Method for preparing silica / silver flower-shaped core-shell structure particles by formaldehyde reduction method

A technology of silica and core-shell structure, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve good dispersion and enhance the effect of dye luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

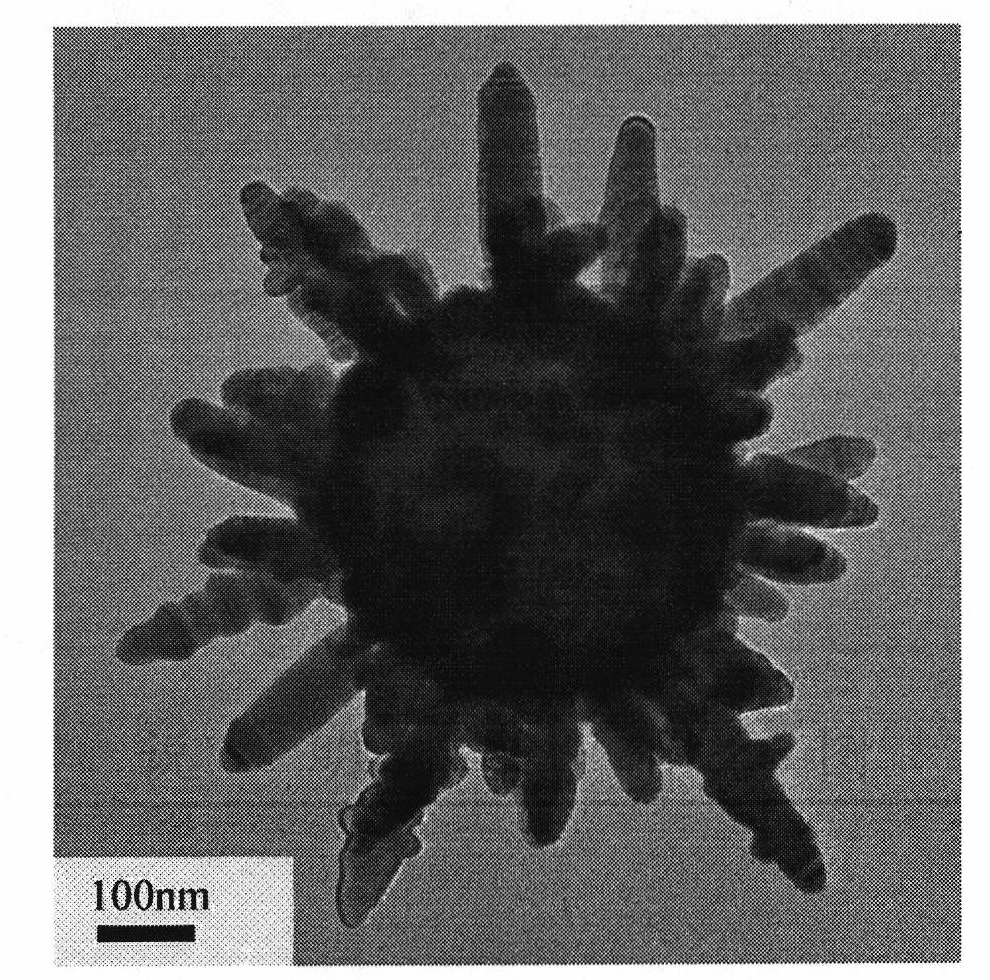

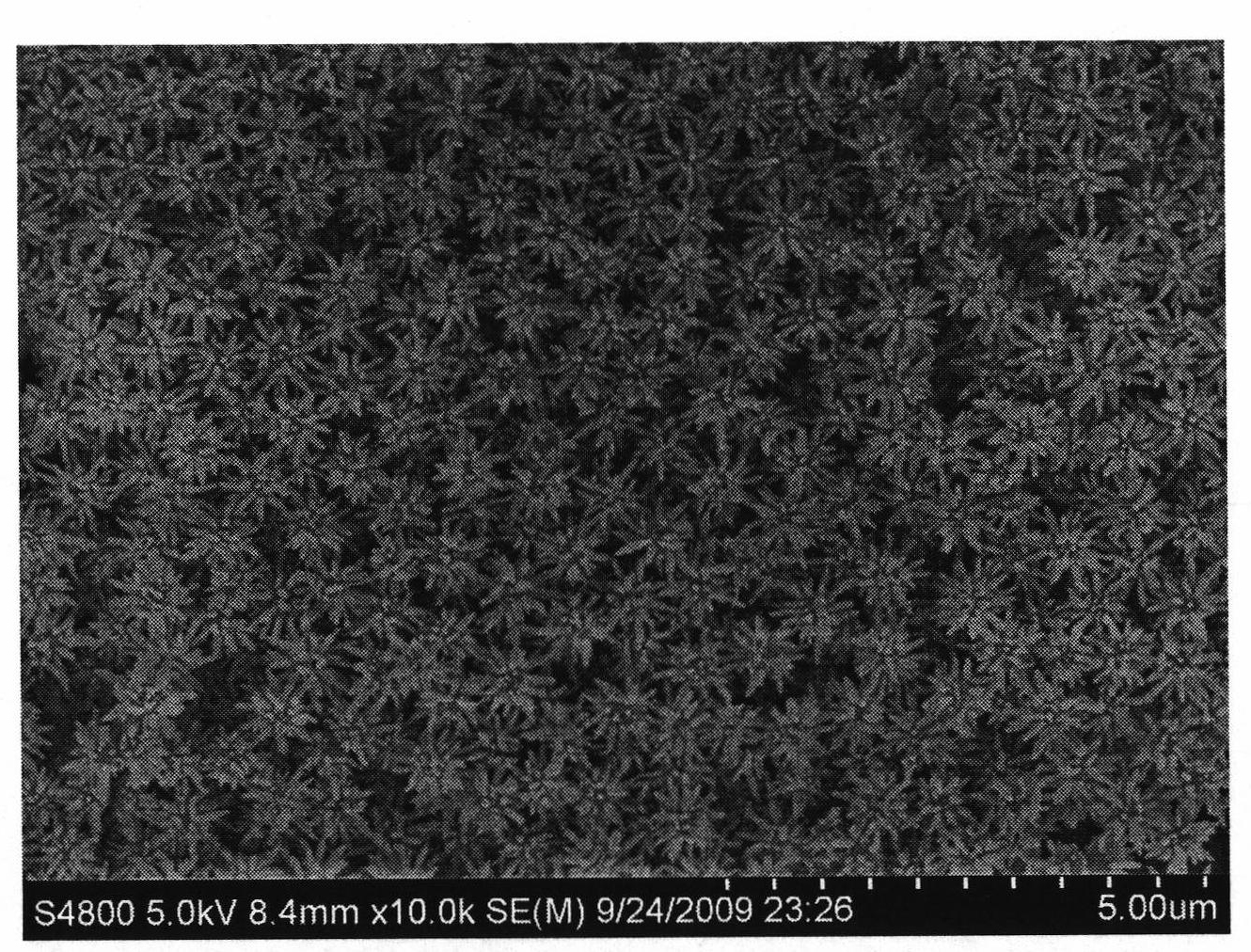

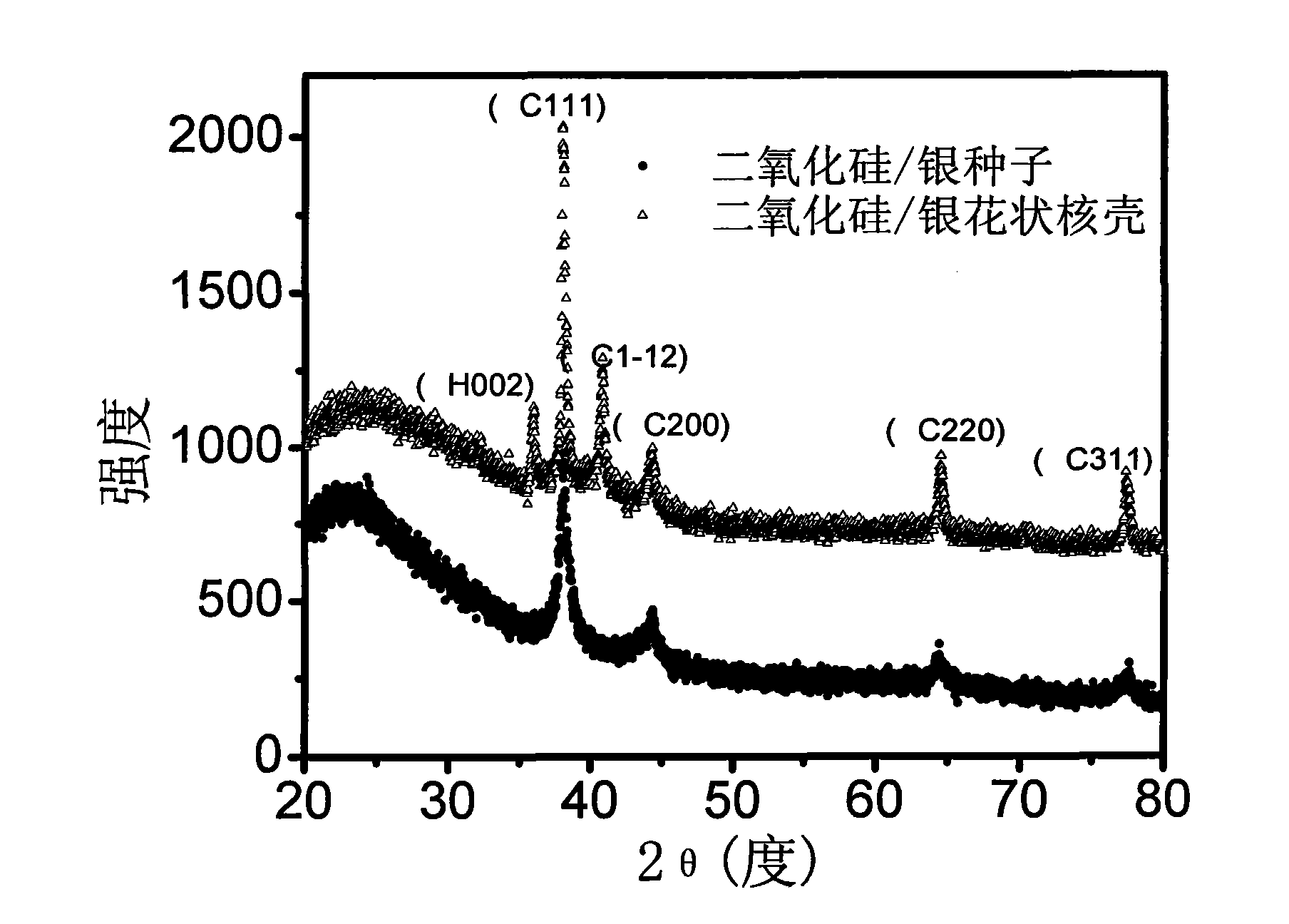

[0017] Add 0.1 g of silica spheres with a diameter of 300 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere solution to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere. Centrifuge with deionized water and disperse into 10 ml of ethanol . Add 0.1 ml of silica sphere solution with small silver particles on the surface to 200 ml of water, add 0.5 ml of 1 mol / liter silver nitrate aqueous solution, then add 0.2 ml of formaldehyde, 0.4 ml of ammonia water, and then add 20 ml of 5% PVP The aqueous solution was stirred, reacted for 2 hours, and cleaned by centrifugal deposition with deio...

Embodiment 2

[0022] Add 0.1 g of silica spheres with a diameter of 100 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere solution to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere. Centrifuge with deionized water and disperse into 10 ml of ethanol . Add 0.1 ml of silica sphere solution with small silver particles on the surface to 200 ml of water, add 0.5 ml of 1 mol / liter silver nitrate aqueous solution, then add 0.2 ml of formaldehyde, 0.4 ml of ammonia water, and then add 20 ml of 5% PVP The aqueous solution was stirred, reacted for 2 hours, and cleaned by centrifugal deposition with deio...

Embodiment 3

[0024] Add 0.1 g of silica spheres with a diameter of 1000 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere solution to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere. Centrifuge with deionized water and disperse into 10 ml of ethanol . Add 0.1 ml of silica sphere solution with small silver particles on the surface to 200 ml of water, add 0.5 ml of 1 mol / liter silver nitrate aqueous solution, then add 0.2 ml of formaldehyde, 0.4 ml of ammonia water, and then add 20 ml of 5% PVP The aqueous solution was stirred, reacted for 2 hours, and cleaned by centrifugal deposition with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com