Aligned carbon nano tube/molybdenum disulfide composite fiber and preparation method and application thereof

A technology of oriented carbon nanotubes and molybdenum disulfide, applied in the field of energy storage devices, can solve the problems of easy agglomeration, small binding force of active materials, poor electrical conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

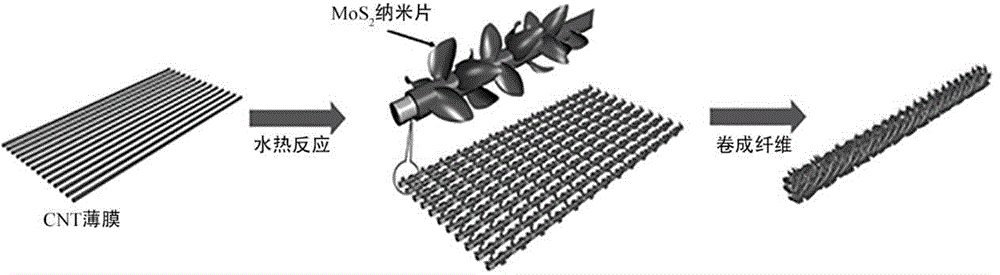

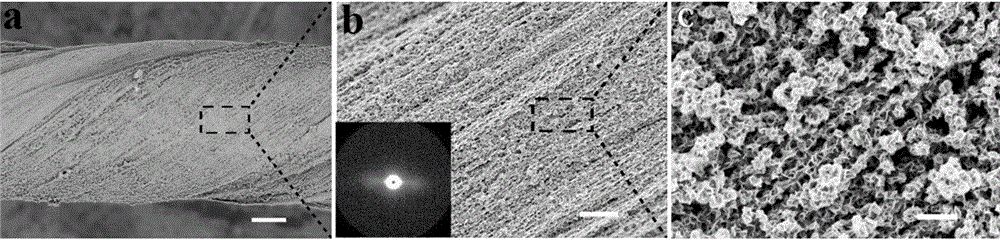

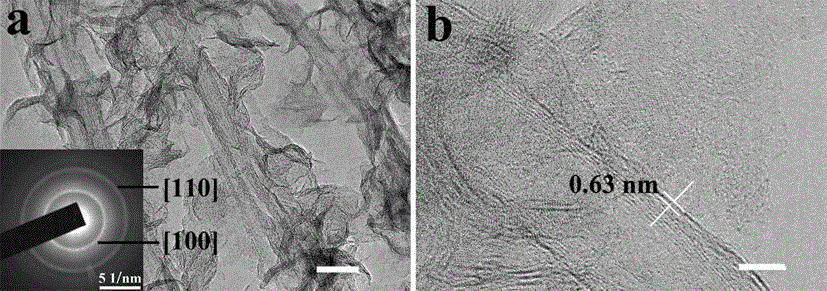

[0039] CNT / MoS 2 Preparation of nanocomposite fibers. Weigh 25 mg of polyvinylpyrrolidone (molecular weight: 40,000), dissolve it in 50 mL of N-dimethylformamide, and stir at high speed for 1 hour. Then 100 mg of ammonium thiomolybdate was added, ultrasonicated for 1 hour and then stirred for 5 hours to obtain a uniform precursor solution. Transfer the precursor solution to a hydrothermal kettle, immerse the aligned carbon nanotube film drawn on a polytetrafluoroethylene plate in the precursor solution, and conduct a hydrothermal reaction at 220°C in a muffle furnace for 5 hours. After cooling to room temperature, the reaction Oriented CNT / MoS after 2 The composite film is rolled into a fiber and dried at 80°C for 12 hours.

[0040] Fabrication of fibrous supercapacitors and lithium-ion batteries. Two aligned CNT / MoS 2 The composite fibers are coated with an electrolyte solution and rolled into a wire-like supercapacitor. The preparation process of the gel electrolyte us...

Embodiment 2

[0042] CNT / MoS 2 Preparation of nanocomposite fibers. Weigh 34.2 mg of polyvinylpyrrolidone (molecular weight: 50,000), dissolve it in 70 mL of N-dimethylformamide, and stir at high speed for 1 hour. Then 137 mg of ammonium thiomolybdate was added, ultrasonically treated for 2 hours and then stirred for 10 hours to obtain a uniform precursor solution. Transfer the precursor solution to a hydrothermal kettle, immerse the aligned carbon nanotube film drawn on a polytetrafluoroethylene plate in the precursor solution, and conduct a hydrothermal reaction at 220°C in a muffle furnace for 6 hours. After cooling to room temperature, the reaction Oriented CNT / MoS after 2 The composite film is rolled into a fiber and dried at 85°C for 12 hours.

[0043] Fabrication of fibrous supercapacitors and lithium-ion batteries. Two aligned CNT / MoS 2 The composite fibers are coated with an electrolyte solution and rolled into a wire-like supercapacitor. The preparation process of the gel el...

Embodiment 3

[0045] CNT / MoS 2 Preparation of nanocomposite fibers. Weigh 50 mg of polyvinylpyrrolidone (molecular weight: 80,000), dissolve it in 100 mL of N-dimethylformamide, and stir at high speed for 1 hour. Then 150 mg of ammonium thiomolybdate was added, ultrasonically treated for 5 hours and then stirred for 12 hours to obtain a uniform precursor solution. Transfer the precursor solution to a hydrothermal kettle, immerse the aligned carbon nanotube film drawn on a polytetrafluoroethylene plate in the precursor solution, and conduct a hydrothermal reaction at 220°C in a muffle furnace for 8 hours. After cooling to room temperature, the reaction Oriented CNT / MoS after 2 The composite film is rolled into a fiber and dried at 90°C for 12 hours.

[0046] Fabrication of fibrous supercapacitors and lithium-ion batteries. Two aligned CNT / MoS 2 The composite fibers are coated with an electrolyte solution and rolled into a wire-like supercapacitor. The preparation process of the gel ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com