Preparing low density porous tin dioxide nano fiber laser target material by electro-static spinning method

An electrospinning method and nanofiber technology, which is applied in the field of laser target material preparation, can solve the problems of complex operation process, expensive experimental equipment, difficult post-processing, etc., and achieve simple equipment, high fiber fineness and uniformity, and long The effect of large diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

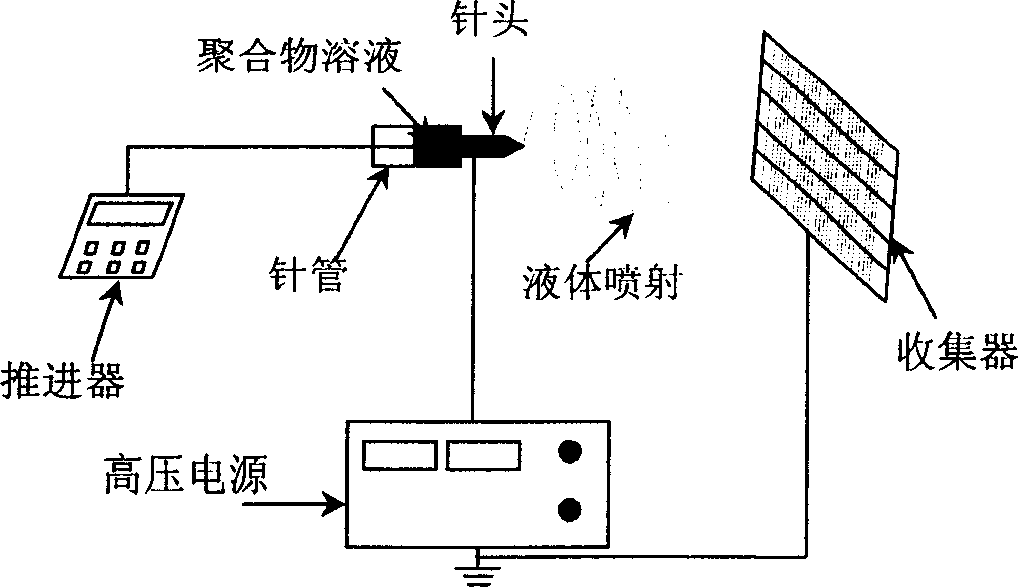

Method used

Image

Examples

preparation example Construction

[0025] low density porous SnO 2 Preparation of nanofibrous materials:

[0026] method one:

[0027] Prepare a 20%-40% (mass ratio) polyvinylpyrrolidone (PVP, Mw=44,000) solution, use absolute ethanol as a solvent, and stir at room temperature for 3 hours until completely dissolved. Weigh tin tetrachloride, add absolute ethanol slowly under stirring according to the proportion of 13-15% (mass ratio), and stir at room temperature for 30 minutes until tin tetrachloride is completely dissolved in ethanol. Then the above two solutions were mixed and vigorously stirred at room temperature for 90 minutes until the solutions were completely mixed to be used as a spinning solution. Fill the above spinneret solution into a 5ml glass syringe with a stainless steel needle. The stainless steel needle can be selected from 5#, 6# and 8#. min driver, the electric field strength is 0.1kv / cm~1kv / cm, and the distance from the receiving screen to the spinneret is 5~30cm. Fibers with different...

Embodiment 1

[0032] Weigh 0.247g SnCl 4 .5H 2 O was dissolved in 2ml of ethanol, stirred for 30min, then slowly added dropwise to 10ml of 20% PVP ethanol solution (dropped at regular intervals), stirred for 90min. The above mixed solution was used as a spinning solution. Use a 5ml glass syringe with a 5# stainless steel needle to inhale 4mL of the above spinning solution, the motor advance speed is 1ml / h, the ambient temperature is 25°C, the humidity is 50%, the voltage is 15kv, the needle tip is 15cm away from the aluminum foil collection device, and the fibers are collected. The obtained fibers were calcined in a muffle furnace at 500 °C for 2 h at a constant temperature to obtain SnO 2 Nanofibers.

Embodiment 2

[0034] Weigh 0.52g SnCl 4 .5H 2O was dissolved in 4ml of ethanol, stirred for 30min, then slowly added dropwise to 8ml of 20% PVP ethanol solution (dropped at regular intervals), stirred for 90min. The above mixed solution was used as a spinning solution. Use a 5ml glass syringe with a 5# stainless steel needle to inhale 4mL of the above spinning solution, the motor advance speed is 1ml / h, the ambient temperature is 25°C, the humidity is 50%, the voltage is 15kv, the needle tip is 15cm away from the aluminum foil collection device, and the fibers are collected. The obtained fibers were calcined in a muffle furnace at 500 °C for 2 h at a constant temperature to obtain SnO 2 Nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com