Process for producing PVP-fullerene complex and aqueous solution thereof

The technology of a fullerene compound and its manufacturing method is applied in the field of manufacturing PVP-fullerene compound and its aqueous solution, which can solve the problems such as difficulty in forming a water-soluble solution and specifically forming an aqueous solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

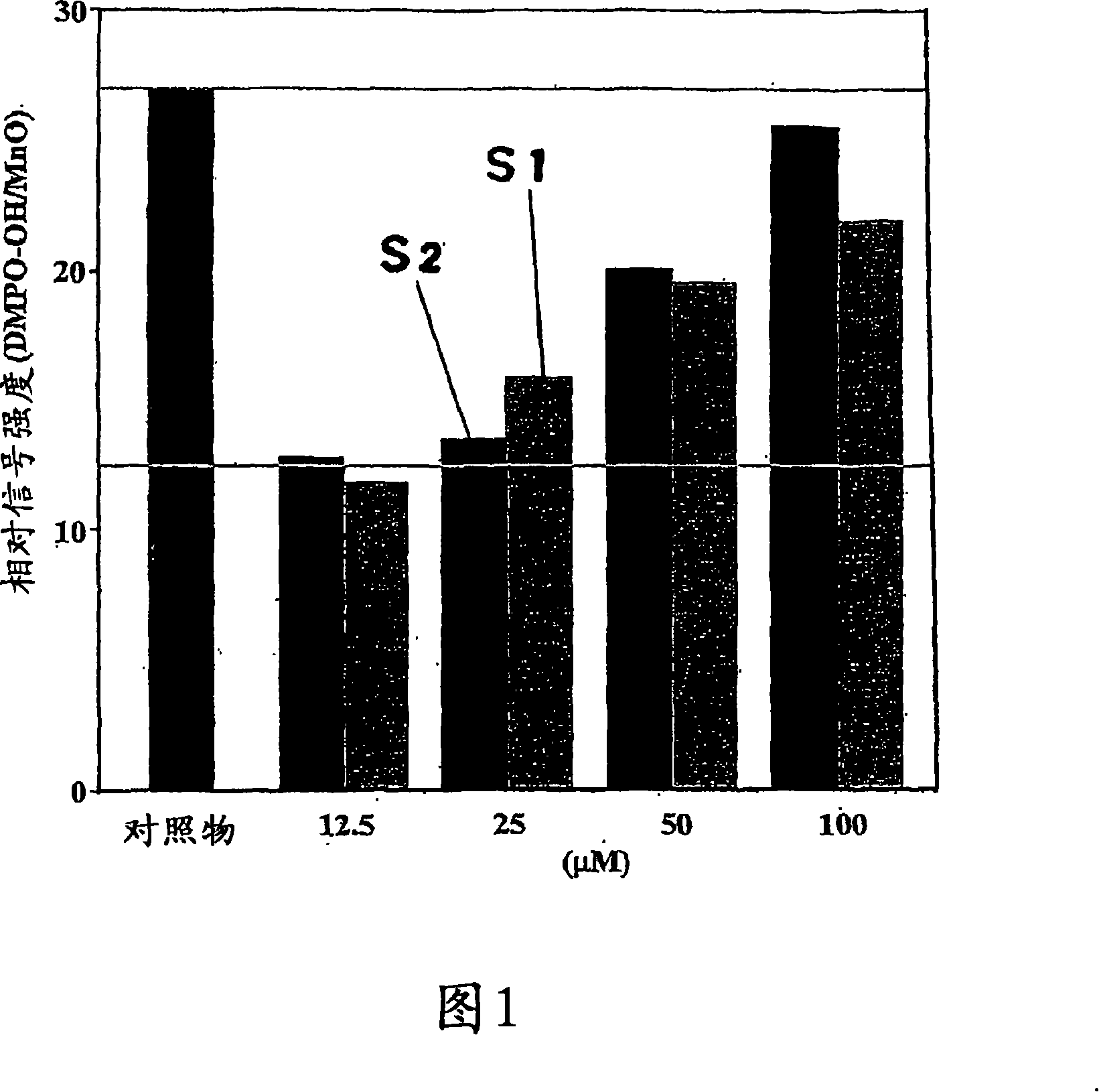

Image

Examples

Embodiment

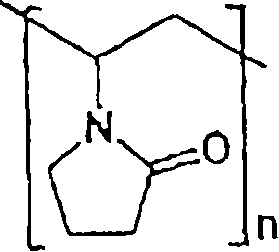

[0035] A solution of 16.0 mg of toluene (20 ml) of MIX (mixed) fullerene (average molecular weight 744: powder) containing C60 fullerene and C70 fullerene, ethanol (10 ml of 2.0 g of PVP of weight average molecular weight 60000) were prepared respectively. ) solution, the two were mixed at room temperature and stirred for 12 hours. Thus, a uniform mixed solution was obtained.

[0036] Then, this homogeneous mixed solution was evaporated to dryness, and then 30 ml of water was added to form a suspension.

[0037] The suspension was evaporated, and the toluene was distilled off by azeotropy to make it dry. Then 30ml of water was added and sonicated for 15 minutes. Thus, an aqueous PVP-fullerene complex solution was obtained. Filtration (0.80 micron filter) was performed to obtain the final PVP-fullerene complex aqueous solution.

[0038] The obtained aqueous solution had high transparency, and no trace of a black precipitate formed when left at room temperature for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com