Compound low dosage natural gas hydrate inhibitor

A hydrate inhibitor, low-dose technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of kinetic inhibitor failure, achieve the effect of reducing cost and logistics support burden, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

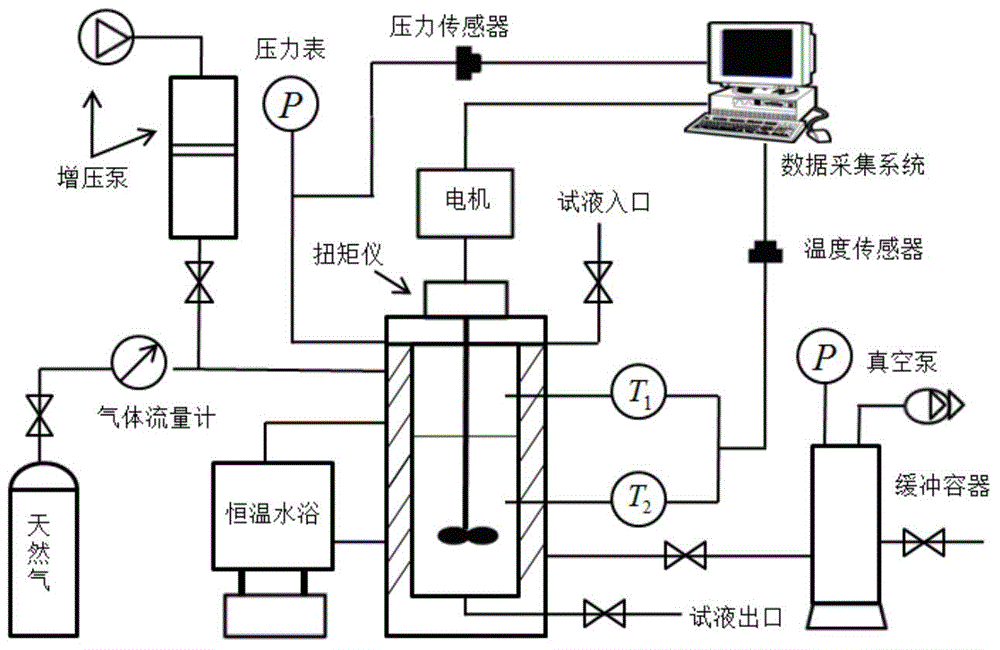

Image

Examples

Embodiment 1

[0042] Polyvinylpyrrolidone and polyoxyethylene were prepared in a mass ratio of 2:1 to prepare a composite low-dose natural gas hydrate inhibitor aqueous solution with a mass percentage of 1.2%. Put it into the reaction kettle of the natural gas hydrate inhibition evaluation experimental device, and simulate the drilling environment at a water depth of 500m, that is, the experimental pressure is 5MPa, the experimental temperature is 2°C, the stirring speed is 200r / min, and no hydrate is formed in the reaction kettle within 16 hours.

Embodiment 2

[0044] Polyvinyl caprolactam and ethylene glycol phenyl ether were prepared according to the mass ratio of 2:1 to prepare a composite low-dose natural gas hydrate inhibitor aqueous solution with a mass percentage of 1.5%. Put it into the reaction kettle of the natural gas hydrate inhibition evaluation experimental device, and simulate the drilling environment at a water depth of 800m, that is, the experimental pressure is 8MPa, the experimental temperature is 2°C, the stirring speed is 200r / min, and no hydrate is formed in the reaction kettle within 16h.

Embodiment 3

[0046] Prepare the copolymer generated by the reaction of vinyl caprolactam, vinyl pyrrolidone, vinyl sulfonic acid and isopropyl methacrylamide, the preparation method is as follows:

[0047] Into a four-neck flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen inlet and outlet, add 200mL of methanol, then add 14.4g of vinylpyrrolidone and 18g of vinylcaprolactam, stir and heat through nitrogen to a temperature of 60°C, add 0.32 g azobisisobutyronitrile. The aqueous solution containing 7g of vinylsulfonic acid was added dropwise to the four-necked flask, and the addition was completed within 2 hours, and the reaction was carried out at 60°C for 8 hours. Add 4.2 g of isopropyl methacrylamide and react at 60° C. for 8 hours to obtain a reaction product. The product was precipitated into excess hexane, redissolved in tetrahydrofuran, reprecipitated into hexane, and dried in vacuo to obtain a sample of the inhibitor.

[0048] The prepared inhibitor sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com