A preparation method of micron-scale spherical copper-zinc-tin-sulfur-selenide single crystal particles

A copper-zinc-tin-sulfur-selenium, single-crystal particle technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problem of growing large-size single-crystal solar cell absorbing layer and high-efficiency thin-film battery preparation And performance optimization difficulties, CZTSSe battery performance disadvantages and other issues, to achieve the effect of easy industrial production, low price, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of Cu by hydrothermal method 2 ZnSnS 4 Nanoparticles: 2 mmol CuCl 2 2H 2 O, 1 mmol ZnCl 2 , 1mmol SnCl 4 ·5H 2 O was dissolved in 30mL deionized water and stirred for 10min to obtain clear solution A; 5 mmol thiourea was dissolved in 20ml deionized water and stirred for 10min to obtain clear solution B; solution B was slowly added to solution A under stirring to obtain white The turbid solution was stirred for 10 min to obtain a mixed solution, and the mixed solution was transferred into a 100ml polytetrafluoroethylene autoclave and placed in the autoclave at 180°C for 16 hours, then cooled to room temperature and deionized water and absolute ethanol were used at 8000r / min. Centrifuge and dry at 60°C for 8 hours to obtain a black sample, that is, CZTS nanoparticles.

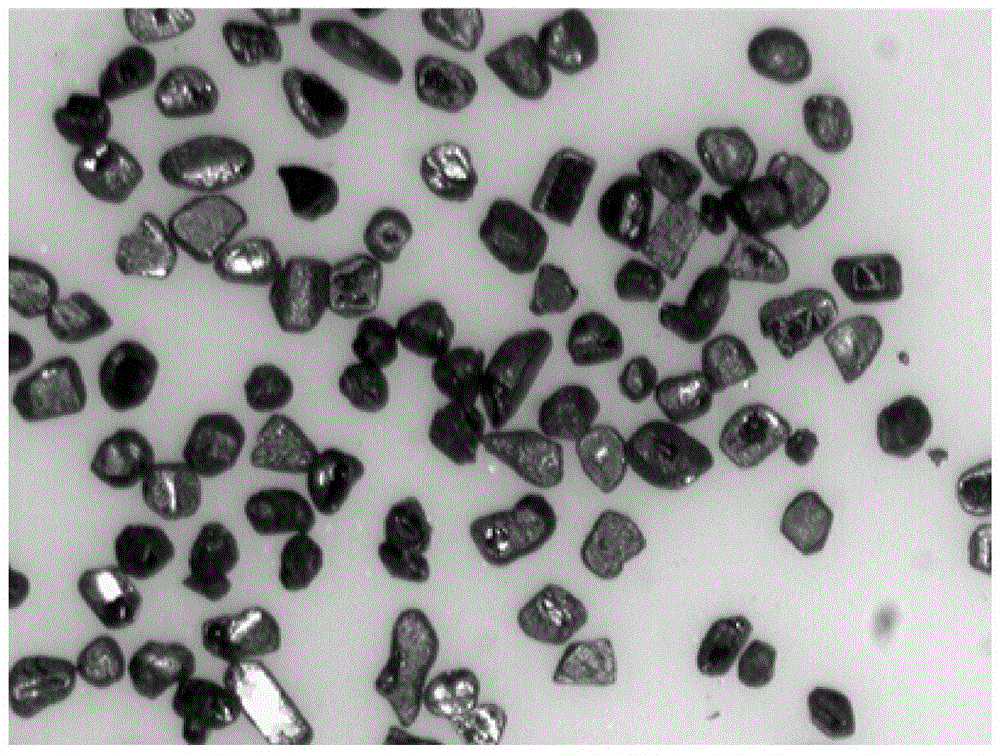

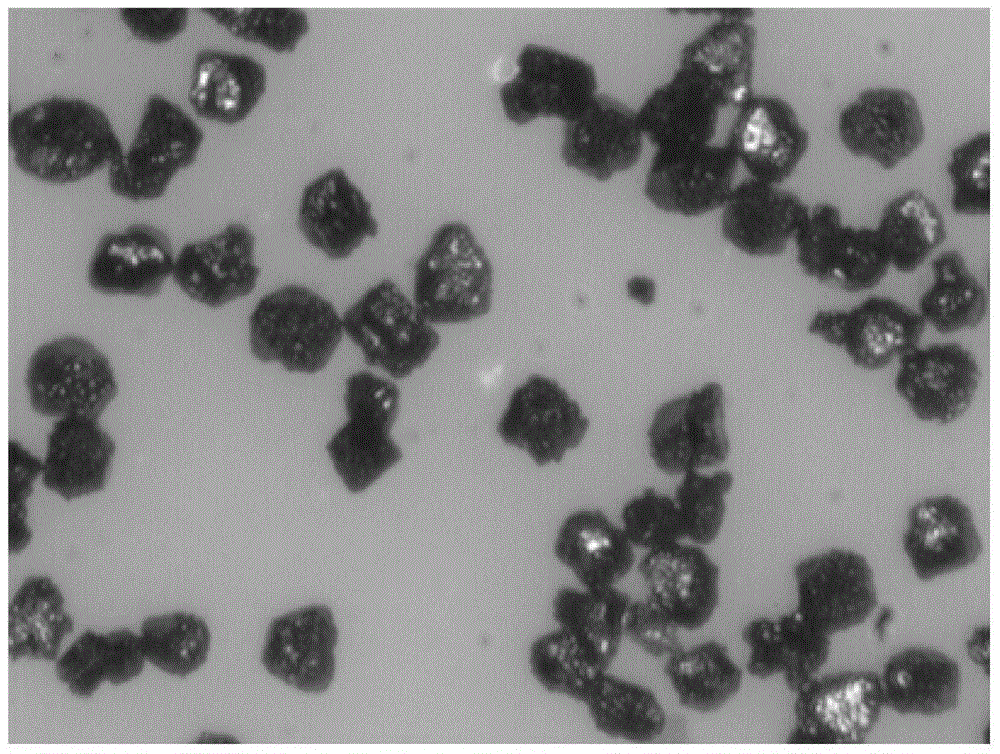

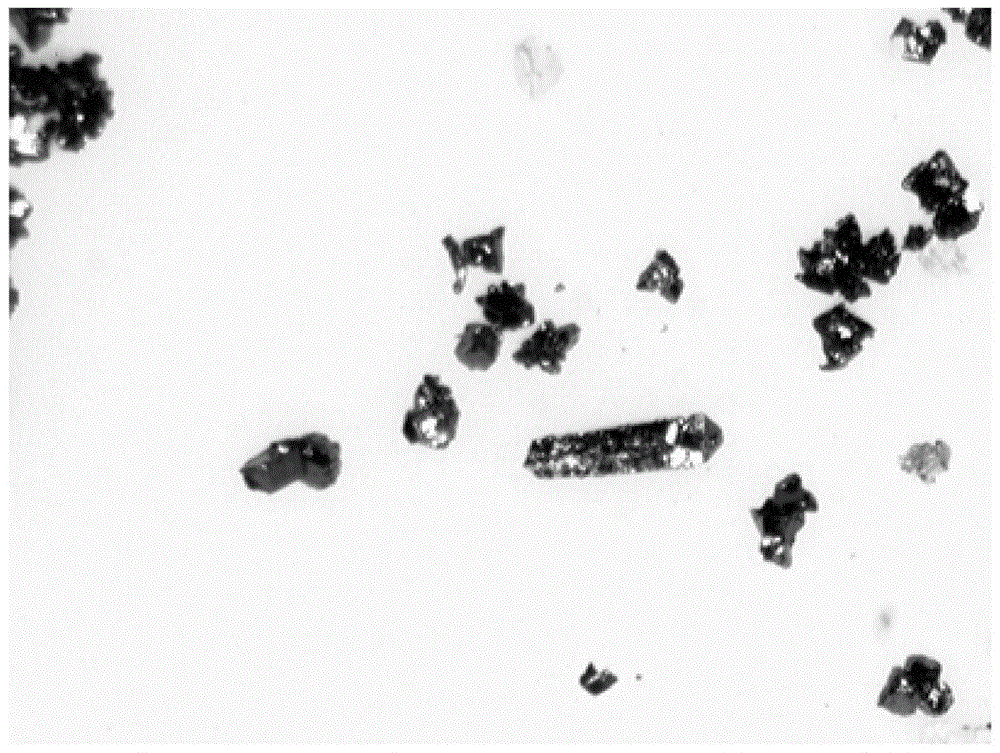

[0044] (2) Preparation of copper zinc tin sulfur selenium single crystal particles by molten salt method: Weigh 18 mmol CuS, 12 mmol ZnS, 10 mmol SnS, 10 mmol Se, 30 mmol CsCl and 20 ...

Embodiment 2

[0046] Weigh 18 mmol CuS, 12 mmol ZnS, 10 mmol Sn, 6 mmol S, 4 mmol Se, 50 mmol CsCl, and add 1 mmol CZTS nanoparticles prepared in step (1) of Example 1, mix and grind thoroughly to make it evenly mixed ;Put the uniformly ground mixed sample into a quartz bottle, and use a vacuum pump unit to evacuate to 10-10 through a three-way valve. 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in an ordinary heating furnace from normal temperature to 800 Keep at ℃ for 48 hours, then cool down to about 600℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); take the sample out of the quartz bottle, remove the flux CsCl after several times of ultrasonic washing, and place the sample in a drying oven at 80℃ After drying for 2 h, particles with crystal luster on the surface were o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com