Flexible transparent conductive oxide nanofiber membrane and preparation method thereof

A transparent conductive, nanofiber technology, applied in the direction of fiber chemical characteristics, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of difficult to meet actual requirements, unfavorable flexible substrate coating, low conductivity of conductive film, etc. Visible light transmittance, low cost, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

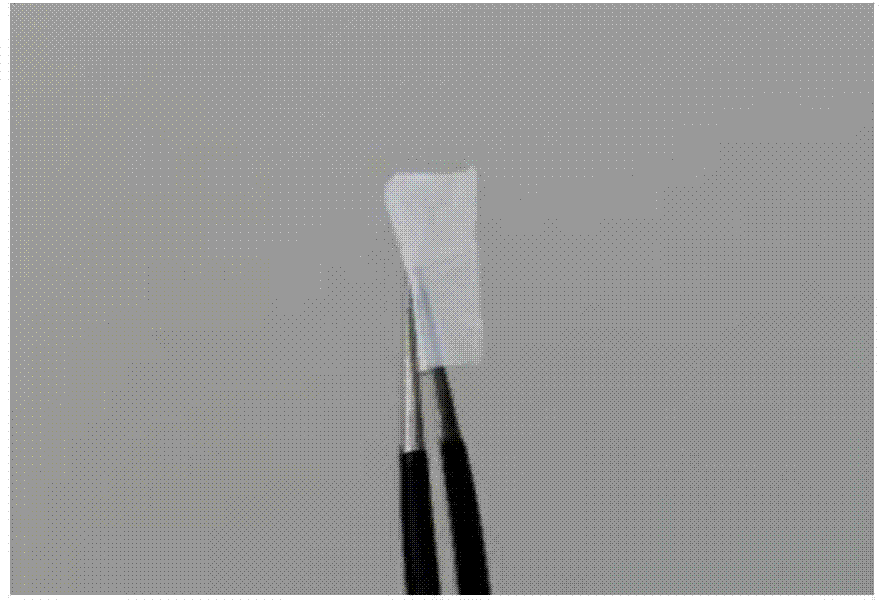

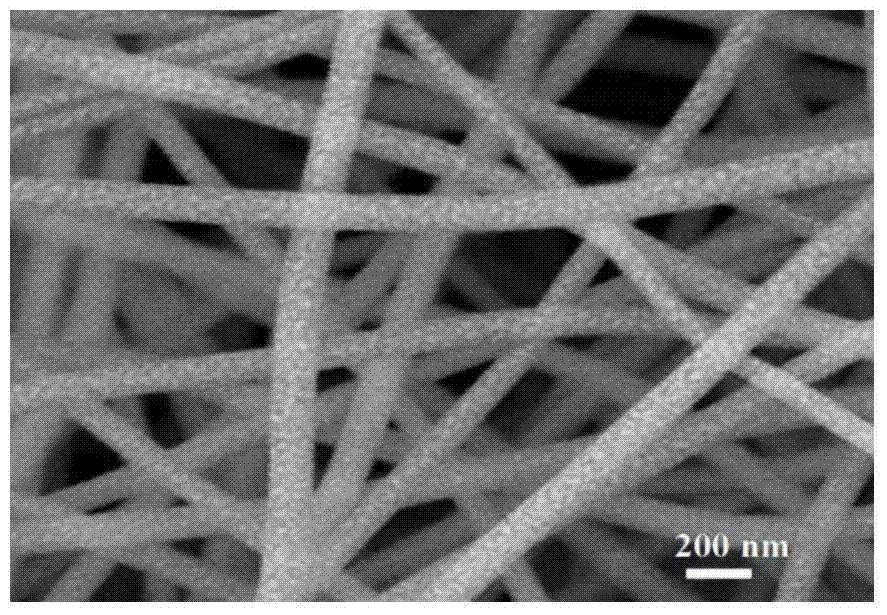

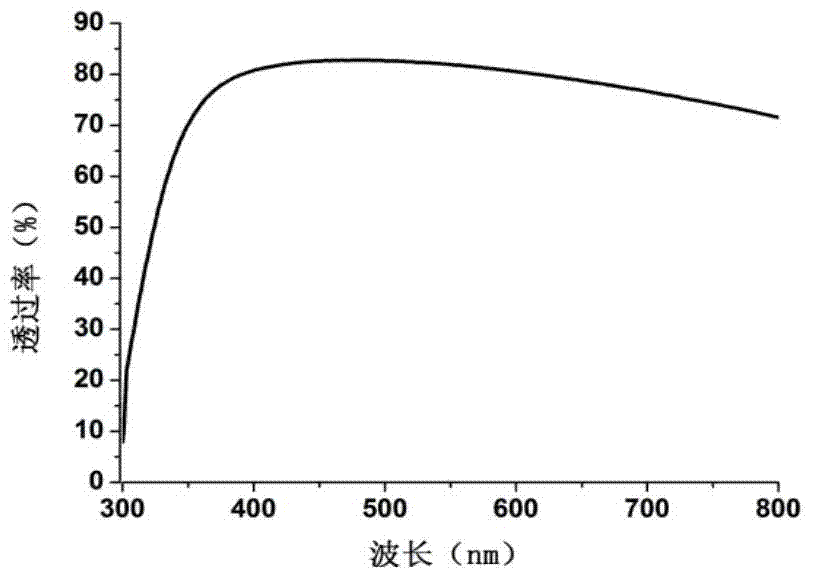

[0025] Embodiment 1: Preparation of flexible transparent conductive oxide film.

[0026] The metal salt used in this example is tin tetrachloride pentahydrate, the salt of the doping element is antimony trichloride, the binder is polyvinylpyrrolidone (PVP), and the solvent is N,N-dimethylformamide (DMF ) and isopropanol mixture.

[0027] 1) At room temperature, mix 1.865g tin tetrachloride pentahydrate and 0.135g antimony trichloride in 7g DMF and isopropanol mixture, wherein the mass ratio of DMF and isopropanol solution is 2:1, and keep stirring . Then add 1 g of high molecular polymer PVP as a binder, and continue to stir to form a precursor with a certain viscosity for later use. Wherein, the molar ratio of antimony trichloride and tin tetrachloride pentahydrate is 1:9, and the mass ratio of the total mass of antimony trichloride and tin tetrachloride pentahydrate to the binder PVP is 2:1, and the bonding Agent PVP: The total mass ratio of solvent DMF and isopropanol is...

Embodiment 2

[0031] Embodiment 2: Preparation of flexible transparent conductive oxide film.

[0032] The metal salt used in this embodiment is tin tetrachloride pentahydrate, the salt of the doping element is cobalt chloride (hydrated), the binder is polyethylene glycol, and the solvent is secondary deionized water.

[0033] 1) At room temperature, mix 1.865g of tin tetrachloride pentahydrate and 0.061g of cobalt chloride (hydrated) in 6.8g of secondary deionized water, and keep stirring. Then add 1.2g of polyethylene glycol as a binder and continue stirring to form a precursor with a certain viscosity for later use. Among them, the molar ratio of cobalt chloride (hydrated) to tin tetrachloride pentahydrate is 1:20, and the mass ratio of the total mass of cobalt chloride (hydrated) to tin tetrachloride pentahydrate to the binder polyethylene glycol The mass ratio of the binder polyethylene glycol: solvent secondary deionized water is 1:5.7.

[0034] 2) Spray the precursor solution in st...

Embodiment 3

[0037] Embodiment 3: Preparation of flexible transparent conductive oxide film.

[0038] The metal salt used in this embodiment is zinc chloride, the salt of the doping element is aluminum trichloride, the binder is polyvinylpyrrolidone (PVP), and the solvent is ethanol and secondary deionized water.

[0039] 1) At room temperature, mix 1.363g of zinc chloride and 0.222g of aluminum trichloride in 6.83g of ethanol and secondary deionized water, wherein the mass ratio of ethanol and secondary deionized water is 1:1, and keep stirring. Then add 1.585g high molecular polymer PVP as a binder, and continue to stir to form a precursor with a certain viscosity for later use. Wherein, the molar ratio of aluminum trichloride and zinc chloride is 1:16.7, the mass ratio of aluminum trichloride and zinc chloride total mass and adhesive PVP is 1:1, adhesive PVP: solvent ethanol and The total mass ratio of secondary deionized water is 1:4.3.

[0040] 2) Spray the precursor solution in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com