Method for preparing lead selenide nanocrystals

A nanocrystal and nanocrystal particle technology is applied in the fields of solvent synthesis chemistry and nano-semiconductor material preparation technology, which can solve the problems of expensive solvent, cumbersome operation process, serious environmental pollution, etc., and achieves low price, simple preparation process, and solvent simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

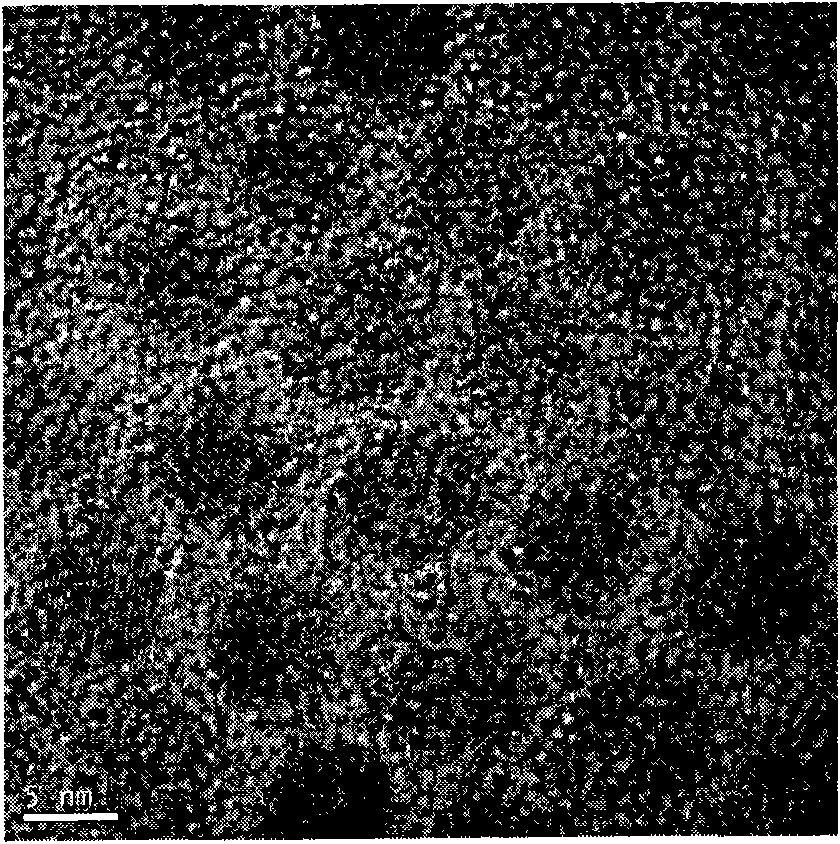

Embodiment 1

[0032] The specific preparation steps of this embodiment are as follows:

[0033] a. First, get 80 mg of selenium powder and put it into a two-necked flask with cooling conditions outside it, drive out the air in the flask, and fill it with argon.

[0034] b. Inject 5 milliliters of oleylamine with a syringe and stir with a magnet.

[0035] c. Heat the above-mentioned selenium powder mixed solution to 220°C with an oil bath, the mixed solution slowly changes from a black suspension to a transparent light orange liquid, and keep at 220°C for more than half an hour.

[0036] d, secondly, get 556 milligrams of lead chloride and put it into a 50 milliliter two-necked flask with condensed water, inject 5 milliliters of oleylamine with a syringe, stir with a magnet, and vacuumize for half an hour.

[0037] e. After heating the above-mentioned lead chloride mixed solution to 160°C with an oil bath, continue to heat up to 220°C after passing in argon gas, the solution becomes a white...

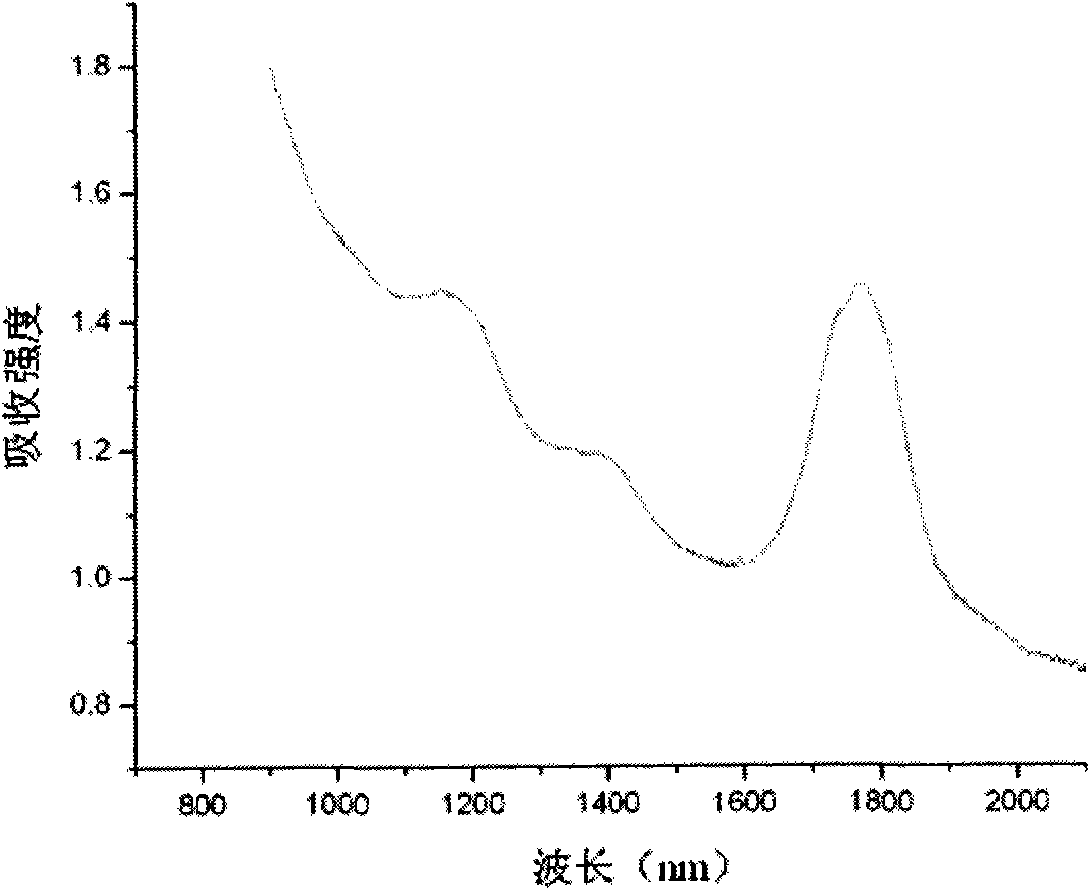

Embodiment 2

[0043] The specific preparation steps of this embodiment are as follows:

[0044] a. First, get 80 mg of selenium powder and put it into a two-necked flask with cooling conditions outside it, drive out the air in the flask, and fill it with argon.

[0045] b. Inject 5 milliliters of oleylamine with a syringe and stir with a magnet.

[0046] c. Heat the above-mentioned selenium powder mixed solution to 220°C with an oil bath, the mixed solution slowly changes from a black suspension to a transparent light orange liquid, and keep at 220°C for more than half an hour.

[0047] d, secondly, get 556 milligrams of lead chloride and put it into a 50 milliliter two-necked flask with condensed water, inject 5 milliliters of oleylamine with a syringe, stir with a magnet, and vacuumize for half an hour.

[0048] e. After heating the above-mentioned lead chloride mixed solution to 160°C with an oil bath, continue to heat up to 220°C after passing in argon gas, the solution becomes a white...

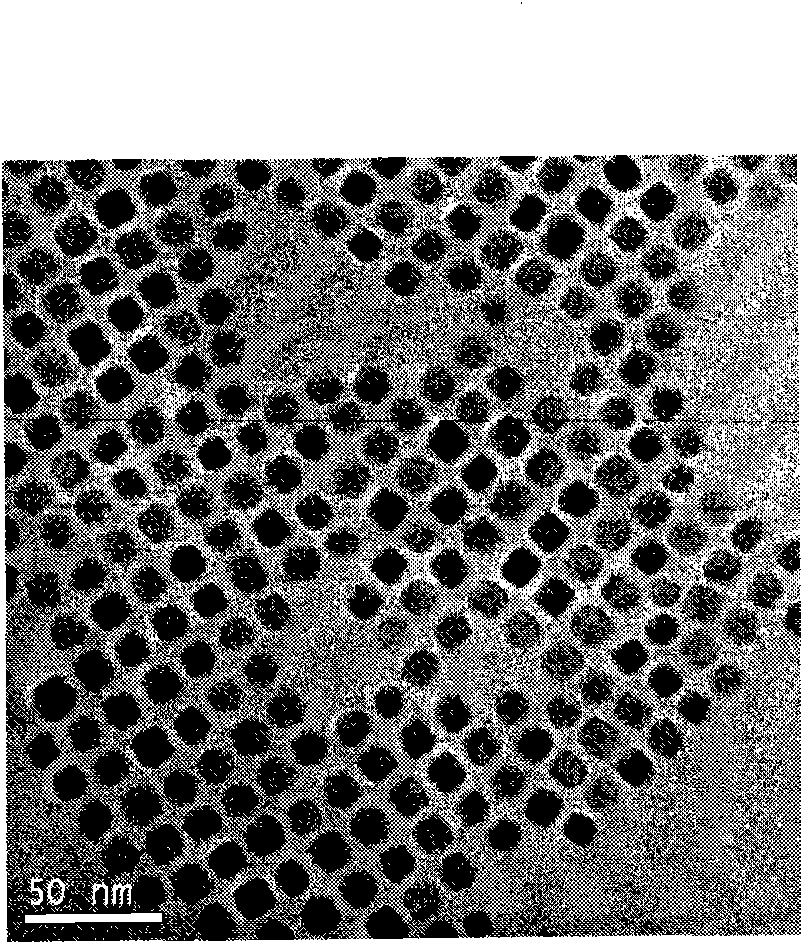

Embodiment 3

[0054] The specific preparation steps of this embodiment are as follows:

[0055] a. First, get 80 mg of selenium powder and put it into a two-necked flask with cooling conditions outside it, drive out the air in the flask, and fill it with argon.

[0056] b. Inject 5 milliliters of oleylamine with a syringe and stir with a magnet.

[0057] c. Heat the above-mentioned selenium powder mixed solution to 220°C with an oil bath, the mixed solution slowly changes from a black suspension to a transparent light orange liquid, and keep at 220°C for more than half an hour.

[0058] d, secondly, get 556 milligrams of lead chloride and put it into a 50 milliliter two-necked flask with condensed water, inject 5 milliliters of oleylamine with a syringe, stir with a magnet, and vacuumize for half an hour.

[0059] e. After heating the above-mentioned lead chloride mixed solution to 160°C with an oil bath, continue to heat up to 220°C after passing through argon, and the solution becomes a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com