Cationic polymer coating agent for water-base drilling fluid and preparation method thereof

A technology of cationic polymer and water-based drilling fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased mud filtration loss, unstable mud performance, and high cost of drilling fluid, and achieve operational Simplicity, cost reduction, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthesis reaction is carried out in a double-layer jacketed enamel reactor with steam heating and electric stirring. Mix 180kg N, N dimethylacrylamide, 60kg acryloyloxyethyltrimethylammonium chloride and 490kg distilled water together, pump the prepared solution into the reaction kettle, after dissolving evenly, add 10kg vinyl sulfonate Acid, 0.7kg sodium formate, 5.2kg urea, after dissolving evenly, add 5.5kg NaOH to adjust the pH of the system to 6-7, so far the preparation of the raw material aqueous solution is completed, and pass N at room temperature 2 15 minutes to 30 minutes, then put the prepared raw material aqueous solution into the reaction tank evenly, add 0.09kg of ammonium persulfate and 0.18kg of sodium bisulfite initiator while draining the liquid, at a temperature of 10°C-30°C The lower solution polymerized for 4 hours, discharged, kneaded and dried in a kneader, and the dried product was further pulverized and sieved to obtain a cationic polymer...

Embodiment 2

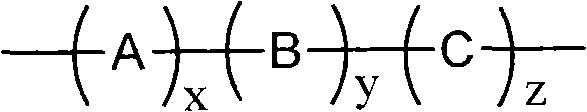

[0047] The synthesis reaction is carried out in a double-layer jacketed enamel reactor with steam heating and electric stirring. Mix 451kg of 40wt% acrylamide, 34.6kg of methacryloyloxyethyltrimethylammonium chloride and 220kg of distilled water together, pump the prepared solution into the reactor, and after dissolving evenly, add 14kg of 2-acrylamide -2 methylpropanesulfonic acid, 0.89kg sodium formate, 4.8kg urea, after dissolving evenly, adjust the pH of the system to 6-8 with 4.5kg KOH. 2 15 minutes to 30 minutes, then put the prepared raw material aqueous solution into the reaction tank evenly, add 0.07kg of ammonium persulfate and 0.12kg of sodium bisulfite initiator while draining the liquid, at a temperature of 10°C-30°C The lower solution polymerized for 4 hours, discharged, kneaded and dried in a kneader, and the dried product was further pulverized and sieved to obtain a cationic polymer coating agent, which has the following structural formula:

[0048]

[004...

Embodiment 3

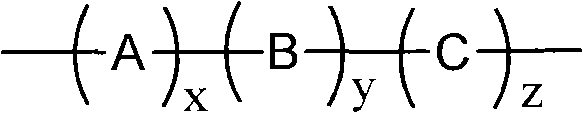

[0058] The synthesis reaction is carried out in a double-layer jacketed enamel reactor with steam heating and electric stirring. Mix 310kg of N,N-diethylacrylamide, 20kg of dimethyl diallyl ammonium chloride and 400kg of distilled water together, pump the prepared solution into the reaction kettle, after dissolving evenly, add 8kg of methacrylic acid, After 0.73kg sodium formate and 4.6kg urea are dissolved evenly, adjust the pH of the system to 6-7 with 2kg NaOH. 2 15 minutes to 30 minutes, then put the prepared raw material aqueous solution into the reaction tank evenly, and add 0.05kg potassium persulfate and 0.08kg sodium bisulfite initiator while draining the liquid, at a temperature of 10°C-30°C The solution was polymerized for 4 hours, discharged, kneaded and dried in a kneader, and the dried product was further pulverized and sieved to obtain a cationic polymer coating agent, which had the following structure:

[0059]

[0060] Where x is 40-120, y is 1-20, and z i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com