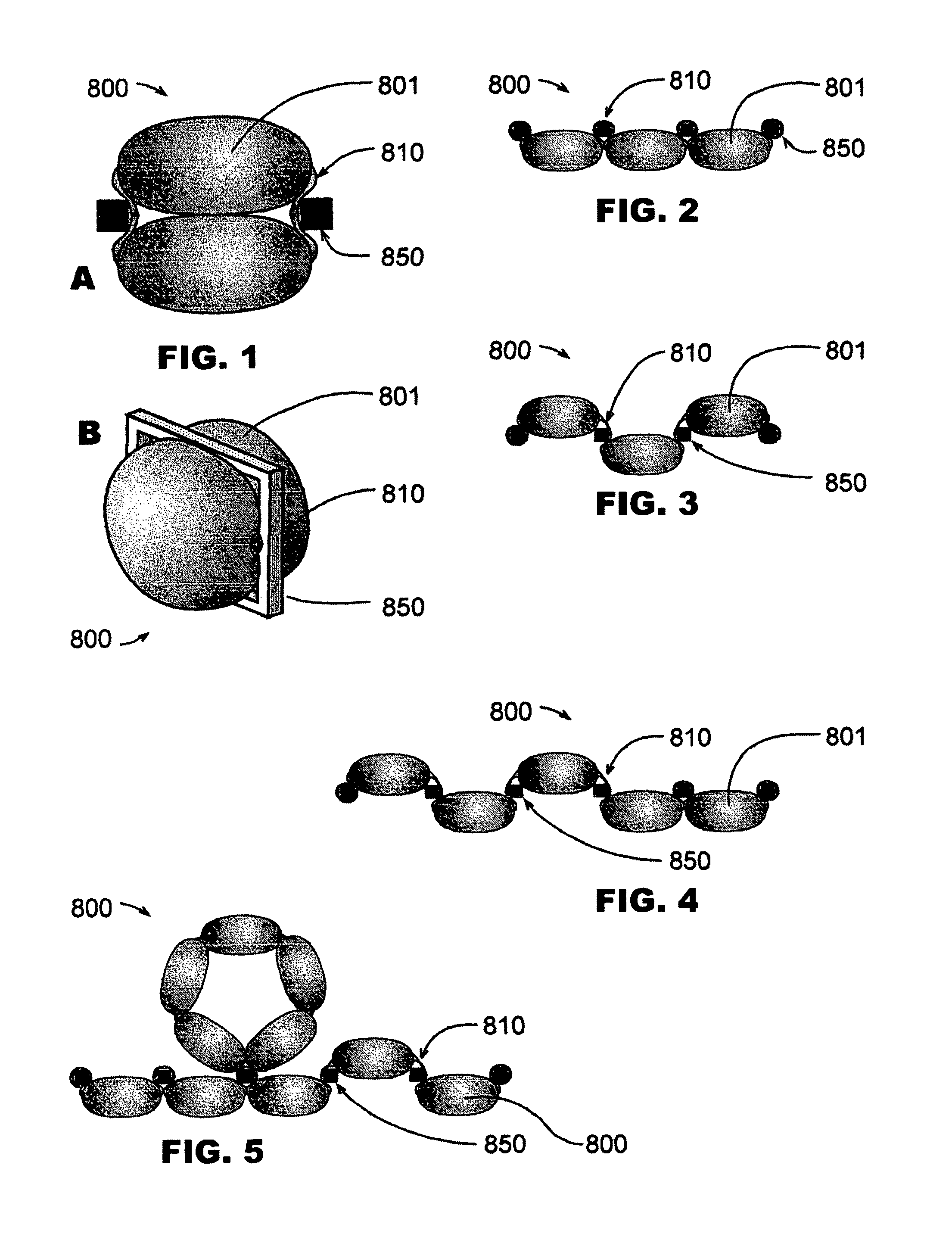

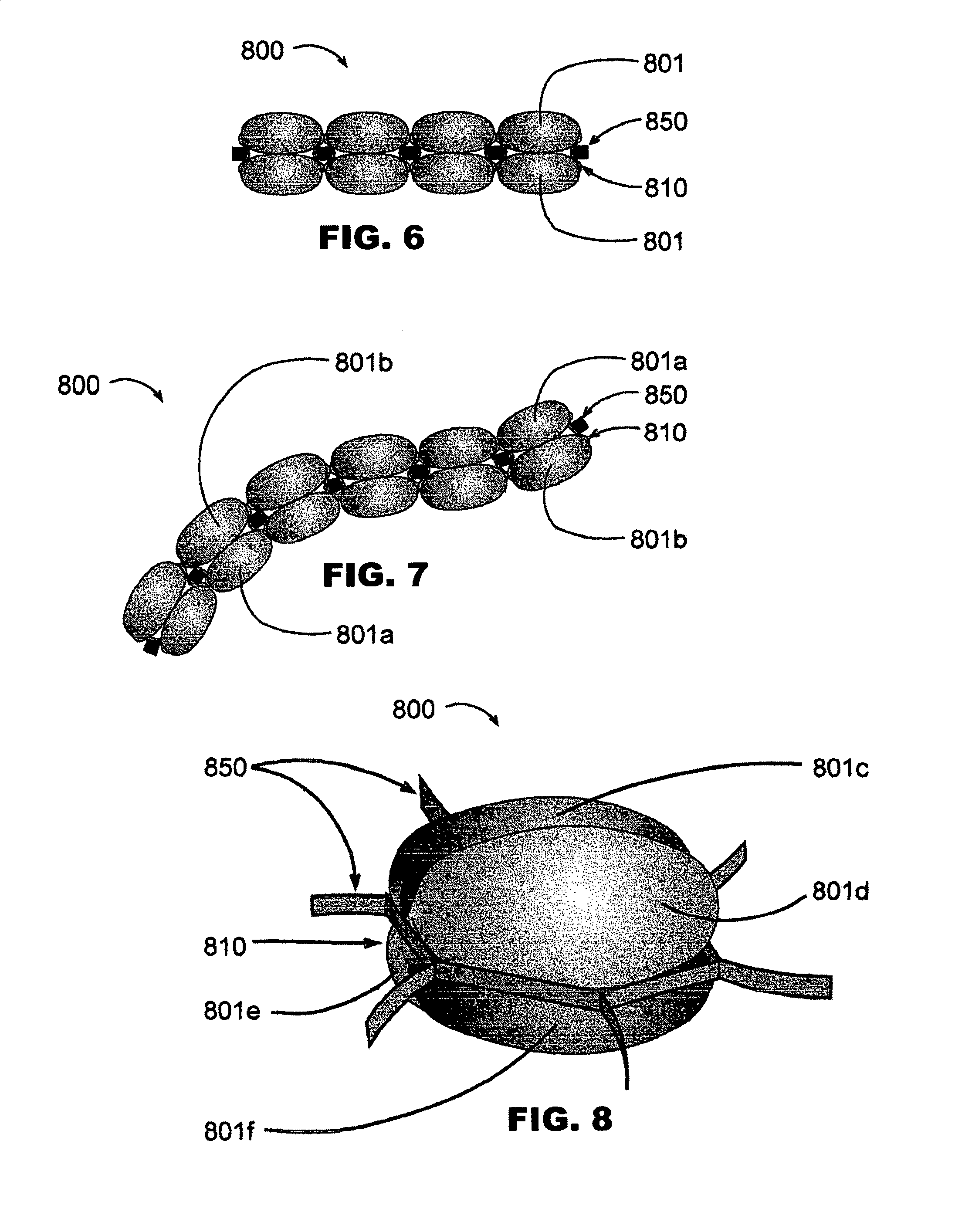

Rouse display systems

A balloon display generally having decorative, informative and / or structural value. The display is comprised of an aperture framework, inflated chambers and connector members that join inflated chambers through apertures small enough to resist the passage of the inflated chambers. There is generally a plurality of connector members associated with each inflated chamber. Connector members from a given inflated chamber start from different locations, go to different locations and do not intersect.

Owner:ROUSE GRAHAM MANLY

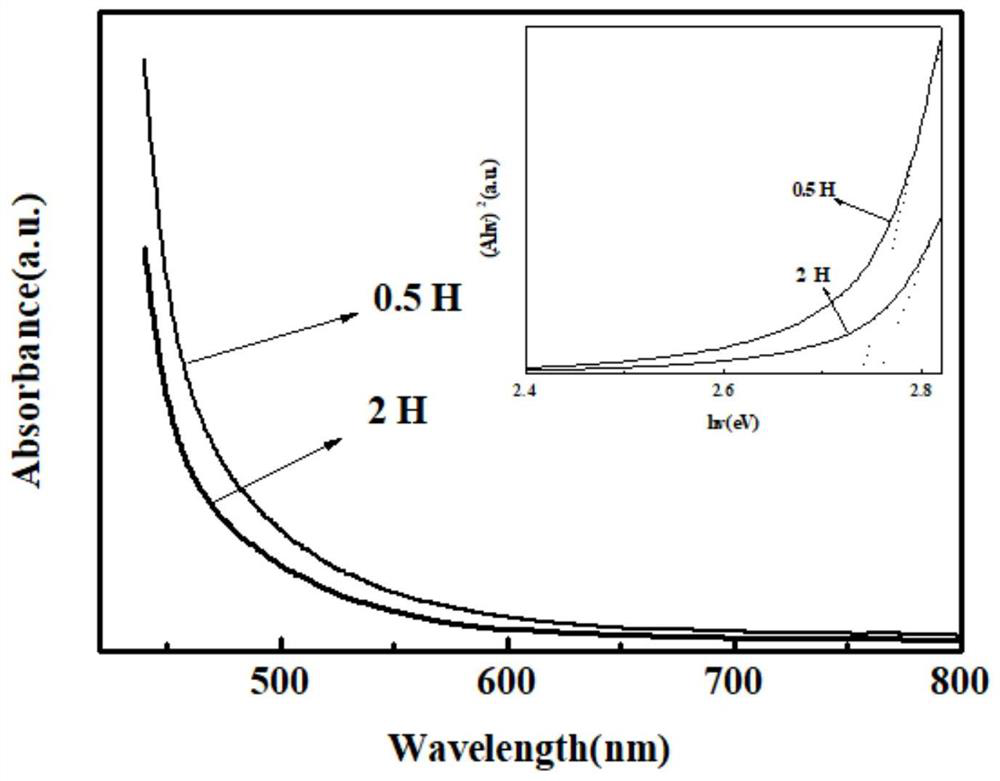

Method for preparing Cu: ZnCdS/ZnS quantum dot luminescent material by one-pot method

PendingCN111662707AGood size controlUniform particle size distributionMaterial nanotechnologyNanoopticsQuantum dotSolar cell

The invention relates to a method for preparing a Cu:ZnCdS / ZnS quantum dot luminescent material. The method comprises the following steps: preparing precursor solutions from a zinc source, a cadmium source, a copper source and a sulfur source and putting each precursor solution into the same reaction container, removing water and oxygen, heating to react to generate a quantum dot luminescent material with a cubic sphalerite structure, and finally mixing the quantum dot with the zinc precursor solutions to react, thereby obtaining the target quantum dot material with a core-shell structure. Bycontrolling the doping amount, the reaction time and the reaction temperature of copper, passivating the surfaces of the quantum dots and the like, controllable preparation of the quantum dots and adjustability of the light-emitting wavelength are realized. The method has the advantages of simple preparation process, low cost and the like, the preparation cost of the luminescent material is greatly reduced, and the prepared quantum dot is controllable in size and adjustable in luminescent wavelength, and has a relatively good application value in the fields of luminescent devices, solar cells,biomedicine and the like.

Owner:WUHAN UNIV OF TECH

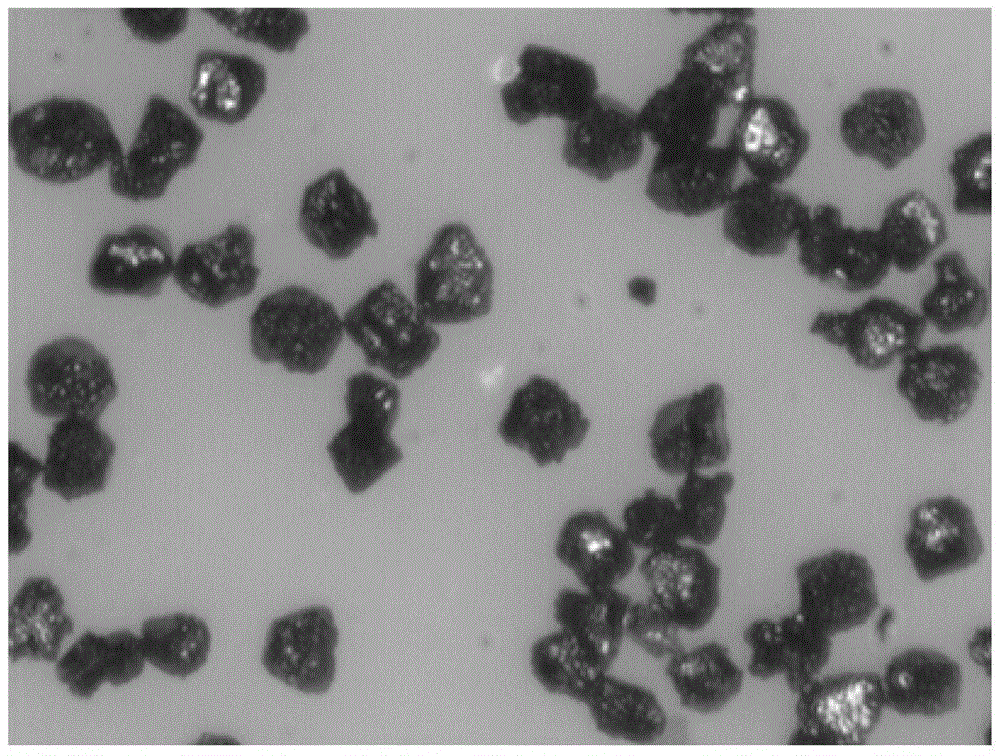

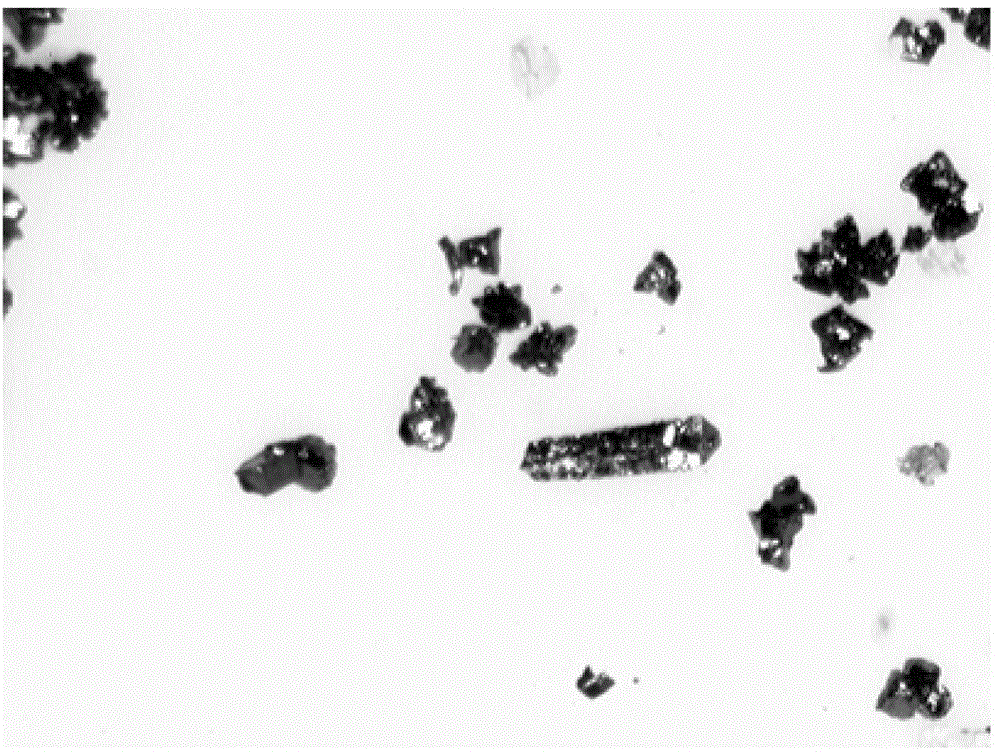

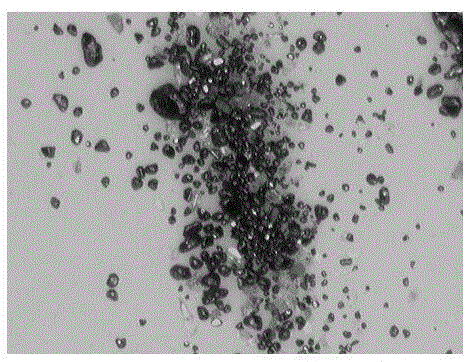

Preparation method of antimony selenide monocrystal microparticles

ActiveCN105603532AEliminate crystal facetsAbundant resourcesPolycrystalline material growthFrom melt solutionsSelenideAntimony

The invention discloses a preparation method of antimony selenide monocrystal microparticles. The method comprises the following steps: grinding and mixing a simple substance antimony, a simple substance selenium and a fluxing agent, encapsulating the mixture in a quartz reaction vessel in a vacuum, keeping the temperature at 600-750 DEG C for 48-120 hours, and quickly cooling the quartz reaction vessel; and taking out the sample, washing and drying to obtain the antimony selenide monocrystal particles. The size of the monocrystal particles can be regulated by utilizing the recrystallization temperature and time; the particle components can be effectively regulated within a certain range through the mole ratio of the elements in the precursor; and the prepared monocrystal particles have the advantages of high uniformity, controllable size and better properties than the monocrystal particles prepared by the traditional method.

Owner:LINGNAN NORMAL UNIV

Cold start up auxiliary system for alcohol and flex engines with air-inlet and alcohol warm up

InactiveUS8646437B2Strong in of in consumptionStrong influenceLiquid surface applicatorsElectrical controlEngineeringInternal combustion engine

The present invention relates to a new auxiliary system of cold start, preferably used in the internal combustion engines that use alcohol as fuel. The engines ‘Flex Fuel’ (alcohol / gasoline / GNV) are included in the possibility of the use of this invention. The cold starting system makes use of resistances (3) positioned in the entrance of the injectors (4); resistances (6) inside of each injector (1) or one resistance (5) for every pipe holder of nozzles (2), and the three possibilities can be used simultaneously, combined two by two or separately, depending on the necessity of warm up alcohol flow and the energy consumption. It can also make use of groups of resistances (11, 12, 13) positioned in the intake. Additionally one or two auxiliary injectors can be foreseen (supplementary) in the intake collector with the same alcohol heating system.

Owner:FIAT AUTOMOVEIS

Process for continuously producing calcium naphthenate

The invention discloses a process for continuously producing calcium naphthenate. The process comprises the following steps: (1) mixing naphthenic acid, methanol, dimethylbenzene and base oil to form a mixed oil raw material; (2) feeding the mixed oil raw material and a calcium hydroxide saturated solution in a first micro-tube type reactor, and carrying out neutralization reaction to obtain an intermediate product; (3) feeding the intermediate product and CO2 in a second micro-tube type reactor, and carrying out carbonation reaction to obtain a coarse product; and (4) directly feeding the coarse product into a coarse product tank from an outlet of the second micro-tube type reactor, distilling the coarse product and carrying out settling filtration on the coarse product to obtain the final product. The process has the beneficial effects that three-phase synthesis of high-base-number nano petroleum calcium naphthenate is carried out in a micro-reaction system, reaction materials can be micro-mixed uniformly instantaneously, the form and the particle size distribution of nanoparticles are controlled effectively, the production efficiency and the quality of products are improved, and stable continuous operation is realized.

Owner:XI'AN PETROLEUM UNIVERSITY

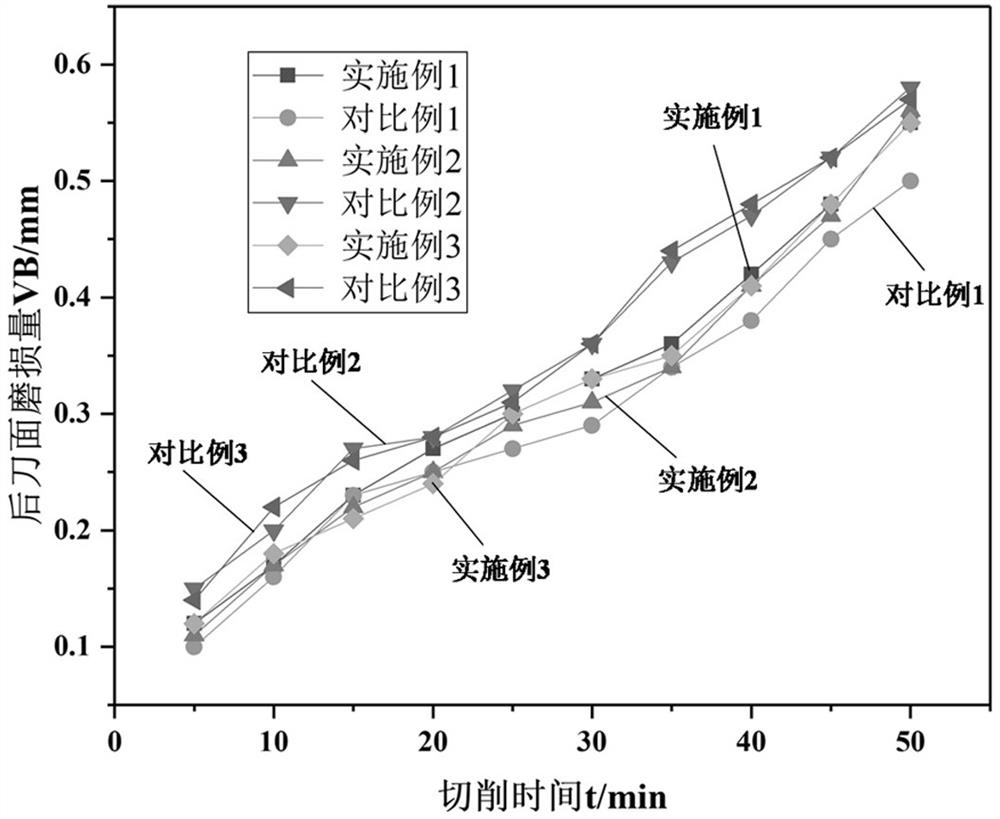

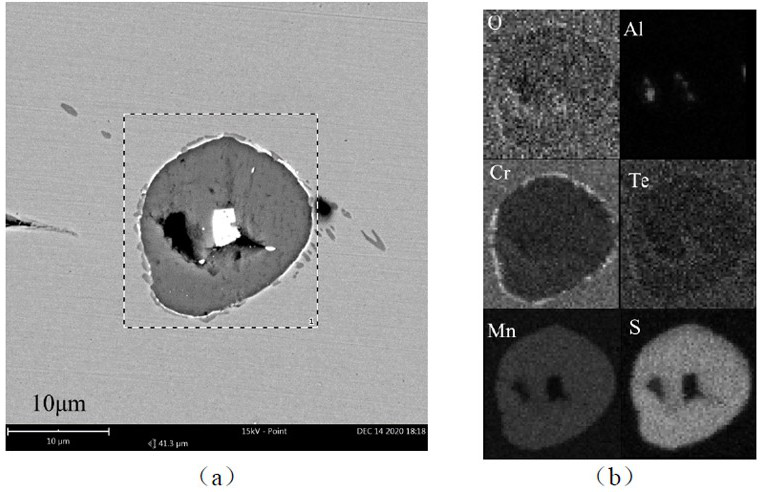

Free-cutting corrosion-resistant steel and preparation method thereof

The invention relates to free-cutting corrosion-resistant steel and a preparation method thereof. The free-cutting corrosion-resistant steel comprises the following components in percentage by mass: 0.015 to 0.024 percent of C; 0.4 to 0.5 percent of Si; 1.2 to 1.3 percent of Mn; 0.24 to 0.3 percent of S; 0.02 to 0.03 percent of P; 1.5 to 1.75 percent of Mo; 19 to 20 percent of Cr; 0.03 to 0.08 percent of Ca; 0.01 to 0.02 percent of Mg; 0.02 to 0.05 percent of Al; 0.012 to 0.03 percent of Te; and the balance Fe and impurities. The method comprises the following steps of uniformly mixing free-cutting steel, a ferrochrome mixture and slag charge, and completely melting at high temperature to obtain a melt; and adding tellurium into the melt, conducting heat preservation treatment, and cooling to obtain the free-cutting corrosion-resistant steel. The free-cutting corrosion-resistant steel disclosed by the invention has the optimal component proportion, and has the comprehensive optimal free-cutting performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

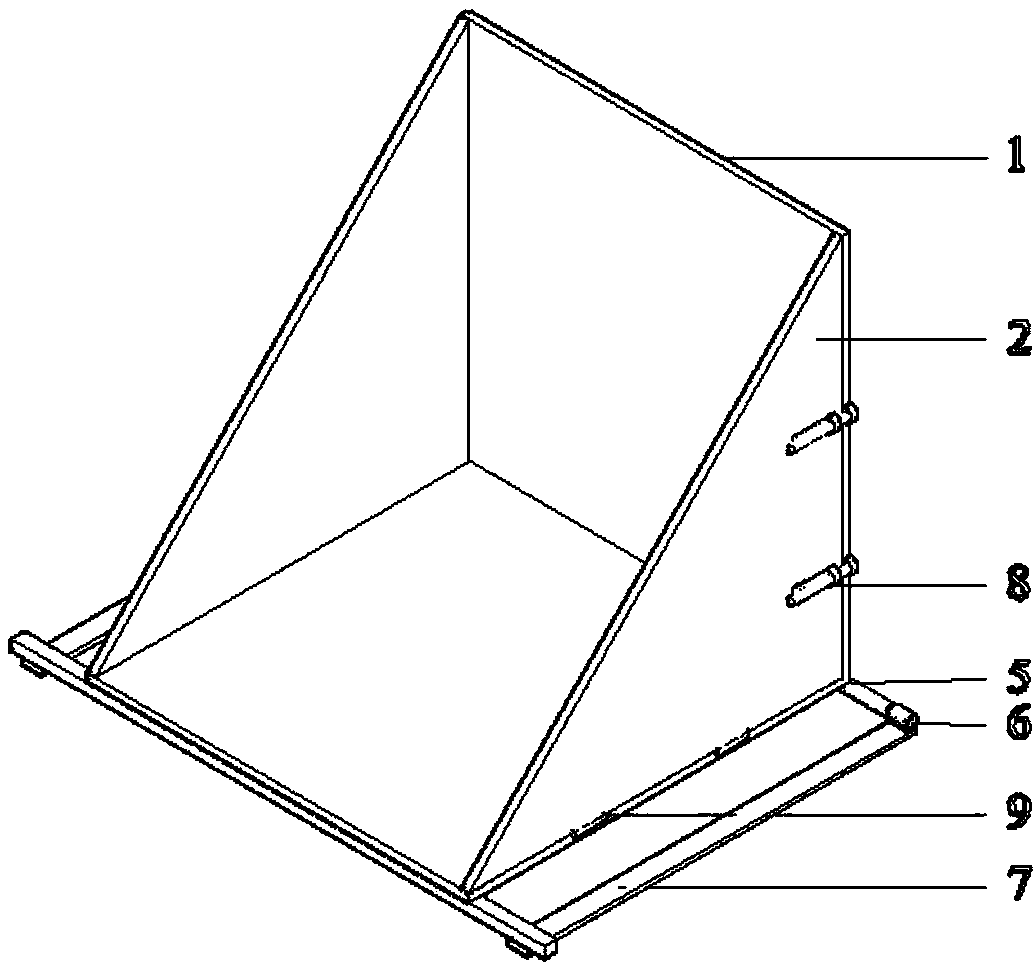

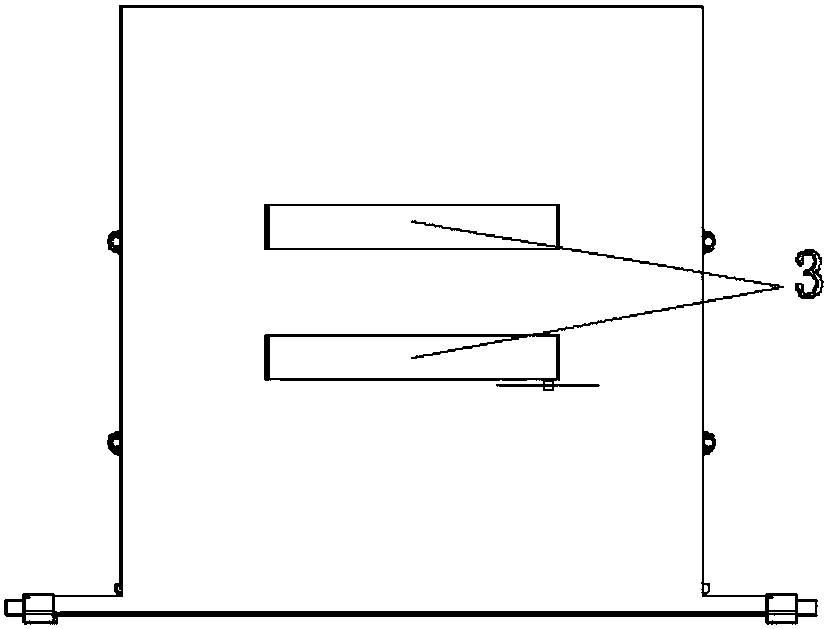

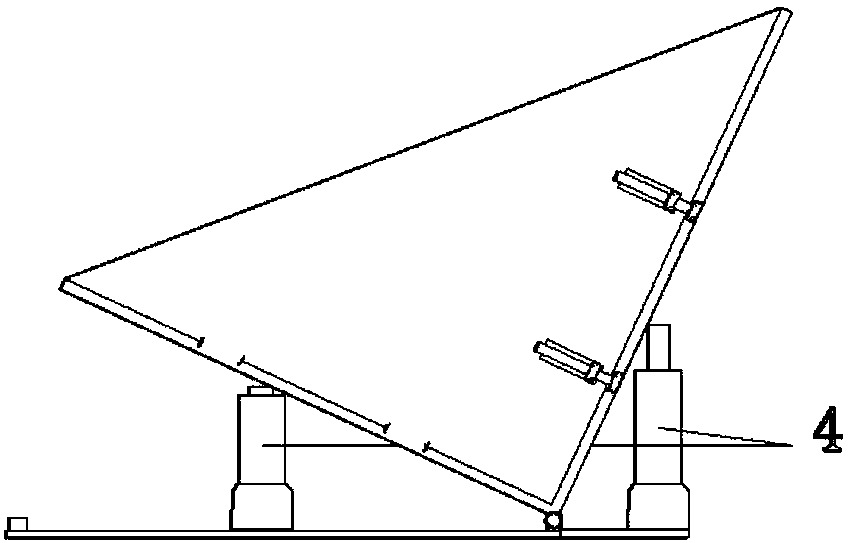

Layered filling production device of tiltable slope model and layered filling method

ActiveCN108088719AEasy to makeSpeed upPreparing sample for investigationClimate change adaptationRear quarterRight triangle

The invention relates to a layered filling production device of a tiltable slope model and a layered filling method. The layered filling production device comprises a base and a wedge-shaped box body,wherein the wedge-shaped box body can rotate relatively to the base; the wedge-shaped box body comprises a bottom plate, a back plate and two side plates; the back plate and the two side plates are vertically connected with the bottom plate; the back plate is rectangular; the two side plates are isosceles right triangles; the two side plates are parallel to each other and are both fixed with theback plate into one; the two side plates are connected with the bottom plates by hinges. According to the layered filling production device, a production process of the slope model is changed from complex to simple, and the device is simple in operation, so that the production time is greatly shortened. Meanwhile, the slope toe of a side slope as well as the dip angle and the form of a slope surface can be well controlled, and the progress of an experiment can be accelerated.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com