Core-shell structure metal/polymer nanofiber and preparation method thereof

A nanofiber, core-shell structure technology, applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, fiber chemical characteristics, etc., can solve the problem of not being able to form nanofibers, achieve easy characterization, low equipment requirements, and promote reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

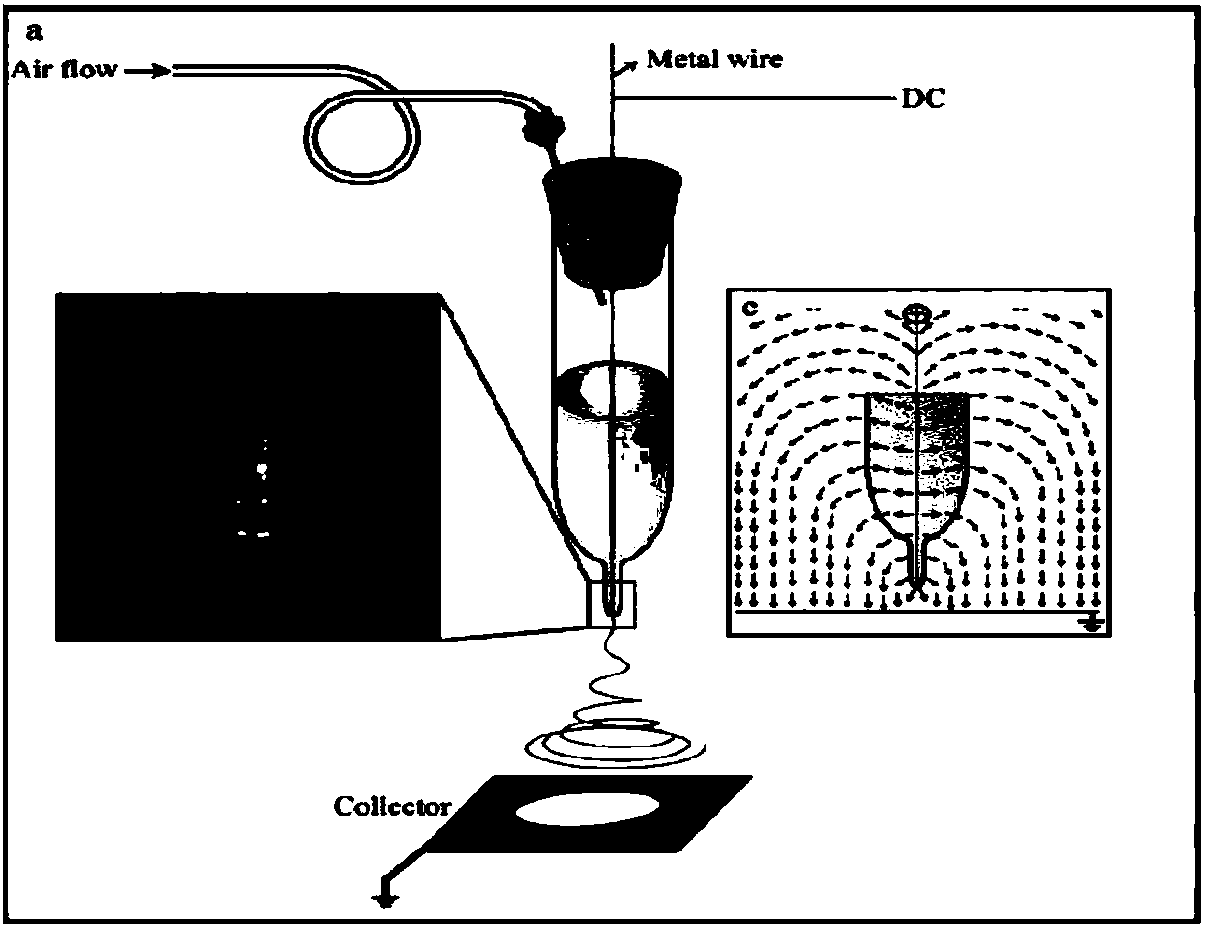

[0030] 1) Dissolve polyvinylpyrrolidone (K90) powder with a weight-average molecular weight of 1,300,000 in ethanol solvent, and magnetically stir for 10 hours to prepare an 8wt% polyvinylpyrrolidone solution;

[0031] 2) dissolving silver nitrate in the polyvinylpyrrolidone solution in step 1), stirring magnetically for 2 hours, to prepare a spinning solution of 30wt% silver nitrate;

[0032] 3) Put the spinning solution in step 2) into the self-made solution supply device, adjust the receiving distance to 25cm, turn on the high voltage power supply, adjust the spinning voltage to 12KV, and control the flow rate to 0.2ml / h;

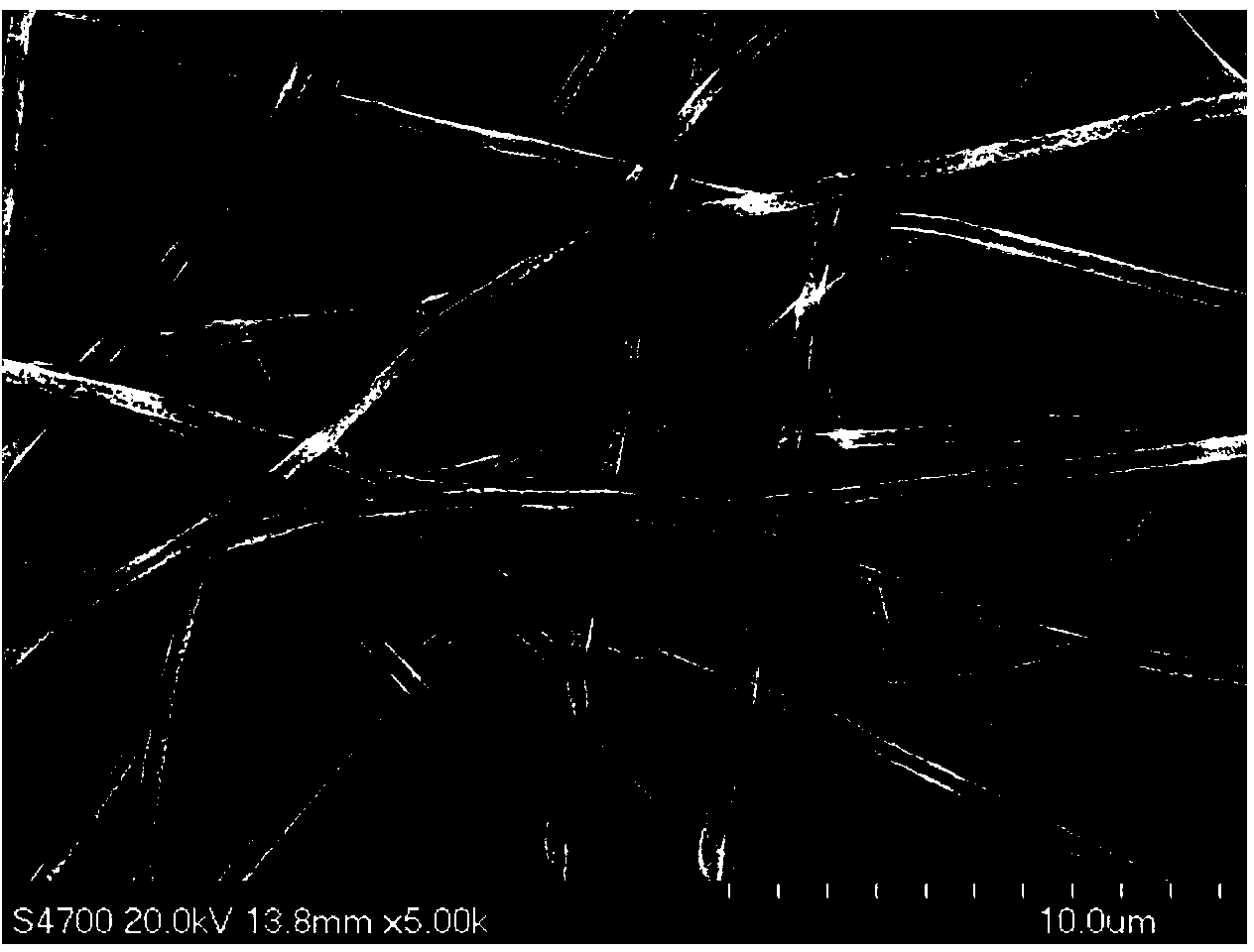

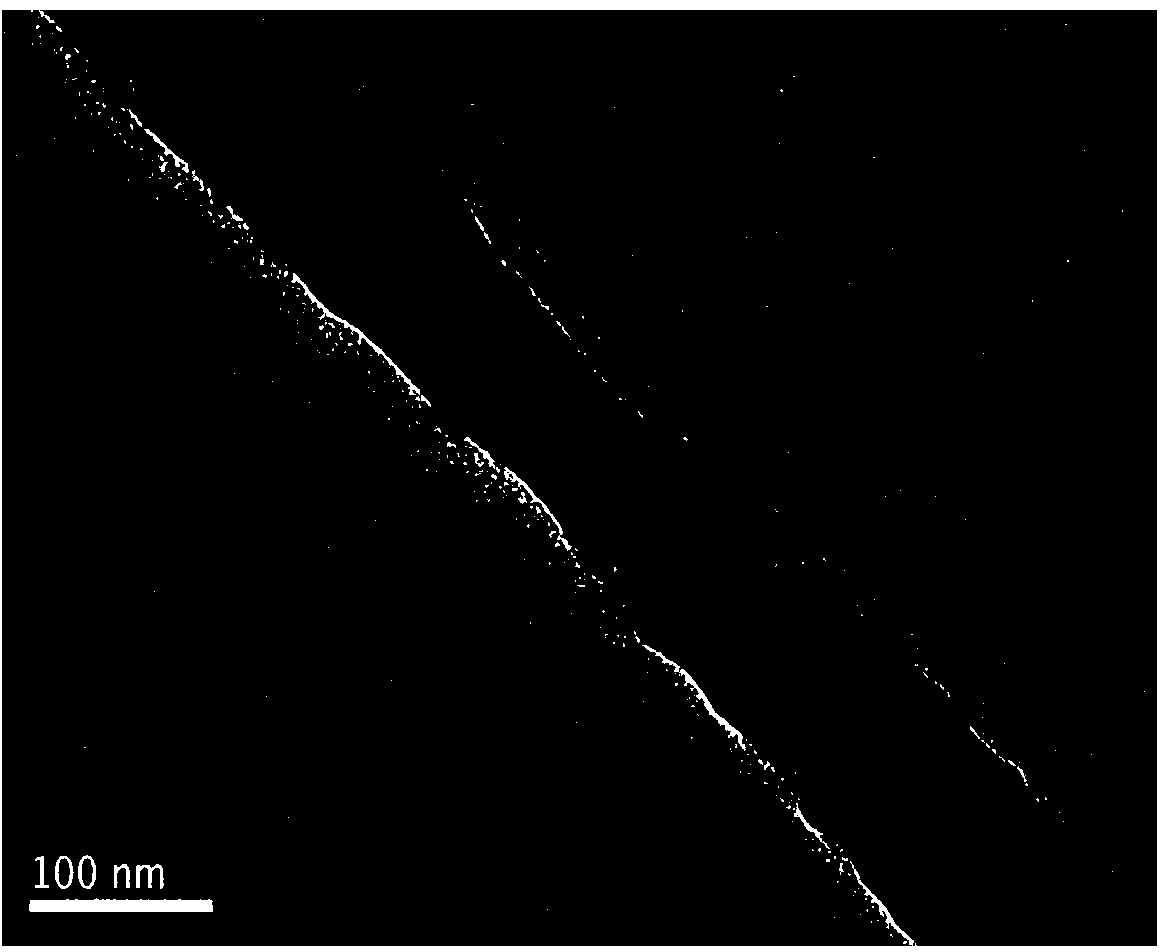

[0033] 4) Electrospinning experiments were carried out under dark conditions, and a metal / polymer nanofiber membrane with a core-shell structure was obtained on an aluminum foil collector. application value;

[0034] 5) The fiber membrane is subjected to heating or ultraviolet irradiation treatment to further promote the reduction of silver ions on the ...

Embodiment 2

[0036] 1) Configure a mixed solvent of ethanol / water=8 / 2 (w / w);

[0037] 2) Dissolve polyvinylpyrrolidone (K90) powder with a weight average molecular weight of 1,300,000 in the solvent of step 1), and stir magnetically for 12 hours to prepare a 10wt% polyvinylpyrrolidone solution;

[0038] 3) dissolving copper chloride in the polyvinylpyrrolidone solution in step 2), and magnetic stirring for 4 hours to prepare a spinning solution of 40wt% copper chloride;

[0039] 4) Put the spinning solution in step 3) into the self-made solution supply device, adjust the receiving distance to 30cm, turn on the high voltage power supply, adjust the spinning voltage to 15KV, and control the flow rate to 0.4ml / h;

[0040] 5) Electrospinning experiments were carried out under dark conditions, and a metal / polymer nanofiber membrane with a core-shell structure was obtained on an aluminum foil collector. application value;

[0041] 6) The fiber membrane is subjected to heating or ultraviolet ir...

Embodiment 3

[0043] 1) Dissolve polyvinyl alcohol powder with a weight average molecular weight of 180,000 in deionized water, and magnetically stir for 20 hours to make a 10wt% polyvinyl alcohol solution;

[0044] 2) Dissolve silver nitrate in the polyvinyl alcohol solution in step 1), add an appropriate amount of nitric acid, adjust the pH value to about 4, and magnetically stir for 10 hours to prepare a spinning solution of 30wt% silver nitrate;

[0045] 3) Put the spinning solution in step 2) into the self-made solution supply device, adjust the receiving distance to 25cm, turn on the high voltage power supply, adjust the spinning voltage to 15KV, and control the flow rate to 0.5ml / h;

[0046] 4) Electrospinning experiments were carried out under dark conditions, and a metal / polymer nanofiber membrane with a core-shell structure was obtained on an aluminum foil collector. application value;

[0047]5) The fiber membrane is subjected to heating or ultraviolet irradiation treatment to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com