Patents

Literature

690 results about "Polyvinylpolypyrrolidone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

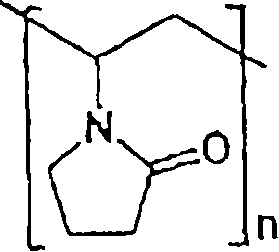

Polyvinylpolypyrrolidone (polyvinyl polypyrrolidone, PVPP, crospovidone, crospolividone or E1202) is a highly cross-linked modification of polyvinylpyrrolidone (PVP). The cross-linked form of PVP is used as a disintegrant (see also excipients) in pharmaceutical tablets. PVPP is a highly cross-linked version of PVP, making it insoluble in water, though it still absorbs water and swells very rapidly generating a swelling force. This property makes it useful as a disintegrant in tablets.

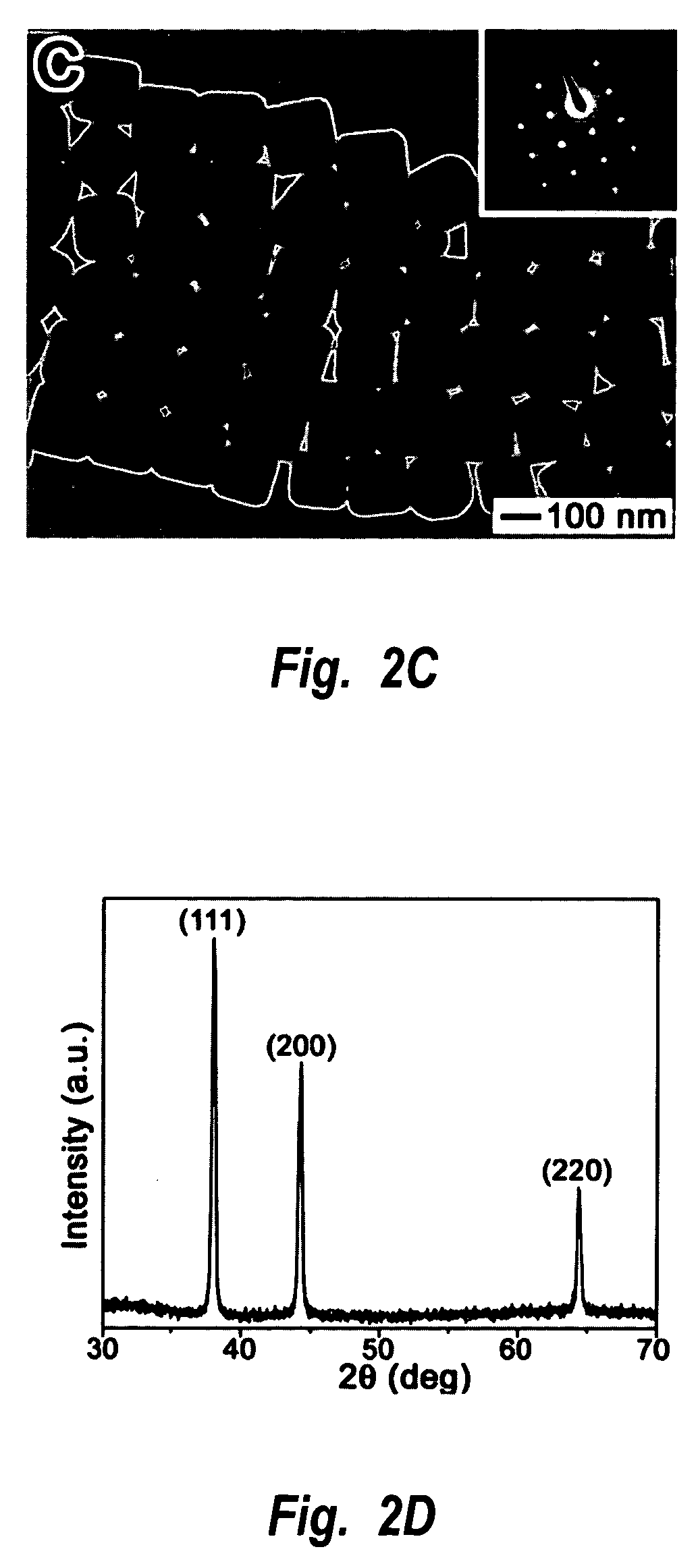

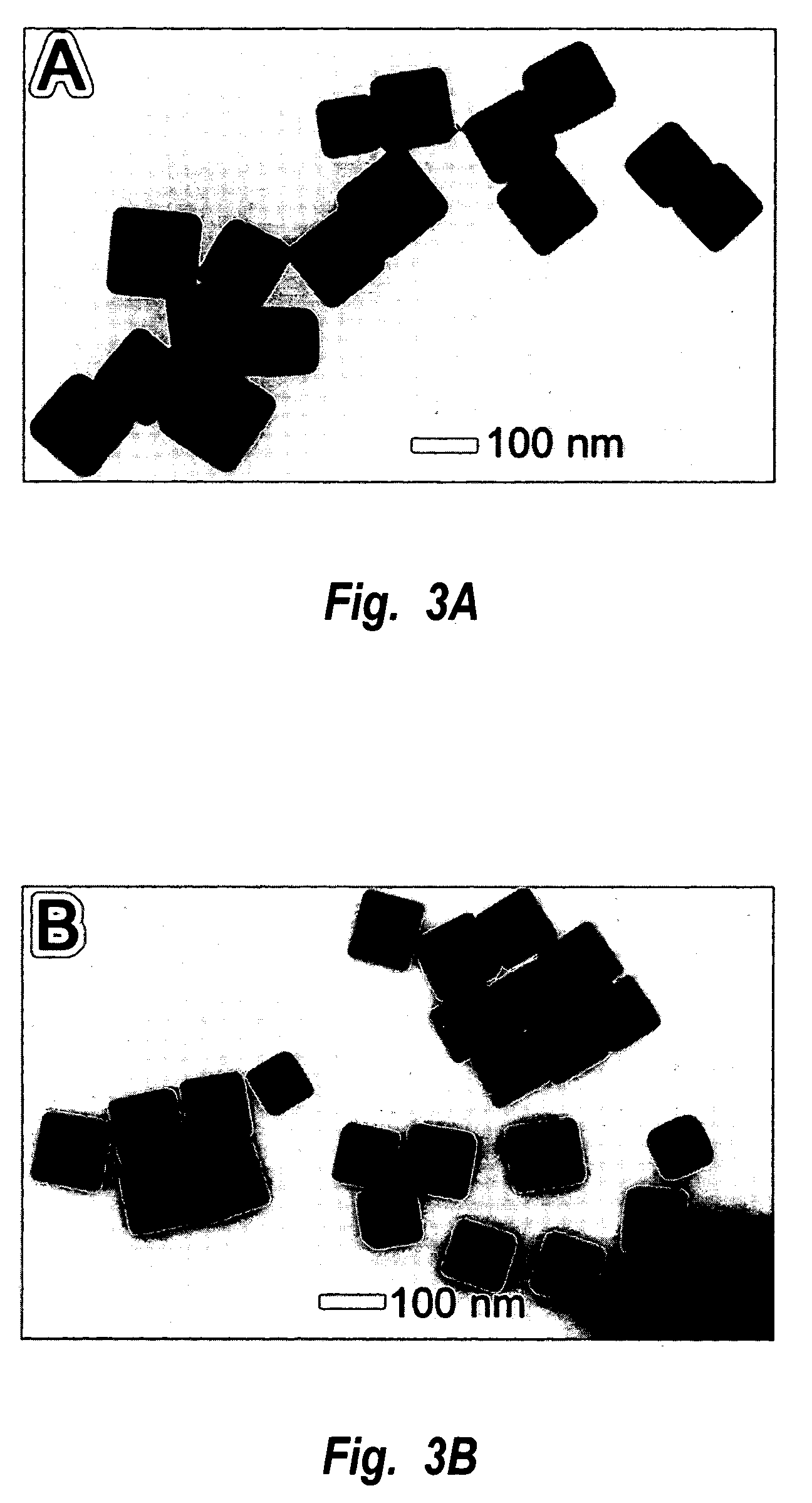

Methods of nanostructure formation and shape selection

Methods for forming nanostructures of various shapes are disclosed. Nanocubes, nanowires, nanopyramids and multiply twinned particles of silver may by formed by combining a solution of silver nitrate in ethylene glycol with a solution of poly(vinyl pyrrolidone) in ethylene glycol. Hollow nanostructures may be formed by reacting a solution of solid nanostructures comprising one of a first metal and a first metal alloy with a metal salt that can be reduced by the first metal or first metal alloy. Nanostructures comprising a core with at least one nanoshell may be formed by plating a nanostructure and reacting the plating with a metal salt.

Owner:UNIV OF WASHINGTON

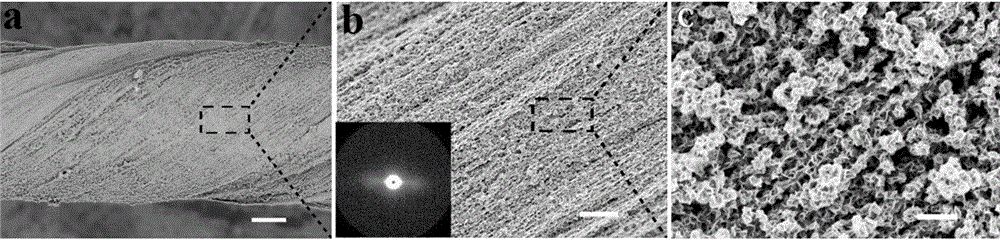

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

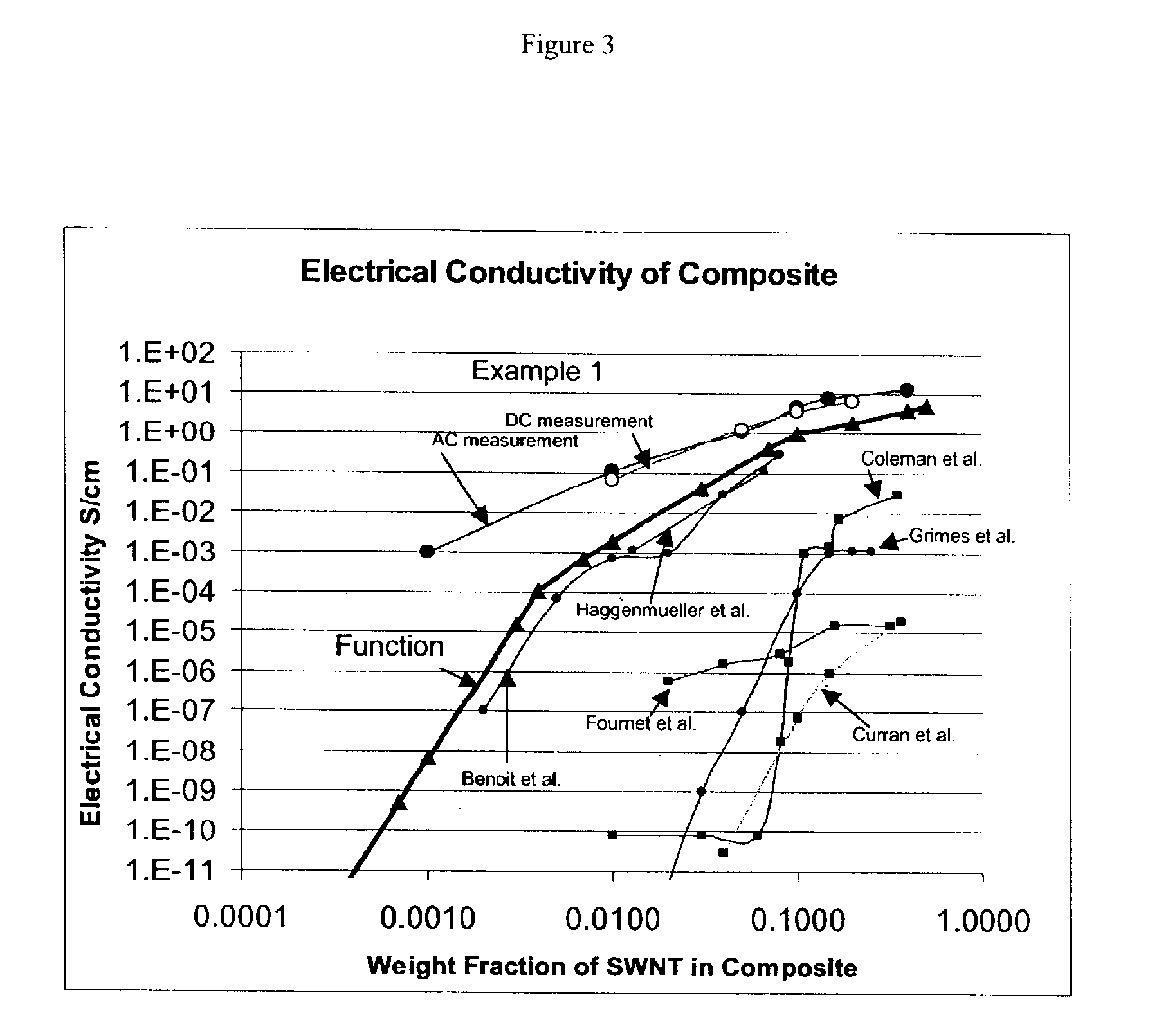

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Oral formulation for delivery of poorly absorbed drugs

InactiveUS20060088592A1Promote absorptionReduce inactivationHeavy metal active ingredientsMultiple-port networksSucrosePolyvinyl alcohol

A composition for oral delivery of a poorly absorbed drug is disclosed. The composition includes the drug, an enhancer for increasing absorption of the drug through the intestinal mucosa, a promoter, which alone does not increase absorption of the drug through the intestinal mucosa, but which further increases the absorption of the drug in the presence of the enhancer, and optionally a protector for protecting the drug from physical or chemical decomposition or inactivation in the gastrointestinal tract. Illustrative enhancers include sucrose fatty acid esters, and illustrative promoters include aminosugars and amino acid derivatives, such as poly(amino acids). Illustrative protectors include methylcellulose, poly(vinyl alcohol), and poly(vinyl pyrrolidone).

Owner:PROCARRIER

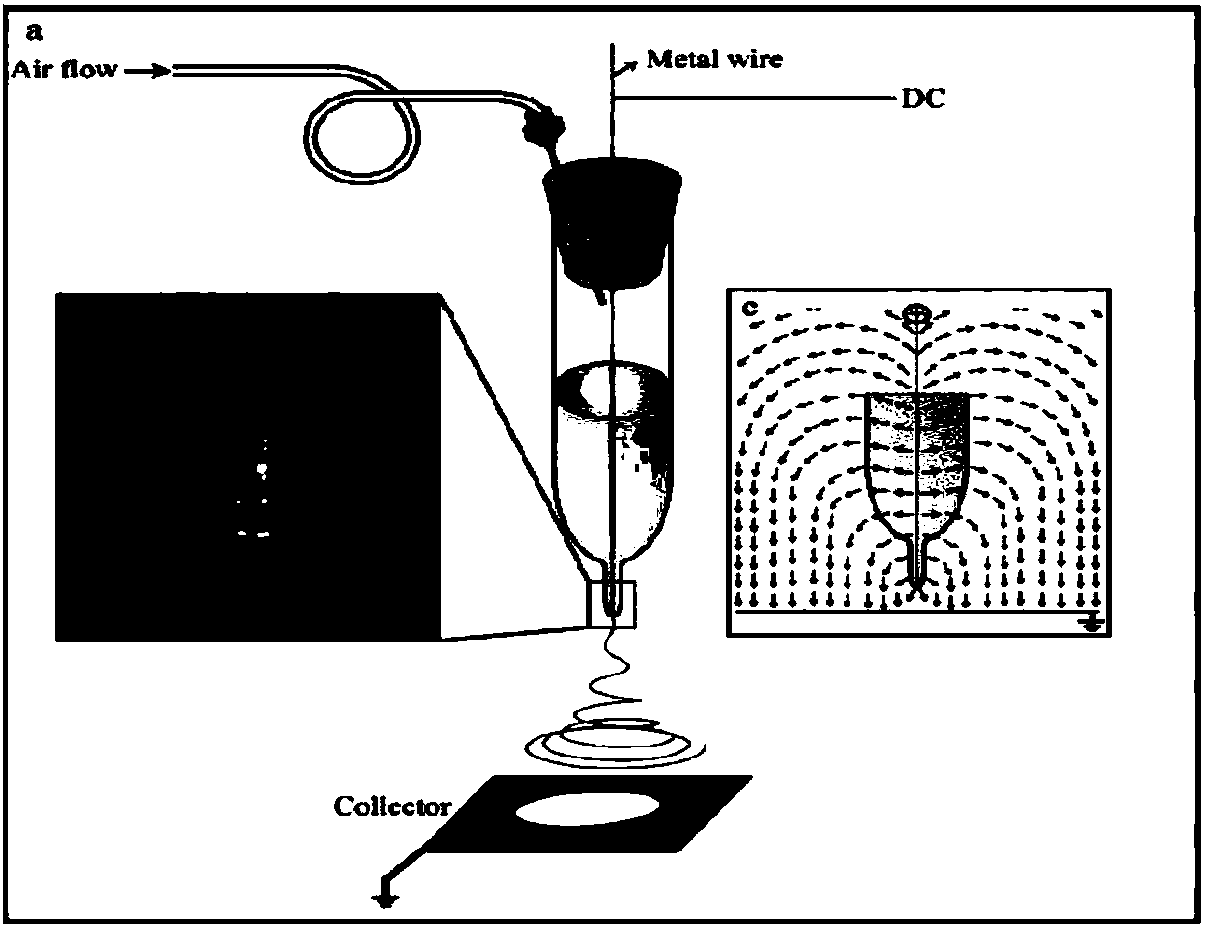

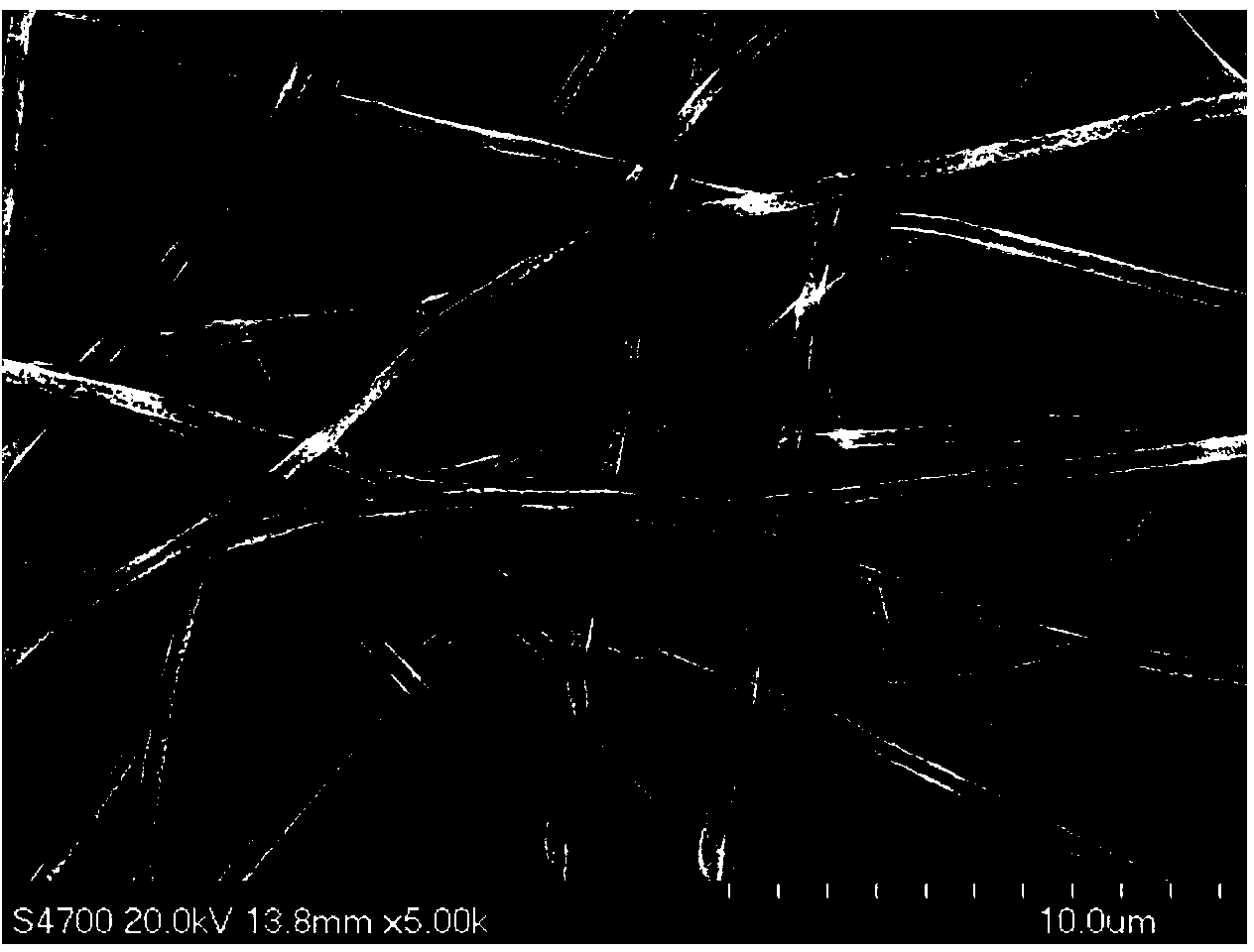

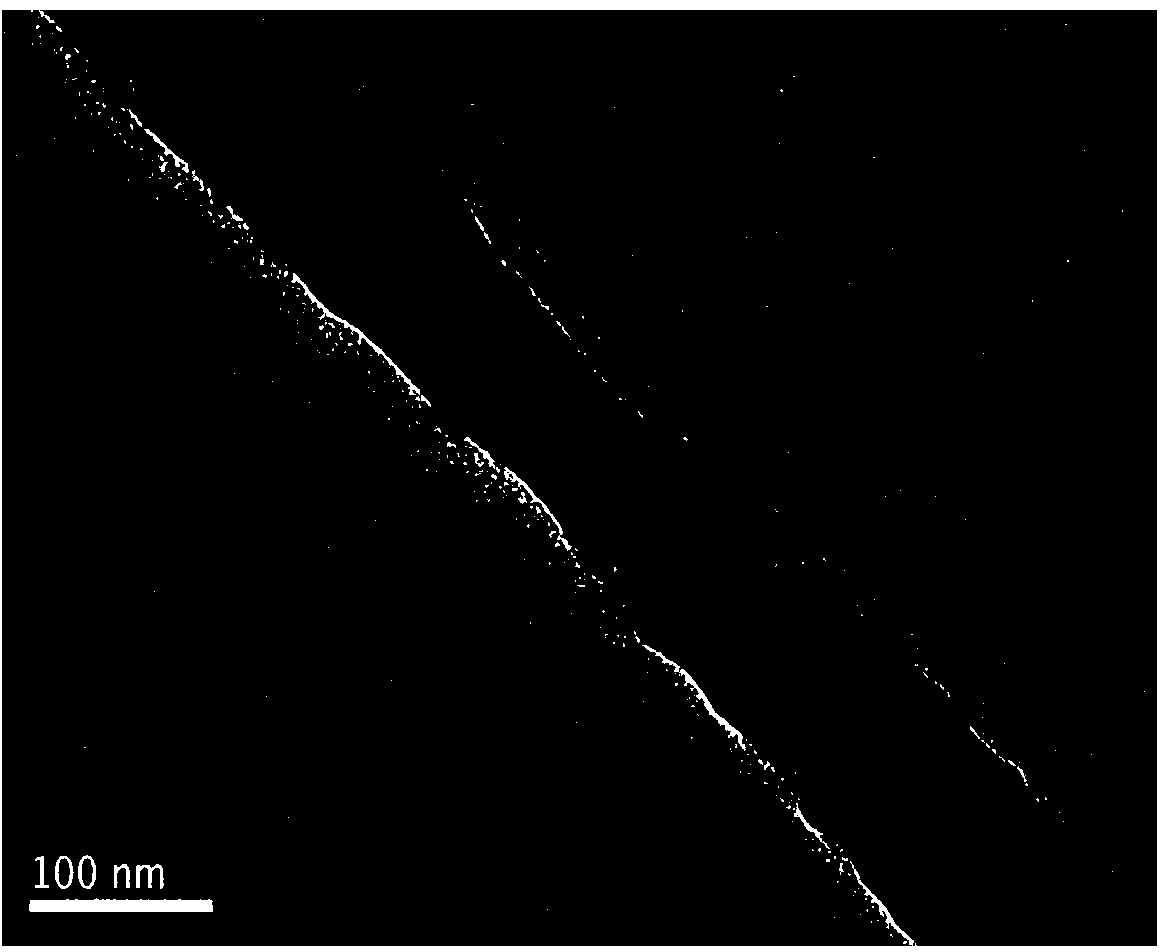

Core-shell structure metal/polymer nanofiber and preparation method thereof

InactiveCN103643347ASmall diameterEasy to form core-shell structureFilament/thread formingConjugated synthetic polymer artificial filamentsPolyvinyl alcoholSolvent

The invention relates to a method for preparing a core-shell structure metal / polymer nanofiber membrane. The prepared fiber membrane uses a polymer as a nuclear layer and uses a nano-metal as a shell layer; the polymer can be polyvinyl pyrrolidone, polyvinyl alcohol, polyoxyethylene, polylactic acid, polyacrylonitrile, hyaluronic acid, chitosan and the like; the nano-metal shell layer comes from metal salt silver nitrate or copper chloride. The core-shell structure metal / polymer nanofiber is prepared by utilizing the electrospinning technique; by controlling the process parameters, the concentration of polymer, the content of metal salt and the proportioning of solvents, the metal / polymer nanofiber membrane is prepared; the fiber membrane has high application value on tissue engineering, recovery of wound, drug transportation, photoelectricity and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

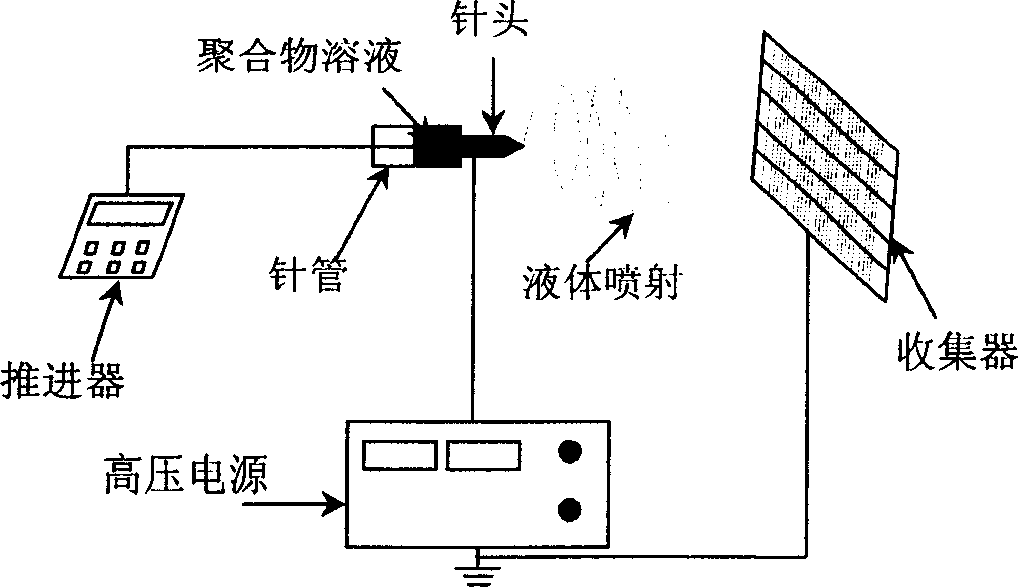

Preparing low density porous tin dioxide nano fiber laser target material by electro-static spinning method

InactiveCN1858308AHigh porosityChemical composition is easy to controlInorganic material artificial filamentsFilament/thread formingTin dioxideVolumetric Mass Density

The electrostatic spinning process for preparing low density porous nanometer SnO2 fiber as laser target material is fast, efficient and simple. The electrostatic spinning process includes compound spinning solution with polyvinyl pyrrolidone, absolute ethyl alcohol, tin tetrachloride in certain weight proportion through mixing at room temperature; electrostatic spinning through spraying the spinning solution with spinning jet to an accepting screen 5-30 cm apart from the jet while applying electric field of 0.1-1 kv / cm, controlling the spraying time and the motion of the accepting screen to obtain fiber of different density and deposited in different areas; and roasting at 450-550 deg.c to obtain the nanometer SnO2 fiber.

Owner:SOUTHEAST UNIV

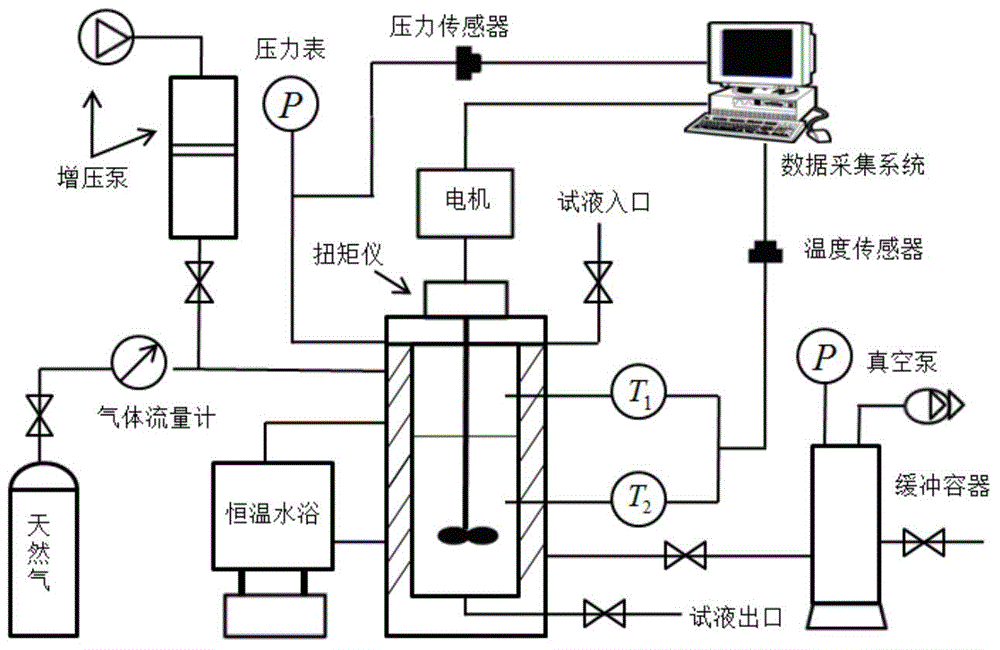

Compound low dosage natural gas hydrate inhibitor

The invention discloses a compound low dosage natural gas hydrate inhibitor. The hydrate inhibitor benchmarked against the mass of water in a deepwater drilling fluid completion fluid comprises, by mass, 0.1-2% of a hydrate kinetic inhibitor, 0.1-2% of a kinetic inhibitor synergist and 0-10% of a hydrate thermodynamic inhibitor. The hydrate kinetic inhibitor is at least one of polyvinyl pyrrolidone, polyvinyl caprolactam, and a copolymer generated through a reaction of vinyl pyrrolidone, vinyl caprolactam, alkenyl sulfonic acid and isopropylmethacrylamide. The kinetic inhibitor synergist is at least one of benzyltributylammonium chloride, tetraheptylammonium bromide, ethylene glycol phenyl ether, propylene glycol phenyl ether, polyoxyethylene and polyoxypropylene. The hydrate inhibitor can effectively inhibit generation of hydrates under a low dosage (0.2-10%), is suitable for deepwater and ultra-deep water drilling and completion, greatly reduces the cost and the logistical support burden, and has small harms to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

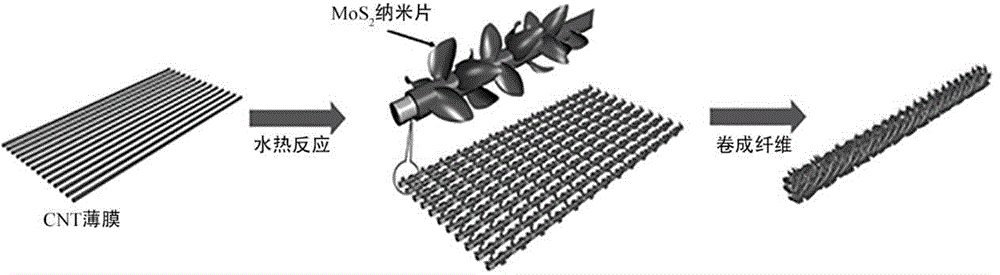

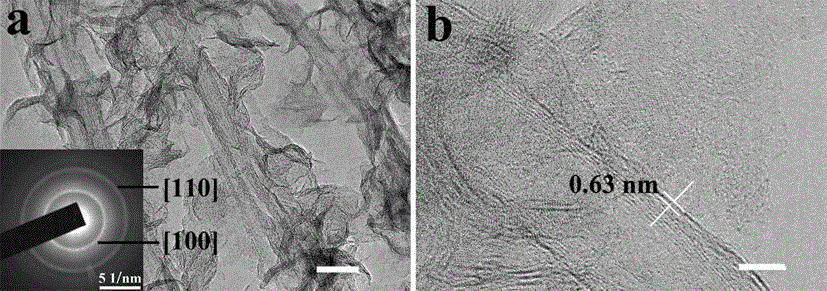

Aligned carbon nano tube/molybdenum disulfide composite fiber and preparation method and application thereof

InactiveCN105047927AImprove conductivityImprove electrochemical performanceHybrid capacitor electrodesCell electrodesFiberSpinning

The invention belongs to the technical field of an energy storage device, in particular relates to an aligned carbon nano tube / molybdenum disulfide composite fiber and a preparation method and application thereof. The preparation method comprises the following steps of: firstly, obtaining an aligned carbon nano tube thin film from a spinnable carbon nano tube (CNT) array by dry spinning; and secondly, immersing the CNT thin film in a precursor liquid in which (NH4)2MoS4 is taken as a precursor and polyvinyl pyrrolidone is taken as a surfactant for hydrothermal reaction to obtain a CNT / MoS2 composite thin film, and winding the thin film into the composite fiber. The aligned CNT / molybdenum disulfide composite fiber has excellent mechanical performance and electrochemical performance; a flexible fibrous supercapacitor and a lithium ion battery which are prepared from the composite fiber both show higher specific capacity than those of the traditional planar / fibrous device; and meanwhile, the two fibrous energy storage devices have favorable flexibility and stitchability, can be easily woven into fabrics, and show good application prospects in next-generation wearable and portable devices.

Owner:FUDAN UNIV

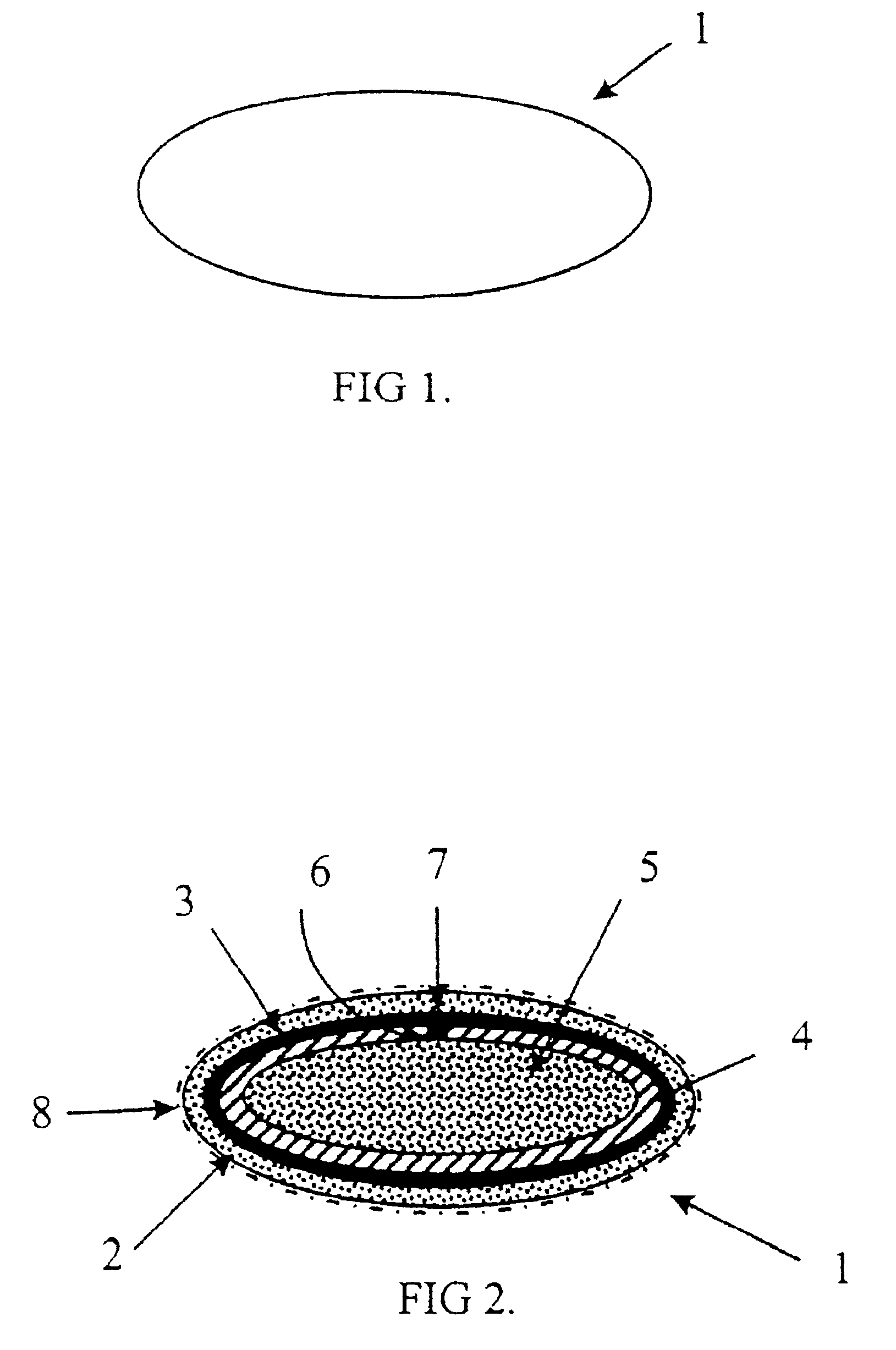

Multi-layered osmotic device

The present invention provides a simple and improved multi-layered osmotic device (1) that is capable of delivering a first active agent in an outer lamina (2) to one environment of use and a second active agent in the core (5) to another environment of use. Particular embodiments of the invention provide osmotic devices in which the first and second active agents are similar or dissimilar. An erodible polymer coat (3) between an internal semipermeable membrane (4) and a second active agent-containing external coat (2) comprises poly(vinylpyrrolidone)-(vinyl acetate) copolymer. This particular erodible polymer results in an improved multi-layered osmotic device possessing advantages over related devices known in the art. The active agent in the core (5) is delivered through a pore (6) containing an erodible plug (7). The osmotic device (1) can be coated by a final finish coat (8).

Owner:OSMOTICA KERESKEDELMI & SZOLGALTATO

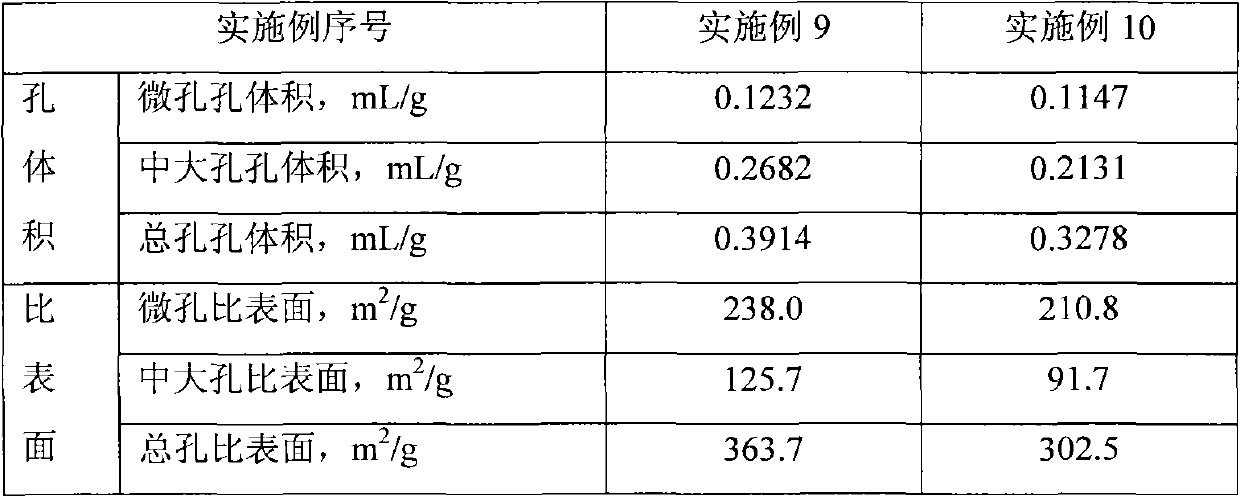

Method for improving pore structure of kaolin microsphere in-situ crystallization product

ActiveCN102019196AHigh molecular weightRegular structureMolecular sieve catalystsCatalyst activation/preparationPolyvinyl alcoholMicrosphere

The invention relates to a method for improving the pore structure of a kaolin microsphere in-situ crystallization product. The method comprises the following steps of: preparing kaolin spray microspheres with the particle sizes of between 20 and 110 mu m by using mixed kaolin grout by spray drying, wherein the mixed grout comprises kaolin, deionized water, a dispersant and an organic pore cannelforming template agent; the dispersant is sodium silicate or sodium pyrophosphate; and the organic pore cannel forming template agent is polyvinyl pyrrolidone or polyvinyl alcohol; baking the spray microspheres at the temperature of between 900 and 1,100 DEG C for 1 to 3 hours so as to obtain kaolin baked microspheres; mixing the kaolin baked microspheres with the mullite content of between 2 and12 percent, sodium silicate, a directing agent, solution of sodium hydroxide and deionized water; crystalizing the mixture at the temperature of between 90 and 95 DEG C for 16 to 36 hours; and filtering and drying so as to obtain a crystallization product which has a medium / large-pore structure and comprises a NaY molecular sieve. The crystallization product has a well-developed large-pore structure and the abrasion index of not more than 1.5 percent and comprises 20 to 50 percent of NaY molecular sieve.

Owner:PETROCHINA CO LTD +1

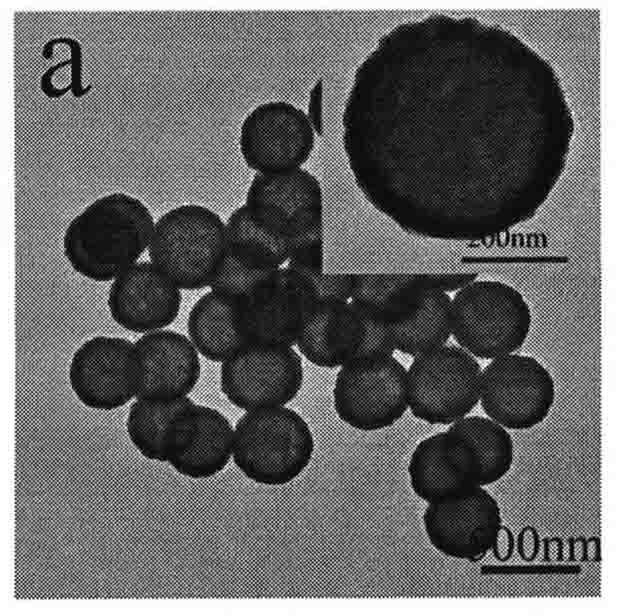

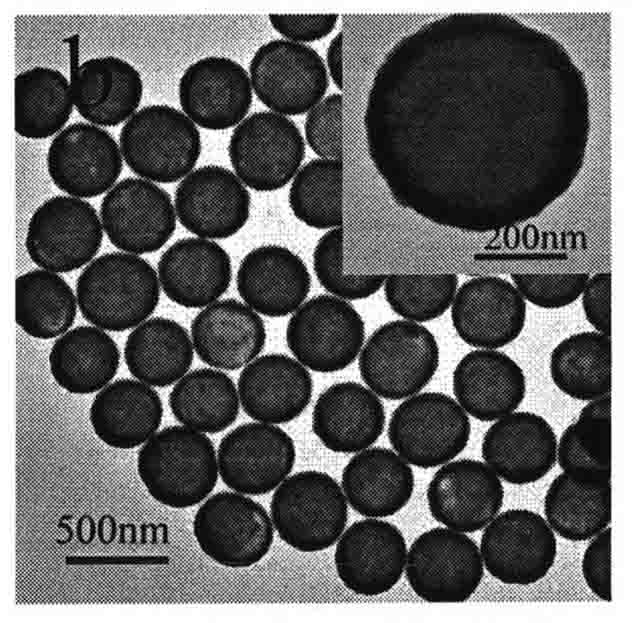

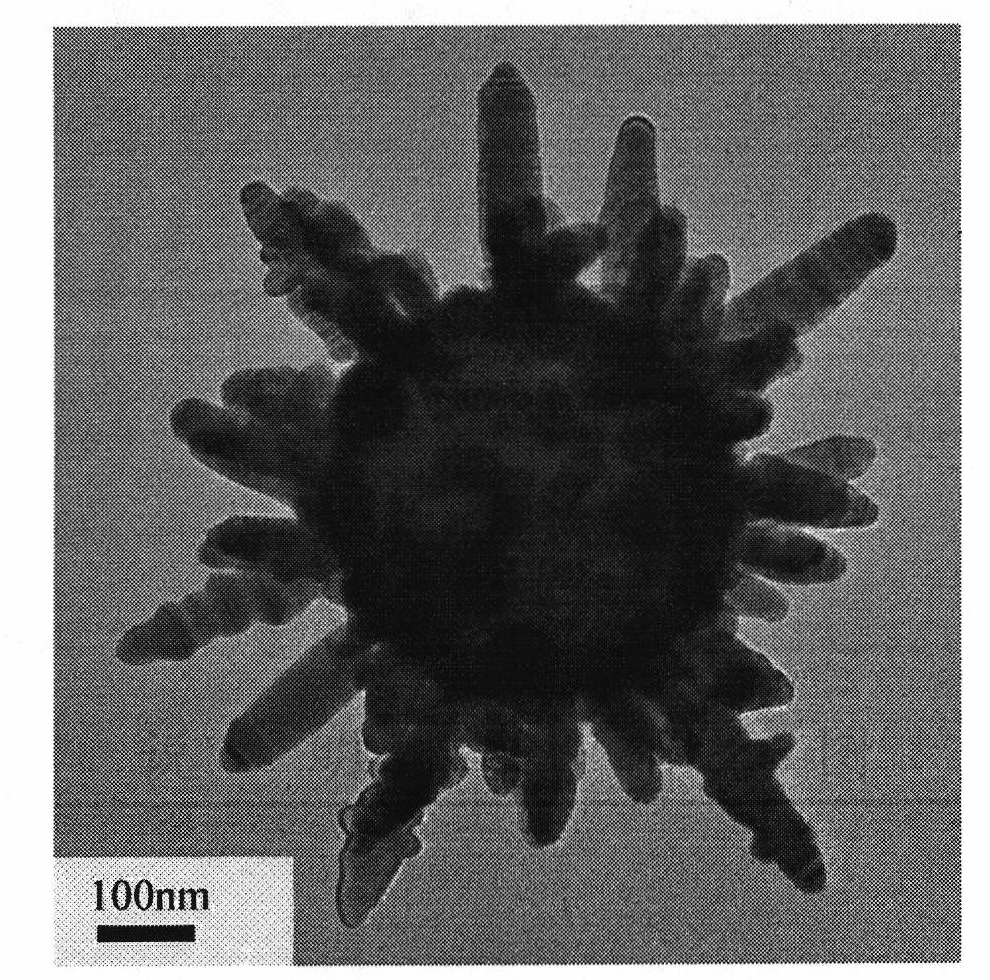

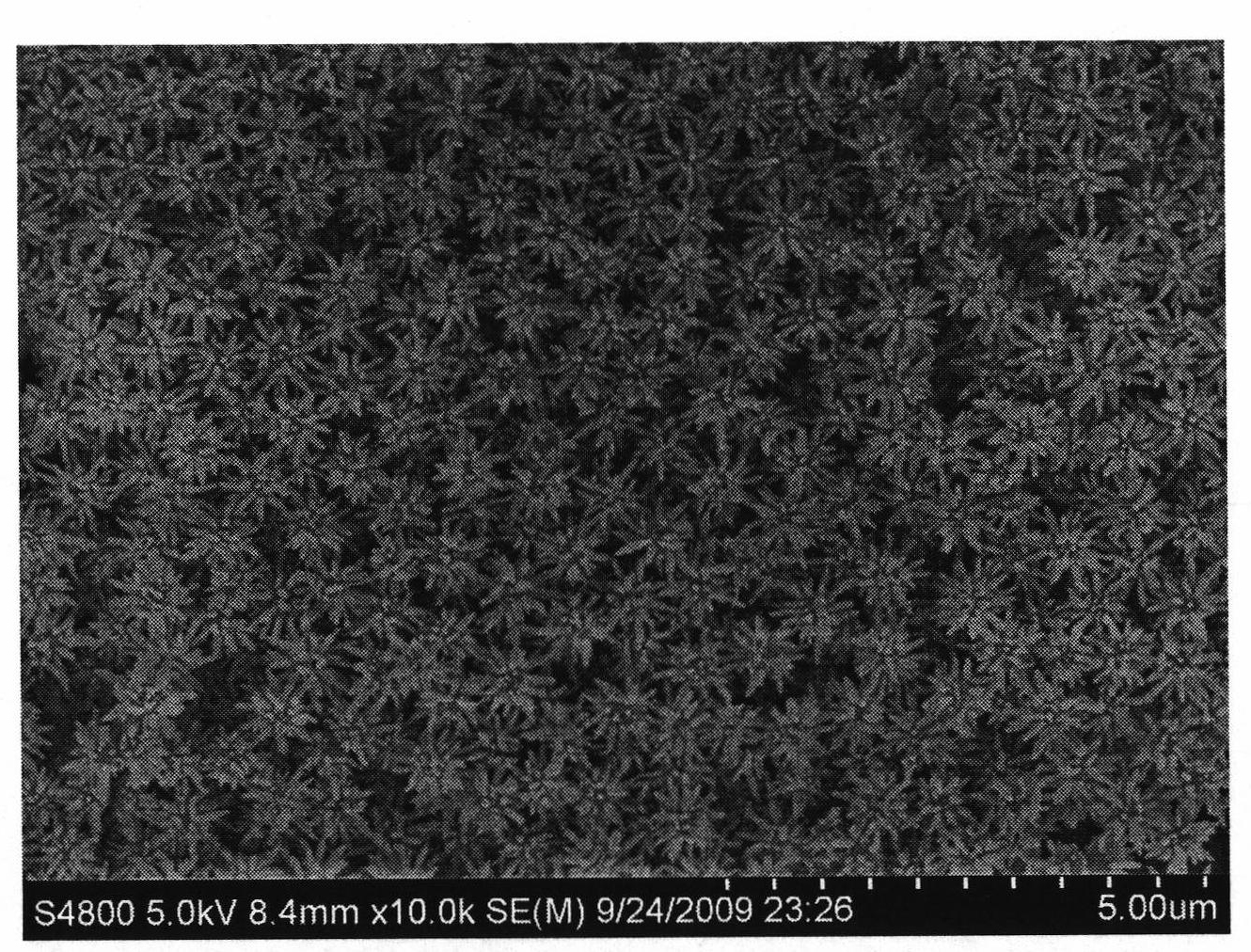

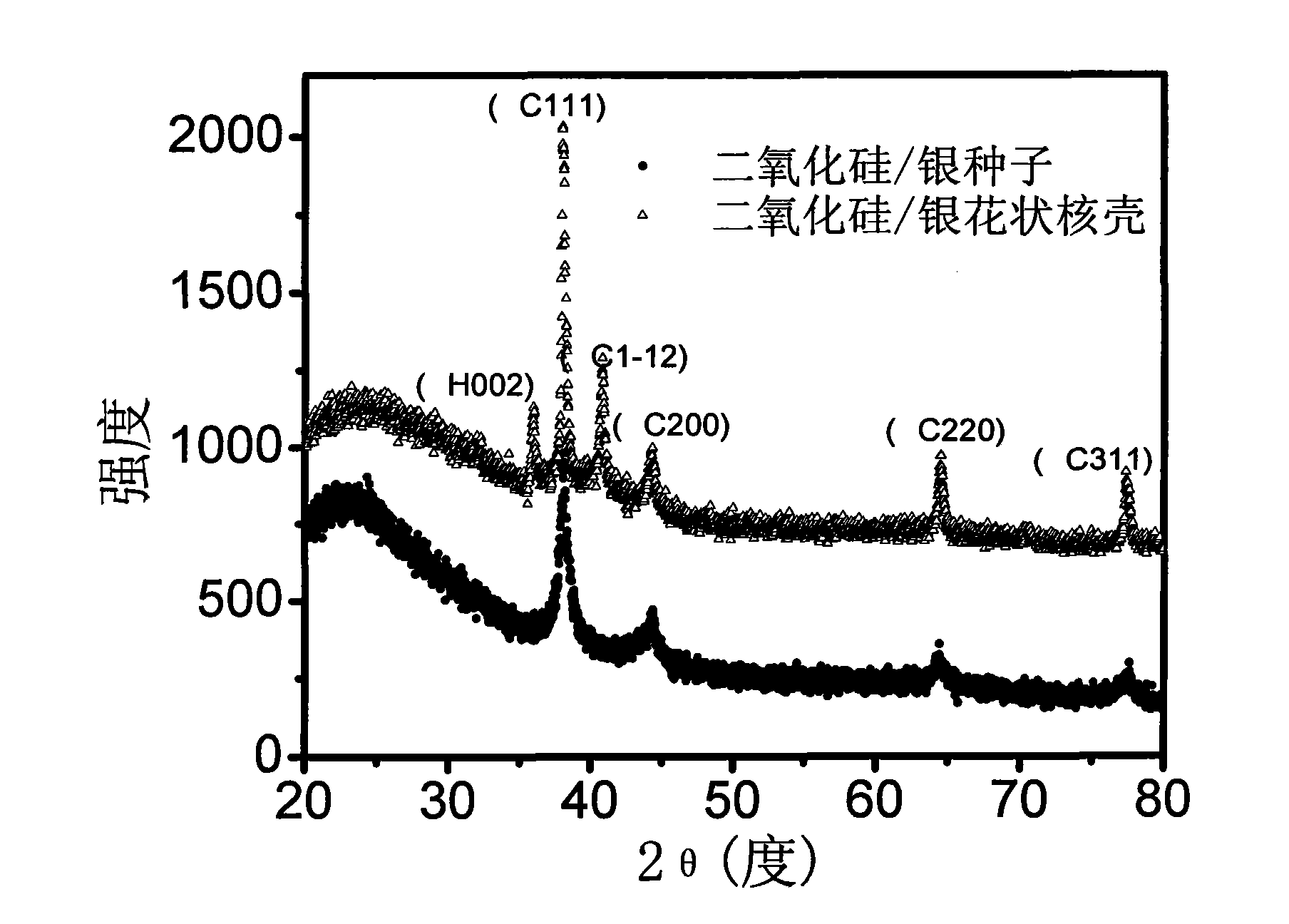

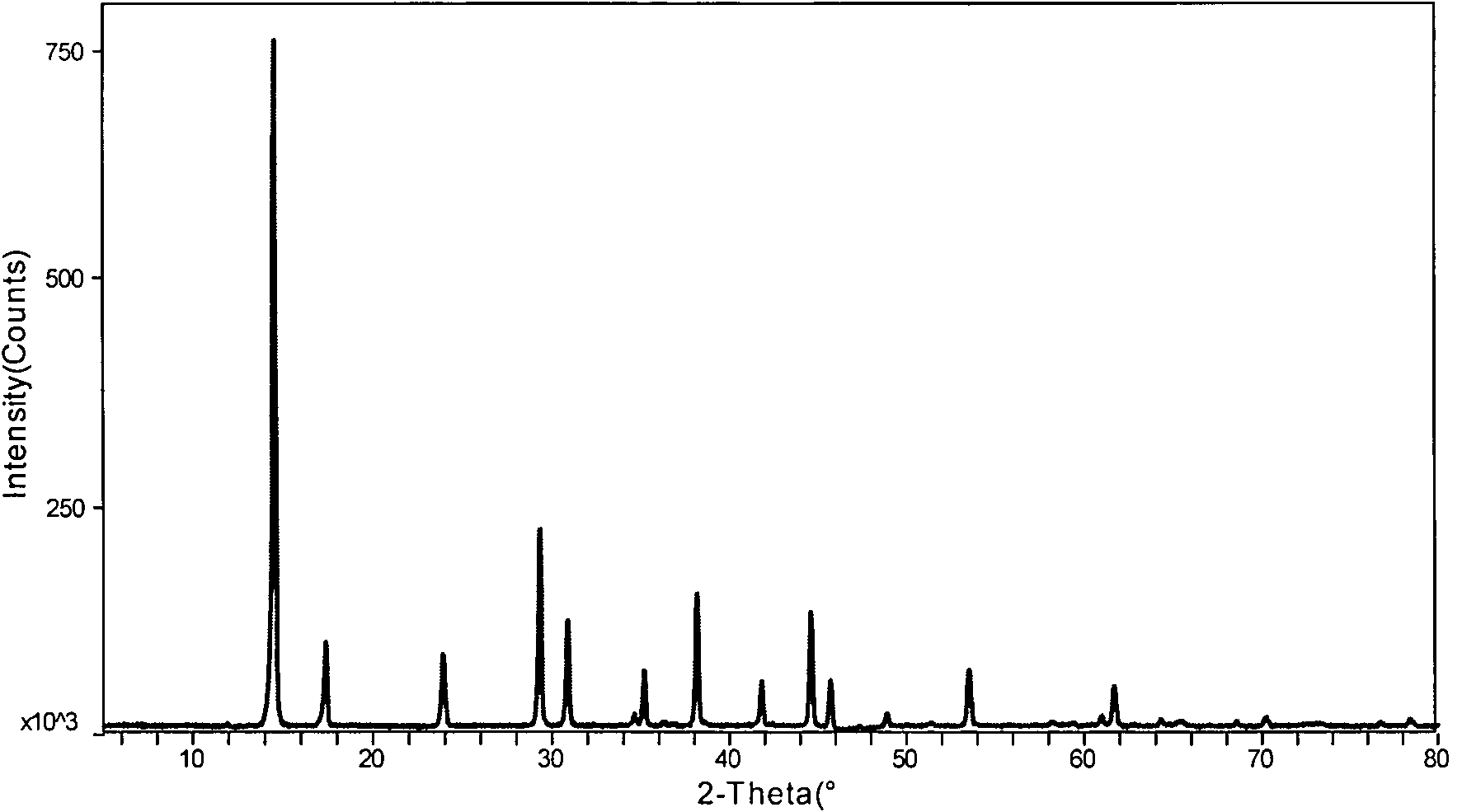

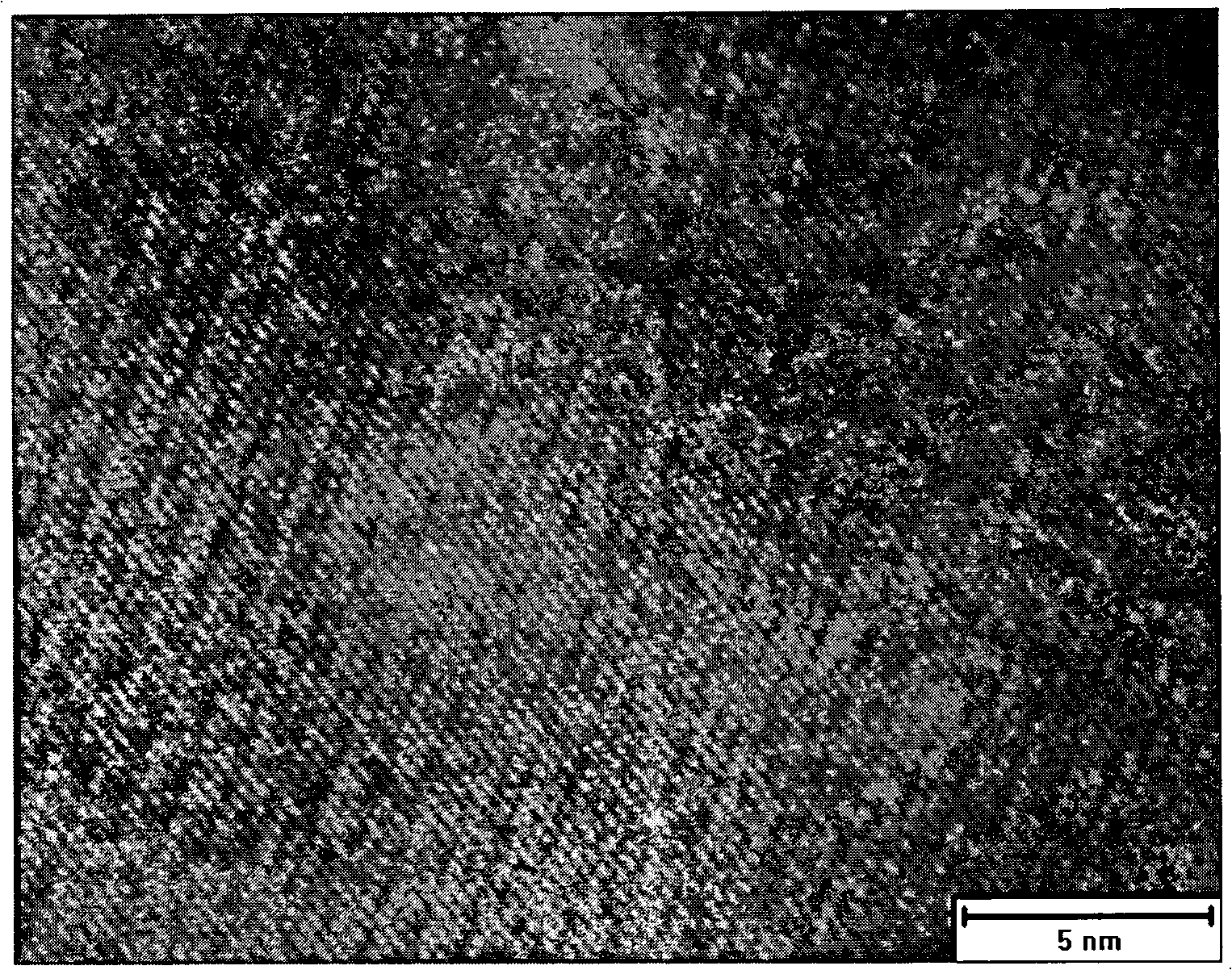

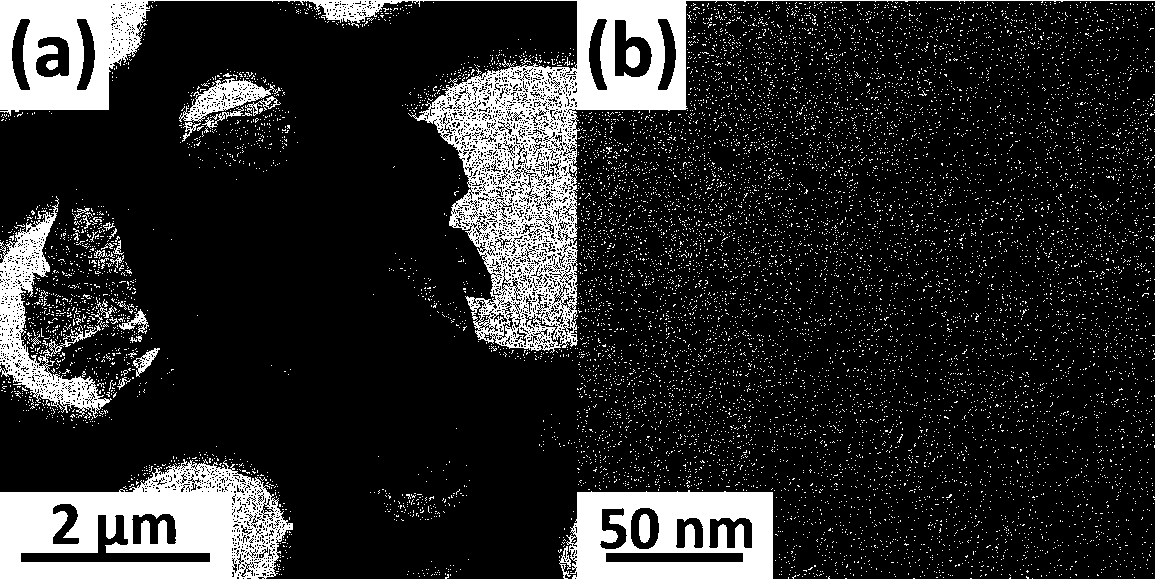

Method for preparing silica/silver nuclear shell structure granules by using polyvinyl pyrrolidone (PVP) in an assistant way

The invention discloses a method for preparing silica / silver nuclear shell structure granules by using polyvinyl pyrrolidone (PVP) in an assistant way. An adopted polyvinyl pyrrolidone assistant nucleation-regrowing two-step growth process comprises the following steps of: (1) preparing submicron silica spheres with surfaces absorbing nano silver granules; (2) dispersing the submicron silica spheres obtained in the step (1) in a polyvinyl pyrrolidone (PVP) water solution, and reducing silver nitrate by using formaldehyde under the catalysis of ammonia water; and (3) centrifugally cleaning reaction liquid obtained in the step (2), and then dispersing into ethanol or water to obtain a colloidal solution of the silica / silver nuclear shell structure granules. The method has the advantages of inexpensive and easily obtainable used drugs, simple and controllable process, good product monodispersity and uniform dimension, can obtain the nuclear shell structure granules with different opticaldelustering peak positions by regulating the thickness of a silver layer, and can be used for photonic crystals, biological detection, surface-enhanced Raman scattering, surface plasmons enhanced luminescence, and the like.

Owner:ZHEJIANG UNIV

Modified graphene and paint containing modified graphene

InactiveCN106519901AGood dispersionImprove bindingAnti-corrosive paintsPigment treatment with macromolecular organic compoundsOrganic solventCoating system

The invention discloses modified graphene. A preparation method of the modified graphene comprises (1) adding graphene oxide into an organic solvent, carrying out ultrasonic dispersion treatment, adding glucose, polyvinylpyrrolidone and a silane coupling agent into the dispersion liquid, and stirring the mixture for 10 to 20 minutes to obtain an initial mixed solution, and (2) carrying out centrifuging washing on the initial mixed solution through an organic solvent to obtain residual solids which are modified graphene. Through modification of the graphene oxide, the hydrophilic groups such as a carboxyl group and a hydroxyl group react to be removed so that lipophilic properties are enhanced. Through use of a non-aqueous solvent in the reaction, interface bonding strength of the modified graphene and organic solvent is improved. The modified graphene can be easily dispersed in an oily coating system and the improvement of the dispersibility is conducive to improvement of the anticorrosive performances of the paint.

Owner:ANHUI YINENG NEW MATERIAL TECH CO LTD

Method of preparing cation fatty acid softening agent

The invention discloses a method for the preparation of a cation fatty acid softening agent, comprising the following steps of: heating stearic acid to a melting state, adding diethylenetriamine into the melting liquid of the stearic acid to obtain a mixed liquid of the diethylenetriamine and the stearic acid, and adding a catalyst to subject the mixed liquid to an amide condensation reaction; adding an alkylating reagent into the products of the amide condensation reaction so as to implement an alkylation reaction; and adding a non-ionic surfactant and polyvinyl pyrrolidone into the products of the alkylation reaction and then cooling to obtain the cation fatty acid softening agent. The invention improves the softness by employing the alkylating reagent that is cationically stronger than acetic acid, enhances whiteness by the addition of the polyvinyl pyrrolidone, and uses the non-ionic surfactant in the process of the preparation so that the obtained softening agent can be used in one-bath with an anionic auxiliary agent so as to overcome the defects of the prior art, therefore, a cation fatty acid soft-flake softening agent having good hand feeling, high whiteness and low yellowing is obtained.

Owner:深圳天鼎新材料有限公司

Synthetic method for micro-size polymer fluorescent microspheres

InactiveCN102115508ASolve the limited scope of applicationCoatingsLuminescent compositionsMaterials sciencePolyvinylpyrrolidone

The invention relates to a synthetic method for micro-size polymer fluorescent microspheres and aims to solve the problem of limited application range since the size of fluorescent microspheres is only defined between nanometer and submicron. The synthetic method comprises the following steps: firstly, synthesizing Na2SeSO3 solution; secondly, synthesizing quantum dots QDs1 with high quality; thirdly, preparing pure quantum dots QDs2; fourthly, adding the quantum dots QDs2 in styrene solution for shaking; fifthly, adding polyvinylpyrrolidone and absolute ethyl alcohol in a four-necked flask, then feeding N2 into the four-necked flask, and dripping the styrene solution to obtain an emulsion sample after polyreaction; and sixthly, performing centrifugal settling, washing and drying to the emulsion sample to obtain polystyrene microspheres. The quantum dots are wrapped in the polymer microspheres by the dispersion polymerization method to obtain 1-10 mu.m fluorescent microspheres, the fluorescent microspheres can be applied to the field of biomarkers, coating fillers, optical encoders and the like, and the method can be used for the synthesis of fluorescent microspheres.

Owner:HEILONGJIANG UNIV

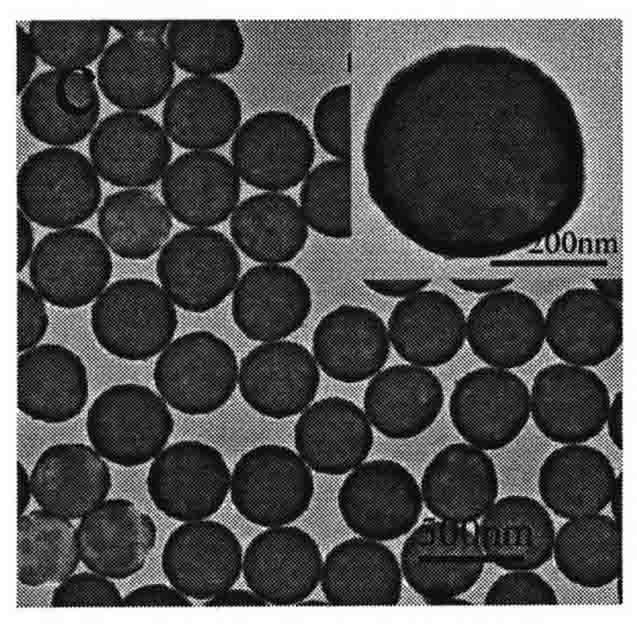

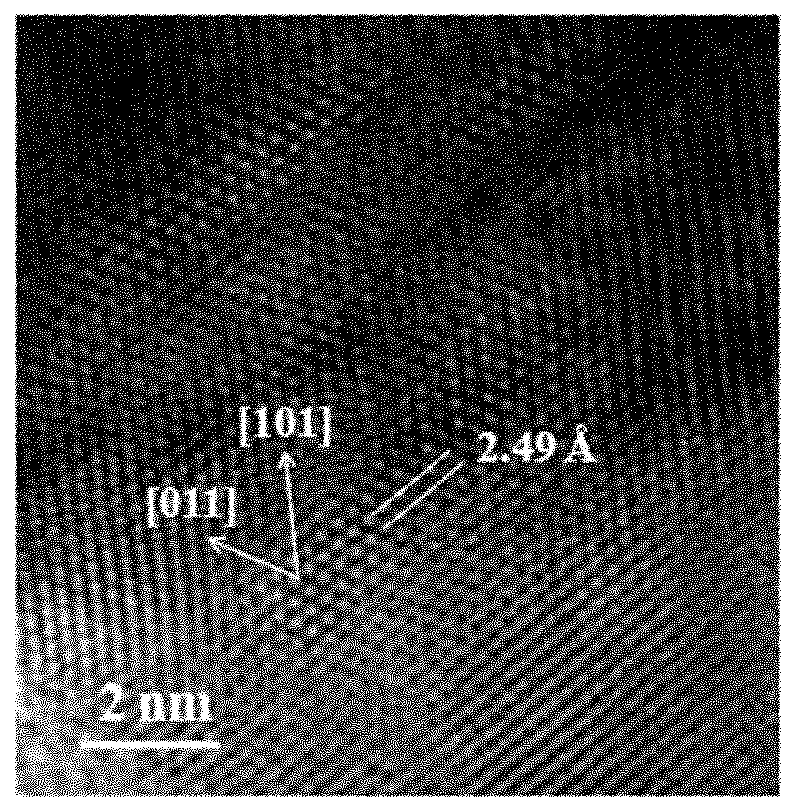

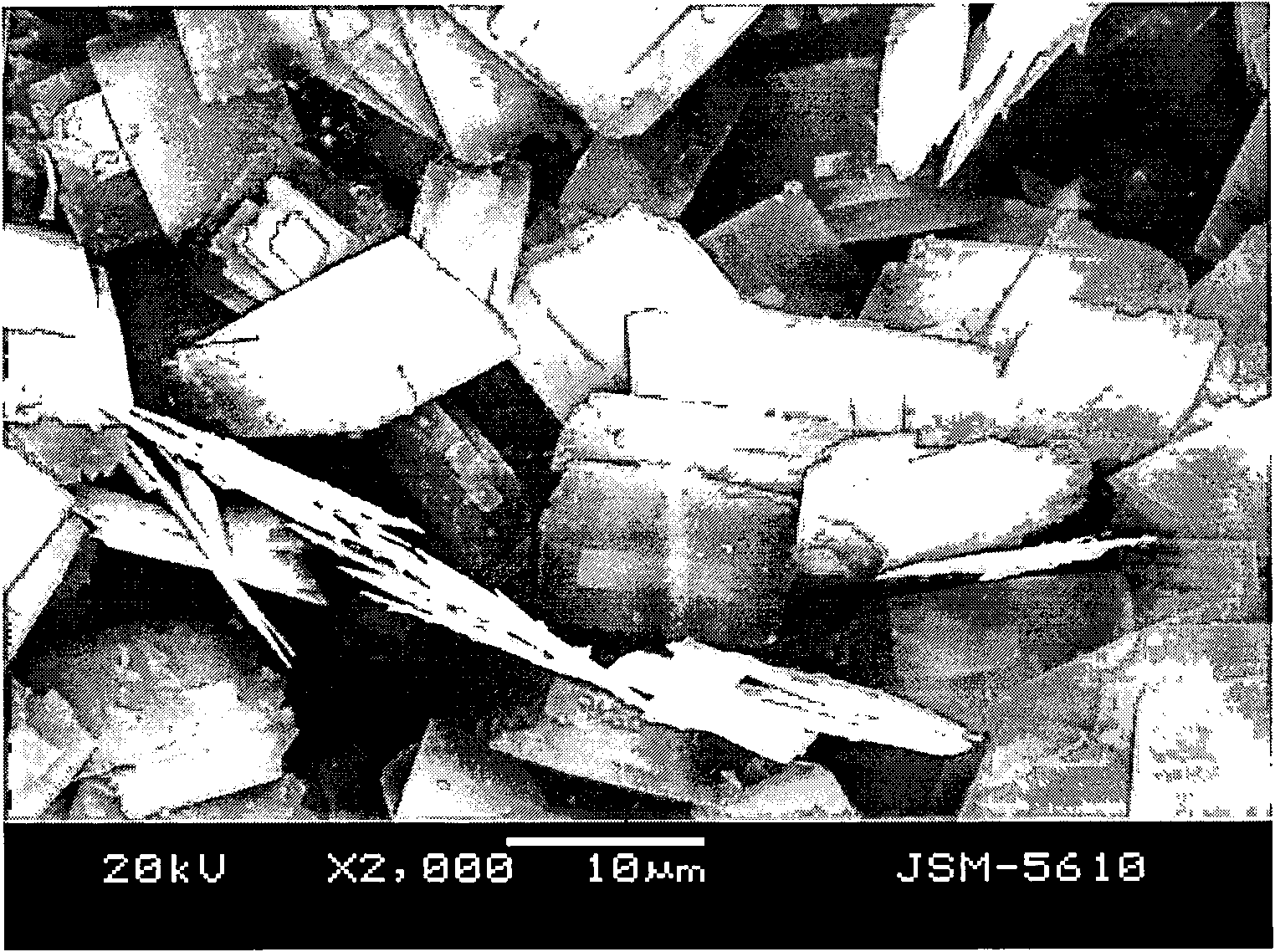

Method for preparing silica / silver flower-shaped core-shell structure particles by formaldehyde reduction method

The invention discloses a method for preparing silica / silver flower-shaped core-shell structure particles by formaldehyde reduction method, which adopts the nucleation-regrowth two-step growth process by the rapid growth of formaldehyde reaction, and comprises the following steps: 1) preparing sub-micron silica balls the surfaces of which absorb silver nanoparticles; 2) dispersing the silica balls obtained from the step 1) in water, reducing silver nitrate with formaldehyde under the catalysis of ammonia, and then adding the aqueous solution of polyvinylpyrrolidone and reacting by stirring; and 3) washing a reaction liquid by centrifuging and then dispersing the reaction liquid in water to obtain the colloidal solution of the silica / silver flower-shaped core-shell structure particles. The method of the invention has simple and controllable process and good monodispersity of products, and the silver in the particles has a face-centered cubic and close-packed hexagonal coexisted unique crystal structure; and the flower-shaped silver core-shell particles have greater specific surface area and roughness, and great amount of hot spots exist in the particles.

Owner:ZHEJIANG UNIV

Hydrogel type dressing containing aqueous emulsion of polyurethane for trauma and preparation method

A hydrogel-type dressing containing polyurethane emulsion for protecting and treating the wound of burn, scald and trauma is prepared from polyvinyl alcohol, polyvinyl pyrrolidone, water, aquatic emulsion of polyurethane, plasticizer, and physical cross-linking agent through proportionally mixing, and heating while physical cross-linking.

Owner:杭州拜康医用产品有限公司

Alkaline barrier polishing slurry

InactiveCN101302405AReduce inhibitorOther chemical processesSemiconductor/solid-state device manufacturingGuanidine derivativesCopper interconnect

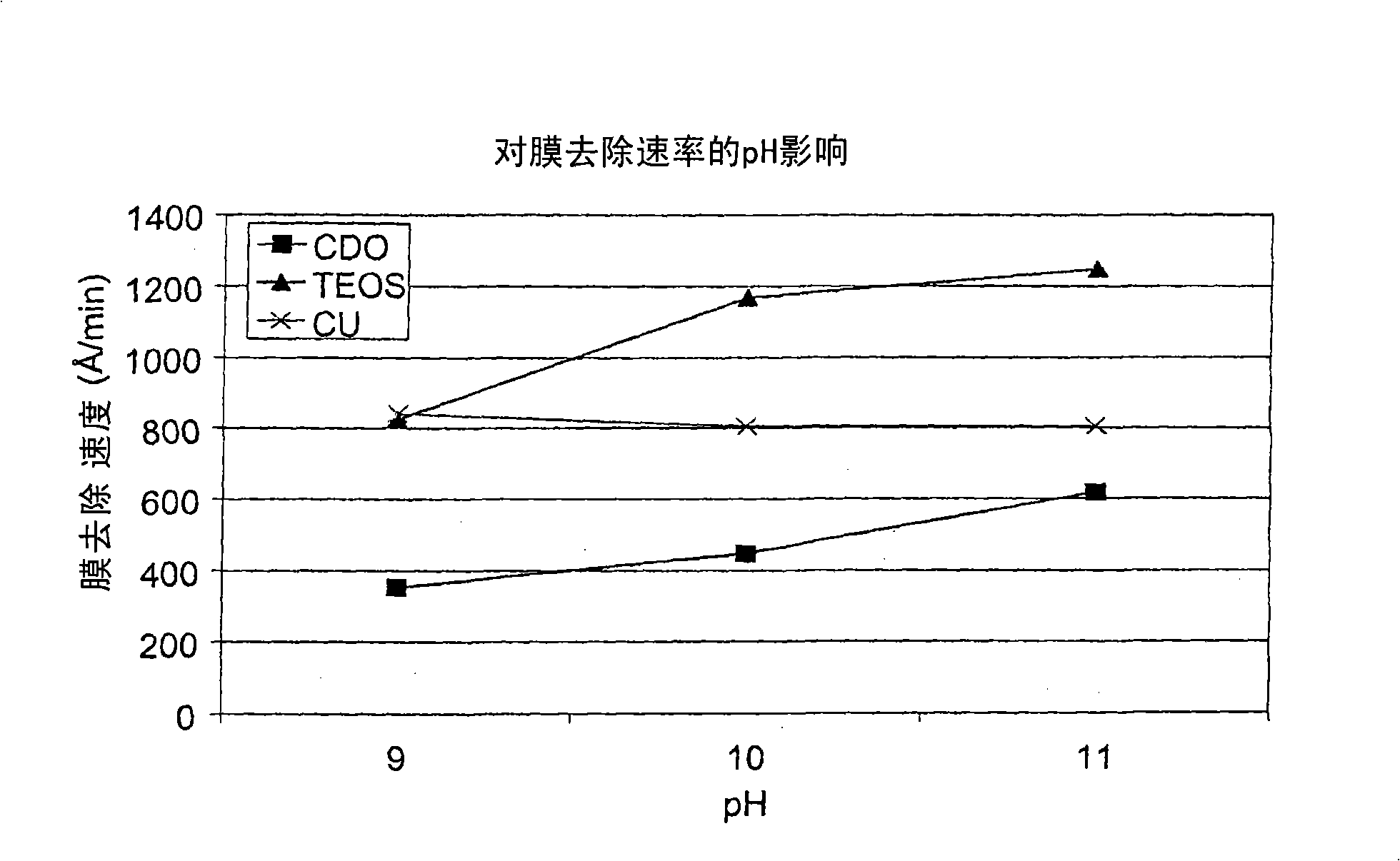

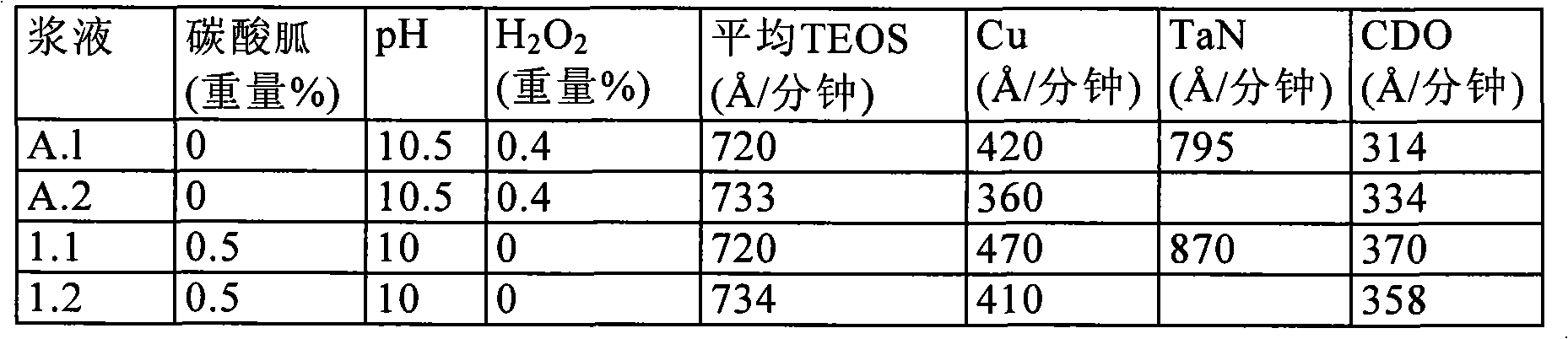

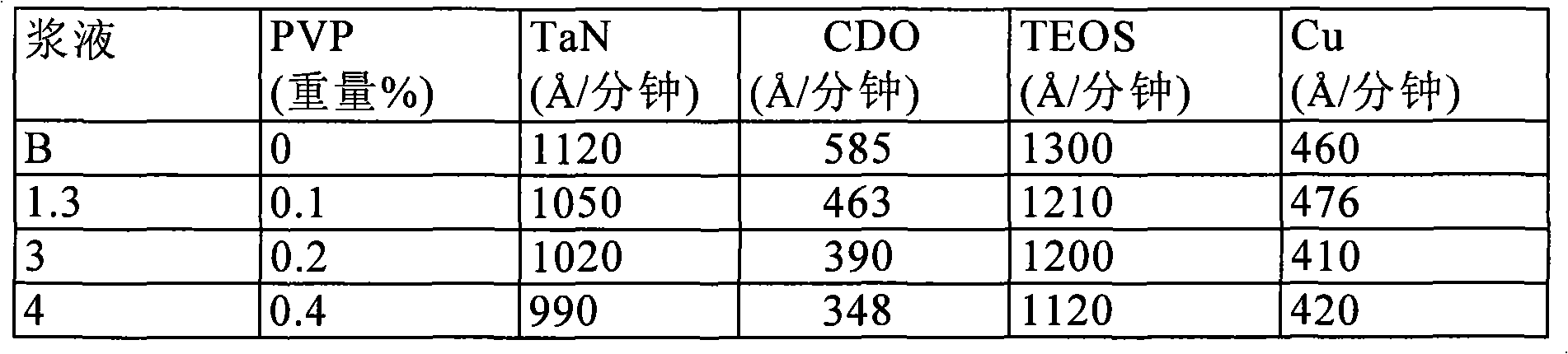

The aqueous slurry is useful for chemical mechanical polishing a semiconductor substrate having a tantalum-containing barrier layer and copper interconnects. The slurry includes by weight percent, 0 to 5 oxidizing agent, 0.1 to 25 silica particles, 0.001 to 3 polyvinyl pyrrolidone, 0.02 to 5 weight percent imine barrier removal agent selected from at least one of formamidine, formamidine salts, formamidine derivatives, guanidine, guanidine derivatives, guanidine salts and a mixture thereof, 0.02 to 5 weight percent carbonate, 0.01 to 10 inhibitor for decreasing static etch of the copper interconnects, 0.001 to 10 complexing agent and balance water; and the aqueous slurry having a pH of 9 to 11.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

High-durability concrete

The invention discloses a high-durability concrete which comprises the following raw materials: cement, river sand, macadam, water, fly ash, nano microbead, natural zeolite micropowder, aluminum oxide, sodium sulfate, diethanolamine, sodium hydroxide, methyl trichlorosilane, ethanol, an air entraining agent, a lignosulfonate water reducing agent, polyvinyl alcohol, mixed fiber, sodium nitrate and polyvinylpyrrolidone. The mixed fiber is the combination of carbon fiber, steel fiber, polypropylene fiber and polyvinyl alcohol fiber in a weight ratio of 1:(2-5):(3-7):(3-6). The high-durability concrete has the advantages of high strength, favorable water impermeability, favorable freezing resistance and favorable durability, and has long service life when being applied to hydrotechnics, harbors, roads and other projects.

Owner:WUWEI HENGJI COMML CONCRETE

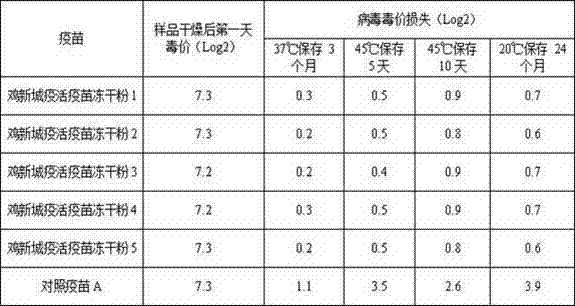

Heatproof freeze-drying protective agent of live vaccine, live vaccine freeze-drying powder and preparation method and preparation method of live vaccine freeze-drying powder

ActiveCN103041383AReduced vital activityImprove heat resistanceViral antigen ingredientsAntiviralsBiotechnologyPyrrolidinones

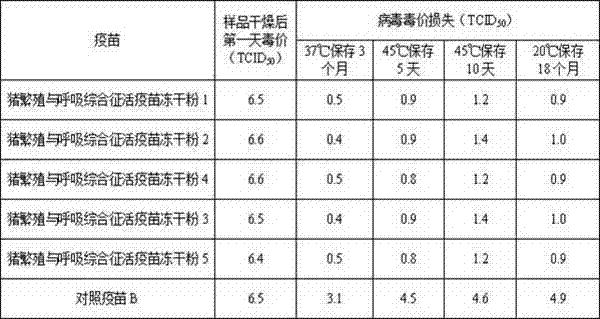

The invention provides a heatproof freeze-drying protective agent, live vaccine freeze-drying powder and a preparation method of the live vaccine freeze-drying powder, and relates to the field of microorganism deposit. The heatproof freeze-drying protective agent comprises 46-90% of oligosaccharide, 1-9% of amino acid, 1-9% of gelatin, 1-9% of casein hydrolysate, 1-9% of polyvinyl pyrrolidone, 1-9% of glycerol and 1-9% of pluronic 68. The preparation method of the live vaccine freeze-drying powder comprises the steps of preparing a protective agent solution and the live vaccine, drying, keeping for 2-6h at -10-2 DEG C and atmospheric pressure, keeping 10-26h for 0-20 DEG C at 100-800mbar, and keeping 2-8h at 0.01-50.mbar and 10-28 DEG C. The heatproof freeze-drying protective agent is reasonable in component and content collocation, and allows the live vaccine to be heatproof. According to the preparation method of the live vaccine freeze-drying powder, formation of ice crystals is avoided, and the obtained live vaccine freeze-drying powder can be kept for 3 months at 37 DEG C and 18 months at 20 DEG C.

Owner:JIANGSU ACAD OF AGRI SCI

Allochroic solid adhesive and preparation method thereof

InactiveCN101608103ASimple recipeEasy to produceEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesTO-18Phenolphthalein

The invention discloses a high-stability allochroic solid adhesive and a preparation method thereof. The allochroic solid adhesive is prepared by the method according to the following steps: adding all the following raw materials in portion by weight into a reaction kettle of which the temperature is between 50 and 100 DEG C: 50 to 75 portions of dispersant water, 10 to 45 portions of bonding agent such as polyvinyl pyrrolidone, 5 to 18 portions of excipient such as sodium stearate, 5 to 15 portions of humectant such as glycerol, 0.1 to 1 portion of developer phenolphthalein, and proper amount of color stabilizer; stirring the raw materials at a temperature of between 80 and 100 DEG C for one hour, and then adjusting the pH to between 9 and 11; and then standing the mixture at a constant temperature, and bottling the mixture to obtain a purple solid adhesive. The allochroic solid adhesive has a reasonable and simple formulation, easy manufacture and production and low cost; the colloid is purple when the allochroic solid adhesive is coated on a substrate material, and the purple disappears in a short time to meet the requirements in specific fields; besides, the allochroic solid adhesive has the most prominent characteristic that the color is stable during storage and is basically unchanged for more than two years.

Owner:NINGBO SONGHE STATIONERY

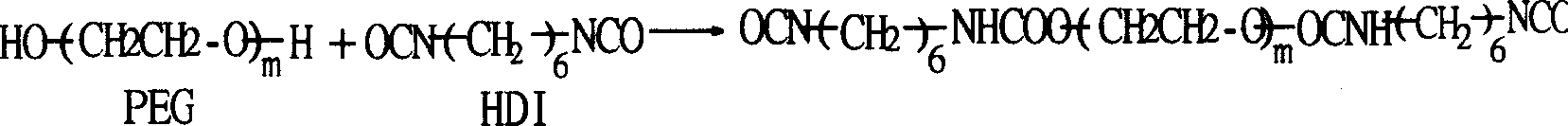

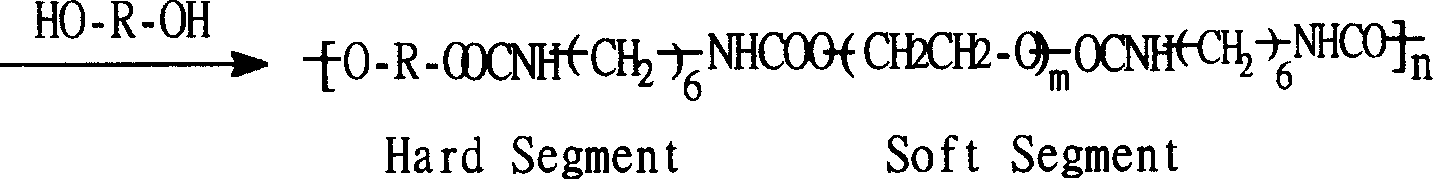

Method for preparing polyurethane function material with surface modified by polyvinyl pyrrolidone

InactiveCN101787136AImprove surface hydrophilicityImprove bindingEnd-groupAtom-transfer radical-polymerization

The invention relates to a method in which atom transfer radical polymerization (ATRP) and 'click' mistry are comprehensively utilized to improve surface hydrophilism of the polyurethane material, specifically, polyvinyl pyrrolidone is grafted on the surface of the polyurethane material to obtain surface functional polyurethane material. The invention aims to provide a simple and practical method for modifying the polyurethane surface and obtaining required high-degree wettability. The method comprises the following steps: first, vinyl pyrrolidone monomer is polymerized to obtain polyvinyl pyrrolidone (Init-PVP-X, X=CI, Br) with a terminal group thereof being halogen atom through the atom transfer radical polymerization reaction, then sodium azide is employed to convert the terminal group of the polyvinyl pyrrolidone from chlorine or bromine to triazon. with the method of the invention, surface hydrophily of high polymer material polyurethane with excellent mechanical properties can be noticeably improved and the question that the PVP combines with polyurethane is solved, so that a novel polyurethane function material featuring simple technology and economy and practicability is formed.

Owner:SOUTHEAST UNIV

High-wear-resistant antibacterial acrylate paint

InactiveCN106366899AImprove wear resistanceGood solvent resistanceFireproof paintsAntifouling/underwater paintsWear resistantUnsaturated polyester

The invention discloses high-wear-resistant antibacterial acrylate paint. The high-wear-resistant antibacterial acrylate paint is prepared from the raw materials: an aqueous acrylate emulsion, alkyd resin, organosilicon modified unsaturated polyester resin, silica sol, cellulose acetate butyrate, polyvinyl pyrrolidone, modified nano-titania, calcium carbonate whiskers, octadecyl trimethyl ammonium chloride modified montmorillonite, hollow glass beads, zinc oxide, ethylene glycol mono-n-propyl ether, di-propanediol butyl ether, triethylene glycol monoethyl ether, an anti-settling agent, a humectant, an antifoamer, per-methoxylation melamine resin, 3,5-dimethyl-2-aminobenzoic acid, trimethylaniline, a leveling agent, vinyl triethoxysilane and deionized water. The high-wear-resistant antibacterial acrylate paint provided by the invention is high in hardness, good in wear resistance, excellent in antibacterial performance and long in service life.

Owner:ANHUI JINDUN PAINT

Preparation method and application of mud-resistant polycarboxylate superplasticizer

The invention provides a preparation method and application of a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer has the advantages of being low in mixing amount, high in water-reducing rate, long in slump resisting time and high in mud resistance when serving as a cement dispersing agent. The synthesis process is simple, the raw material utilization rate is high, a solvent is convenient to recycle, and production cost is low. According to the preparation method of the mud-resistant polycarboxylate superplasticizer, the mud-resistant polycarboxylate superplasticizer is obtained through the free radical polymerization reaction of specific unsaturated acid monomers, specific unsaturated polyether macromonomers and poly(N-vinyl pyrrolidone) chain containing PVP macromonomers, and the molar weight of the unsaturated polyether macromonomers is 50% to 100% that of the PVP macromonomers.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Process for producing PVP-fullerene complex and aqueous solution thereof

An aromatic hydrocarbon solution of a fullerene or a fullerene mixture is mixed with an ethanol solution of polyvinylpyrrolidone (PVP), water is added to the mixed solution, the solvent is removed and then an aqueous solution of a complex of a fullerene or a fullerene mixture with polyvinylpyrrolidone (PVP) is obtained. Under a condition free from a halogen, a PVP / fullerene complex excellent in manifestation of fullerene properties, stability and safety and an aqueous solution thereof are obtained.

Owner:VITAMIN C60 BIORES

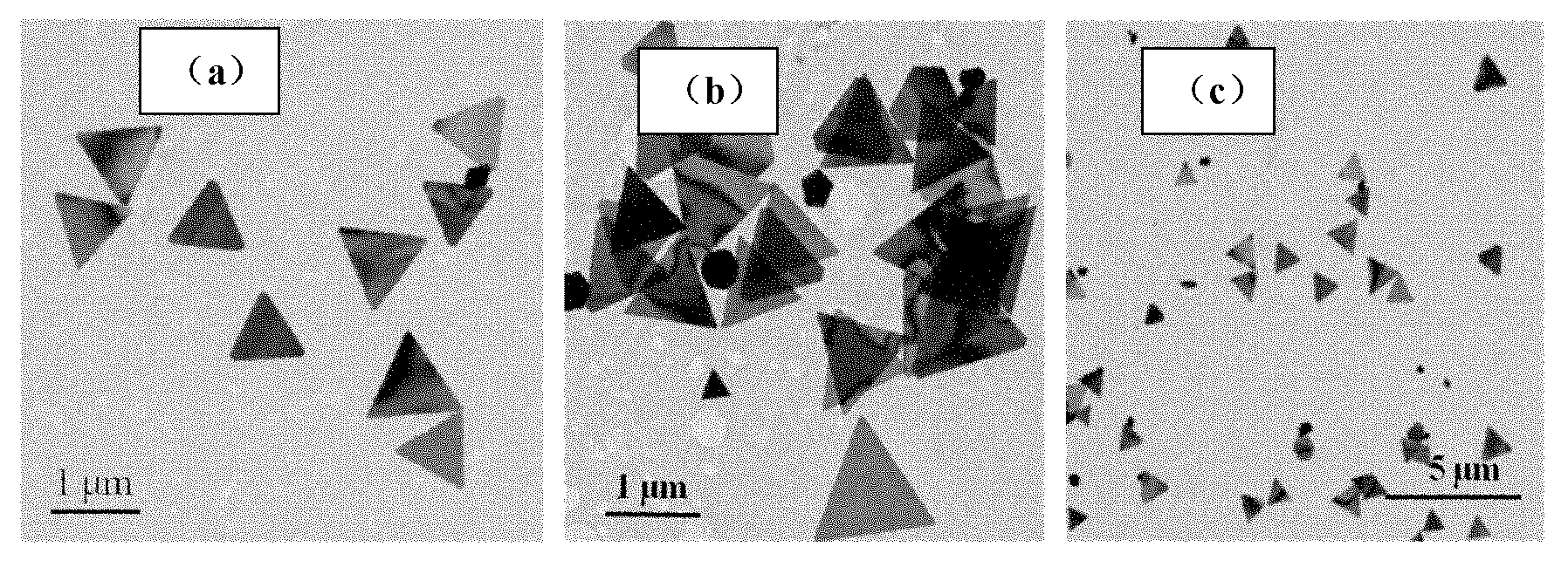

Preparation method of environment-friendly micron-size triangular silver sheet

The invention discloses a preparation method of an environmentally-friendly micron-size triangular silver sheet. The method comprises the following steps of: preparing a silver nitrate oxidation liquid and a reduction liquid containing polyvinyl pyrrolidone (PVP) and D(+)-dextrose, stirring at room temperature and dropwise adding the silver nitrate oxidation liquid into the reduction liquid to obtain a uniform yellow solution; placing the obtained mixed liquor into a drying oven, preserving heat at the temperature between 75 DEG C and 95 DEG C for 48-72 hours to obtain a silver-gray fulmarginsolution; cooling and standing the fulmargin solution, centrifuging and separating; washing nano silver powder obtained by centrifuging with acetone and cold ethanol respectively; and re-dispersing the washed nano silver powder into the ethanol for later use. The prepared micron-size triangular silver sheet has the advantages of high yield, regular shape, difficulty in aggregating, high stability, simple synthesizing process, environmentfriendliness and preparation on a large scale.

Owner:SOUTH CHINA UNIV OF TECH

Poly N-vinyl pyrrolidone-contained amphiphilic copolymer grafted by natural high polymer or water-solubility derivative thereof and preparation method thereof

InactiveCN101643531AImprove complexation stabilization effectGood hydrophobic associationSolubilityPolymer science

The invention provides a poly N-vinyl pyrrolidone-contained amphiphilic copolymer grafted by natural high polymer or water-solubility derivative thereof and a preparation method thereof, and a complexof the copolymer and iodin. After natural high polymer or the water-solubility derivative thereof is dissolved, an initiating agent is added to initiate grafting copolymerization; hydrophilic monomercontaining poly N-vinyl pyrrolidone is added to be polymerized into hydrophilic chain segments, and meanwhile, hydrophobic monomer is added to carry out grafting copolymerization, and then an amphiphilic grafting copolymer derivative containing the polyvinyl pyrrolidone chain segments of natural high polymer or water-solubility derivative thereof, is obtained. The derivative keeps high biologicalactivity and degradability of the natural high polymer or water-solubility derivative thereof and good fixing effect of polyvinyl pyrrolidone having good complexing performance to iodin, and meanwhile, an amphiphilic structure gives the good hydrophobic association and surface activity to the derivative; moreover, the complexing effect of the polyvinyl pyrrolidone chain segments and iodin in thecopolymer is further enhanced.

Owner:陈煜

Preparation method of macroporous adsorbent resin for toxin substance adsorption

ActiveCN105085829ALarge specific surface areaRich pore structureOther chemical processesPolymer scienceParaquat

The invention provides a preparation method of a macroporous adsorbent resin for toxin substance adsorption, which comprises the following steps: preparing a lower-crosslinking-degree macroporous styrene-divinylbenzene resin, crosslinking the lower-crosslinking-degree macroporous styrene-divinylbenzene resin by a Friedel-Crafts process to obtain an ultrahigh-crosslinked-structure macroporous adsorbent resin, and introducing acylation reaction and grafting reaction in the ultrahigh-crosslinked-structure macroporous adsorbent resin preparation process to successfully prepare the carboxylic-acid-group-containing polyvinylpyrrolidone-grafted ultrahigh-crosslinking-degree macroporous adsorbent resin for toxin substance adsorption. The resin has the advantages of huge specific area and abundant pore structure, contains part of carboxylic acid ion groups, and is grafted by the polyvinylpyrrolidone on the resin surface. Therefore, the adsorption capacity for paraquat, acetochlor and other toxin substances containing cations or basic groups can be enhanced by utilizing the potential energy effect caused by hydrophobicity and huge specific area of the particular polystyrene skeleton of the ultrahigh-crosslinking-degree adsorbent resin, the pore screening action of the abundant pore structure and the charge action of the carboxylic acid groups. Besides, the polyvinylpyrrolidone is grafted on the resin surface to enhance the compatibility of the resin with blood.

Owner:TIANJIN STANDARD BIOLOGICS CO LTD +1

Method for preparing Co3O4 nanometer sheet

InactiveCN102139929AHigh purityNo complicated preparationNanotechnologyCobalt oxides/hydroxidesSemiconductor industryCobalt chloride

The invention discloses a method for preparing cobalt oxide (Co3O4) serving as an inorganic material, and particularly relates to a method for preparing a Co3O4 nanometer sheet, which comprises the following steps of: dissolving cobalt chloride and urea in distilled water, and adding polyvinyl pyrrolidone to form mixed solution; putting the mixed solution into a reaction kettle for reacting for a certain time period, and cooling naturally to the room temperature; performing precipitating, centrifugal separation and washing on a reaction material to obtain Co2(OH)2CO3 serving as a precursor; and calcining the precursor to obtain the Co3O4 nanometer sheet serving as the product. The method has the advantages of high process controllability, low cost and high purity of the prepared product, and is easy to operate. The prepared product has the wide application range in semiconductor industry.

Owner:ZHEJIANG SCI-TECH UNIV

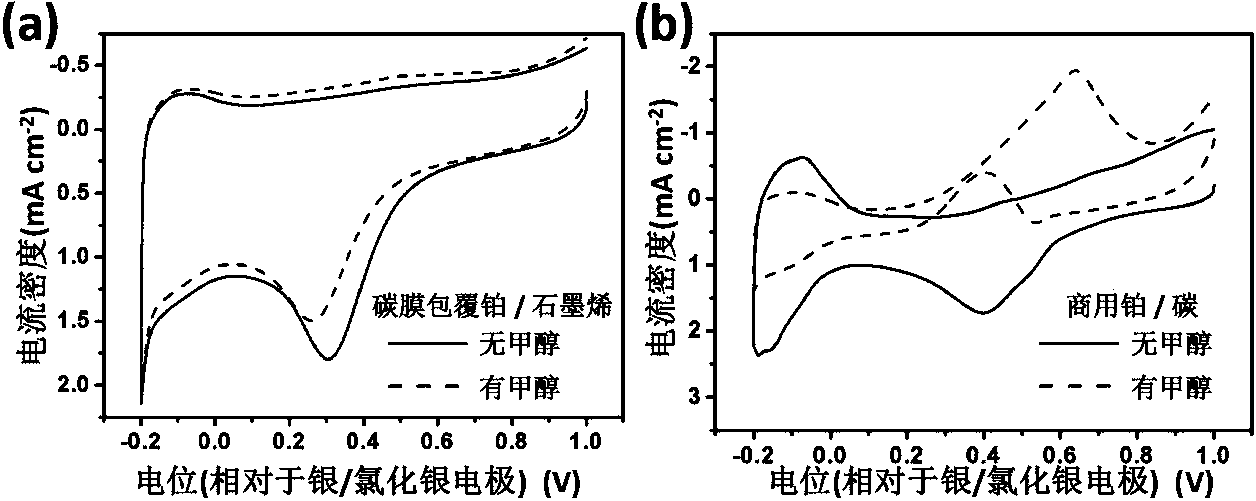

Preparation method of carbon film coated platinum/graphene catalyst

InactiveCN104014333AHigh reactivityImprove cycle performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon filmCarbonization

The invention discloses a preparation method of a carbon film coated platinum / graphene catalyst. Graphene is adopted as a carrier for the catalyst to hydrothermally reduce oxidized graphene, saccharides, polyvinyl pyrrolidone and chloroplatinic acid, and then high-temperature carbonization is carried out to obtain a cathode oxygen reduction reaction catalyst of a fuel battery, wherein the platinum loading amount is 10-50wt%. The catalyst has excellent methanol tolerance and catalytic cycle stability, the performances of the catalyst are greatly improved in 1000 times of cyclic voltammetry testing, and the catalyst is superior to the commercial platinum / carbon catalyst.

Owner:安徽百特新材料科技有限公司

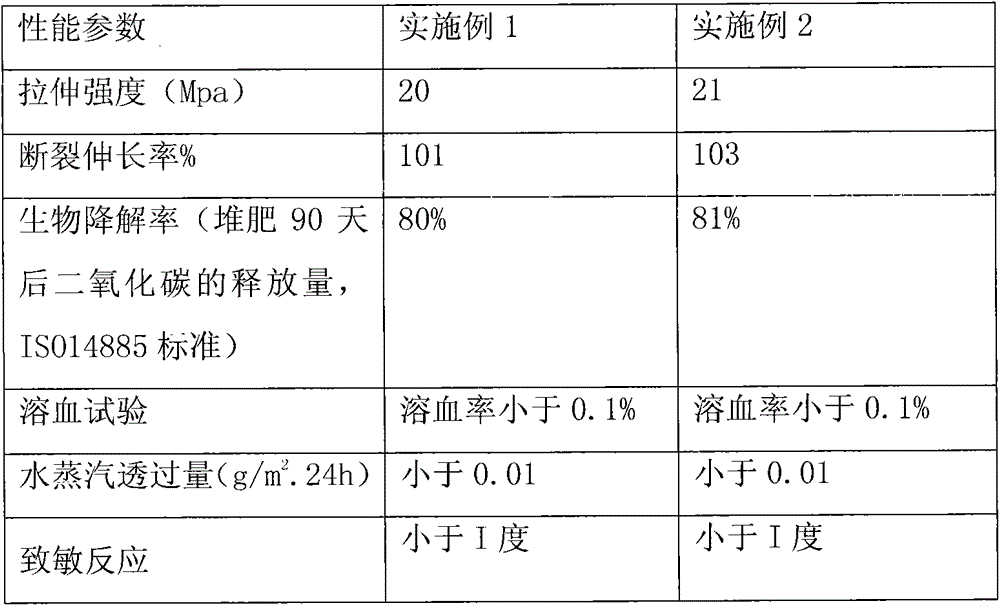

Degradable packaging plastic for electric power systems

InactiveCN104387657AImprove mechanical propertiesSimple manufacturing methodFlexible coversWrappersLow-density polyethylenePolyvinyl alcohol

The invention belongs to the field of electric power materials, and discloses a degradable packaging plastic for electric power systems, which is prepared from the following raw materials in parts by weight: 30 parts of low-density polyethylene, 20 parts of polyvinyl alcohol, 15 parts of poly(butylene succinate), 12 parts of polyvinylpyrrolidone, 9 parts of hydroxymethyl cellulose, 7 parts of polyhydroxyacetic acid, 6 parts of chitosan, 4 parts of polylactic acid, 3 parts of triethyl phosphate, 3 parts of micalex powder, 2 parts of talcum powder, 2 parts of corn starch, 1 part of sodium succinate and 1 part of epoxy soybean oil. The plastic material has favorable tensile strength, elongation at break and biodegradability, and greatly lowers the environmental pollution.

Owner:STATE GRID CORP OF CHINA +1

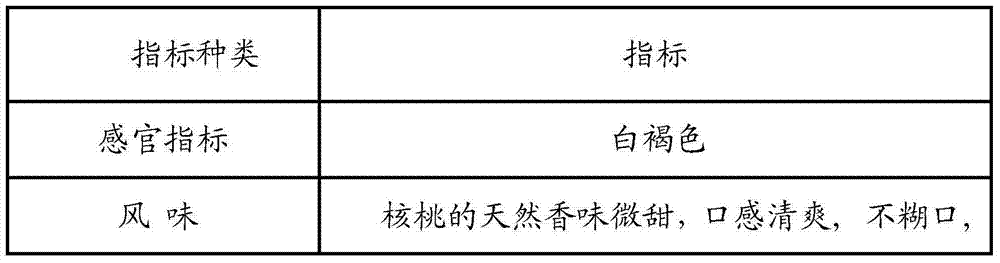

Walnut antioxidant polypeptide chewing flake and preparation method thereof

InactiveCN103932286AIncrease contentRich varietyFood shapingFood ultrasonic treatmentNutritive valuesUltrasonic assisted

The invention discloses a walnut antioxidant polypeptide chewing flake and a preparation method of the walnut antioxidant polypeptide chewing flake. The walnut antioxidant polypeptide chewing flake is 1.0g+ / -0.05g in weight, the walnut polypeptide powder added to each flake is 0.7g+ / -0.035g, the soybean fructo-oligose is 0.2g+ / -0.01g, and the walnut antioxidant polypeptide chewing flake also comprises 2.0-2.5% of hydroxypropyl methyl cellulose, 3-5% of polyvinylpolypyrrolidone, 1-1.5% of magnesium stearate, and the balance of water. The preparation method comprises the following steps: degreasing walnut powder; soaking; adjusting pH; performing ultrasonic-assisted mixing, centrifuging, removing an oil layer and a lower layer sediment; adjusting the pH of the solution; performing enzymolysis; performing enzyme deactivation; adding soybean polysaccharide; homogenizing; spray drying; mixing the walnut polypeptide powder, the soybean fructo-oligose and the auxiliary materials; preparing soft particles; pelletizing; drying; straightening; tabletting; sterilizing; and packaging into the product. The walnut antioxidant polypeptide chewing flake is stable in preparation process, reliable and optimal in technical index, high in nutritive value, high in utilization rate of protein, and quick to digest and absorb inside a body, and has the functions of having low antigenicity, promoting muscle erythrocyte recovery, helping recovery from fatigue and the like.

Owner:辽宁通正检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com