Method for preparing Cu: ZnCdS/ZnS quantum dot luminescent material by one-pot method

A quantum dot luminescence and quantum dot technology, which is applied in the field of preparing Cu:ZnCdS/ZnS quantum dot luminescent materials, can solve problems such as affecting the fluorescence luminous efficiency, and achieve the effects of good repeatability, low cost and controllable quantum dot size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of Zn precursor solution

[0026] Weigh 0.4405g of zinc acetate dihydrate and add it to a three-necked flask, use a pipette to measure 1.6mL OAm (oleylamine) and 18.4mL ODE (octadecene) respectively and add them to the three-necked flask, heat and stir while first evacuating Then argon was circulated, and vacuum-passed argon three times to remove moisture and oxygen in the three-necked flask. Then the temperature was raised to 160°C until the solution turned into a light green transparent clear liquid, the argon gas valve was closed and the mixture was transferred to a glass sample bottle, and placed in a constant temperature drying oven at 50°C for later use.

[0027] (2) Preparation of Cd precursor solution

[0028] Weigh 0.5328g of cadmium acetate dihydrate and add it to a three-necked flask, and use a pipette gun to measure 4mL OA (oleic acid) and 16mL ODE respectively and add them to the three-necked flask. While heating, first vacuum and then argo...

Embodiment 2

[0039] This example is basically the same as Example 1, except that the amount of Cu precursor solution added in step (6) is 0.1 mL (0.001 mmol).

Embodiment 3

[0041] This example is basically the same as Example 1, except that the amount of Cu precursor solution added in step (6) is 0.4mL (0.004mmol).

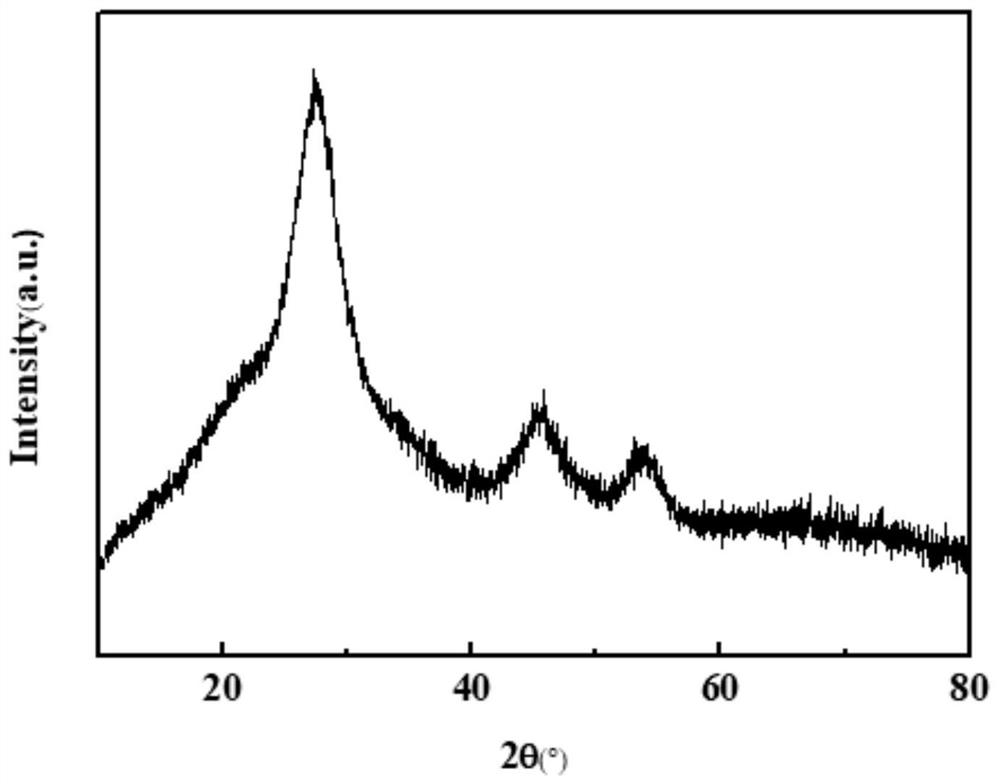

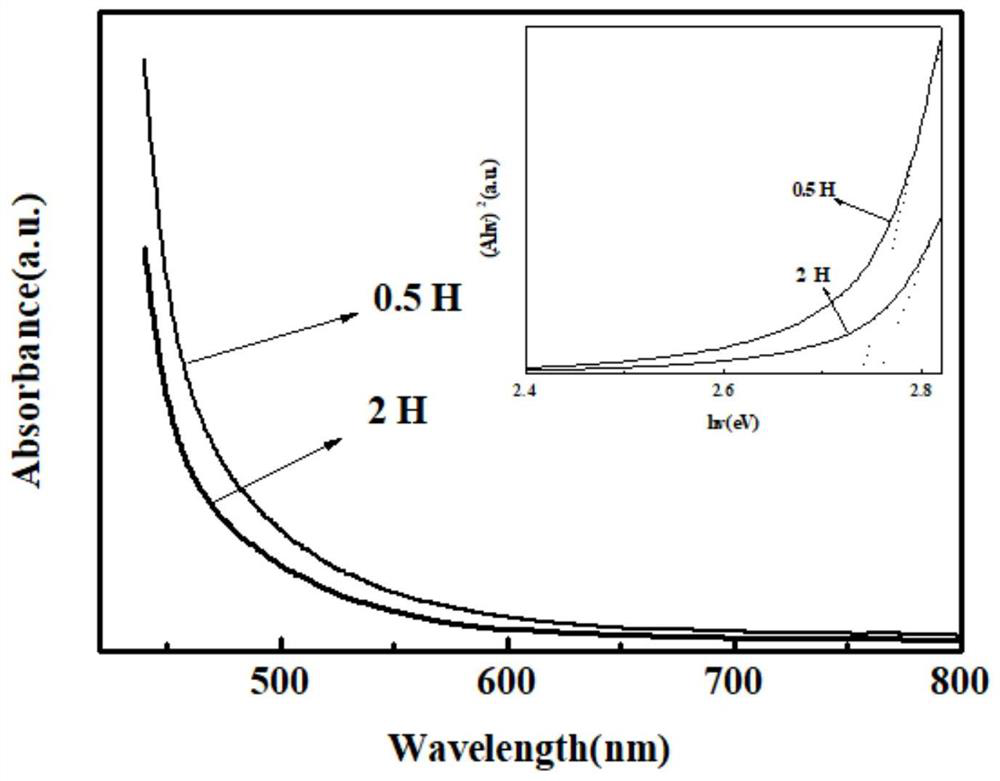

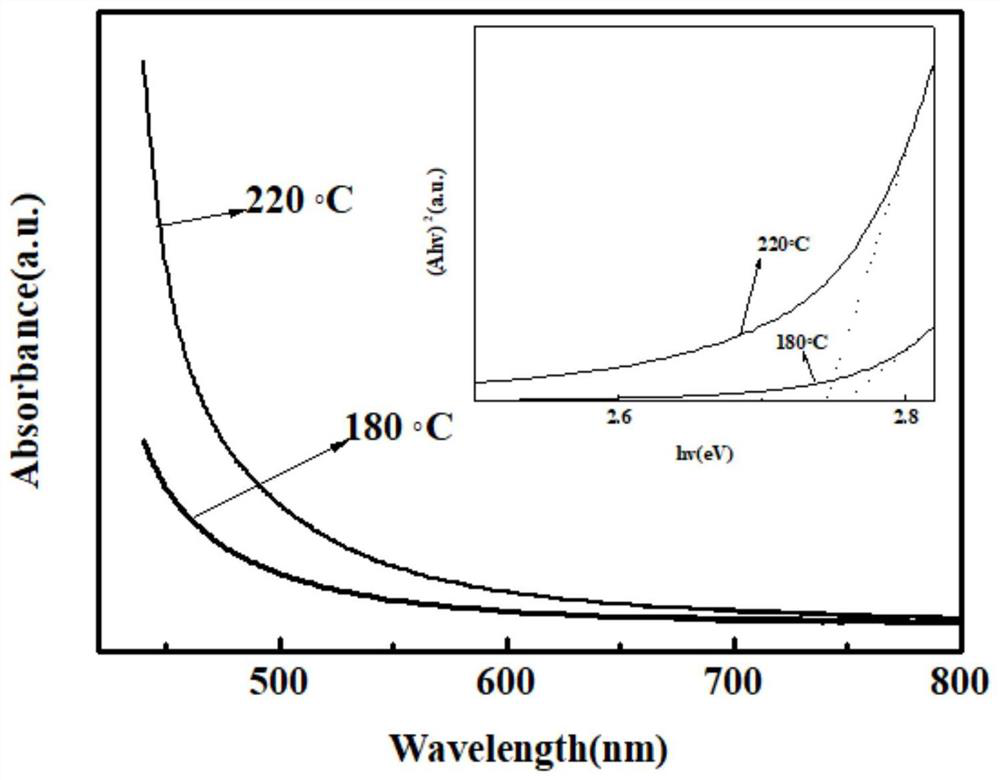

[0042] The Cu:ZnCdS quantum dots prepared in Example 2-3 were similarly analyzed and tested, and compared with the results of Comparative Document 1, it was found that with the increase of the Cu / Zn molar ratio, the XRD diffraction peaks of the samples gradually shifted to the diffraction of ZnS peak, demonstrating that the interplanar spacing is about 0.32 nm at a Cu / Zn molar ratio of 1:100. It can be seen from the comprehensive TEM images that the interplanar spacing decreases and the crystal particle size decreases with the increase of doping concentration. Absorption and emission spectra demonstrate the integrity of the grain growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com