Ozone-catalytic functional ceramic membrane, preparation method thereof and circulating coating device

A technology of functional ceramics and ozone catalysis, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc. Low, unable to realize the integration of membrane filtration and ozone catalytic functions, etc., to achieve good effluent quality, promote the decomposition of ozone, and good degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

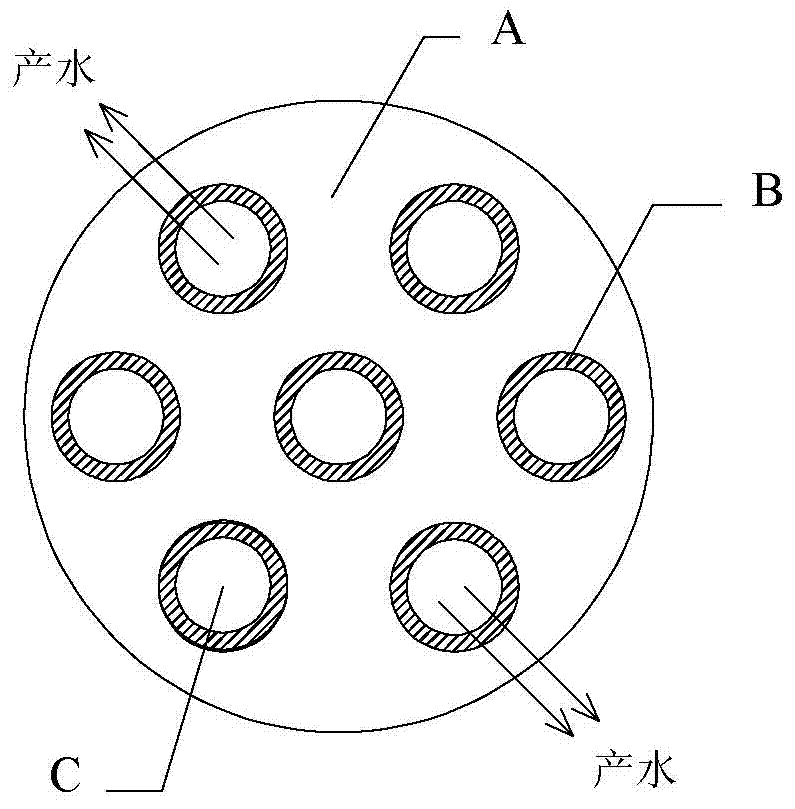

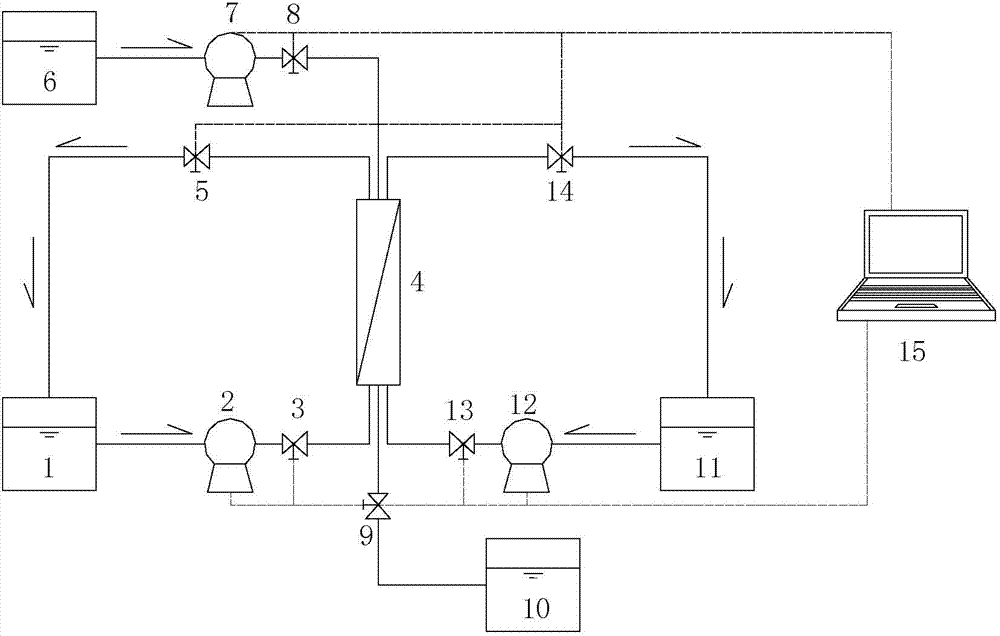

[0051] (1) Preparation of metal-supported ceramic membrane matrix

[0052] 1) Prepare 500 mL of manganese nitrate solution with a concentration of 0.1 mol / L at a room temperature of 25°C;

[0053] 2) Immerse the selected tubular ceramic membrane in 0.1mol / L manganese nitrate aqueous solution for 4 hours, and shake it in a constant temperature shaker to ensure sufficient injection and adsorption;

[0054] 3) After taking it out, dry it at 25°C for 12 hours;

[0055] 4) Then dry at 85°C for 12 hours;

[0056] 5) Calcining at a high temperature of 550° C. for 1 h to prepare a metal manganese-loaded ceramic membrane substrate.

[0057] (2) Preparation of manganese oxide dip coating solution

[0058] Adopt equivalent reaction method of potassium permanganate and manganese chloride:

[0059] 1) At room temperature 25°C, quickly mix 180mL manganese chloride solution with a concentration of 2mmol / L and 120mL potassium permanganate solution with a concentration of 2mmol / L (requires...

specific Embodiment approach 2

[0071] The difference between this embodiment and specific embodiment 1 is that in step (1), the prepared metal-loaded ceramic membrane substrate is a metal iron-manganese composite loaded ceramic membrane substrate, and the specific steps are as follows:

[0072] (1) Preparation of metal-loaded ceramic membrane matrix

[0073] 1) At a room temperature of 25°C, prepare 500mL of a mixed solution of manganese nitrate and ferric nitrate with a total concentration of 0.1mol / L, and the molar ratio of iron and manganese is 1:1;

[0074] 2) Immerse the selected tubular ceramic membrane in a mixed aqueous solution of 0.1mol / L manganese nitrate and ferric nitrate for 4 hours, and shake it in a constant temperature shaker to ensure sufficient injection and adsorption;

[0075] 3) After taking it out, dry it at 25°C for 12 hours;

[0076] 4) Then dry at 85°C for 12 hours;

[0077] 5) Calcining at a high temperature of 550° C. for 1 h to prepare a metal iron-manganese composite loaded c...

specific Embodiment approach 3

[0078] The difference between this embodiment and specific embodiment 1 is that in step (1), the prepared metal-loaded ceramic membrane substrate is a metal iron-manganese-potassium composite loaded ceramic membrane substrate, and the specific steps are as follows:

[0079] (1) Preparation of metal-loaded ceramic membrane matrix

[0080] 1) At a room temperature of 25°C, prepare 500 mL of a mixed solution of manganese nitrate, ferric nitrate and potassium nitrate with a total concentration of 0.1 mol / L, and the molar ratio of iron, manganese and potassium is 1:1:1;

[0081]2) Immerse the selected tubular ceramic membrane in a mixed aqueous solution of 0.1mol / L manganese nitrate, ferric nitrate and potassium nitrate for 4 hours, and shake it in a constant temperature shaker to ensure sufficient injection and adsorption;

[0082] 3) After taking it out, dry it at 25°C for 12 hours;

[0083] 4) Then dry at 85°C for 12 hours;

[0084] 5) Calcining at a high temperature of 550° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com