Ultrasonic welding method of Al/Ti dissimilar metal TIG (Tungsten Inert Gas) electrical arc micro-melting brazing and following welding

A dissimilar metal, ultrasonic welding technology, applied in the field of Al/Ti dissimilar metal TIG arc micro-melting brazing with welding ultrasonic welding, can solve the problems of difficult welding, metal brittle fracture, etc., to suppress shrinkage, achieve isochronous and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

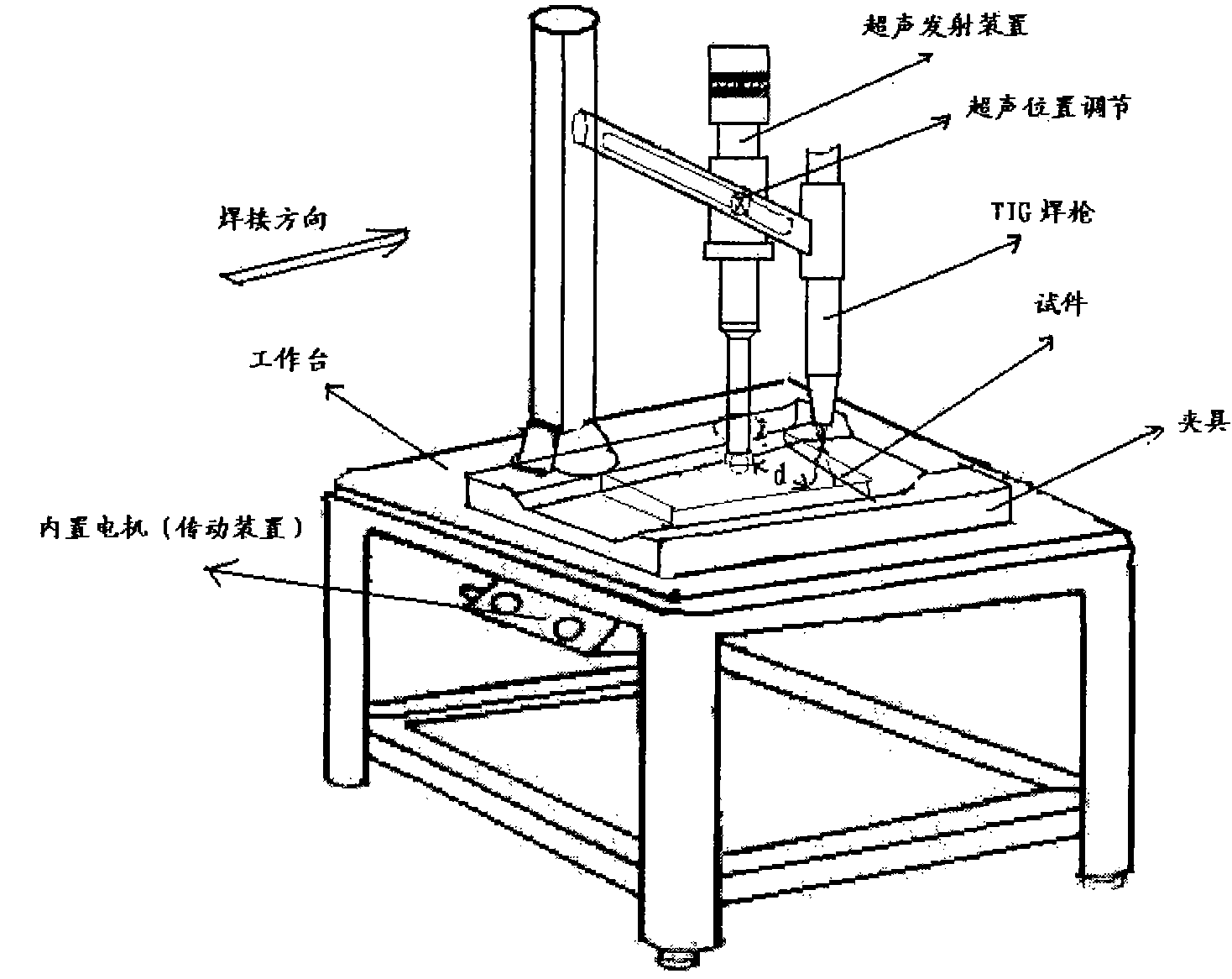

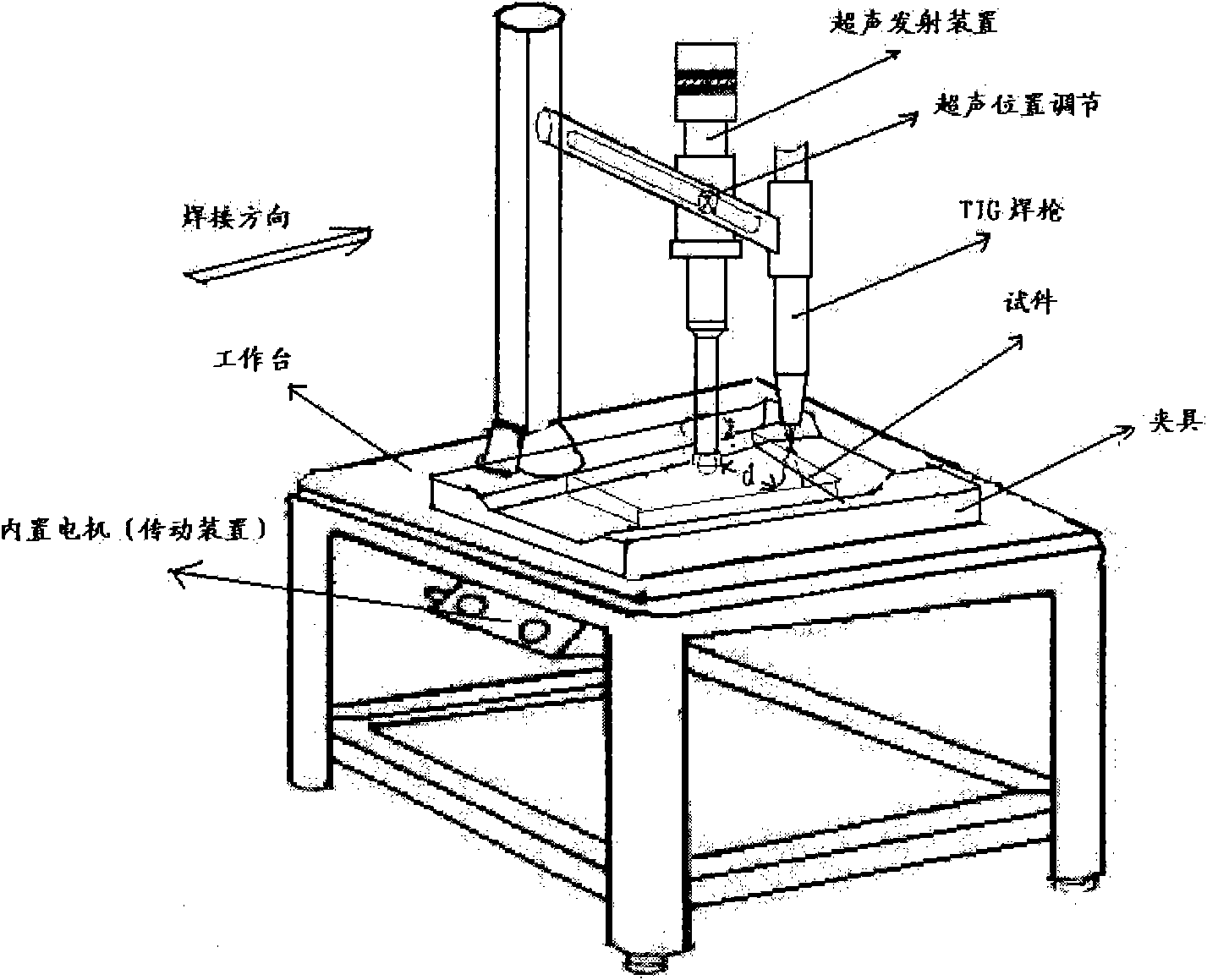

[0017] Example 1: Combining figure 1 , figure 2 , a kind of Al / Ti dissimilar metal TIG electric arc micro-melting brazing with welding ultrasonic welding method, the steps are as follows:

[0018] Step 1: The aluminum plate and the titanium plate are connected in a V-shaped notch, clamped on the workbench by a clamp, and cleaned on the surface;

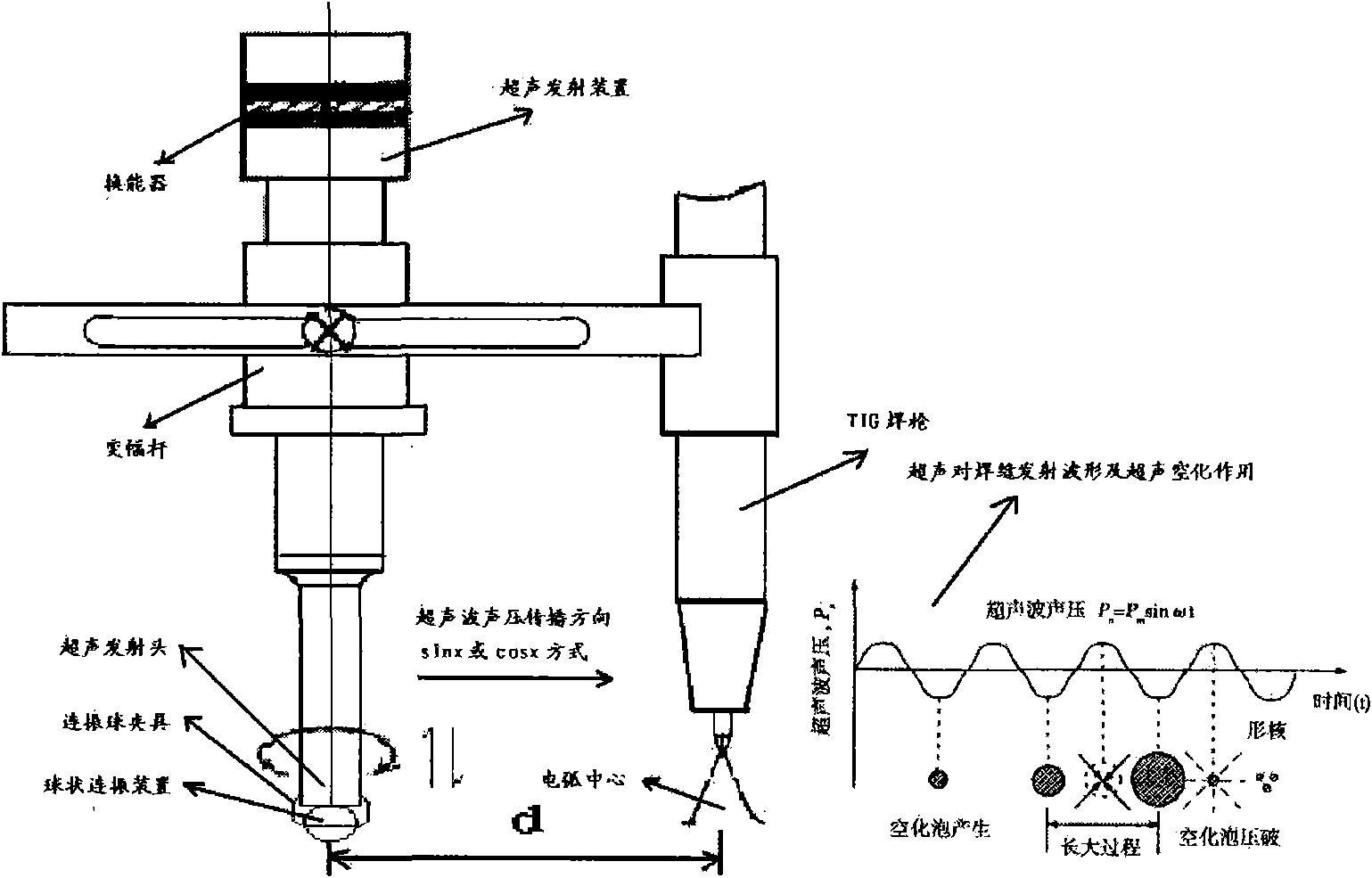

[0019] Step 2: By adjusting the position of the welding torch up and down to make the tungsten electrode of the welding torch and the test piece reach a reasonable welding height; adjust the ultrasonic emitting device up and down so that the vibrating ball is close to the surface of the test piece, the ultrasonic emitting device and the TIG welding torch always maintain a fixed position, and the ultrasonic vibration The distance between the action position and the center of the weld is always the same;

[0020] Step 3: By adjusting the ultrasonic generator left and right, measure the distance d from the contact point between the vi...

Embodiment 2

[0022] Embodiment 2: The present invention is based on solving the problems of intermetallic compounds and shrinkage cavities in the connection and welding process of aluminum / titanium dissimilar materials, how to add ultrasound and how to realize the isochronism and stability of welding ultrasonic and TIG micro-melting brazing It is a difficult problem in TIG micro-melting brazing with welding ultrasonic vibration. We invented an efficient welding-with-welding ultrasonic-assisted loading method to solve the problems in the aluminum / titanium-with-welding ultrasonic welding process. Firstly, a spherical continuous vibration device is designed to solve the isochronism and stability of welding ultrasonic and TIG welding torches. Secondly, the coaxial movement of the welding ultrasonic and the TIG welding torch in the same direction makes the introduction of welding ultrasonic vibration into Al / Ti dissimilar metal TIG arc micro-melting brazing a reality. Thirdly, a set of semi-au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com