Method for generating liquid droplet array on microfluidic chip

A technology of microfluidic chips and microwell arrays, applied in biochemical equipment and methods, measurement/testing of microorganisms, fluid controllers, etc., can solve problems such as cross-contamination of micropores, high price and complexity of surfactants, etc. Achieve the effect of good physical isolation, convenient assembly and large tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, generate the micro-droplet array of uniform size

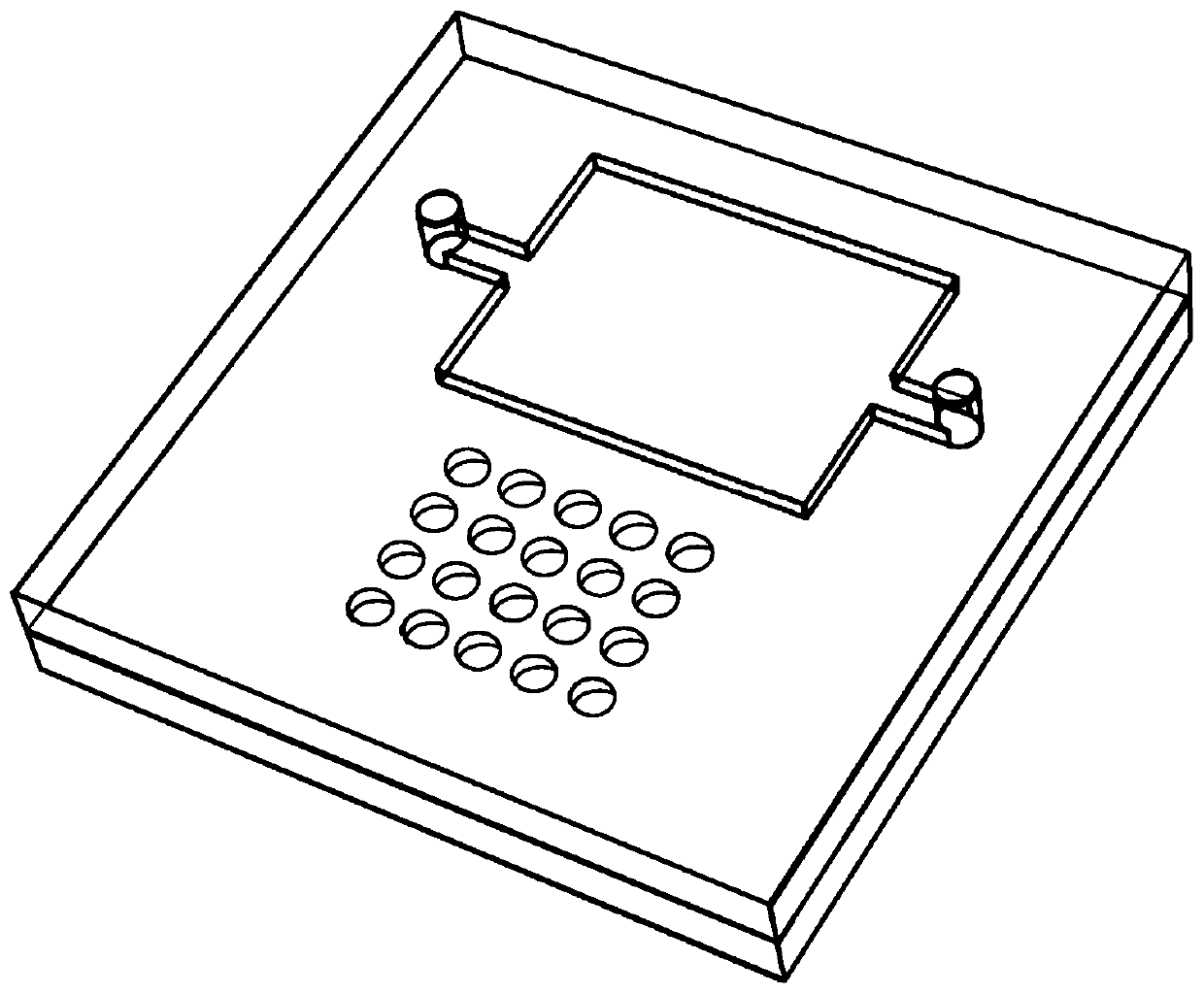

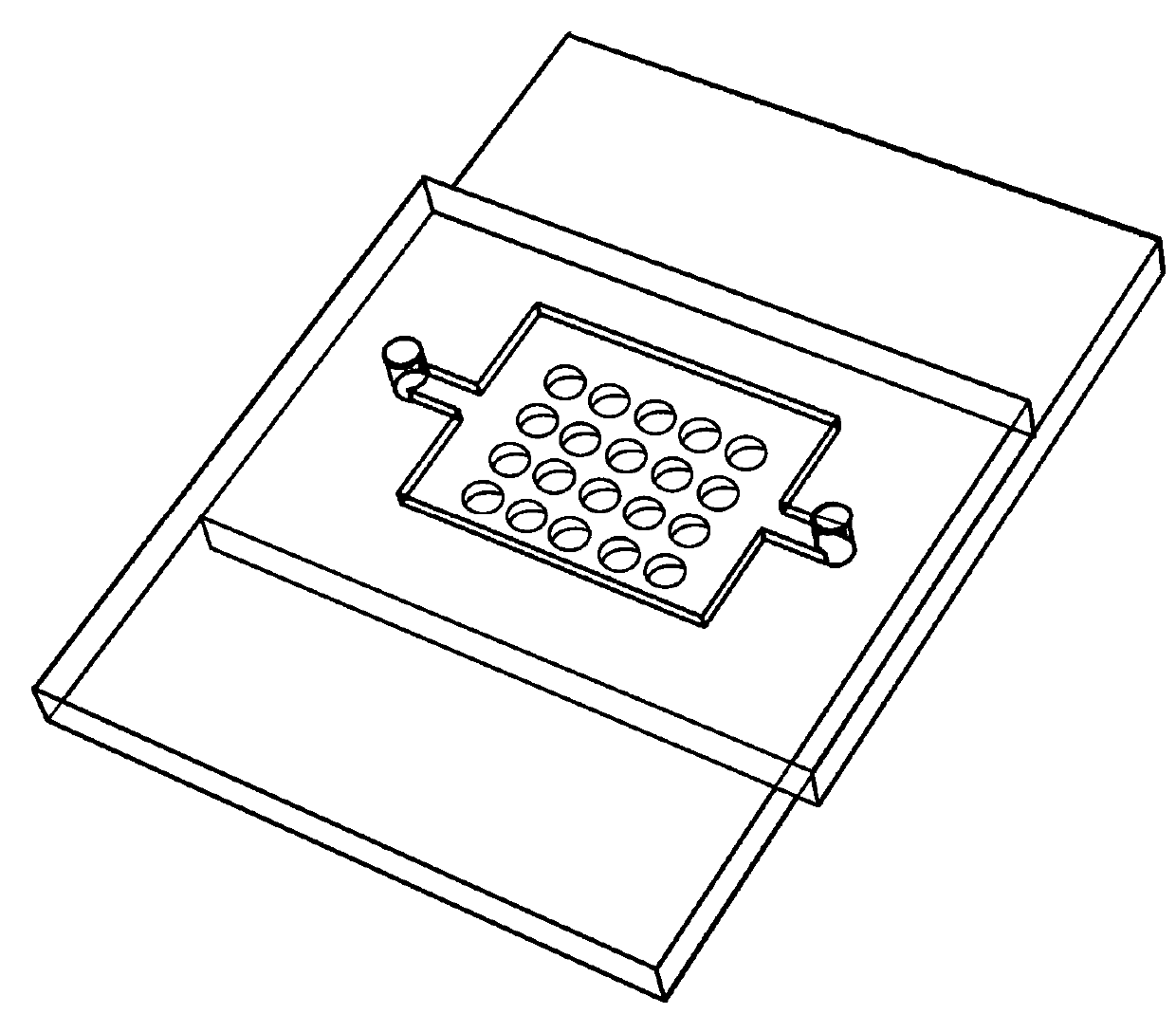

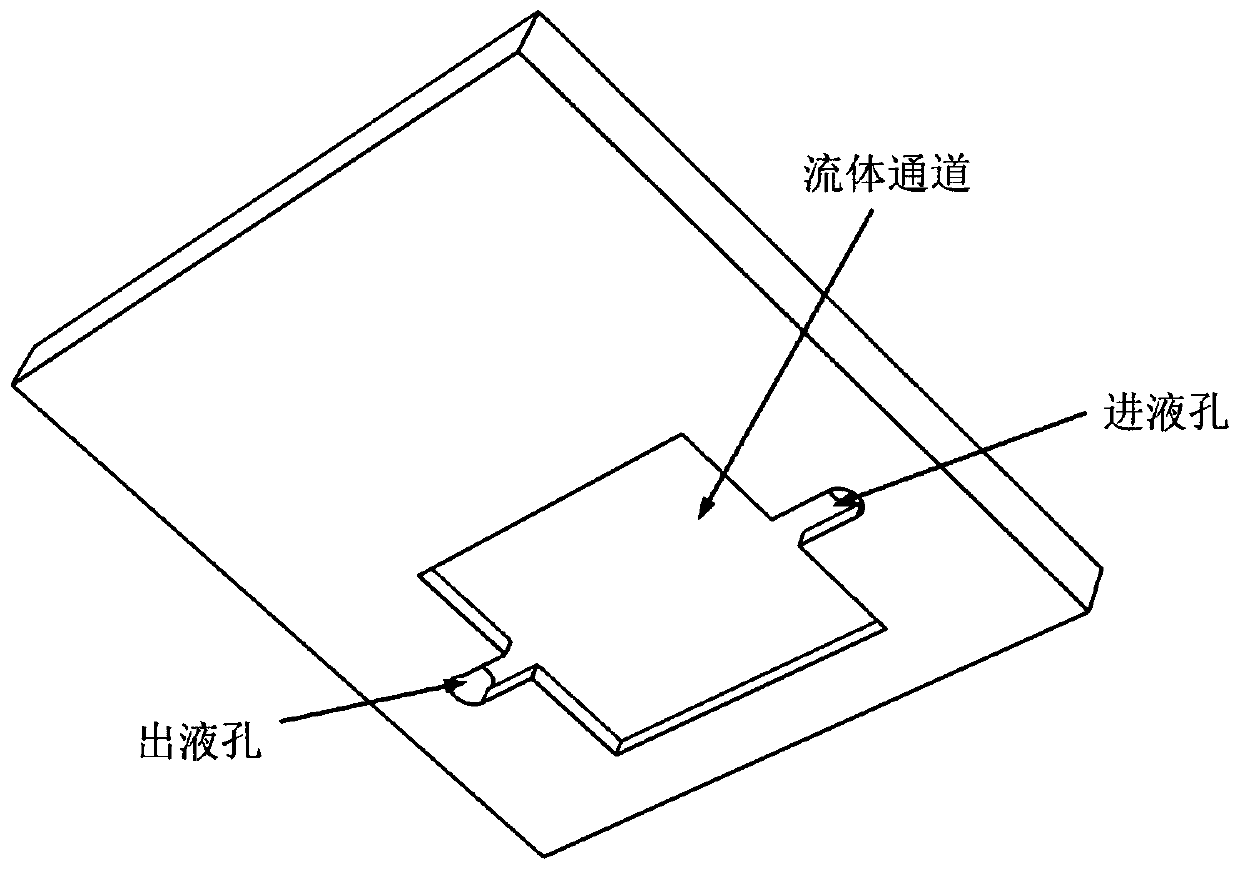

[0040] In this embodiment, an upper chip is prepared on a glass material by a wet etching method (such as image 3 shown) and lower chip (as Figure 4 shown). The fluid channel on the chip has a width of 5 mm, a length of 15 mm, and a depth of 50 microns. The upper chip contains a liquid inlet and a liquid outlet. The lower chip contains 5000 microwells distributed in an area of 4.5 mm wide by 12.5 mm long. The etched microholes of the lower chip have a diameter of 80 microns and a depth of 25 microns. The surface of the chip adopts the gas-phase silanization method, and uses dimethyl dichlorosilane to carry out hydrophobic modification treatment on the glass surface. The organic phase components were mineral oil and tetradecane mixed in equal volumes.

[0041] After the upper chip and the lower chip are assembled, a layer of organic phase liquid is added between the upper and lower chips, and the ...

Embodiment 2

[0044] Embodiment 2, digital PCR experiment

[0045] Chip preparation was the same as in Example 1. The upper chip and the lower chip are prepared on the glass material by wet etching. The fluid channel on the chip has a width of 5 mm, a length of 15 mm, and a depth of 50 microns. The upper chip contains a liquid inlet and a liquid outlet. The lower chip contains 5000 microwells distributed in an area of 4.5 mm wide by 12.5 mm long. The etched microholes of the lower chip have a diameter of 80 microns and a depth of 25 microns. The surface of the chip adopts the gas-phase silanization method, and uses dimethyl dichlorosilane to carry out hydrophobic modification treatment on the glass surface. The organic phase components were mineral oil and tetradecane mixed in equal volumes. A layer of organic phase liquid is added between the upper and lower chips. When the combination is at the initial position of sample addition, the connected fluid channels of the upper chip and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com