Patents

Literature

178 results about "Vinylsulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

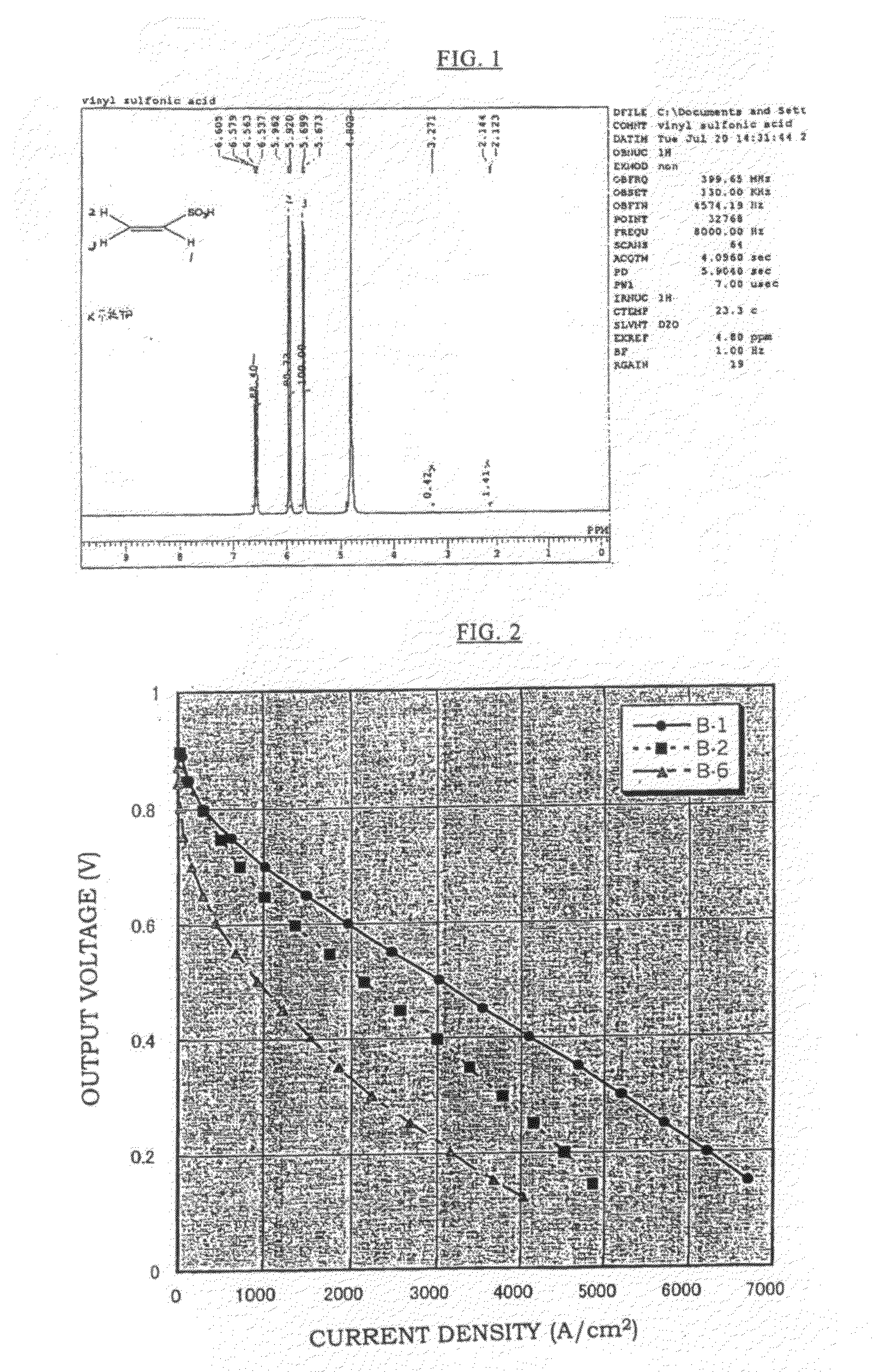

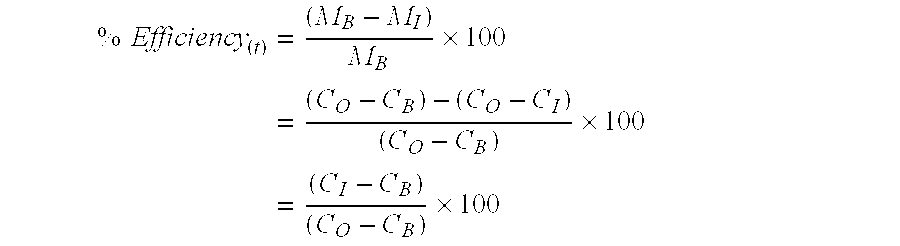

Vinylsulfonic acid is the organosulfur compound with the formula CH₂=CHSO₃H. It is the simplest unsaturated sulfonic acid. The C=C double bond is a site of high reactivity. polymerize gives polyvinylsulfonic acid, especially when used as a comonomer with functionalized vinyl and (meth)acrylic acid compounds. It is a colorless, water-soluble liquid, although commercial samples can appear yellow or even red.

Fabric softening laundry detergent

InactiveUS20100190679A1Easy to cleanAvoidingOrganic detergent compounding agentsNon-ionic surface-active compoundsMethacrylamideVinylsulfonic acid

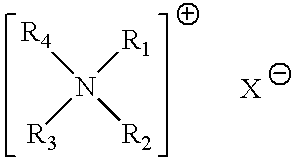

Aqueous laundry detergent compositions containing surfactants and fatty acid, having a pH of from about 6 to about 11 and containing a polymer having a number average molecular weight of from about 700,000 to about 4,000,000 and comprising monomeric units including: nonionic monomers selected from acrylamide, N,N-dialkyl acrylamide, methacrylamide, N,N-dialkylmethacrylamide, hydroxyalkyl acrylate and vinyl pyrrolidone, vinyl acetate, vinyl alcohol, and mixtures thereof; cationic monomers selected from N,N-dialkylaminoalkyl methacrylate, N,N-dialkylaminoalkyl acrylate, N,N-dialkylaminoalkyl acrylamide, N,N-dialkylaminoalkylmethacrylamide, methacylamidoalkyl trialkylammonium chloride, acrylamidoalkylltrialkylammonium chloride, vinylamine, quaternized vinyl imidazole and diallyl dialkyl ammonium chloride, and mixtures thereof; and anionic monomers selected from acrylic acid, methacrylic acid, maleic acid, vinyl sulfonic acid, styrene sulfonic acid, acrylamidopropylmethane sulfonic acid (AMPS), salts thereof, and mixtures thereof; in a specified mole ratio.

Owner:THE PROCTER & GAMBLE COMPANY

Polyether-containing copolymer

Owner:BASF CONSTR SOLUTIONS

Polyether-containing copolymer

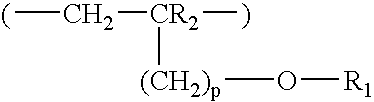

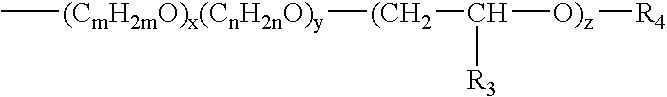

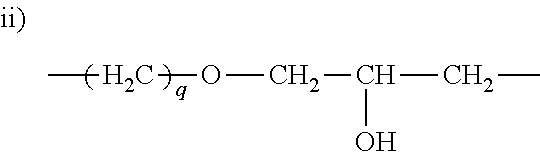

Copolymers include two monomer components, a) an olefinic unsaturated monocarboxylic acid comonomer or an ester or a salt thereof of an olefinic unsaturated sulfuric acid comonomer or a salt thereof, and b) an ether comonomer of the general formula (I) Components a) and b) are present in amounts of from 30 to 90 mol-% and from 70 to 10 mol-%, respectively, and comonomer component a) is selected from the group consisting of acrylic acid, methacrylic acid, crotonic acid, isocrotonic acid, allylsulfonic acid, vinylsulfonic acid and a salt thereof or an alkyl or hydroxyalkyl ester. Compositions including a hydraulic binder such as cement, gypsum, lime and anhydrite and the copolymer are also disclosed. The copolymer can be used as superplasticizer or dispersant for non-hardened (wet) and a hydraulic binder containing compositions.

Owner:BASF CONSTR POLYMERS

High-Temperature Crosslinked Polymer for Use in a Well

A method comprising the steps of: (A) forming a fluid comprising a crosslinked polymer, wherein the crosslinked polymer comprises: (i) a first monomeric unit of one or more N-vinyl lactams; and (ii) a crosslinker selected from the group consisting of: divinyl ether, diallyl ether, vinyl or allyl ethers of polyglycols or polyols, divinylbenzene, 1,3-divinylimidazolidin-2-one, divinyltetrahydropyrimidin-2(1H)-one, dienes, allyl amines, N-vinyl-3(E)-ethylidene pyrrolidone, ethylidene bis(N-vinylpyrrolidone), and any combination of any of the foregoing; and (B) introducing the fluid into a portion of a well. The crosslinked polymer may additionally comprise: a second monomeric unit selected from the group consisting of: acrylamide, N-substituted acrylamides, methacrylamide, N-substituted methacrylamides, acrylates, methacrylates, acrylic acid, methacrylic acid, N-vinylamides, N-allyl amides, vinyl alcohol, vinyl ethers, vinyl esters, allyl alcohol, allyl ethers, allyl esters, vinylpyridine, vinyl sulfonates, allyl sulfonates, vinylimidazole, allylimidazole, diallyldimethylammonium chloride, and any combination of any of the foregoing.

Owner:HALLIBURTON ENERGY SERVICES INC

Cationic polymer coating agent for water-base drilling fluid and preparation method thereof

InactiveCN101775272AModerate molecular weightMild reaction conditionsDrilling compositionWater basedPolymer science

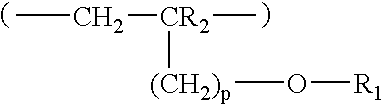

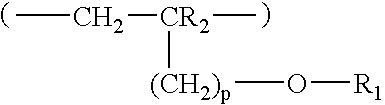

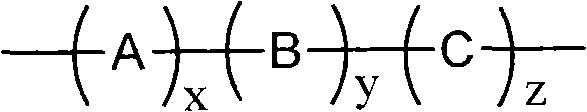

The invention relates to a cationic polymer coating agent for water-base drilling fluid, which has the following structural formula, wherein A is a first monomer which is selected from one of N,N-dimethylacrylamide, acrylamide or N,N-diethylacrylamide, B is a second monomer which is selected from one of methacryloyloxyethyl trimethyl ammonium chloride, dimethyldiallylammonium chloride or acryloyloxyethyl trimethyl ammonium chloride, and C is a third monomer which is selected from 2-acrylamido-2-methylpropanesulfonic acid, vinyl sulfonic acid or methacrylic acid, wherein x is 40-120, y is 1-20, and z is 1-10. The invention also relates to a preparation method of the cationic polymer coating agent. When the cationic polymer coating agent of the invention is used for a water-base drilling fluid system, the cationic polymer coating agent has good rock debris coating effect and can improve the performance of the water-base drilling fluid system.

Owner:CHINA NAT OFFSHORE OIL CORP +2

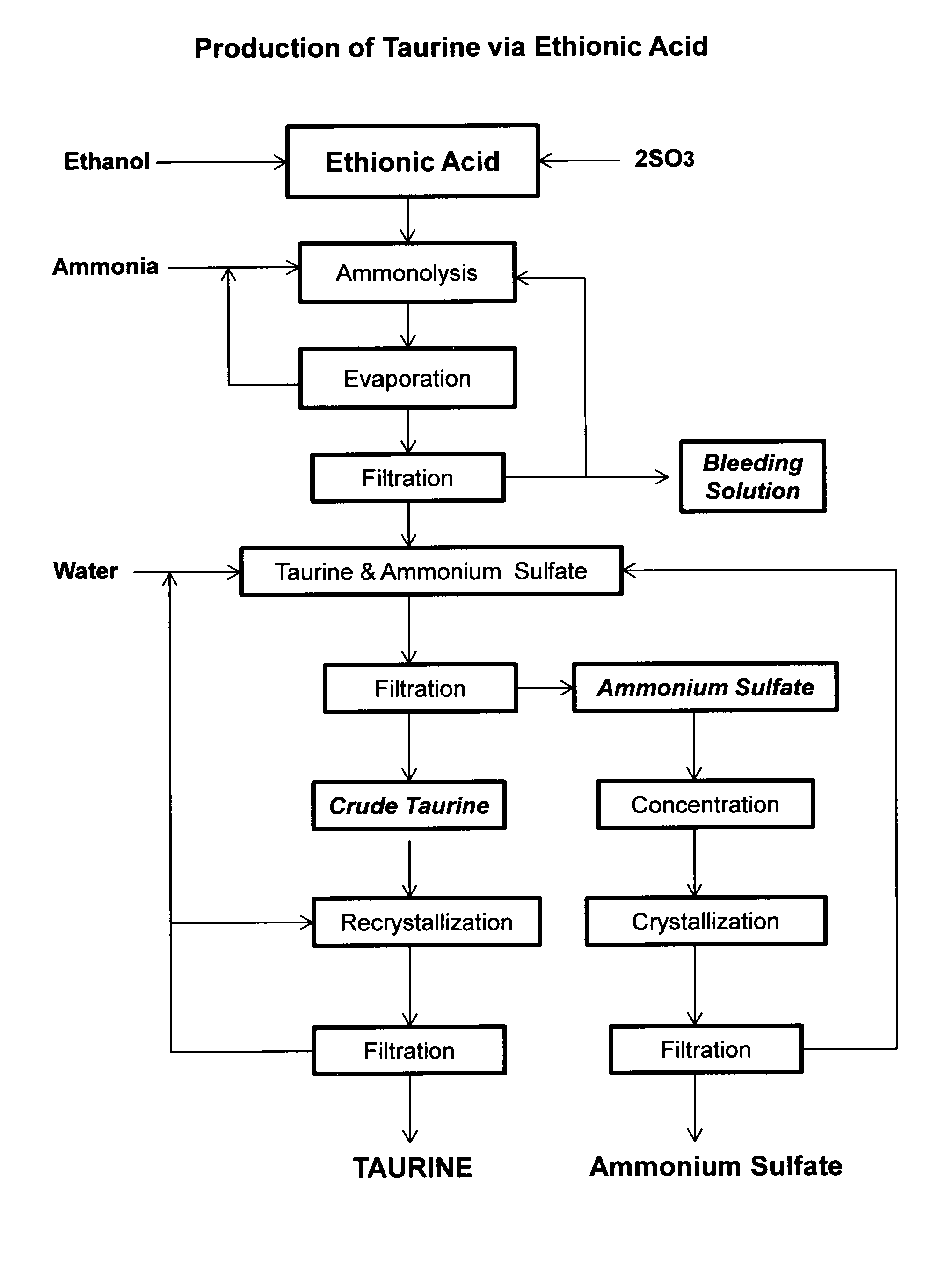

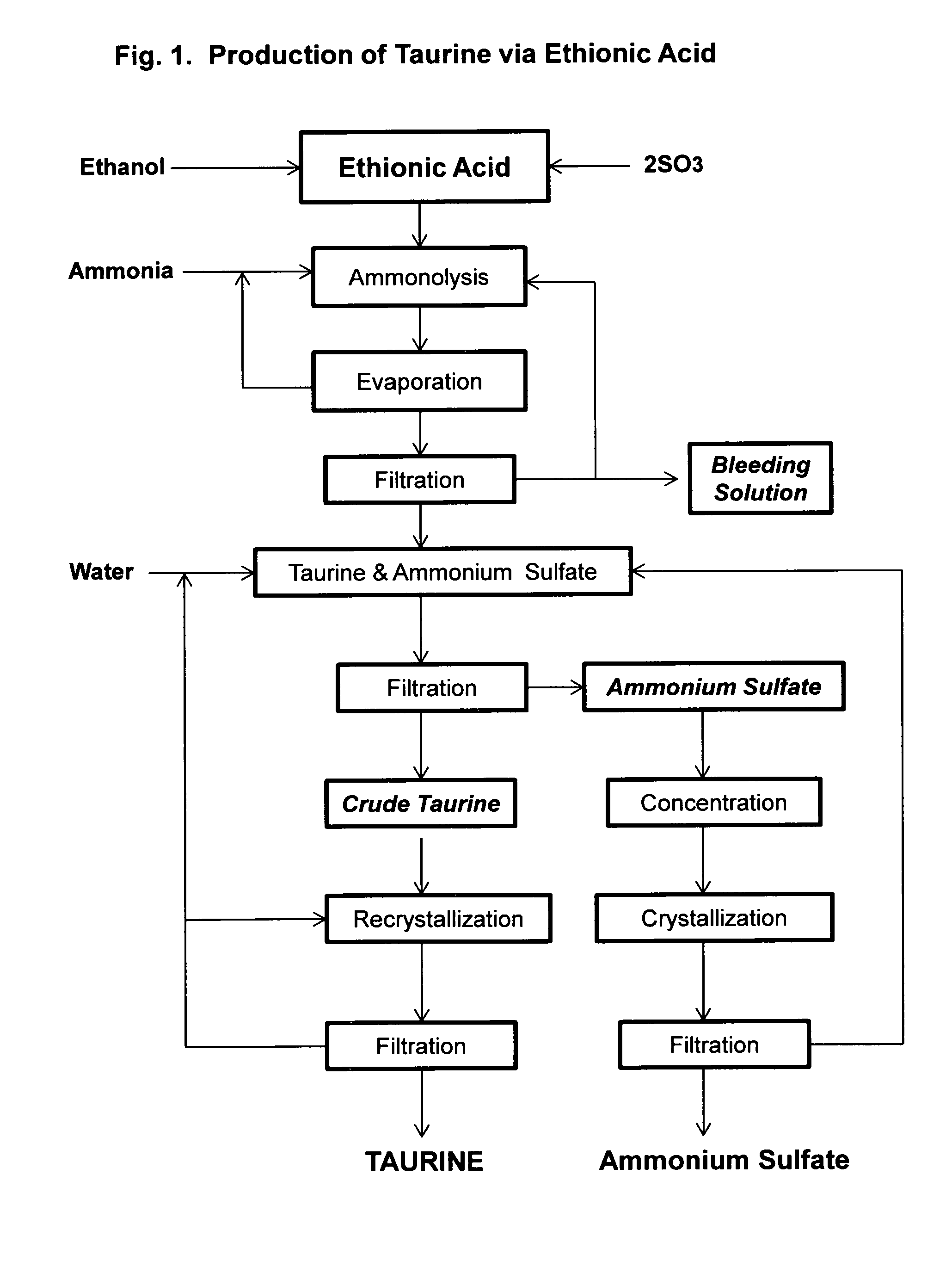

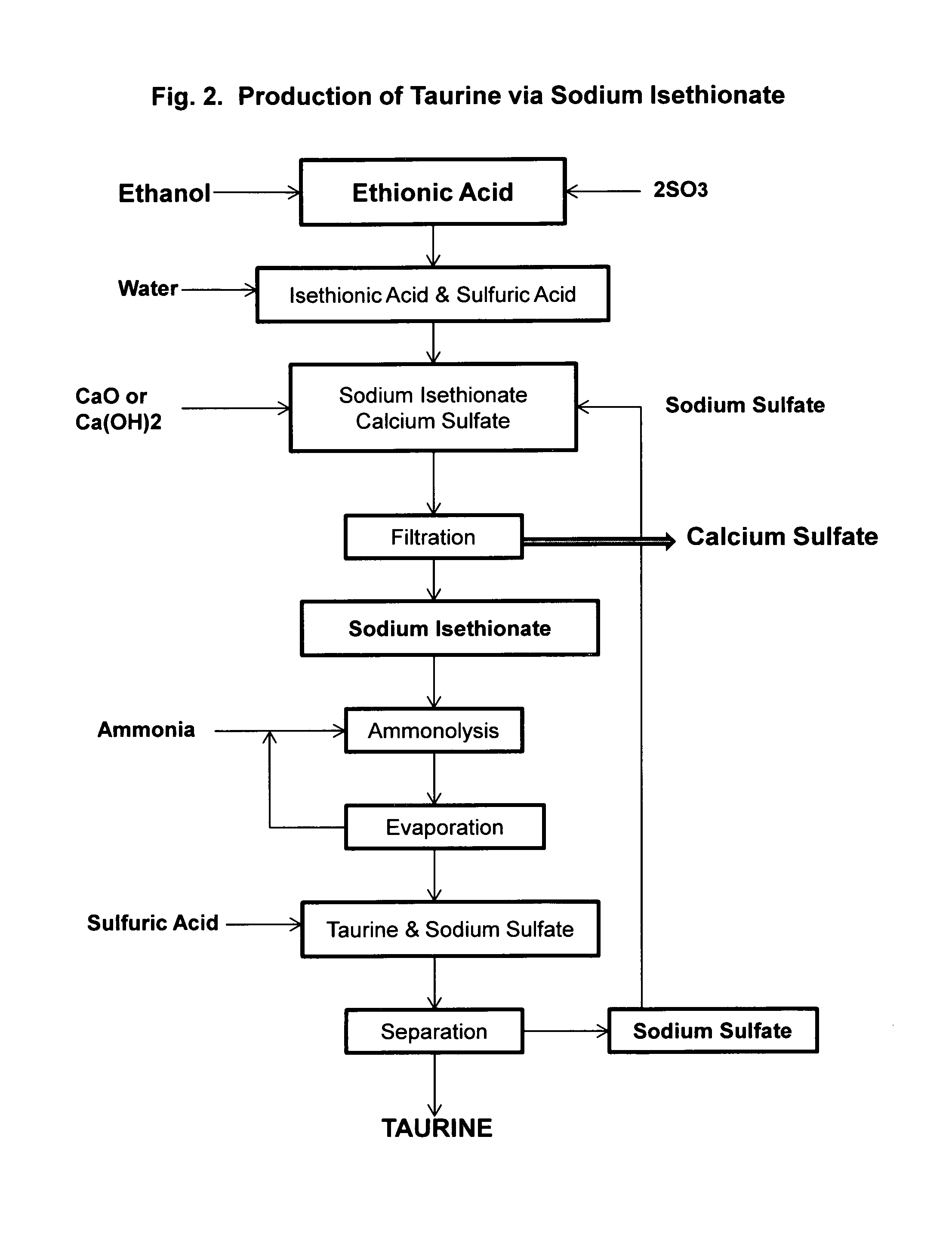

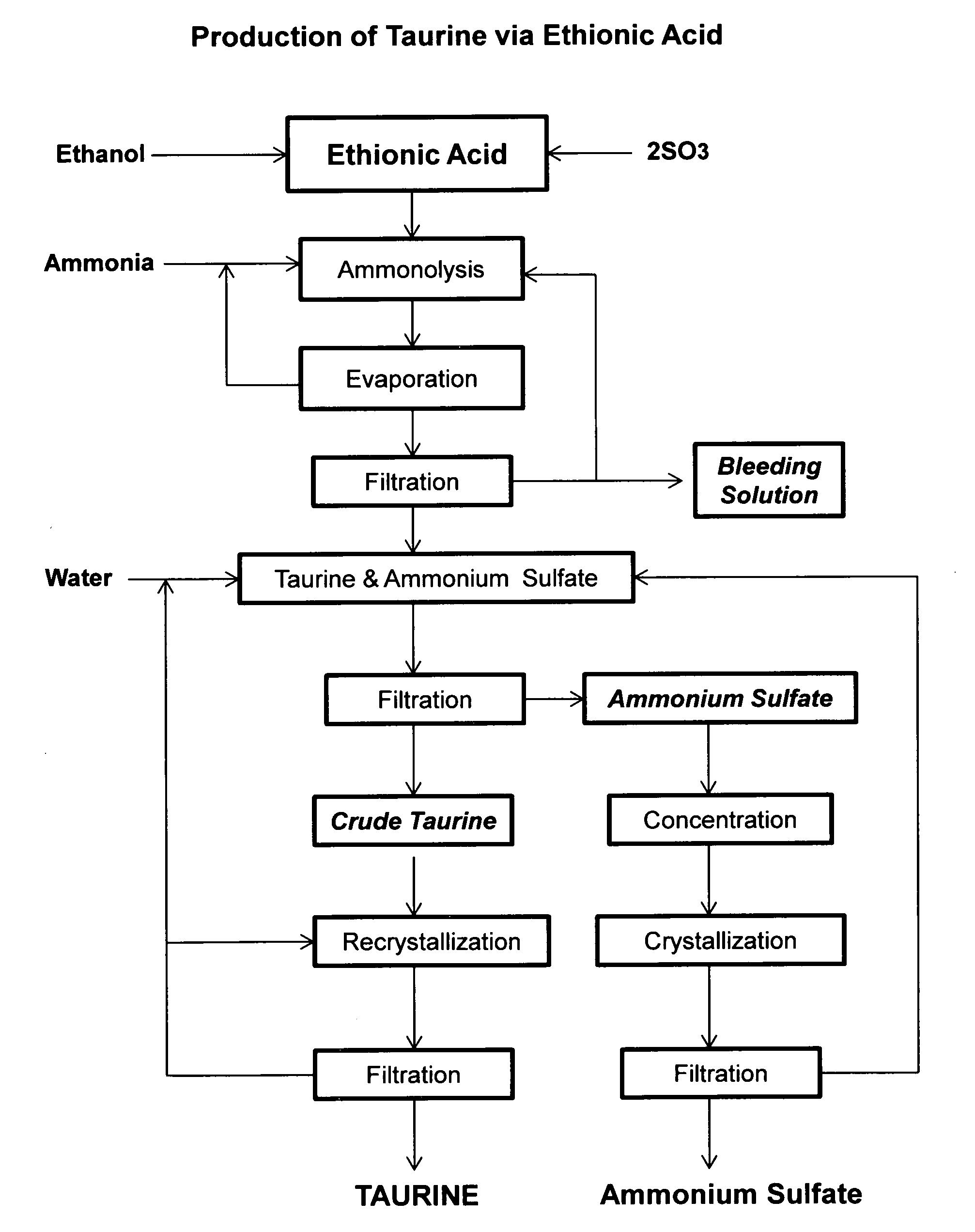

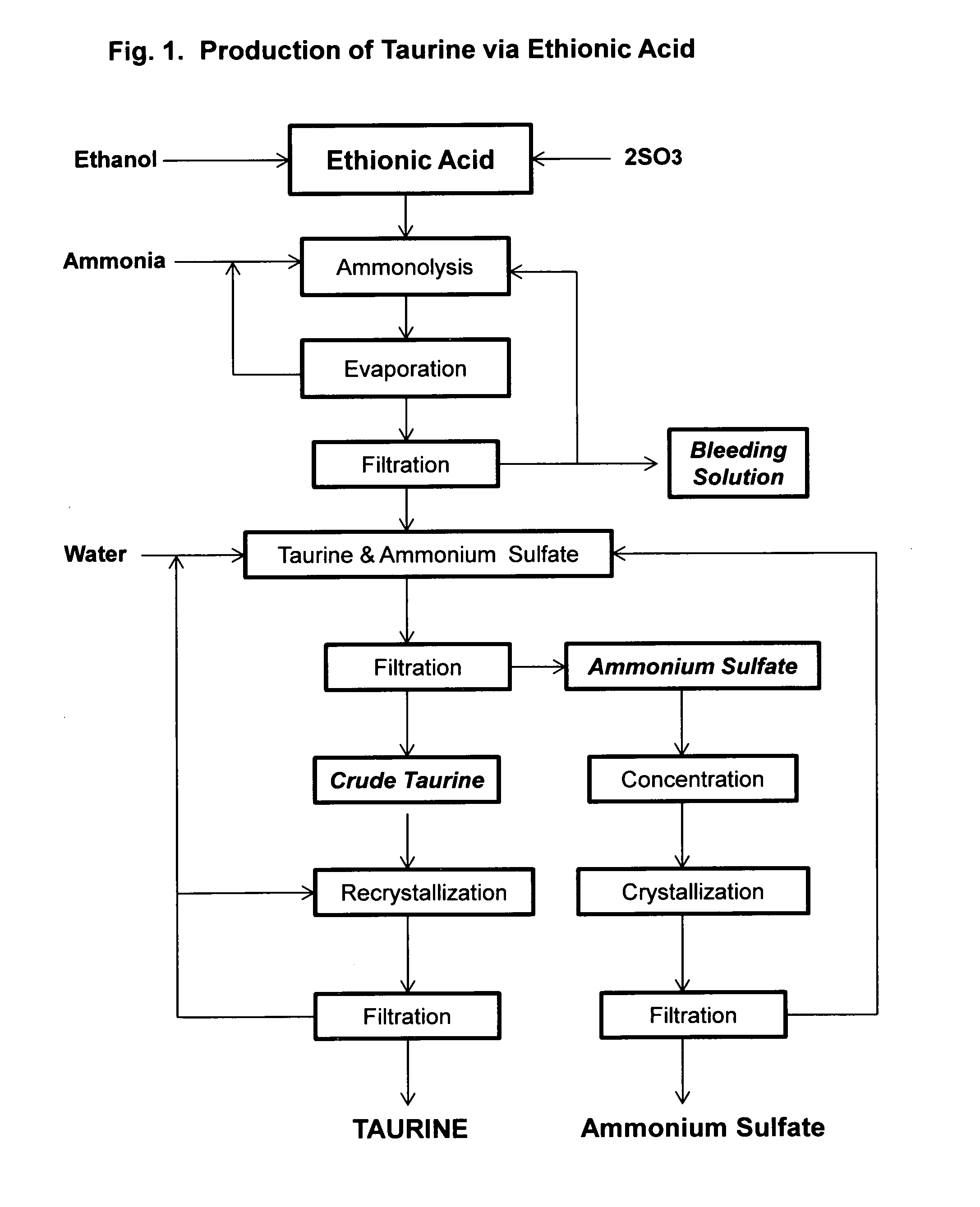

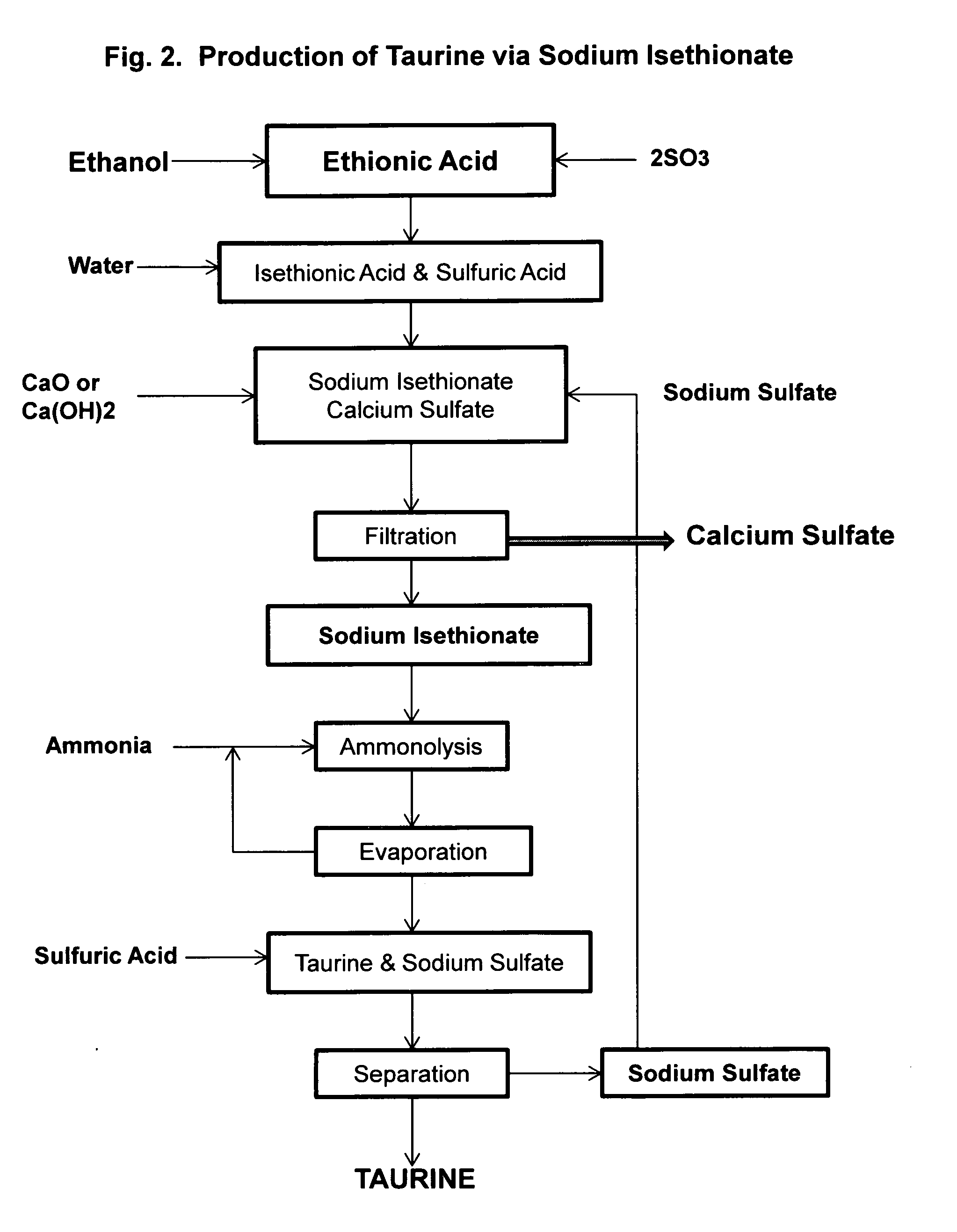

Process for the production of taurine from ethanol

ActiveUS9108907B1Production cost is further reducedSulfonic acids salts preparationSulfonic acid preparationAcetic acidSodium Isethionate

Owner:VITAWORKS IP LLC

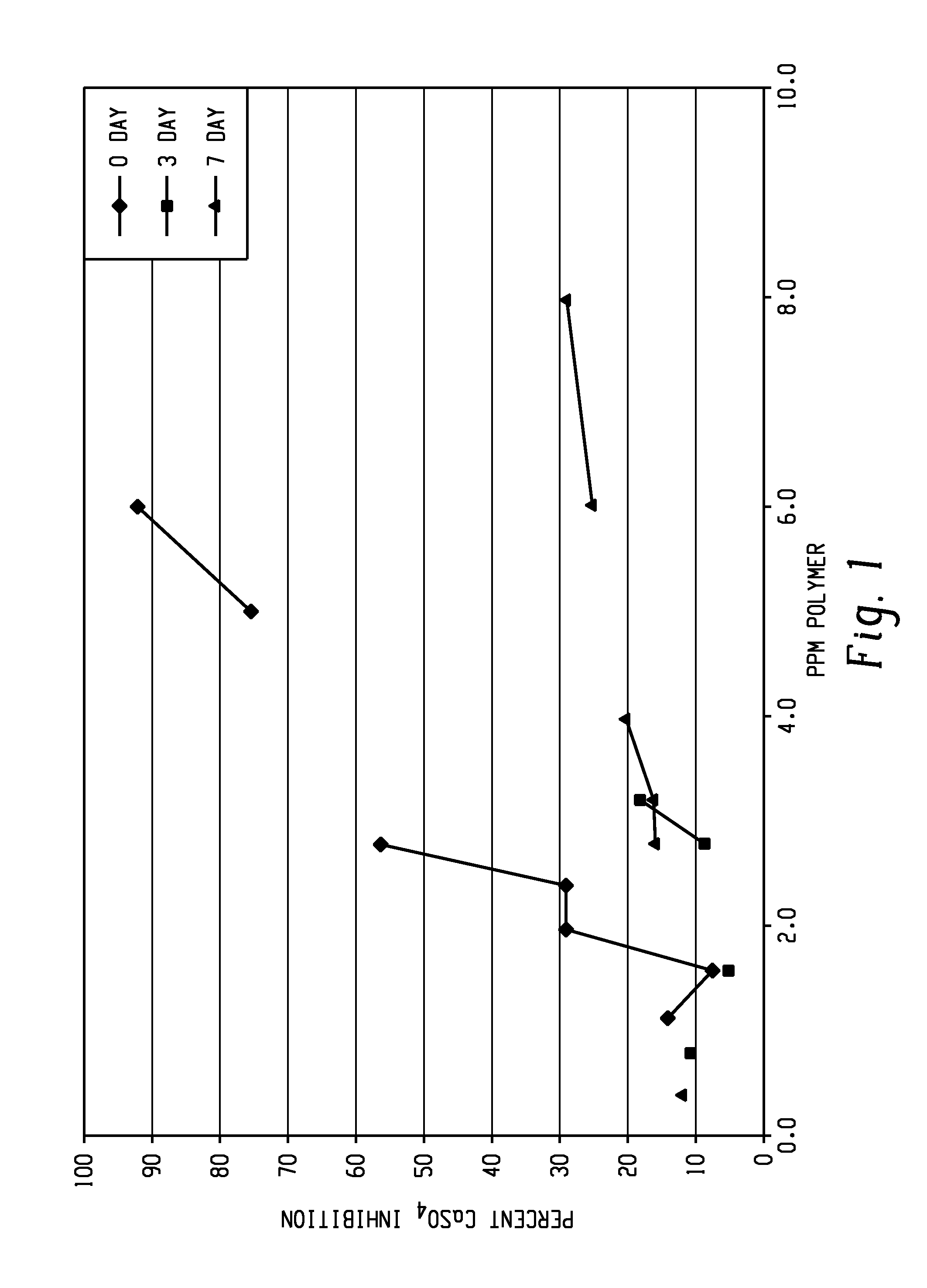

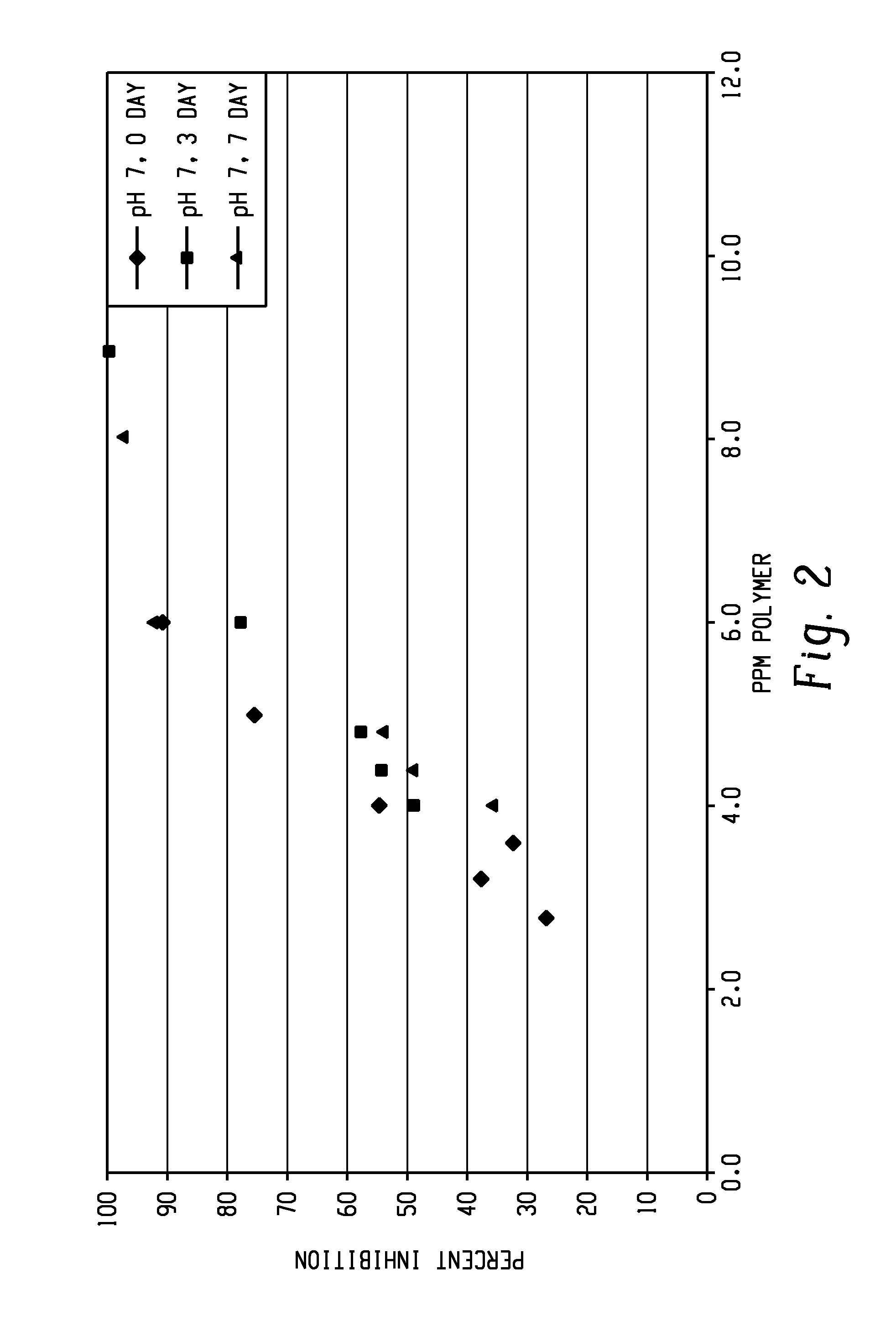

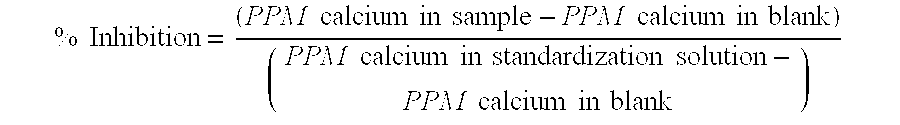

Thermally Stable Scale Inhibitor Compositions

InactiveUS20120118575A1Prevent scalingEasy to understandWaste water treatment from quariesWater treatment parameter controlVinylsulfonic acidMaleic anhydride

Methods for scale inhibition treatment of oil or gas production wells generally include injecting a scale inhibition composition into the oil or gas production well, wherein the scale inhibition composition comprises one or more polymers, each polymer comprising recurring units of a first monomer and a second monomer, wherein: (i) the first monomer is selected from maleic acid, maleic anhydride, fumaric acid, acrylic acid, salts thereof, or combinations thereof; and (ii) the second monomer is selected from vinyl sulfonic acid, allyl sulfonic acid, methallylsulfonic acid, salts thereof, or combinations thereof; wherein the concentration of the polymers in the composition is about 10 to about 60 percent of the polymers by weight of the composition; and wherein the composition has a pH of about 7 to about 8.5.

Owner:KEMIRA OY

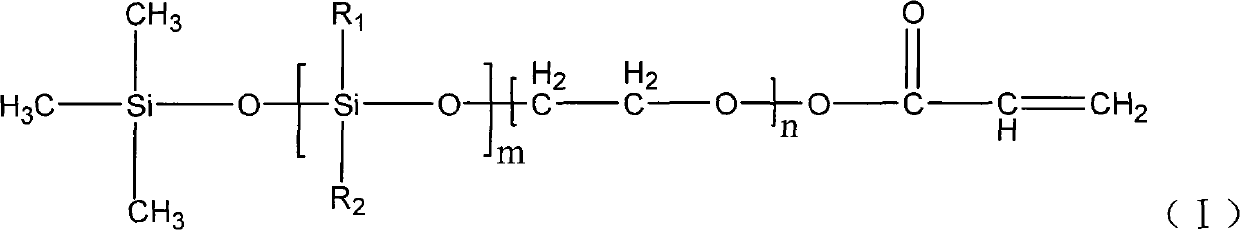

Poly-carboxylic acid water reducing agent and preparation method thereof

ActiveCN101792281AHigh bleed air performanceStrong molecular weight selectivityCis-Butenedioic AcidCarboxylic acid

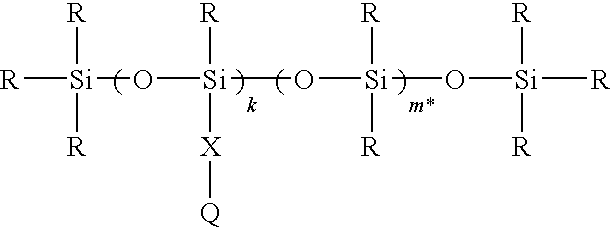

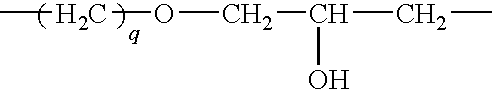

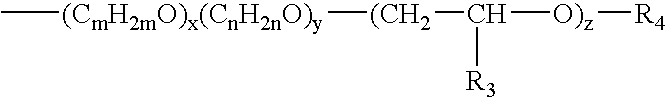

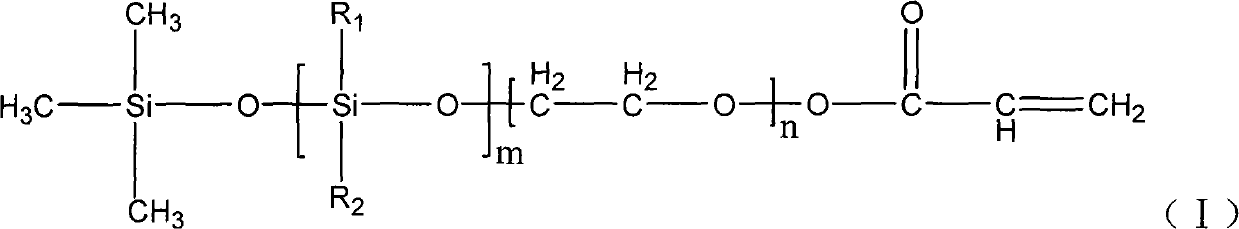

The invention provides a concrete poly-carboxylic acid water reducing agent which is a polymer with the weight-average molecular weight of 10000-30000 formed by copolymerization of three monomers of A, B and C, wherein the molar ratio of the monomer A to the monomer B is 0.1-0.5:1,and the molar ratio of the monomer A to monomer C is 5-10:1; the monomer A is monohydroxy silicone oil polyoxyethylene ether acrylate, and the structure is shown in the formula (I) as follows, wherein R1 and R2 are methyl or amino; m is an integral number from 1 to 10; n is the integral number from 13 to 49; the monomer B is one of maleic anhydride, maleic acid, acrylic acid or methylacrylic acid; the monomer C is one of sodium vinyl sulfonate, sodium allyl sulfonate, sodium styrene sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, methyl methacrylate, methyl acrylate or vinyl acetate. The water reducing agent has the advantages of stable performance, high water reducing rate, strong adaptability of cement, high air entraining performance and no environmental pollution. The invention further provides a preparation method of the water reducing agent, which has the advantages of simple process, strong operationability, low energy consumption and the like.

Owner:LIAONING OXIRANCHEM INC

Sulfonic acid type hydrophilic chain extender and preparation method thereof

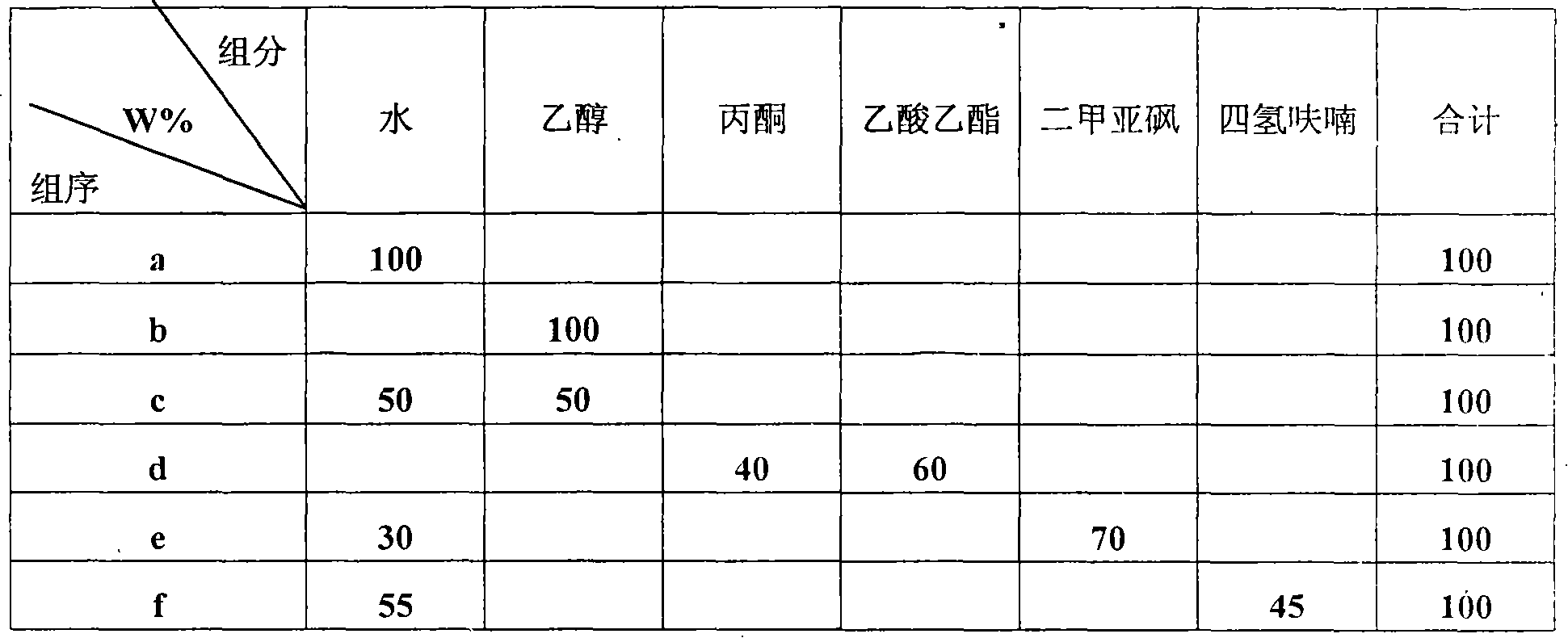

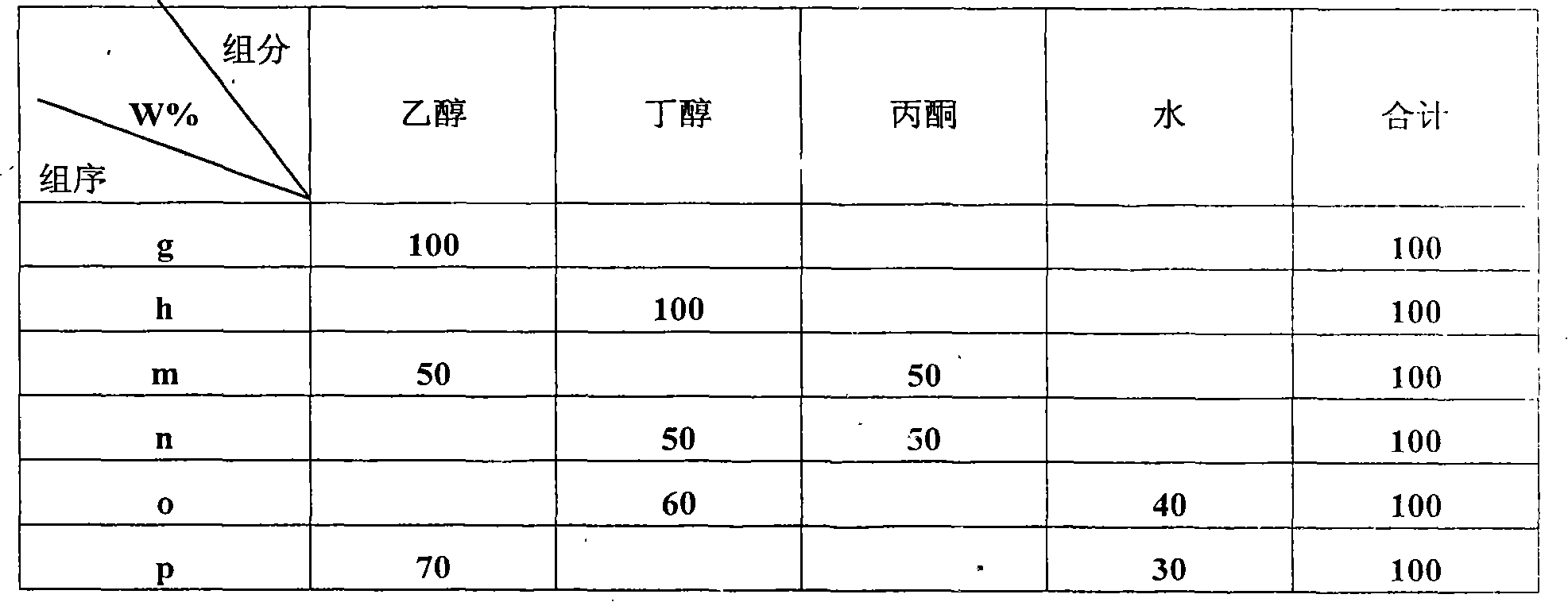

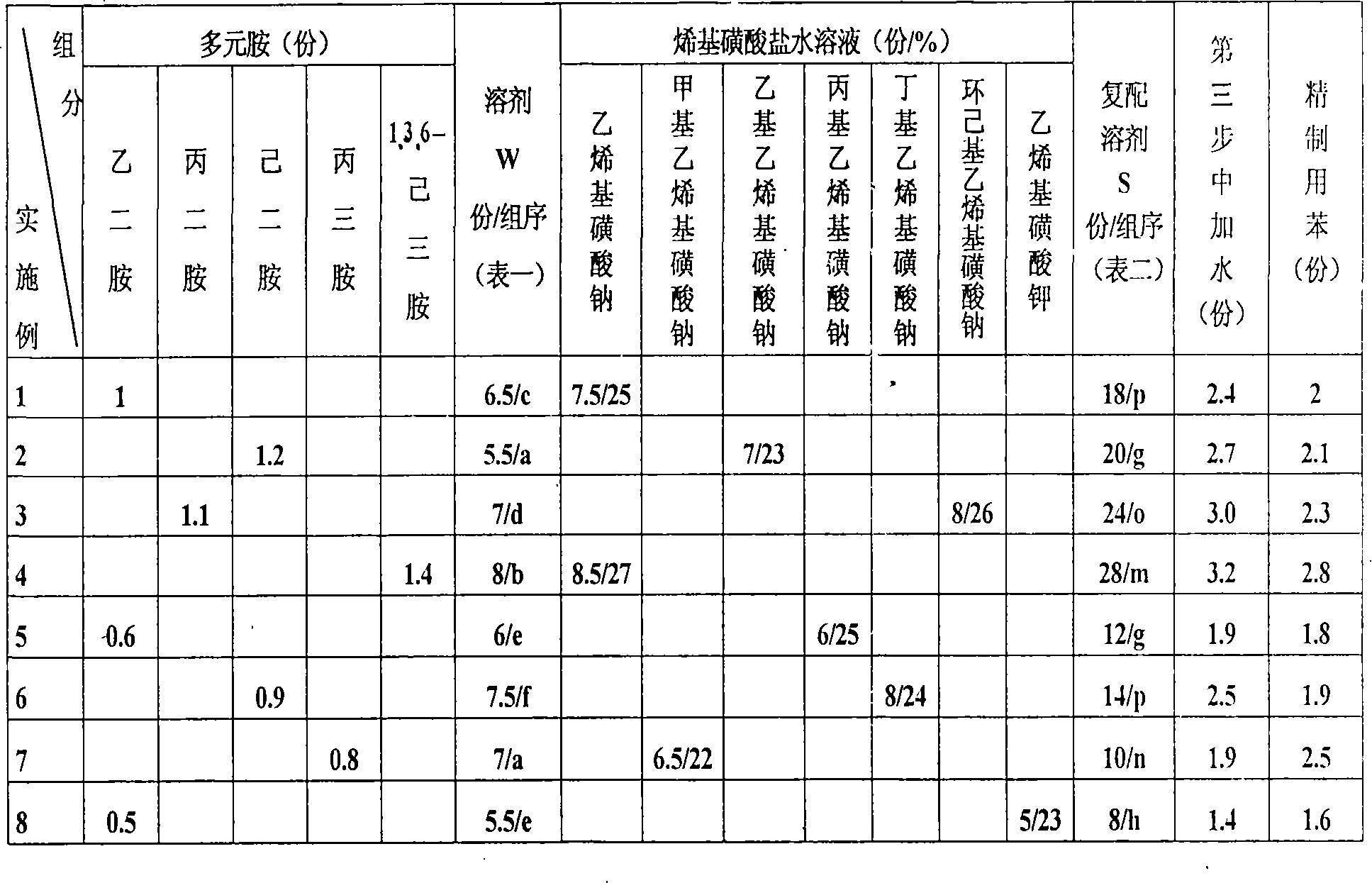

A hydrophilic chain extender of sulfonic acid type which pertains to chemical product, and preparation thereof. The invention mainly aims to solve the problems of slow reaction rate of hydrophilic chain extender used in aqueous polyurethanel industry, low content of aqueous resin, low heat resistance, low adhesion strength when applying to adhesive. The eligible product is obtained by fully dissolving multi-amine such as 0.5-1.5 parts of ethylenediamine into solvent, reacting with olefin sulfonate such as 5-9 parts of vinyl sodium sulfonate solution with about 25% of water for 4-30 hours at the temperature of 40-100 DEG C., vacuum distilling to remove solvent, dissolving with water, alcohol or ketone, vacuum distilling to remove all solvent for another time after deposition and filter. Stability treatment for storage is further carried out by adding water. The final product is slightly turbid vicous liquid in light yellow color and oil state, with density at 1.16-1.21 g / ml, pH at 11-12, content of ammonia at 6.9+-0.9g NH3 / 100g, effective content 40-55%. The invention can widely used into production of aqueous polyurethane of different fields, which has a fast reaction rate, high yield, highly enhanced content of solid in prepared aqueous resin, and obviously improved resistance of heat, acid, alkali, hard water, and is greatly beneficial for preparation of adhesive.

Owner:北京林氏精化新材料有限公司

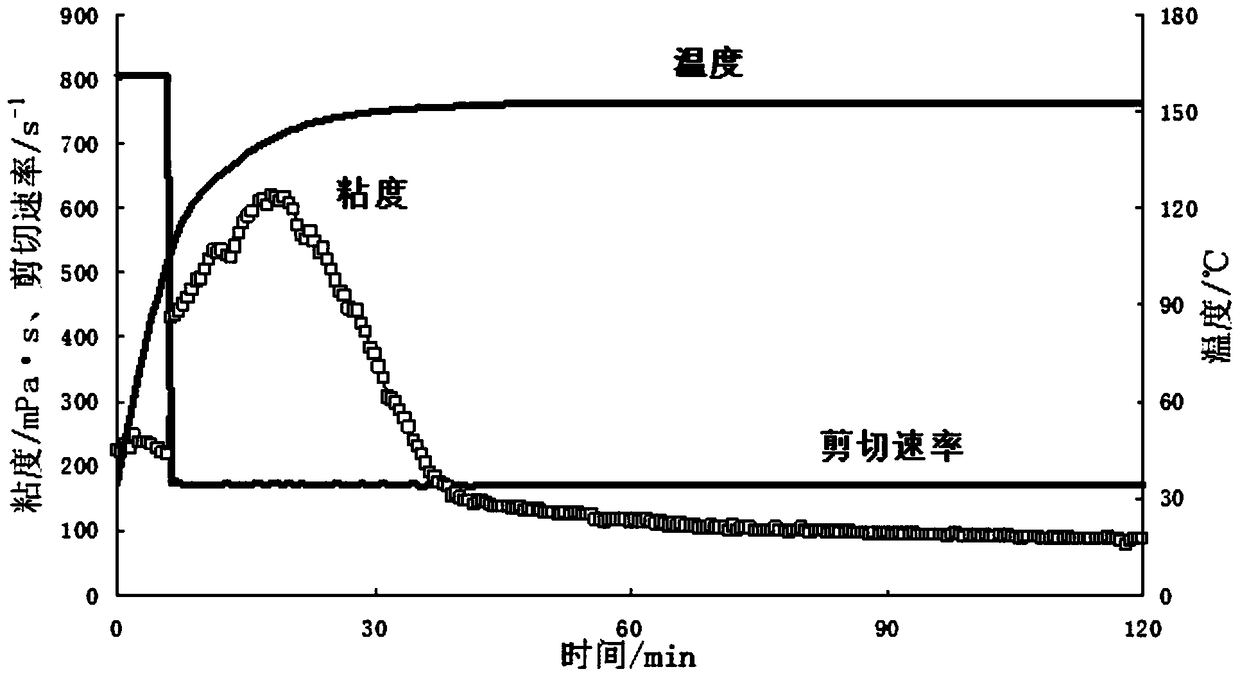

Temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer and preparation method thereof

ActiveCN104892838AHigh interface activityReduce the amount of adsorptionDrilling compositionMethacrylateSolubility

The invention relates to a temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer and a preparation method thereof. The temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer is prepared by copolymerizing a monomer A, a monomer B and a monomer C, wherein the weight ratio of the monomer A to the monomer B to a monomer C is 10: (0.5-1.5): (0.05-0.15); the monomer A is acrylamide; the monomer B is 2-acrylamido-2-methyl propane sulfonate (AMPS), alpha-alkenyl sulphonate or vinyl sulfonate; the monomer C is poly(ethylene glycol) octadecyl methacrylate (OEMA). With a sulfonic acid group, the copolymer has excellent water solubility and temperature resistance; meanwhile, with a non-ionic hydrophobic unit, the copolymer has unique shear resistance and viscosifying ability; the copolymer has excellent performance, has a wide application prospect in the oil and gas resource exploitation under high temperature, high salt, low permeability, and can be used in an oil field displacement agent and a fracturing fluid thickener.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

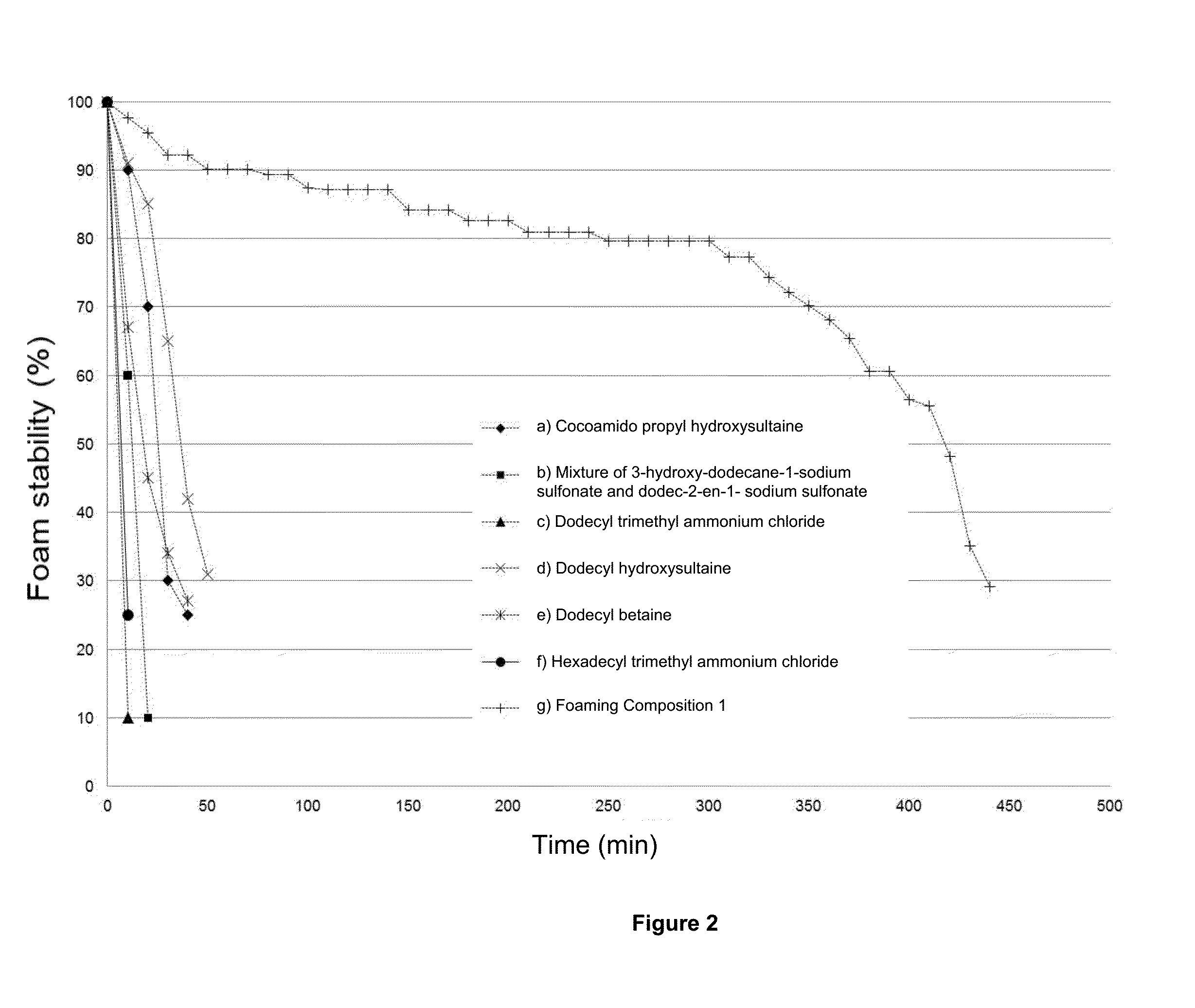

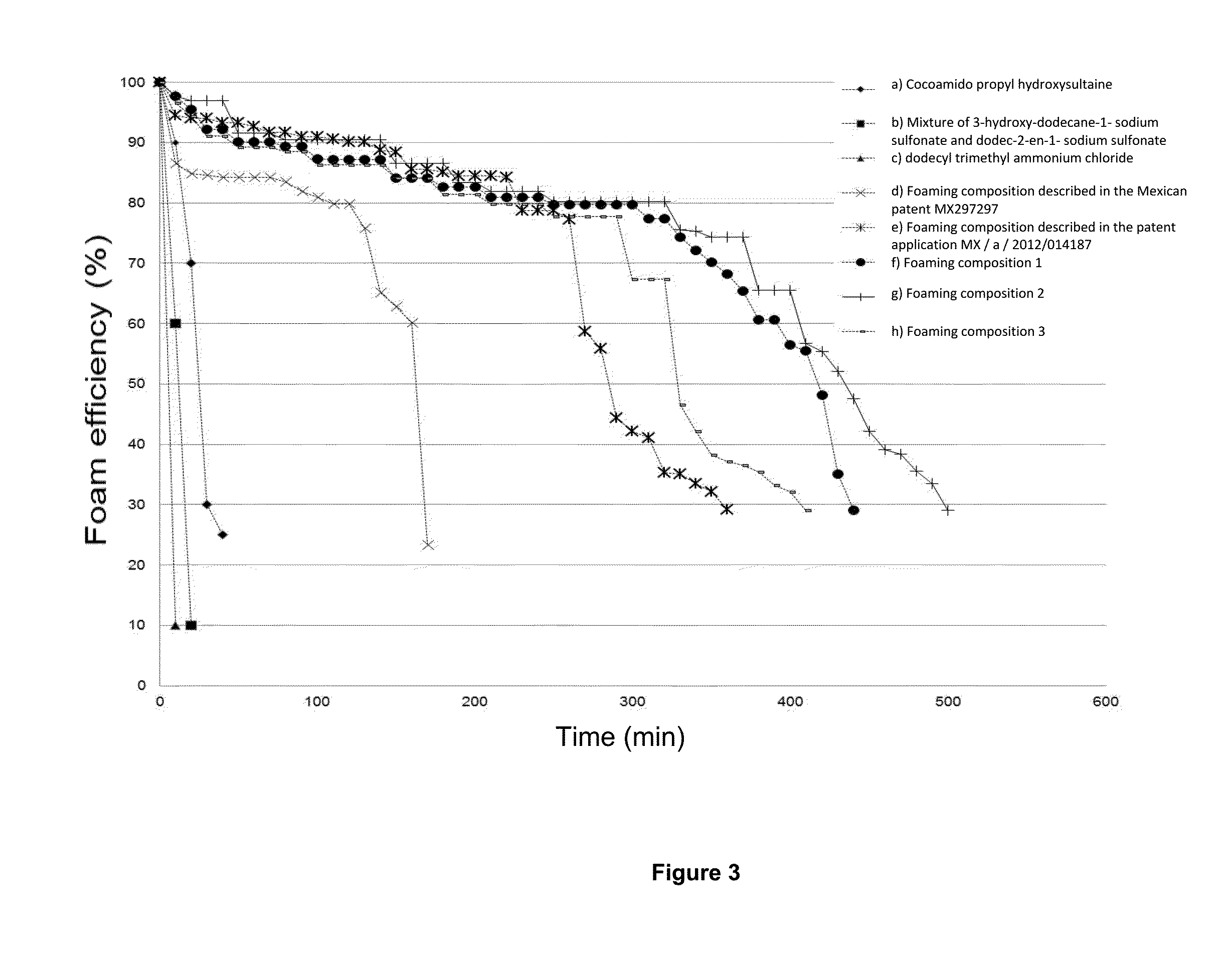

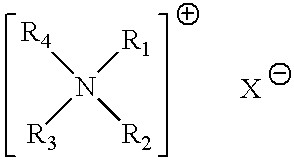

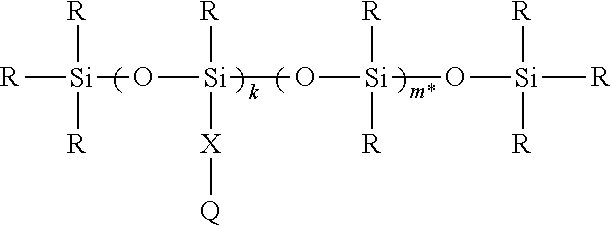

Multifunctional foaming composition with wettability modifying, corrosion inhibitory and mineral scale inhibitory/dispersants properties for high temperature and ultra high salinity

The present invention is related to the obtaining and using of multifunctional foaming compositions with wettability modifying, corrosion inhibitory and inhibitory / dispersants mineral scale properties with high stability in environments of high temperature, high pressure and tolerance to high concentrations of divalent ions such as calcium, magnesium, strontium and barium. The multifunctional foaming compositions are obtained from the combination of supramolecular complexes resulting from interactions of alkyl amido propyl hydroxysultaines and / or alkyl amido propyl betaines and / or alkyl hydroxysultaines and / or alkyl betaines and anionic surfactant of type alkyl hydroxyl sodium sulfonate and alkenyl sulphonates of sodium, with cationic surfactants as tetra-alkyl ammonium halides and copolymers derivatives of itaconic acid / sodium vinyl sulfonate and / or terpolymers derived from itaconic acid / sodium vinyl sulphonate / aconitic acid. These multinational foaming compositions control the gas channeling and favorably change the wettability and increase the recovery factor of crude oil in naturally fractured reservoirs of carbonate type and heterogeneous lithology. In addition to this, the multifunctional foaming compositions of this invention exhibit anti-corrosive properties in typical environments of production tubing of crude oil and antifouling / dispersants of mineral salts as calcium carbonate, calcium sulfate, barium and strontium in the reservoir and in the production and injection pipelines.

Owner:INST MEXICANO DEL GASOLINEEO

Fabric softening laundry detergent

InactiveUS7994112B2Organic detergent compounding agentsNon-ionic surface-active compoundsMethacrylatePolymer science

Aqueous laundry detergent compositions containing surfactants and fatty acid, having a pH of from about 6 to about 11 and containing a polymer having a number average molecular weight of from about 700,000 to about 4,000,000 and comprising monomeric units including: nonionic monomers selected from acrylamide, N,N-dialkyl acrylamide, methacrylamide, N,N-dialkylmethacrylamide, hydroxyalkyl acrylate and vinyl pyrrolidone, vinyl acetate, vinyl alcohol, and mixtures thereof; cationic monomers selected from N,N-dialkylaminoalkyl methacrylate, N,N-dialkylaminoalkyl acrylate, N,N-dialkylaminoalkyl acrylamide, N,N-dialkylaminoalkylmethacrylamide, methacylamidoalkyl trialkylammonium chloride, acrylamidoalkylltrialkylammonium chloride, vinylamine, quaternized vinyl imidazole and diallyl dialkyl ammonium chloride, and mixtures thereof; and anionic monomers selected from acrylic acid, methacrylic acid, maleic acid, vinyl sulfonic acid, styrene sulfonic acid, acrylamidopropylmethane sulfonic acid (AMPS), salts thereof, and mixtures thereof; in a specified mole ratio.

Owner:THE PROCTER & GAMBLE COMPANY

Process for the production of taurine from ethanol

ActiveUS20150210633A1Production cost is further reducedSulfonic acids salts preparationSulfonic acid preparationSodium IsethionateSulfonate

Owner:VITAWORKS IP LLC

Polymerization of fluoropolymers using non-fluorinated surfactants

ActiveUS8697822B2Organic-compounds/hydrides/coordination-complexes catalystsFibre treatmentFluoropolymerALLYL SUCROSE

Owner:ARKEMA INC

Anti-antisludging disperser and preparation method thereof

ActiveCN101186394AExcellent anti-calcium carbonate scale functionExcellent ability to disperse iron oxideScale removal and water softeningWater/sewage treatment bu osmosis/dialysisHigh concentrationReverse osmosis

The invention provides a dirt dispersion agent which is a copolymer of acrylic acid, acrylamide and organic compounds with sulfonic acid groups, the mass ratio of which is 5-40 to 1-15 to 1-15 and a preparation method thereof. The copolymer has the solid content of 30-40 percent and the molecular weight of 1000-10000; the organic compounds with sulfonic acid groups are vinyl sulfonic acid, 2-acrylamido-2-methyl-1- propane sulfonate, sodium allylsulfonate or 2-acrylamide dodecyl sulfonate. The dirt dispersion agent of the invention also comprises amido, carboxyl and sulfonate functional groups, thus leading the agent to have good function of inhibiting calcium carbonate scale as well as good performance of dispersing ferric oxide. The dirt dispersion agent still has high performance of dirt dispersion even in water with inorganic salt of high concentration and can be widely applied to a treatment system of industrial water, such as industrial circulating water and reverse osmosis water, etc.

Owner:OCHEMATE MATERIAL TECH CO LTD

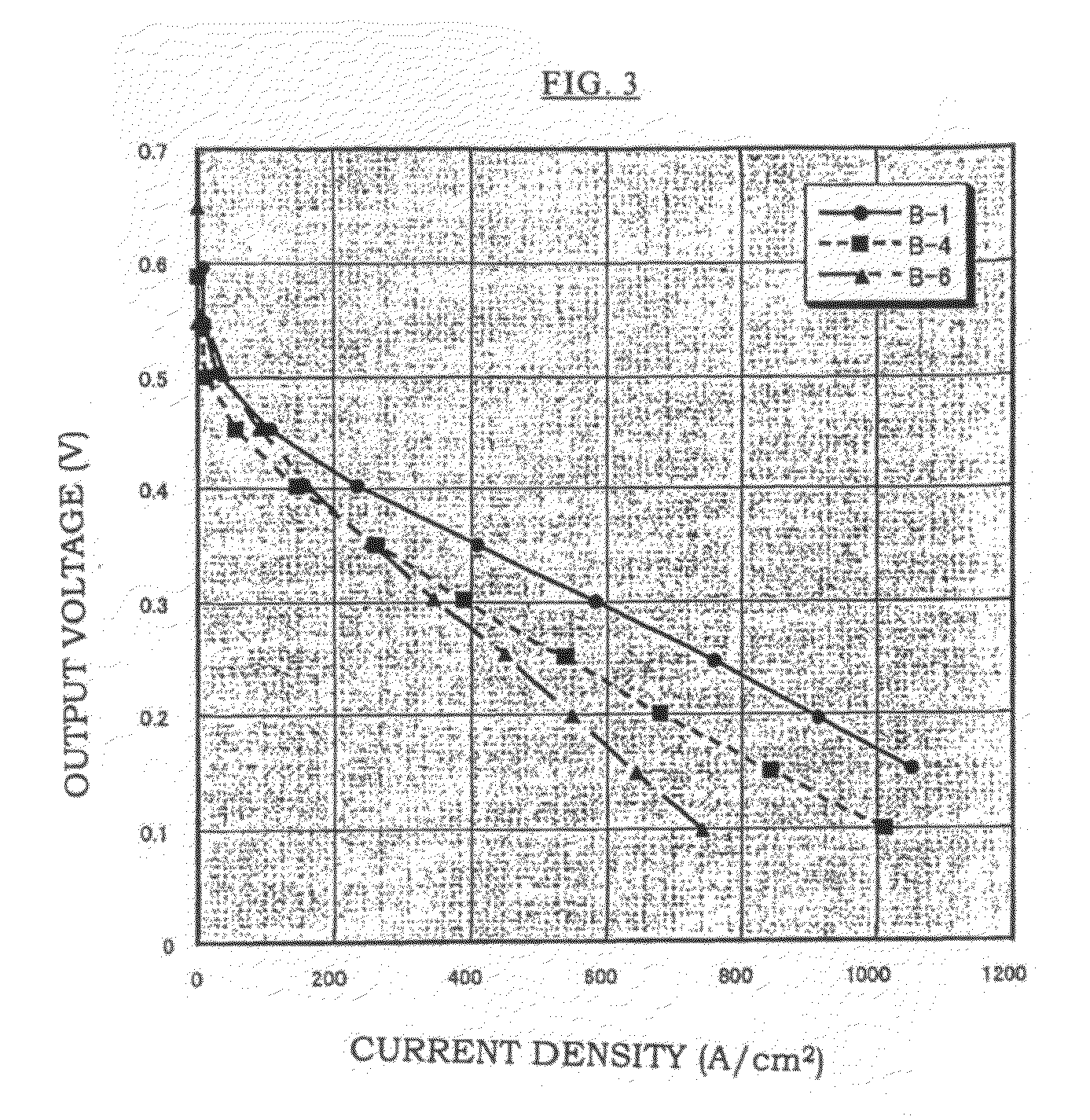

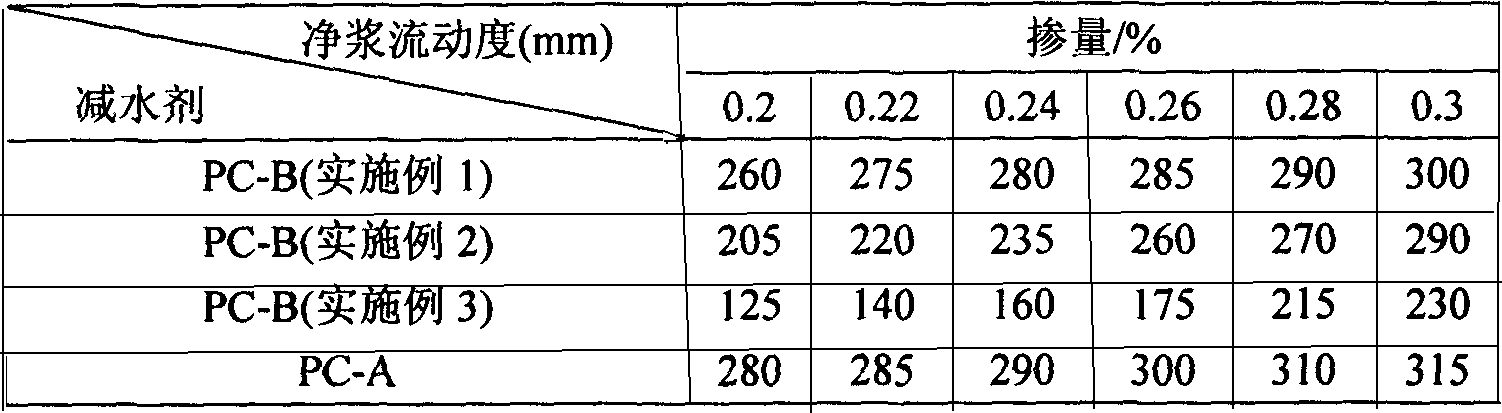

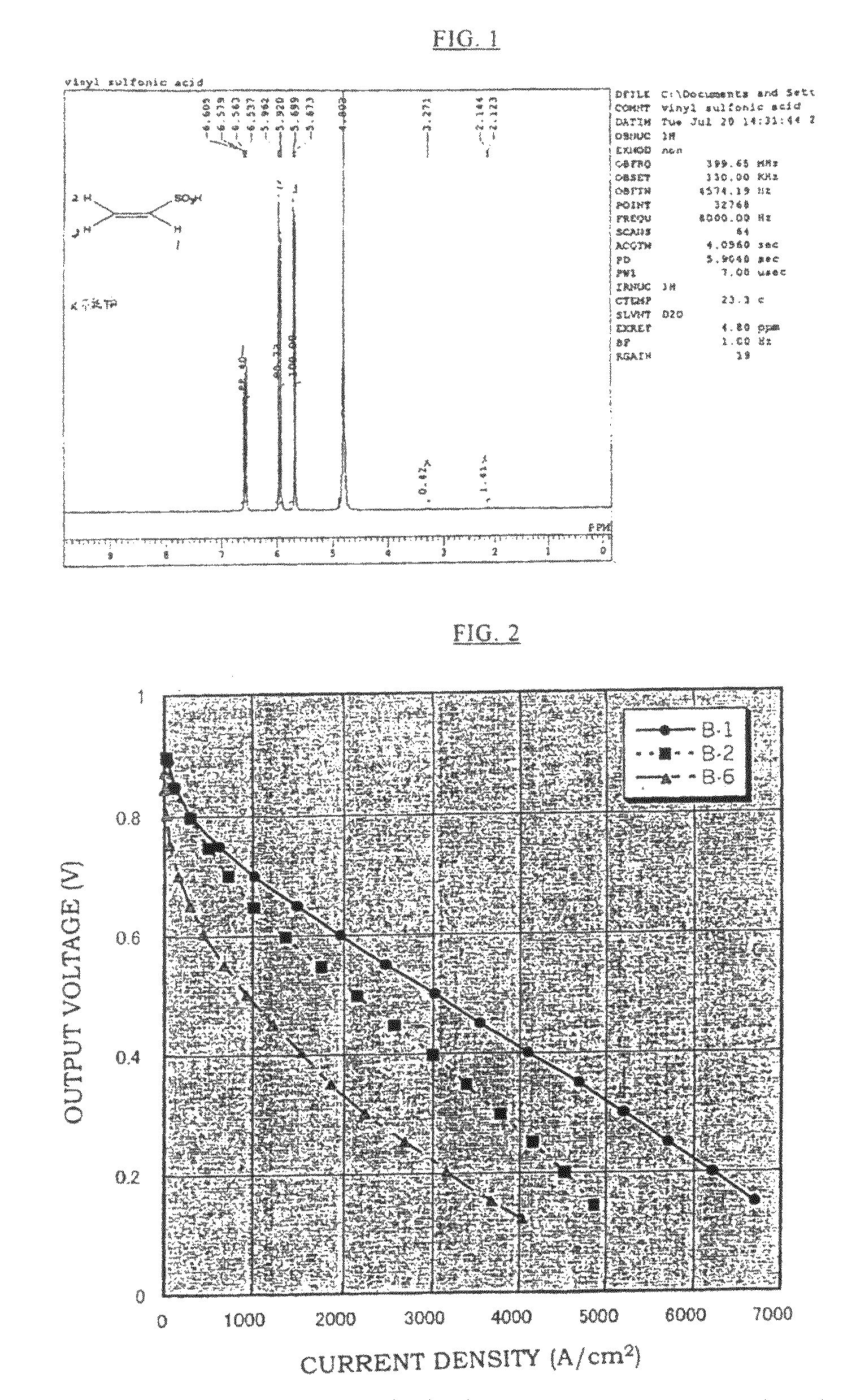

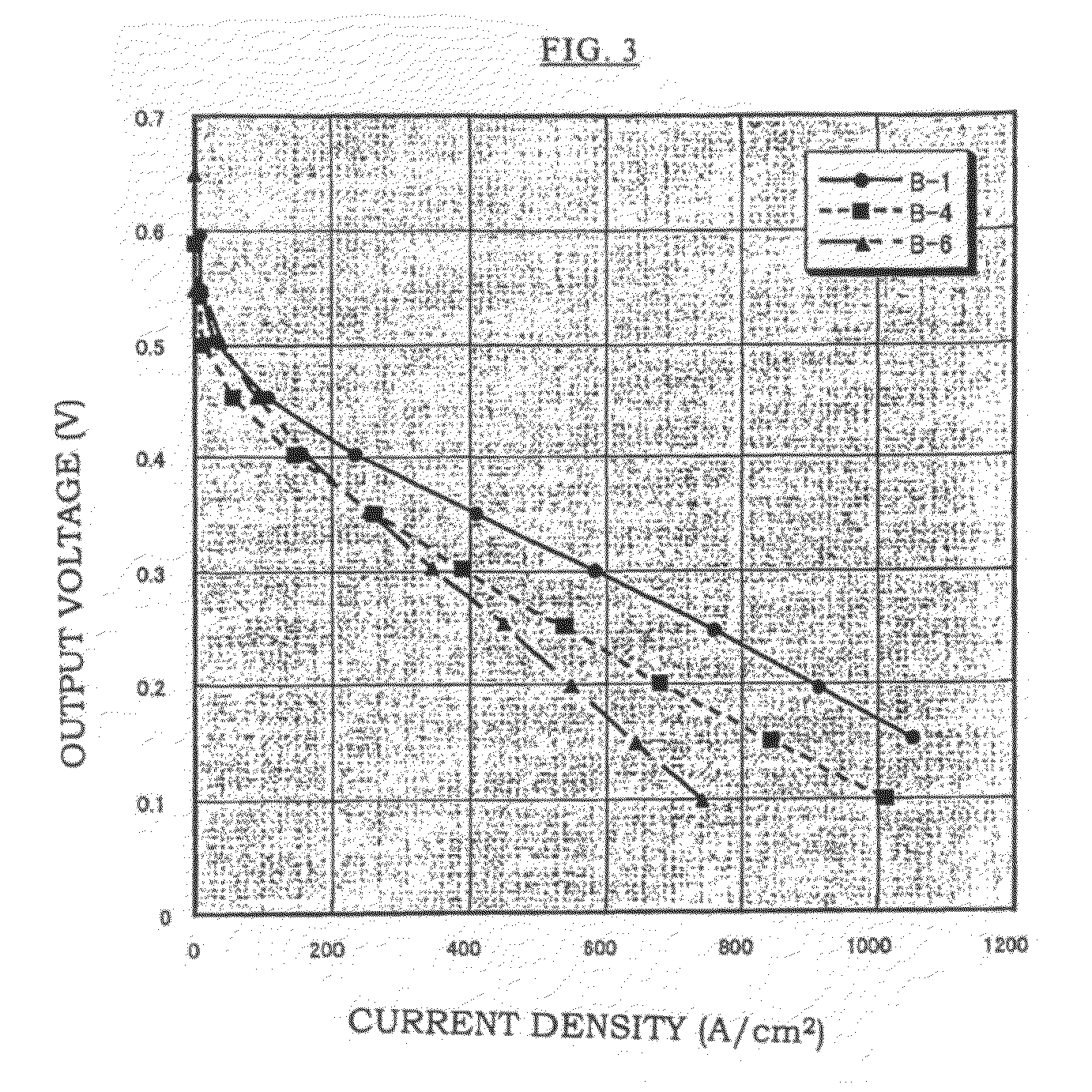

Production method of electrolyte membrane, electrolyte membrane and solid polymer fuel cell using same

InactiveUS20090297909A1Improve proton conductivityConvenient ArrangementElectrolyte holding meansSolid electrolytesFuel cellsHydrogen

Disclosed is an electrolyte membrane which enables a fuel cell to have a high maximum output when used therein since it has high proton conductivity and high hydrogen gas impermeability. Also disclosed are a method for producing such an electrolyte membrane, and a solid polymer fuel cell using such an electrolyte membrane. A method for producing an electrolyte membrane including a step for impregnating a porous base with a solution containing a sulfonic acid group-containing vinyl monomer and then polymerizing the monomer is characterized in that 80% by mole or more of vinyl sulfonic acid having purity of 90% or more, and / or a salt thereof is contained as the sulfonic acid group-containing vinyl monomer, and the concentration of the vinyl sulfonic acid and / or a salt thereof in the solution is set at 35% by weight or more.

Owner:NITTO DENKO CORP

Non-cyanide pre-plating copper plating solution

The invention provides a non-cyanide pre-plating copper plating solution, which is an aqueous solution containing a bivalent cupric salt and a complexing agent, wherein the plating solution also contains an auxiliary agent which comprises at least two of an alkali metal salt of sulfamidic acid, an alkali metal salt of dithiocarbonic acid, an alkali metal salt of allyl sulphonic acid, allyl sulfonamide, an alkali metal salt of vinyl sulphonic acid and saccharin; and the pH value of the plating solution is between 6.5 and 7.5. According to the non-cyanide pre-plating copper plating solution, thebonding force between a pre-plating copper layer prepared from the non-cyanide pre-plating copper plating solution and a base material is good, and simultaneously a plated product has a smooth and bright appearance and good temperature impact resistance and high-temperature baking resistance.

Owner:BYD CO LTD

Method of producing fluoropolymers using acid-functionalized monomers

A fluoropolymer latex is obtained by emulsion polymerization of one or more fluoromonomers in the presence of one or more acid-functionalized monomers such as vinyl sulfonic acid or a salt thereof. A fluorosurfactant need not be present.

Owner:ARKEMA INC

Ampholytic modified grafted starch flocculant

InactiveCN102250291AGood decolorization effectWater/sewage treatment by flocculation/precipitationFlocculationGraft reaction

The invention discloses an ampholytic modified grafted starch flocculant. The flocculant is characterized in that the preparation method comprises the following steps: under the action of an initiator, starch is used to perform a grafting reaction with an acrylic or vinyl sulfonate monomer the mass of which is 0.05-5 times that of starch to obtain an anionic starch graft polymer, and then the anionic starch graft polymer reacts with a cationic monomer the mass of which is 0.05-5 times that of starch to prepare the flocculant. The ampholytic modified grafted starch flocculant not only has the functions of coagulation and flocculation, but also has the decoloring effect and can be widely used in the industries such as petroleum, coal, sewage treatment, sludge dehydration and papermaking. In addition, the preparation method of the flocculant has the advantages of simple method, high productivity and the like.

Owner:何善媛

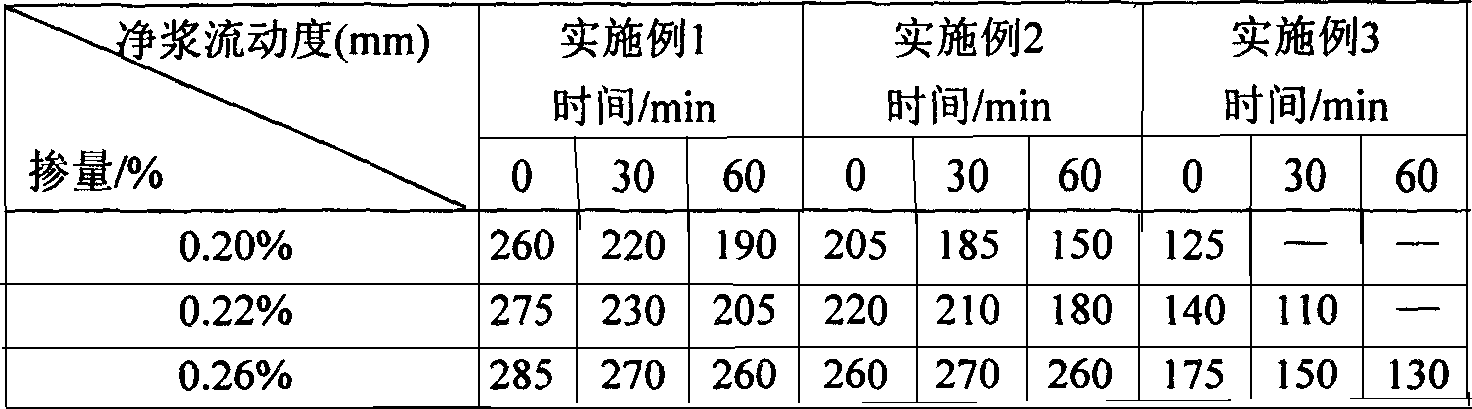

Poly carboxylic acid series super plasticizer and its preparing method

The present invention is serial polycarboxylic acid super plasticizers and their preparation process, and belongs to the field of concrete admixture technology. The super plasticizer is prepared with acrylic acid, methoxy polyglycol-1000 and sodium vinyl sulfonate, and through the esterification of acrylic acid and methoxy polyglycol-1000 in water bath to prepare intermediate polyglycol acrylate, and the subsequent free radical polymerization of polyglycol acrylate, sodium vinyl sulfonate and acrylic acid under the action of initiator in water solution. The preparation process has easily controlled condition, simple operation, no pollution, low cost and other features. The product of the present invention may be used as concrete super plasticizer suitable for different kinds of cement.

Owner:CHONGQING UNIV

Preparation method of positive pole piece containing positive electrode material coated by electricity and lithium conducting composite material and lithium-ion battery

ActiveCN110148709AEasy transferImprove performanceSecondary cellsPositive electrodesCross-linkPole piece

The invention provides a preparation method of a positive pole piece containing a positive electrode material coated by an electricity and lithium conducting composite material, and belongs to the technical field of lithium-ion batteries. The preparation method comprises the steps of uniformly stirring a vinyl sulfonic acid monomer, a cross-linking agent, an initiator and a solvent, then adding apositive electrode material, removing the solvent after impregnation, reacting for 10h at a temperature of 90 DEG C to obtain a positive electrode material coated by a cross-linked polymer; preparinga mixed solution by lithium salt and a low-boiling-point solvent, adding the positive electrode material coated by the cross-linked polymer, removing the low-boiling-point solvent until sulfonate or sulfonic acid cations in a coating layer of the positive electrode material is / are converted into lithium sulfonate structure to obtain a positive electrode material coated by a lithium sulfonate cross-linked polymer electrolyte; and uniformly mixing the positive electrode material coated by the lithium sulfonate cross-linked polymer electrolyte, a binder, a lithium conducting material and a conductive agent, and then forming a positive pole piece after coating and drying. The positive electrode material has lithium ion and electricity conducting properties, and improves the performances of thelithium-ion batteries.

Owner:ZHUHAI COSMX BATTERY CO LTD

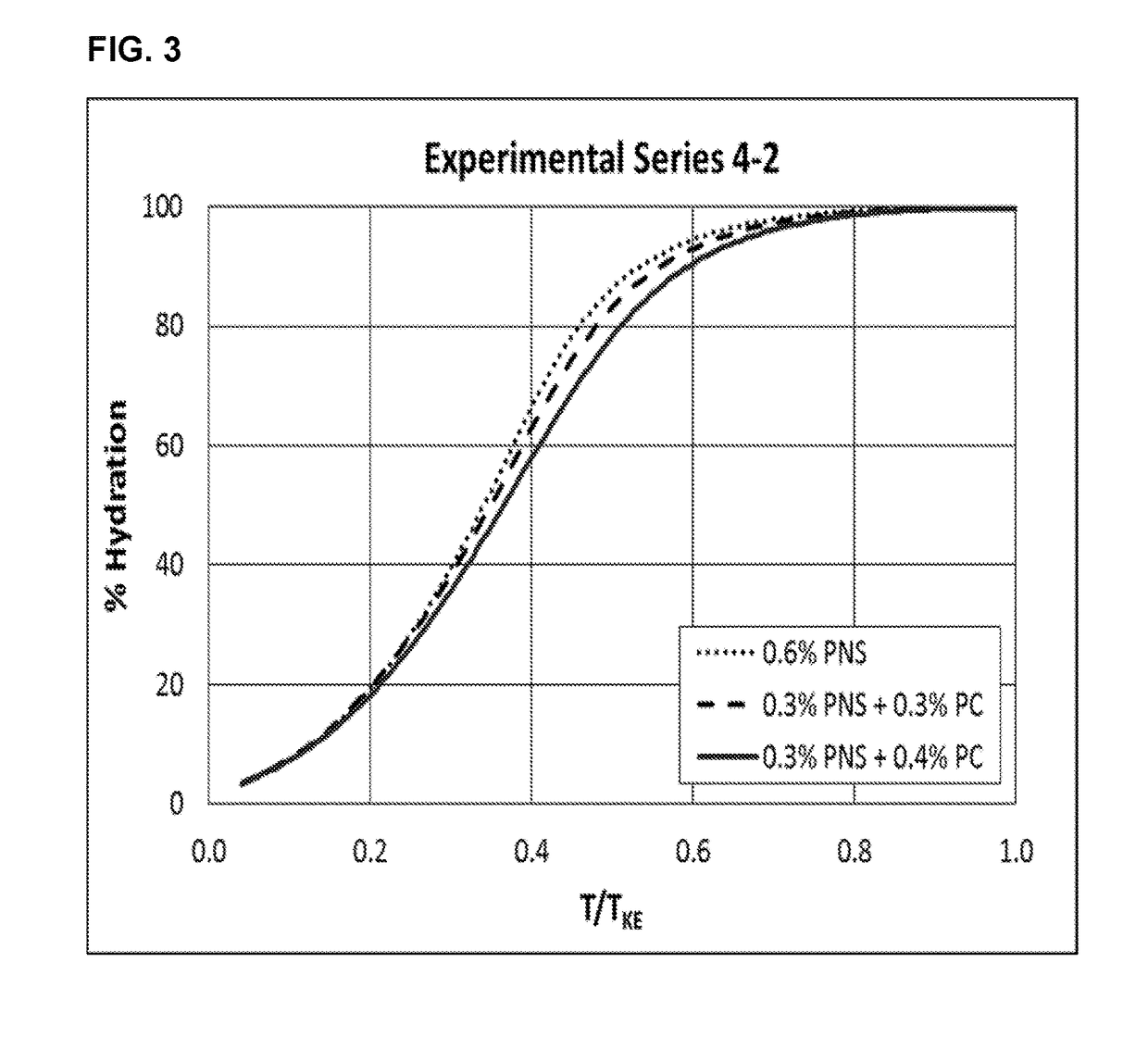

Well cement additives, compositions and methods

Improved well cement additives, compositions and methods of using the compositions are provided. The well cement additives are basically comprised of a first monomer selected from the group of 2-acrylamido-2-methylpropane sulfonic acid, 2-allyloxy-2-hydroxy-1-propane sulfonic acid and vinylsulfonic acid, a second monomer selected from the group of N,N-dimethylacrylamide, acrylamide, N-vinylpyrrolidone, N-vinylacetamide and acrylonitrile and a third monomer selected from the group of C6 to C22 dimethylaminopropylmethacrylamide bromide, chloride and iodide and C6 to C22 dimethylaminoethylmethacrylate bromide, chloride and iodide.

Owner:HALLIBURTON ENERGY SERVICES INC

Cotton-polyester fabric burn-out printing gum and preparation method thereof

InactiveCN101942771AQuality improvementGood printing paste fluidityDyeing processPolyesterPotassium persulfate

The invention relates to cotton-polyester fabric burn-out printing gum and a preparation method thereof. The raw materials of the gum comprise the following components in parts by weight: 115-120 parts of acrylic acid, 8-10 parts of acrylamide, 17-19 parts of itaconic acid, 76-80 parts of sodium ethylenesulfonate, 220-240 parts of ammonia water, 3.0-3.5 parts of potassium persulfate, 1.8-2.5 parts of sodium bisulfite, 112-116 parts of corn starch and 480-510 parts of water. The preparation method comprises the following steps: performing solution polymerization, then adding corn starch in the copolymer to perform gelatinization and filtering to obtain the gum. The gum of the invention has good fluidity and stability, high permeability, good permeability, high definition of printing patterns and wide range of application temperature, is easy to wash with water and can obviously increase the quality of the printing product.

Owner:LIAONING FIXED STAR FINE CHEM

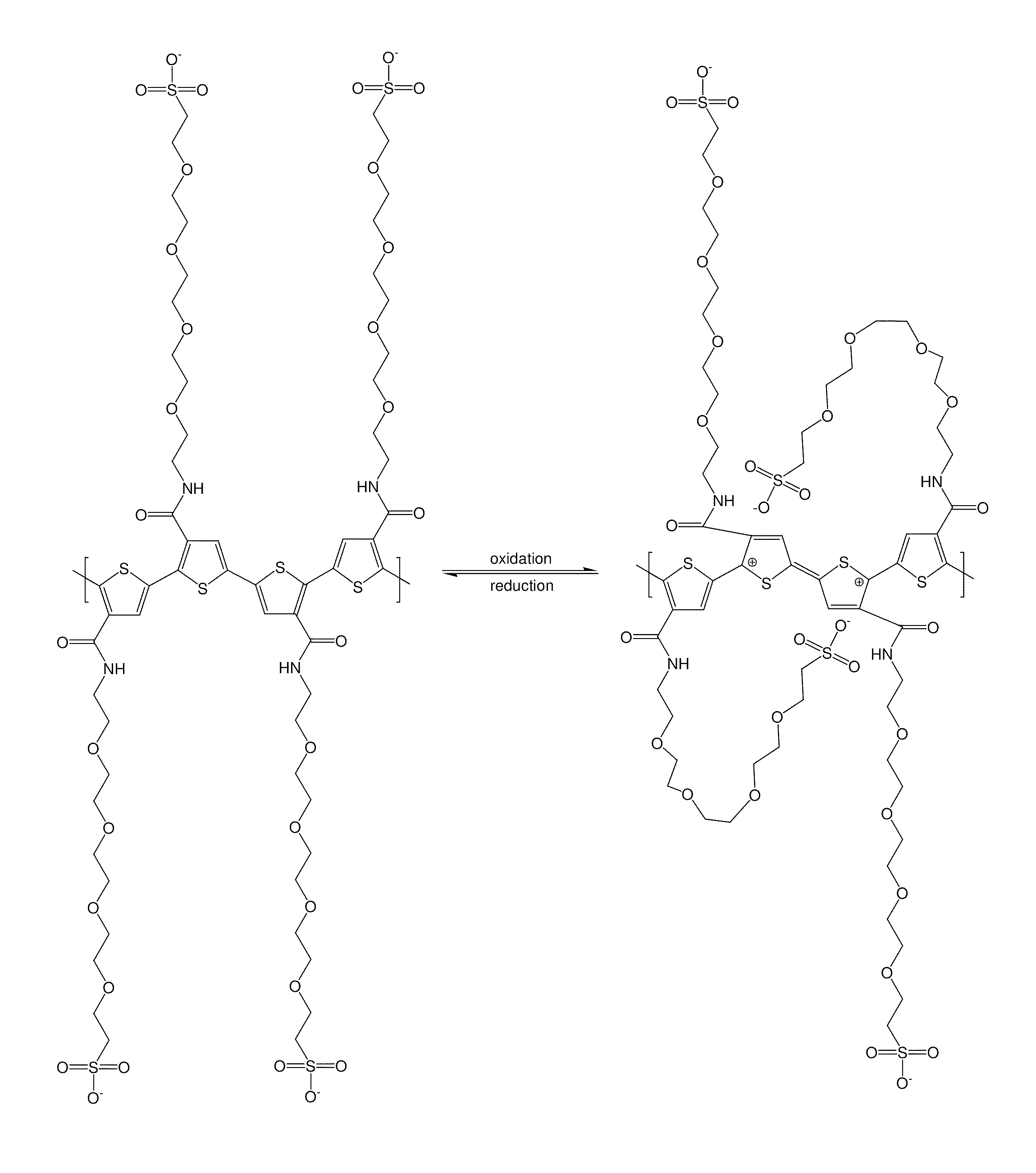

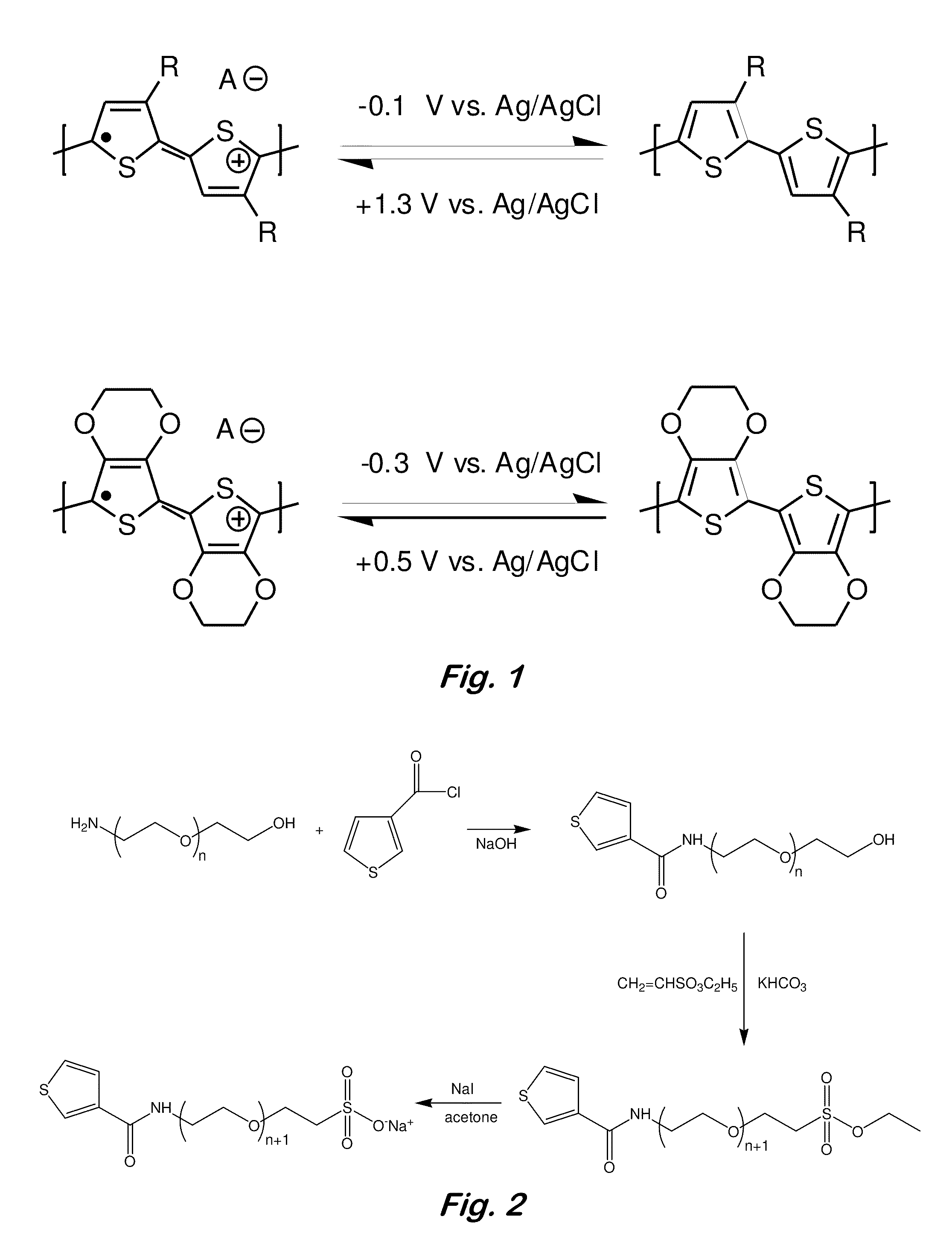

Tether-containing conducting polymers

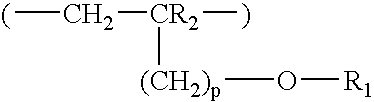

A compound having the formula below. X is hydroxyl, a sulfonic ester or salt thereof, a phosphonate or salt thereof, a carboxylate or salt thereof, or a boronic ester or salt thereof. The value n is an integer greater than or equal to 2. A polymer made by polymerizing the compound. A method of: reacting NH2—(CH2—CH2—O)n—CH2—CH2—OH with thiophene acid chloride to form a (SC4H3)—CO—NH—(CH2—CH2—O)n—CH2—CH2—OH amide; reacting the amide with a vinyl sulfonic ester, a vinyl phosphonate, a vinyl carboxylate, or a vinyl boronic ester to form an intermediate; and converting the intermediate to a salt form.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

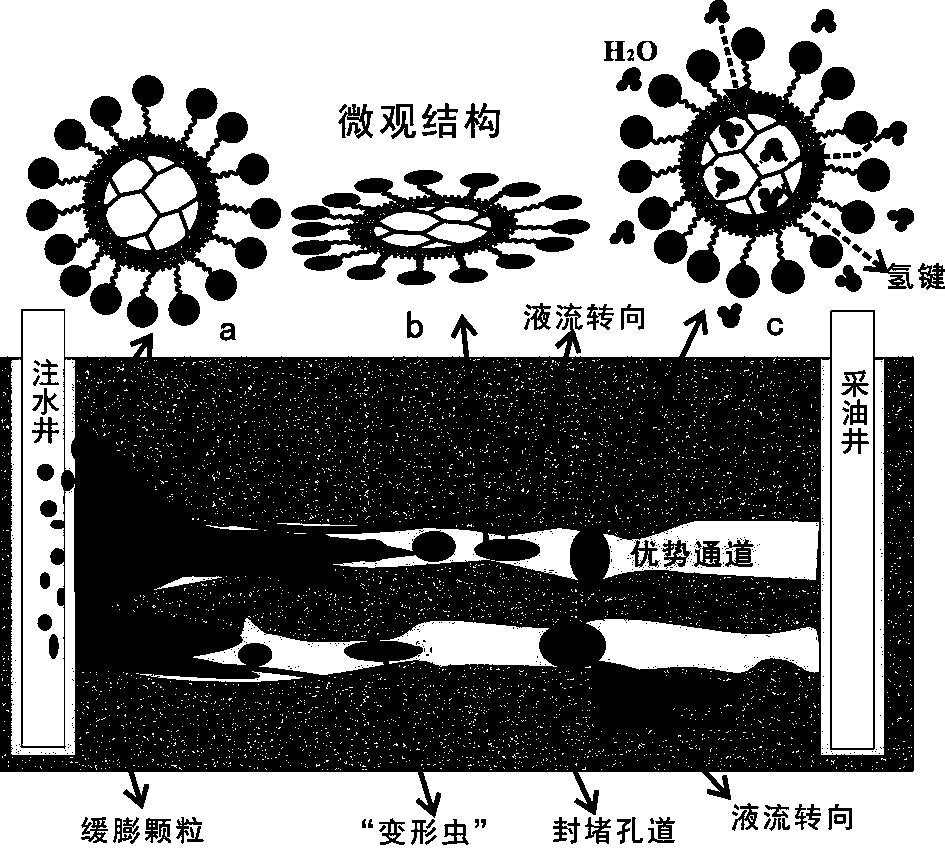

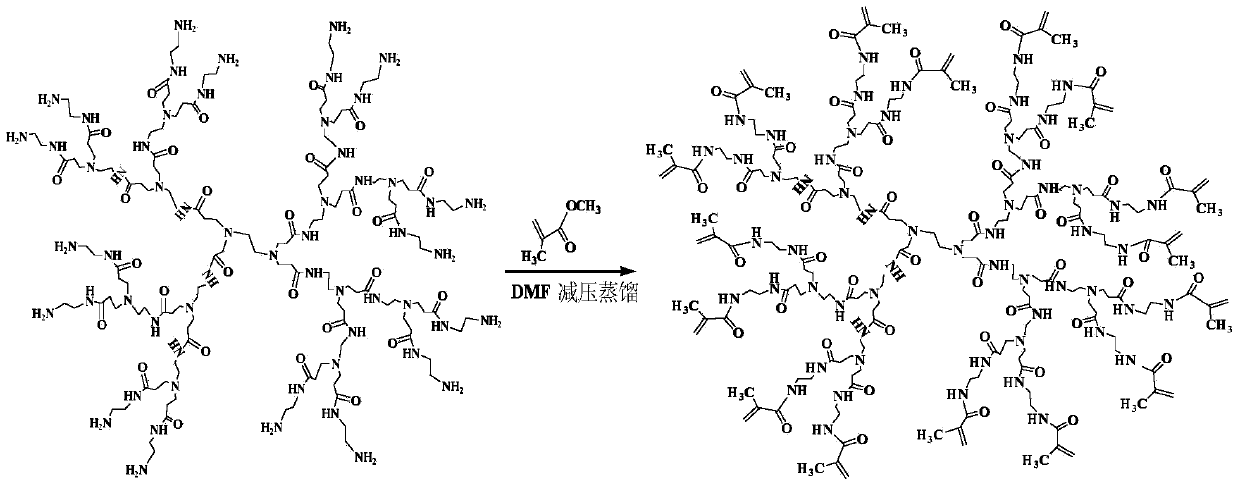

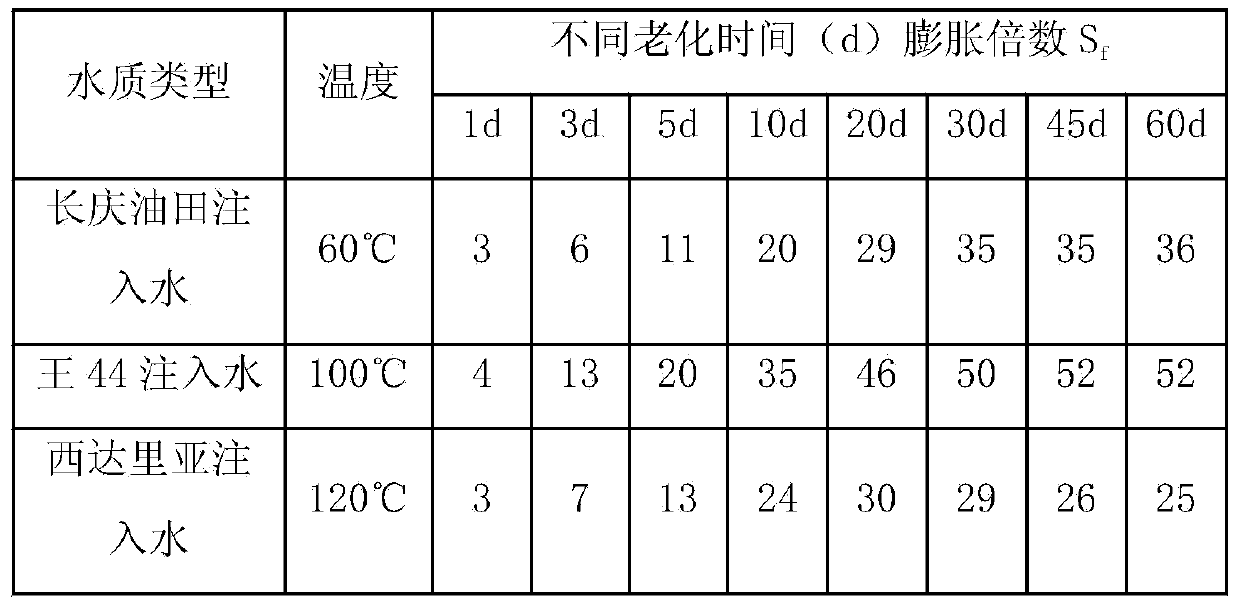

Hyperbranched slow-swelling profile control particles and preparation method thereof

ActiveCN103555305ARegular structureWater swelling process is slowDrilling compositionPolymer scienceNetwork structure

Owner:SOUTHWEST PETROLEUM UNIV

Gypsum slurries with linear polycarboxylate dispersants

ActiveUS20170334778A1Effective dispersionAvoid problemsConstructions elementsWater-setting substance layered productSulfonateSlurry

A gypsum slurry includes water, a hydraulic component including calcium sulfate hemihydrate and a linear polycarboxylate dispersant. The linear polycarboxylate anionic dispersant includes a first monomeric repeating unit and a second monomeric repeating unit. The first repeating unit of the linear polycarboxylate dispersant is an olefinic unsaturated carboxylic acid repeating unit or salt thereof. The second repeating unit of the linear polycarboxylate dispersant is a vinyl sulfonate. The slurry can be made into a gypsum panel. Methods of making gypsum slurry and a gypsum panel are also disclosed.

Owner:UNITED STATES GYPSUM CO

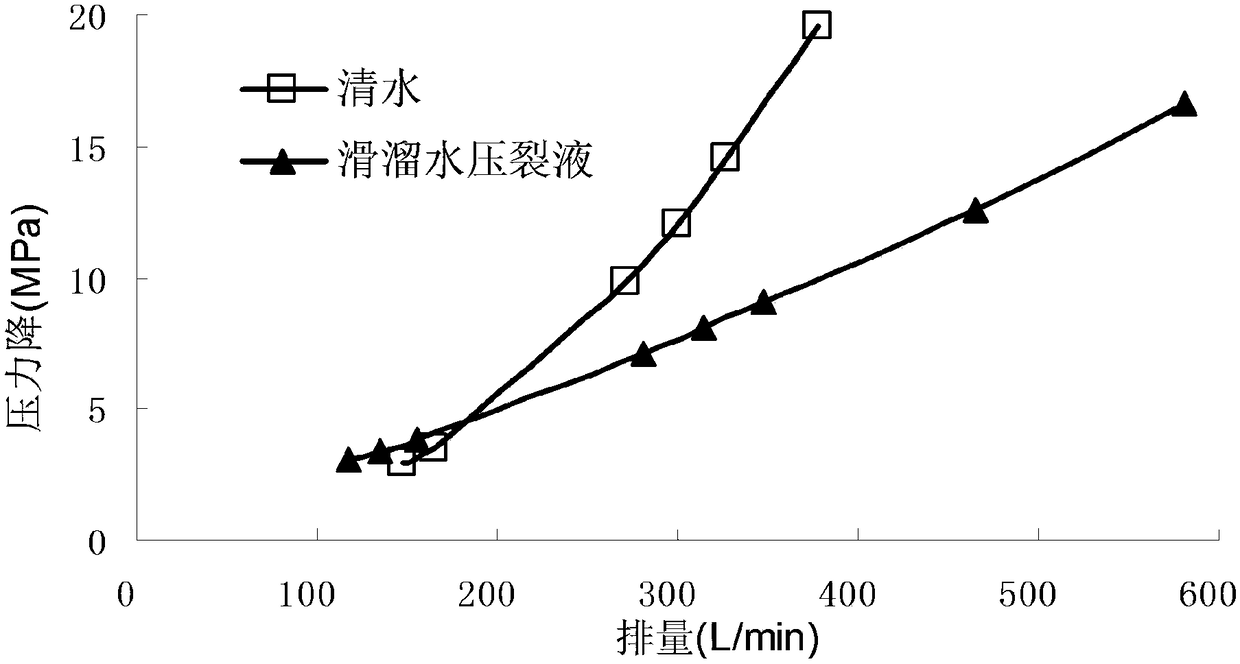

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Scale control composition for high scaling environments

InactiveUS20050282712A1Inhibition formationOther chemical processesWater softeningSulfonatePhosphate

Barium sulfate and / or calcium carbonate scale inhibitor composition composed of a water-soluble polymer having incorporated phosphate functionality, the polymer being formed from at least one ethylenically unsaturated carboxylic acid monomer, at least one ethylenically unsaturated vinyl sulfonate monomer, or a mixture thereof. The scale inhibitor composition can be used as a means of detecting inhibitor composition in downhole and topside oilfield treatments by means that are faster and more accurate than turbidometric measurement.

Owner:AKZO NOBEL NV

Production method of electrolyte membrane, electrolyte membrane and solid polymer fuel cell using same

InactiveUS7785751B2Improve proton conductivityConvenient ArrangementElectrolyte holding meansSolid electrolytesFuel cellsHydrogen

Disclosed is an electrolyte membrane which enables a fuel cell to have a high maximum output when used therein since it has high proton conductivity and high hydrogen gas impermeability. Also disclosed are a method for producing such an electrolyte membrane, and a solid polymer fuel cell using such an electrolyte membrane. A method for producing an electrolyte membrane including a step for impregnating a porous base with a solution containing a sulfonic acid group-containing vinyl monomer and then polymerizing the monomer is characterized in that 80% by mole or more of vinyl sulfonic acid having purity of 90% or more, and / or a salt thereof is contained as the sulfonic acid group-containing vinyl monomer, and the concentration of the vinyl sulfonic acid and / or a salt thereof in the solution is set at 35% by weight or more.

Owner:NITTO DENKO CORP

Polycarboxylic dispersant for oil-well cement and preparation method of polycarboxylic dispersant

ActiveCN107602773AImprove salt toleranceImprove temperature resistanceDrilling compositionSulfonatePolymer science

The invention discloses a polycarboxylic dispersant for oil-well cement and a preparation method of the polycarboxylic dispersant, and belongs to the technical field of oil-well cement additives. Thepolycarboxylic dispersant is a copolymer which is prepared from monomers composed of acrylic acid, N-vinyl pyrrolidone, itaconic acid, 2-acrylamido-2-methylpropanesulfonic acid, sodium vinyl sulfonate, sodium vinyl benzenesulfonate and allyl polyethylene glycol, wherein the weight-average molecular weight of allyl polyethylene glycol is 300-2400, and when the total mass of the monomers is 100%, the monomers comprises 0.5-20% of acrylic acid, 0.5-15% of N-vinyl pyrrolidone, 0.5-10% of itaconic acid, 5-60% of 2-acrylamido-2-methylpropanesulfonic acid, 0.5-30% of sodium vinyl sulfonate, 0.5-30% of sodium vinyl benzenesulfonate and 20-70% of allyl polyethylene glycol; the weight-average molecular weight of the polycarboxylic dispersant is 5000-250,000. The polycarboxylic dispersant has the advantages of good salt tolerance, high temperature resistance and rheological properties.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com