Heatproof freeze-drying protective agent of live vaccine, live vaccine freeze-drying powder and preparation method and preparation method of live vaccine freeze-drying powder

A technology of heat-resistant freeze-drying and live vaccines, applied in the field of heat-resistant freeze-drying protective agents for live vaccines, can solve the problems of limited heat resistance, low stability, damage, etc., to reduce physical damage and enhance heat resistance , The effect of heat resistance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of heat-resistant lyoprotectant

[0030] Unless otherwise specified, the percentages in this embodiment are percentages by weight.

[0031] Among them, casein hydrolyzate was purchased from ShanHai Richu Bioscience Co..Ltd, batch number 090901; polyvinylpyrrolidone (K-30) was purchased from Sinopharm Chemical Reagent Co., Ltd., batch number F20111009; Pluronic F 68 was purchased from From Shanghai Sangon Biotechnology Co., Ltd., batch number HJ0522B2012.

[0032] Heat-resistant lyoprotectant 1 formula:

[0033] Trehalose 68%,

[0034] Glycine 6%,

[0035] Gelatin 3%,

[0036] Casein Hydrolyzate 6%,

[0037] Polyvinylpyrrolidone 6%,

[0038] Glycerin 5%,

[0039] Plunik 68 6%.

[0040] Heat-resistant lyoprotectant 2 formula:

[0041] Trehalose 38%, Sucrose 20%,

[0042] Arginine 1%, glycine 1%, methionine 1%, glutamic acid 1%, isoleucine 3%,

[0043] Gelatin 8%,

[0044] Casein Hydrolyzate 4%,

[0045] Polyvinylpyrrolidone 9%,

[0046...

Embodiment 2

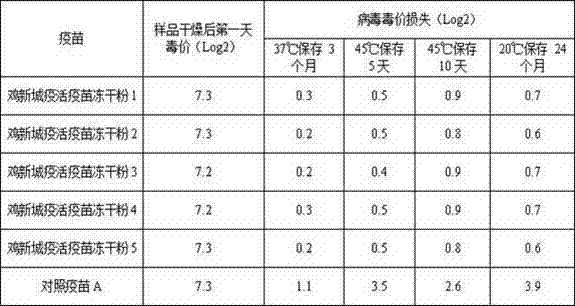

[0074] Example 2 Preparation and Heat Resistance of Newcastle Disease Live Vaccine Freeze-dried Powder

[0075] (1) Preparation of heat-resistant lyoprotectant

[0076] Heat-resistant lyoprotectant 1-5 was prepared according to the method in Example 1.

[0077] (2) Preparation of chicken Newcastle disease virus liquid (live virus liquid)

[0078] Chicken Newcastle disease virus liquid (live virus liquid) was provided by Nanjing Tianbang Biotechnology Co., Ltd. Specific preparation method: According to the relevant requirements of "Compilation of Quality Standards for Veterinary Biology" (2006-2008), chicken Newcastle disease virus liquid (La Sota strain) was prepared, and the virus content of each virus liquid was 10 7.5 EID 50 (chicken embryo test method).

[0079] (3) Preparation of freeze-dried powder of Newcastle disease live vaccine

[0080] Mix the heat-resistant lyoprotectant 1 with sterile water for injection at a mass ratio of 3:7, and after the heat-resistan...

Embodiment 3

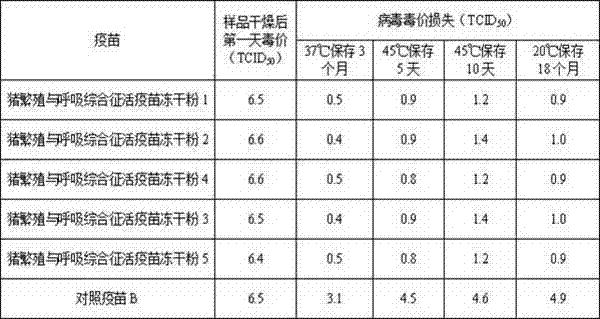

[0097] Example 3 Preparation and heat resistance of porcine reproductive and respiratory syndrome live vaccine freeze-dried powder

[0098] (1) Preparation of heat-resistant lyoprotectant

[0099] Heat-resistant lyoprotectants 1-5 were prepared according to the method in Example 1.

[0100] (2) Preparation of porcine reproductive and respiratory syndrome virus liquid (live virus liquid)

[0101] Porcine reproductive and respiratory syndrome virus liquid (live virus liquid) was provided by Nannong Hi-Tech Biological Products Co., Ltd. Specific preparation method: According to the relevant requirements of the "Compilation of Quality Standards for Veterinary Biology" (2006-2008), the porcine reproductive and respiratory syndrome virus liquid (R98 strain) was prepared, and the virus content of each virus liquid was 10 6.0 TCID 50 (cytometry).

[0102] (3) Preparation of lyophilized powder of porcine reproductive and respiratory syndrome live vaccine

[0103] The correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com