Composite material for making degradable ureteral stent and application thereof

A ureteral stent tube and composite material technology are applied in the field of degradable ureteral stent tube composite materials, which can solve the problems of large friction between the ureteral stent and the ureteral wall, slow degradation of composite materials, and excessive degradation time, and achieve excellent physiological inertia and Biocompatibility, wet friction reduction, effect of increasing degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

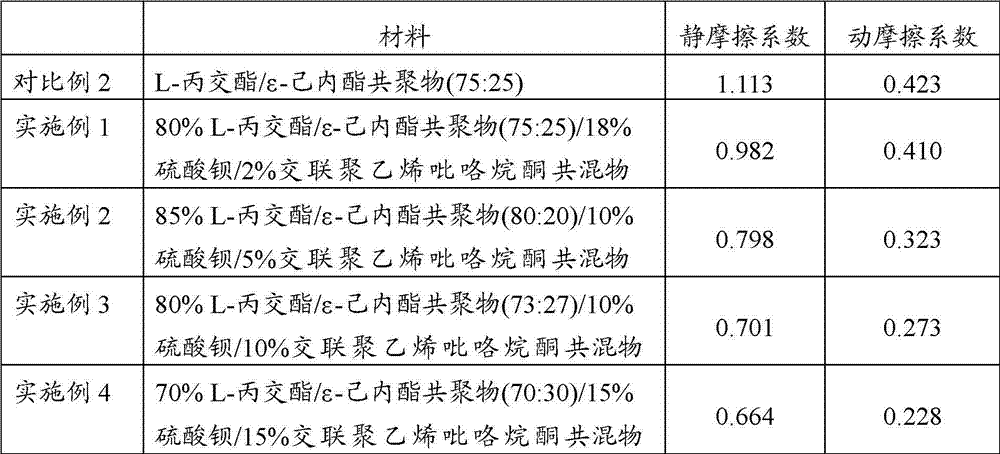

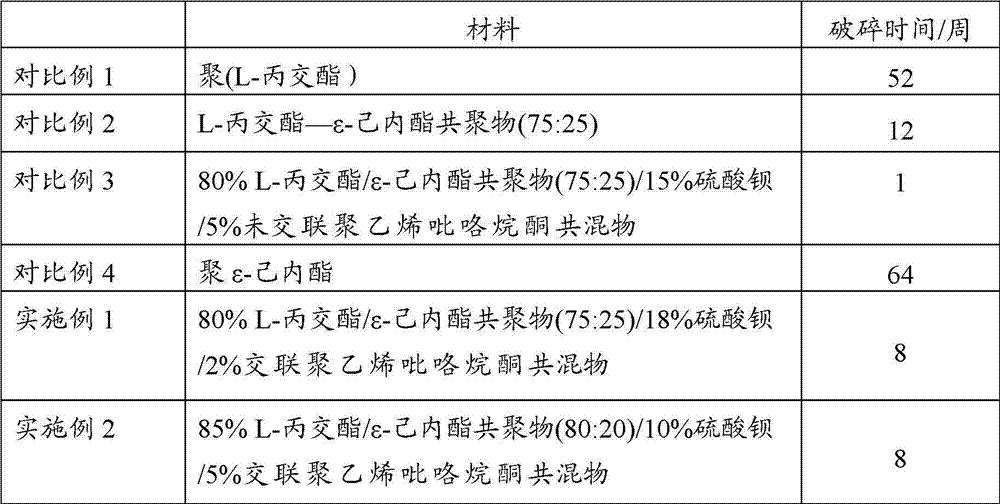

Examples

Embodiment 1

[0027] Put 180 grams of ε-caprolactone monomer and 320 grams of L-lactide that have been dehydrated and purified into a 2500ml reaction bottle, then add 0.01% stannous octoate catalyst, and react under vacuum at 150°C for 8 hours , to obtain an elastic copolymer, the copolymer was dissolved in acetone, precipitated with ethanol, and the precipitate was dried in a vacuum dryer for 48 hours to obtain the L-lactide / ε-caprolactone copolymer elastomer composite material. The molecular weight of the product is measured by gel permeation chromatography (GPC) and the weight average molecular weight is 380,000. Through nuclear magnetic 1H spectrum measurement, the mol ratio of L-lactide and ε-caprolactone structural unit in this polymer is 75: 25 , The glass transition temperature (Tg) of the L-lactide / ε-caprolactone copolymer measured by differential scanning calorimetry was 0.67°C.

[0028] 10 grams of cross-linked polyvinylpyrrolidone (particle size 5 ~ 50 μm, commercial brand: Poly...

Embodiment 2

[0030]150 grams of ε-caprolactone monomer and 350 grams of L-lactide treated by dehydration and purification are placed in a 2500ml reaction bottle, and then 0.01% stannous octoate catalyst is added, and reacted under vacuum conditions at 150°C for 6 hours to obtain Elastic copolymer, the copolymer is dissolved in acetone, precipitated with ethanol, and the precipitate is dried in a vacuum dryer for 48 hours to obtain the L-lactide / ε-caprolactone copolymer elastomer composite material. The molecular weight of the product is measured by gel permeation chromatography (GPC) and the weight average molecular weight is 455,000. Measured by nuclear magnetic 1H spectrum, the mol ratio of L-lactide and ε-caprolactone structural unit in the polymer is 80:20 , The glass transition temperature (Tg) of the L-lactide / ε-caprolactone copolymer measured by differential scanning calorimetry was 7°C. Using a melt blending method, using a twin-screw extruder, under the condition of 155 ° C, prepa...

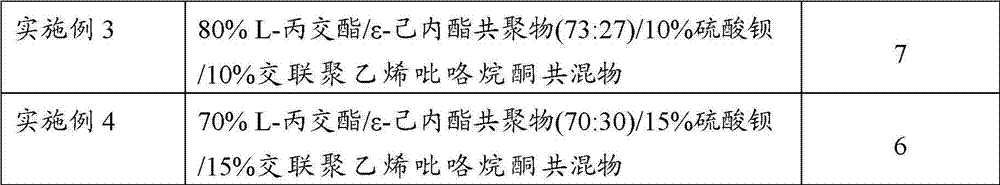

Embodiment 3

[0033] 200 grams of ε-caprolactone monomer and 350 grams of L-lactide that were dehydrated and purified were placed in a 2500ml reaction bottle, and then 0.01% stannous octoate catalyst was added, and reacted at 150°C for 8 hours under vacuum conditions to obtain Elastic copolymer, the copolymer is dissolved in acetone, precipitated with ethanol, and the precipitate is dried in a vacuum dryer for 48 hours to obtain the L-lactide / E-caprolactone copolymer elastomer composite material. The molecular weight of product is measured by gel permeation chromatography (GPC) and is 330,000 average molecular weights, and through nuclear magnetic 1H spectrum measurement, the mol ratio of L-lactide and ε-caprolactone structural unit in this polymer is 73: 27 , The glass transition temperature (Tg) of the L-lactide / E-caprolactone copolymer measured by differential scanning calorimetry was -1°C. With the solution blending method, with reference to the steps of Example 1, prepare L-lactide / ε-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com