A kind of copper-iron-zinc-tin-sulfur micron single crystal particle and its preparation method and its application in the preparation of solar cells

A copper-iron-zinc-tin-sulfur, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulty in growing large-sized single crystal particles, difficulty in preparation and performance optimization of high-efficiency thin-film cells, and improve utilization high efficiency, easy industrial production, and the effect of eliminating crystal plane edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

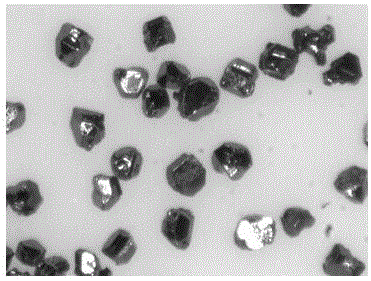

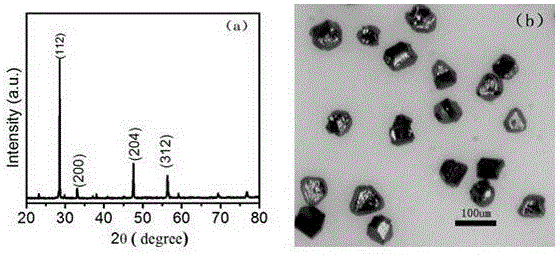

[0035] Weigh the reaction raw materials 10mmol CuS, 1.5mmol FeS, 3.5mmol ZnS, 5mmol SnS and flux 50mmol CsI, mix and grind thoroughly to make it evenly mixed; put the mixed sample into a quartz bottle, and use a vacuum pump unit to evacuate to 10~10 2Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in a common heating furnace and heat it from normal temperature to 800 Keep the temperature at ℃ for 72h, then cool down to 600℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux CsI, and then place the sample in a drying oven at 80℃ After drying for 2 hours, black particles with crystalline luster on the surface were obtained, and finally the obtained sample was s...

Embodiment 2

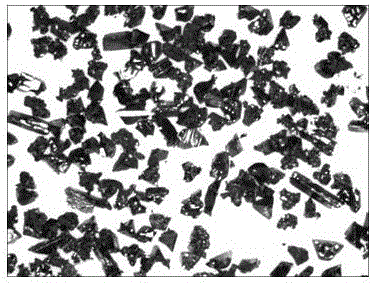

[0038] Weigh the reaction raw materials 10mmol Cu, 3.5mmol FeS, 1.5mmol Zn, 5mmol Sn, 18mmol S and flux 60mmol CsCl, mix and grind thoroughly to make it evenly mixed; put the mixed sample into a quartz bottle, and use a vacuum pump unit Vacuum up to 10~10 2 Pa (can also be protected with inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with mixed samples in a common heating furnace and heat it from normal temperature to 750 Keep at ℃ for 72 hours, then cool down to 600℃, take out the quartz bottle and quickly cool it down to room temperature (put in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux CsCl, and then put the sample in a drying oven at 80℃ After drying for 2 hours, black particles with crystalline luster on the surface were obtained, and finally the obtained sample was sieved to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com