Method for preparing Co3O4 nanometer sheet

A technology of nanosheets and cobalt chloride, which is applied in the field of preparation of cobalt oxide nanosheets to achieve the effects of easy operation, low cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

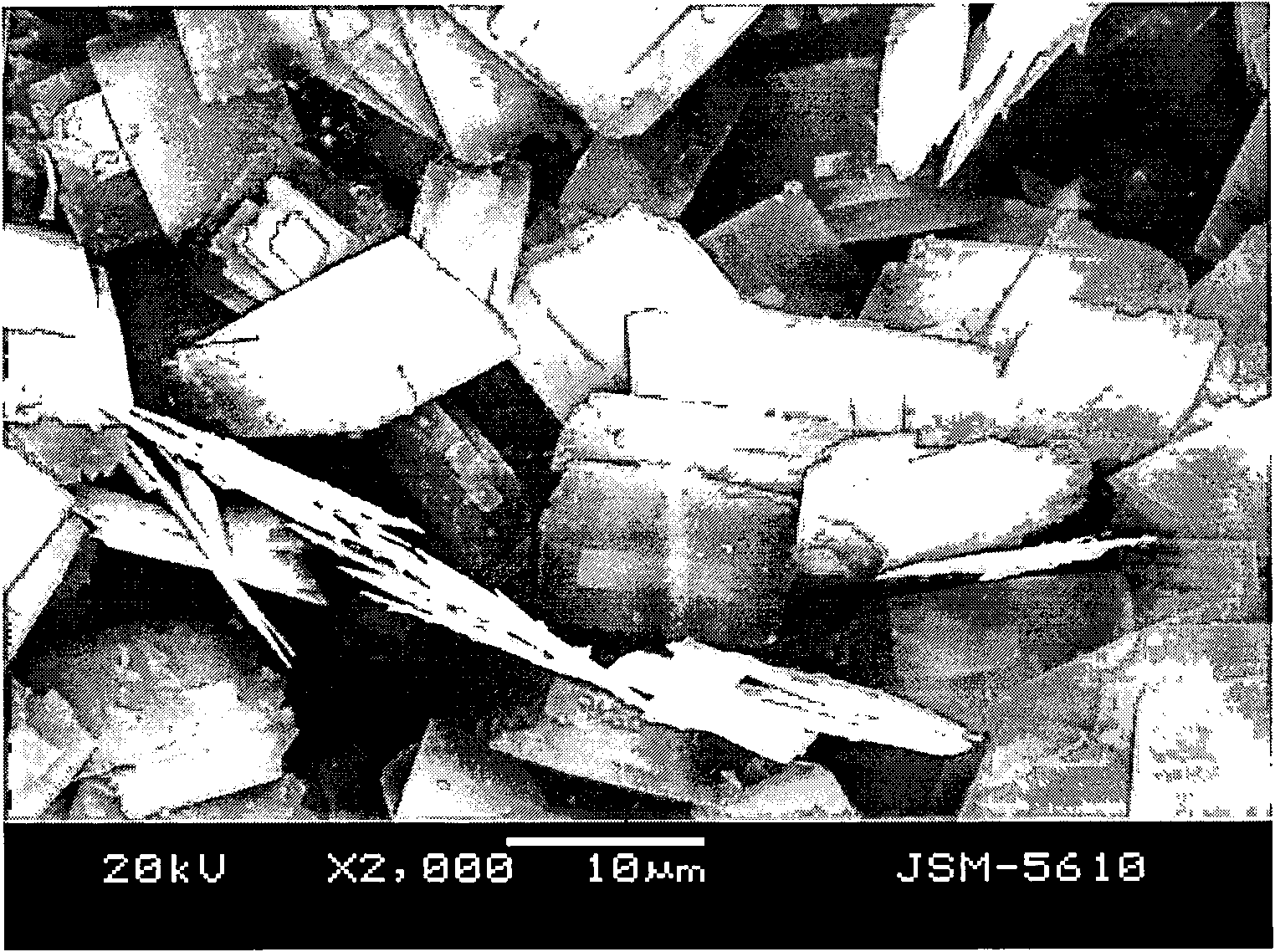

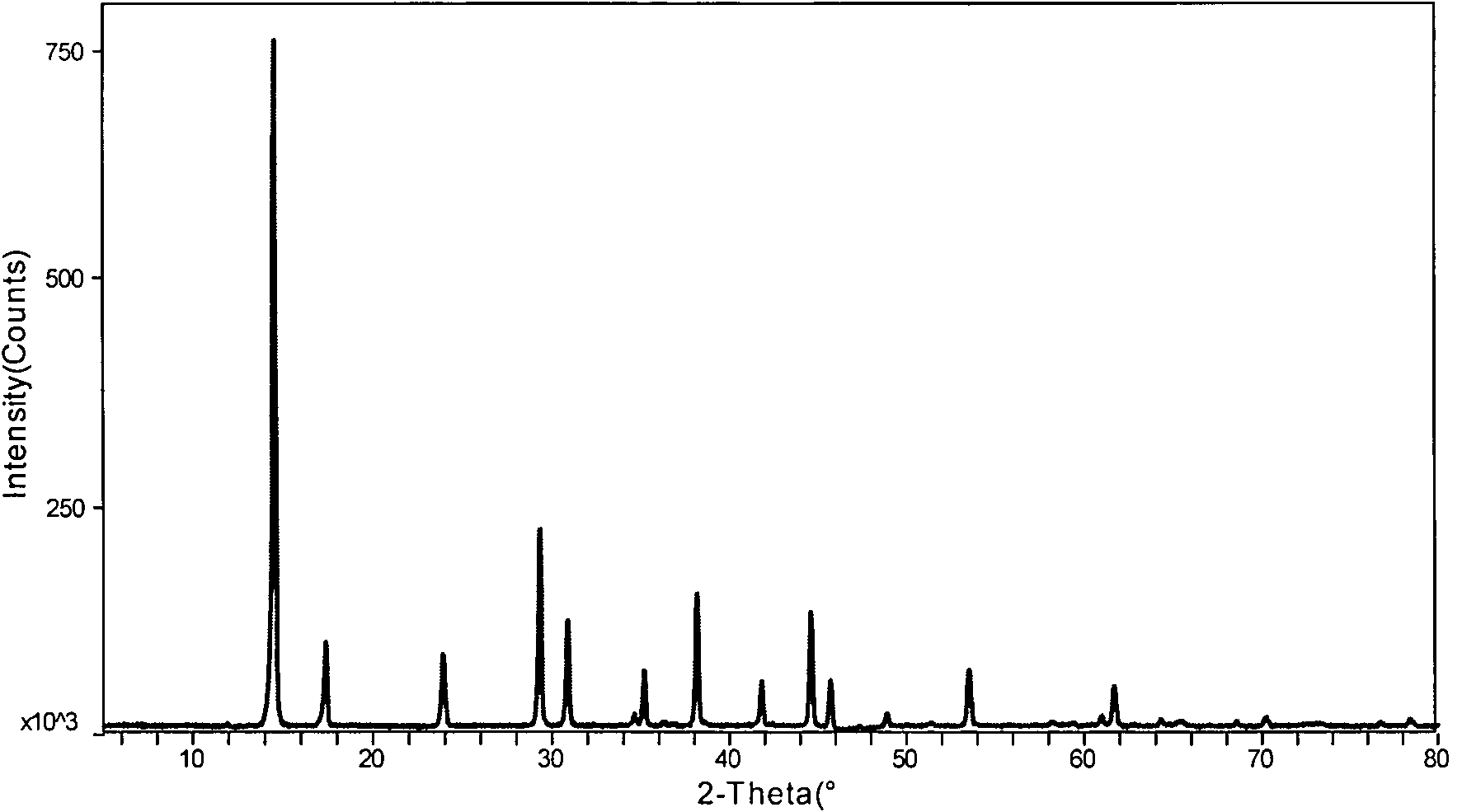

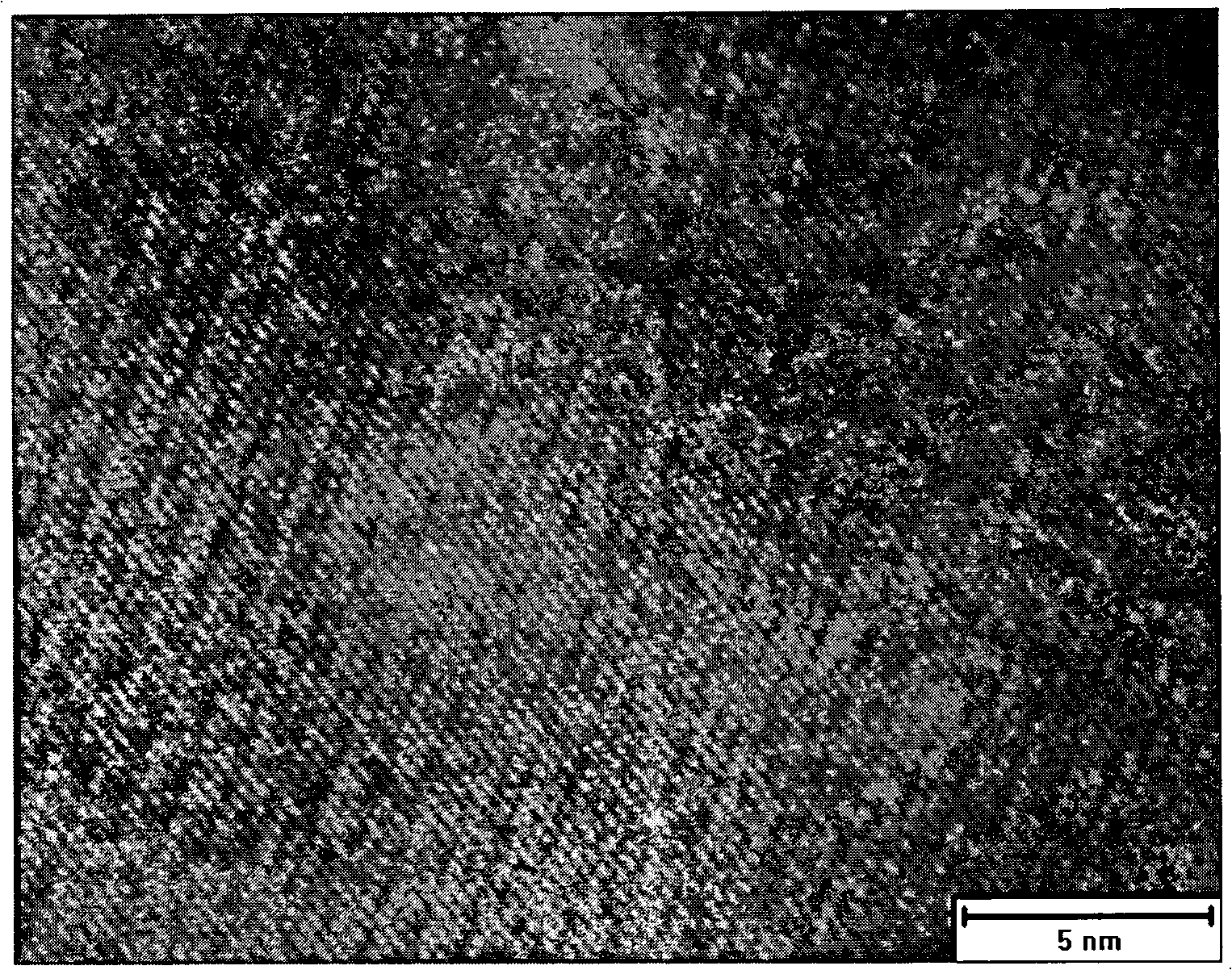

[0020] 2mmol cobalt chloride CoCl 2 ·6H 2 O, 6mmol urea CO(NH 2 ) 2 Dissolve in 20mL of distilled water, then add 1.005g of PVP, and dissolve it completely under magnetic stirring, transfer the mixed solution into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, the filling degree is 80%, after sealing It was heated to 160° C., kept at a temperature of 8 hours, and then naturally cooled to room temperature. The gray precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 80° C. for 6 hours to obtain the precursor. Then calcined at 500°C for 5 hours, the obtained black product is Co 3 o 4 Nanosheets. The resulting black product was directly observed under a scanning electron microscope to obtain figure 1 As shown in the structure, it can be found that the precursor product is composed of a large number of rectangular nanosheets. These nanosheets are uniform in size, with a length and width of about 5 μm×...

Embodiment 2

[0022] 2mmol cobalt chloride CoCl 2 6H2O, 6mmol urea CO(NH 2 ) 2 Dissolve in 20mL of distilled water, then add 1.005g of PVP, and dissolve it completely under magnetic stirring, transfer the mixed solution into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, the filling degree is 80%, after sealing It was heated to 160° C., kept at this temperature for 12 hours, and then naturally cooled to room temperature. The gray precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 80° C. for 6 hours to obtain the precursor. Then calcined at 500°C for 5 hours, the obtained black product is Co 3 o 4 Nanosheets. The morphology of the product, properties such as structure and composition are all similar to Example 1.

Embodiment 3

[0024] 2mmol cobalt chloride CoCl 2 ·6H 2 O, 6mmol urea CO(NH 2 ) 2 Dissolve in 20mL of distilled water, then add 1.005g of PVP, and dissolve it completely under magnetic stirring, transfer the mixed solution into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, the filling degree is 80%, after sealing It was heated to 180° C., kept at this temperature for 8 hours, and then naturally cooled to room temperature. The gray precipitate was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 80° C. for 6 hours to obtain the precursor. Then calcined at 500°C for 5 hours, the obtained black product is Co 3 o 4 Nanosheets. The morphology of the product, properties such as structure and composition are all similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com