Preparation method of antimony selenide monocrystal microparticles

A single crystal particle, antimony selenide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problem of difficult to grow large-sized single crystals, etc., to improve conversion efficiency, advanced optical properties, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

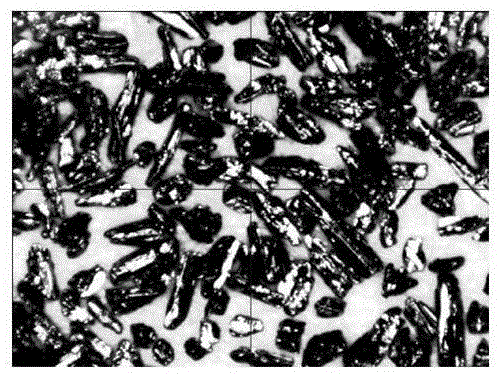

[0034] Weigh the reaction raw materials 2mmolSb, 3mmolSe and flux 10mmolCsCl, mix them to obtain the precursor, grind the precursor fully to make it evenly mixed; put the mixed sample into a quartz bottle, and use the vacuum pump unit to evacuate to 10-10 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in an ordinary heating furnace and heat it from normal temperature to 700 Keep the temperature at ℃ for 72h, then cool down to 450℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux CsCl, and then put the sample in a drying oven at 80℃ Dry for 2 hours to obtain micron-sized Sb with crystal luster on the surface 2 Se 3 Single crystal particles, about 55 micr...

Embodiment 2

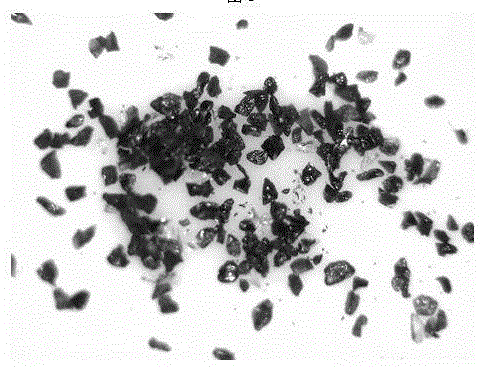

[0037] Weigh the reaction raw materials 2mmolSb, 4mmolSe and flux 30mmolCsI, mix them to obtain the precursor, grind the precursor thoroughly to make it evenly mixed; put the mixed sample into a quartz bottle, and use the vacuum pump unit to vacuum up to 10-10 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in an ordinary heating furnace and heat it from normal temperature to 650 Keep the temperature at ℃ for 96 hours, then cool down to 450℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux CsI, and then put the sample in a drying oven at 80℃ Dry for 2 hours to obtain micron-sized Sb with crystal luster on the surface 2 Se 3 Single crystal particles, abou...

Embodiment 3

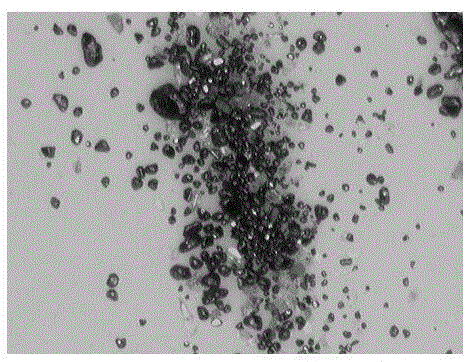

[0040] Weigh the reaction raw materials 2mmolSb, 6mmolSe and flux 64mmolKI, and mix them to obtain the precursor. Grind the precursor fully to make it evenly mixed; put the mixed sample into a quartz bottle, and use the vacuum pump unit to evacuate to 10-10 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in an ordinary heating furnace and heat it from normal temperature to 600 Keep at ℃ for 120h, then cool down to 450℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux KI, and then put the sample in a drying oven at 80℃ Dry for 2 hours to obtain micron-sized Sb with crystal luster on the surface 2 Se 3 Single crystal particles, about 50 microns.

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Band gap width | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com