Slim hole explosion crack generation assisted hydraulic fracturing method

A hydraulic fracturing and wellbore technology, which is applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., to achieve the effects of improving seepage capacity, avoiding explosion, and avoiding fracture bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

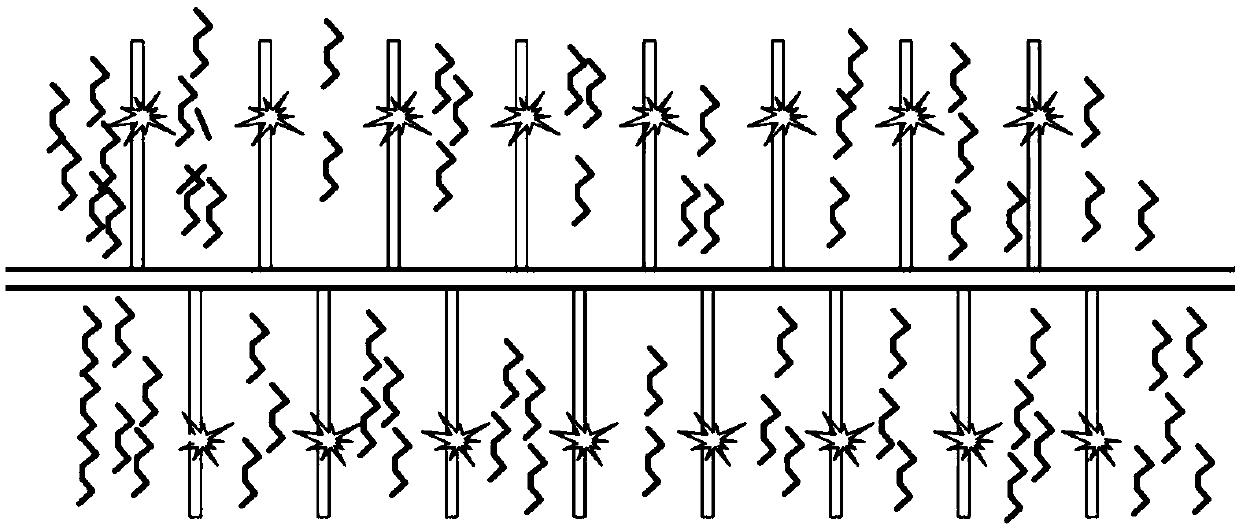

[0063] A shale gas reservoir has a buried depth of 4000m and a reservoir thickness of 50m. In order to achieve the purpose of increasing shale gas production, the designed fracture length must be greater than 250m.

[0064] The horizontal wellbore length is 1200m. Combined with the logging data and relevant parameters of the detonator, the positions of 22m, 201m, 402m, 802m and 1002 in the horizontal section are selected as the slim hole positions.

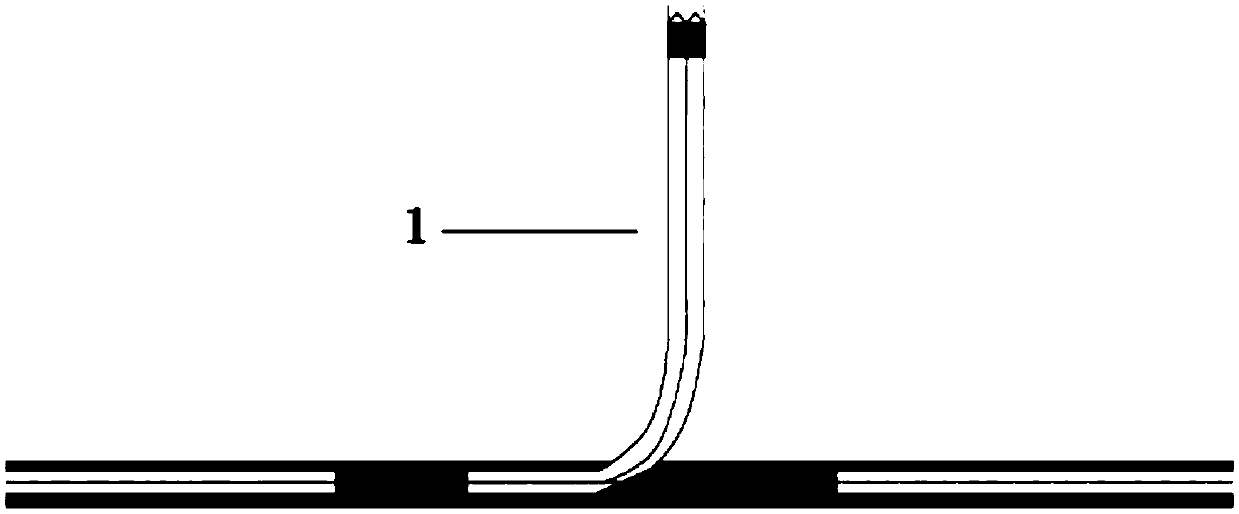

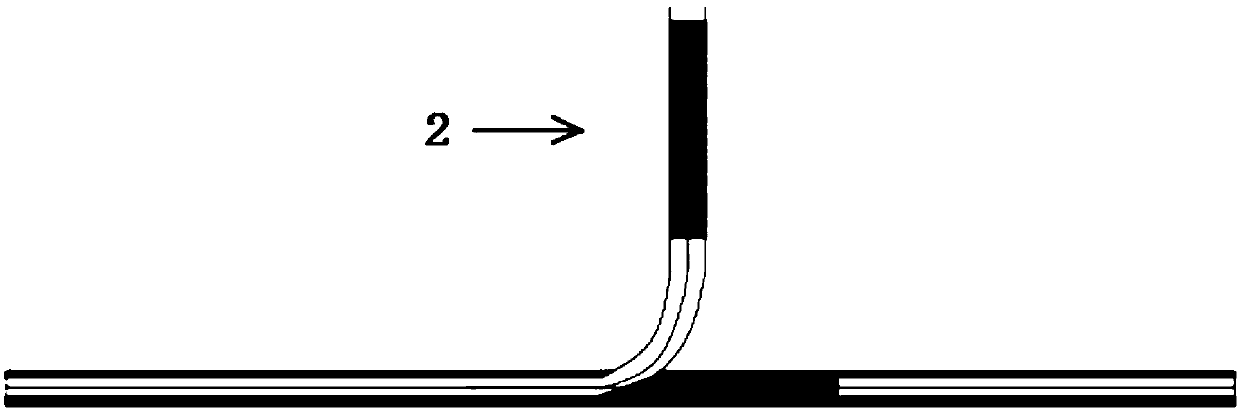

[0065] Horizontal open holes were drilled and detonated at 21m, 201m, 402m, 802m, and 1002m in horizontal sections by means of horizontal sidetracking. For the convenience of expression, the horizontal sections 21m, 201m, 402m, 802m, and 1002m are referred to as the 1st, 2nd, 3rd, 4th, and 5th explosion points for short. Taking the fifth explosion point as an example, after running the skewer and completing the window repair work, the screw drilling tool and drill bit are used to complete the drilling of the radial and horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com