Preparation method of environment-friendly micron-size triangular silver sheet

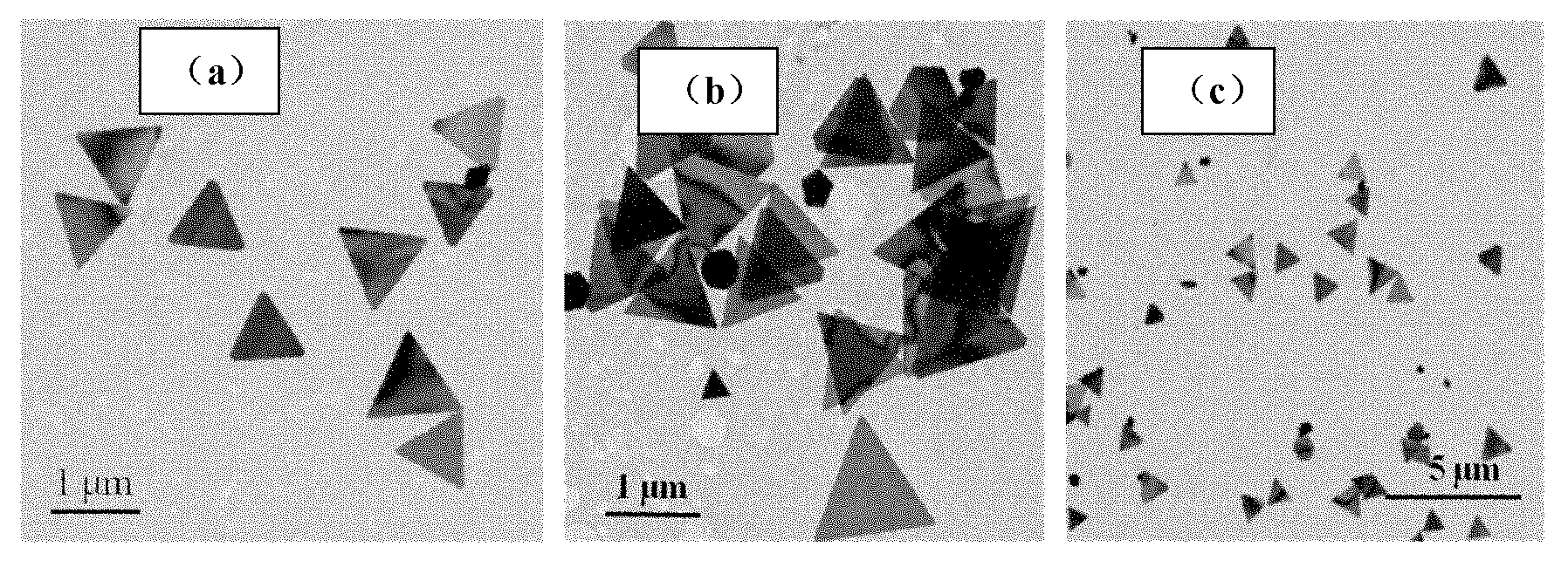

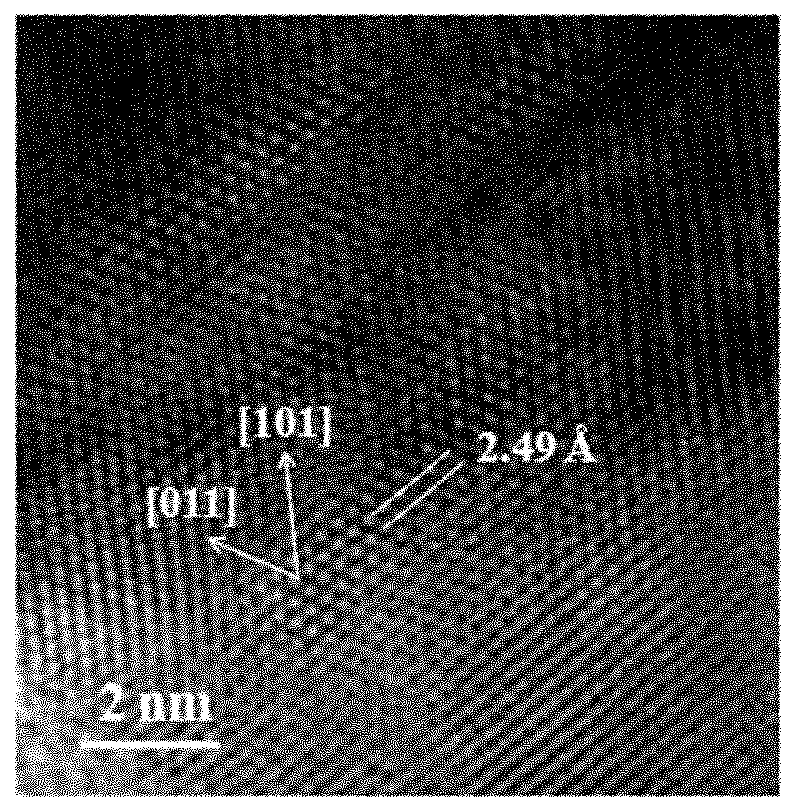

An environmentally friendly, micron-scale technology is applied in the field of preparing micron-scale triangular silver flakes by using double weak reducing agents, which can solve the problems of environmental pollution of organic solvents and reducing agents, increase the difficulty of experimental operation, and low yield of triangular silver flakes. The effect of good oxidation resistance and anti-agglomeration, low experimental conditions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an environmentally friendly micron-scale triangular silver flake, comprising the steps of:

[0035] 1. Dissolve 1.5g of solid silver nitrate in 20mL of deionized water to prepare silver nitrate oxidation solution, fully dissolve it for later use; dissolve 3.0g of polyvinylpyrrolidone (PVP) and 1.67g of D(+)-glucose in another Part 20mL deionized water, made into reducing solution;

[0036] 2. Add the silver nitrate oxidizing solution dropwise to the reducing solution at a rate of 1 mL / min while stirring at room temperature. After the dropwise addition is complete, continue to stir vigorously for 30 minutes to obtain a uniform yellow solution;

[0037] 3. Stop stirring, place the resulting mixed solution in an oven, and keep the temperature at 90 degrees Celsius for 48 hours to obtain a silver-gray silver colloidal solution;

[0038] 4. Naturally cool the silver colloid solution to room temperature, then place it in ice water for 15 minutes, centr...

Embodiment 2

[0043] A method for preparing an environmentally friendly micron-scale triangular silver flake, comprising the steps of:

[0044] 1. Dissolve 0.30g of solid silver nitrate in 20mL of deionized water to make silver nitrate oxidation solution, fully dissolve it for later use; dissolve 0.6g of polyvinylpyrrolidone (PVP) and 0.33g of D(+)-glucose in another Part 20mL deionized water, made into reducing solution;

[0045] 2. Add the silver nitrate oxidizing solution dropwise to the reducing solution at a rate of 1 mL / min while stirring at room temperature. After the dropwise addition is complete, continue to stir vigorously for 30 minutes to obtain a uniform yellow solution;

[0046] 3. Stop stirring, place the obtained mixed solution in an oven, and keep the temperature at 75 degrees Celsius for 72 hours to obtain a silver-gray silver colloidal solution;

[0047] 4. Cool the silver colloid solution to room temperature naturally, then place it in ice water for 15 minutes, centrifuge...

Embodiment 3

[0052] A method for preparing an environmentally friendly micron-scale triangular silver flake, comprising the steps of:

[0053] 1. Dissolve 0.9g of solid silver nitrate in 20mL of deionized water to prepare silver nitrate oxidation solution, fully dissolve it for later use; dissolve 1.8g of polyvinylpyrrolidone (PVP) and 1.00g of D(+)-glucose in another Part 20mL deionized water, made into reducing solution;

[0054] 2. Add the silver nitrate oxidizing solution dropwise to the reducing solution at a rate of 1 mL / min while stirring at room temperature. After the dropwise addition is complete, continue to stir vigorously for 30 minutes to obtain a uniform yellow solution;

[0055] 3. Stop stirring, place the resulting mixed solution in an oven, and keep the temperature at 95 degrees Celsius for 48 hours to obtain a silver-gray silver colloidal solution;

[0056] 4. Naturally cool the silver colloid solution to room temperature, then place it in ice water for 15 minutes, centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com