High-adhesion aqueous thermosetting acrylic resin, preparation method and applications thereof

An acrylic resin, high adhesion technology, applied in the direction of coating, etc., can solve the problems of poor gloss and water resistance of the final product, limit the application of emulsion, etc., achieve excellent protection performance, improve comprehensive performance, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

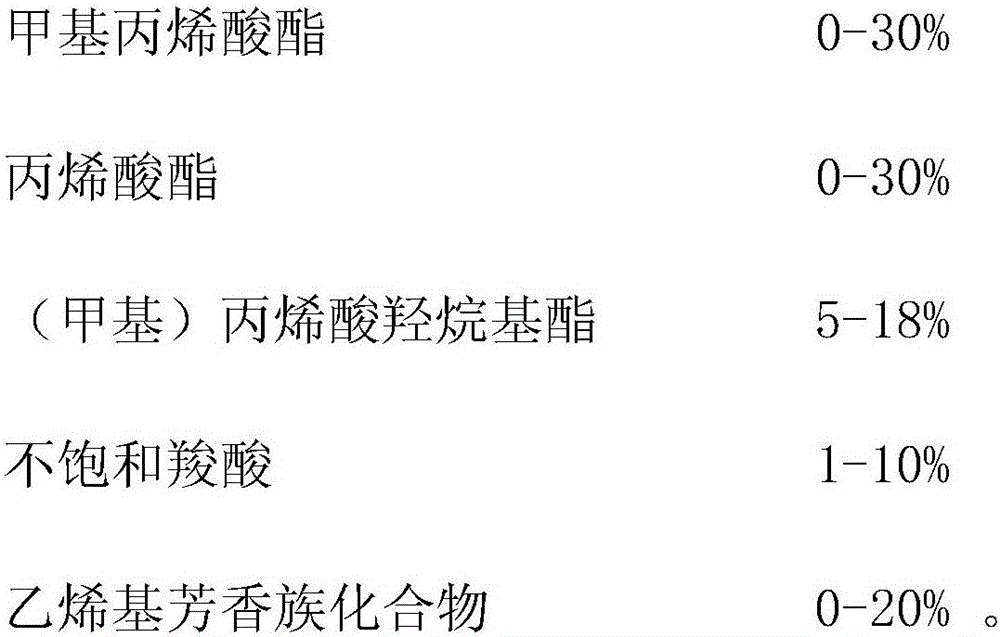

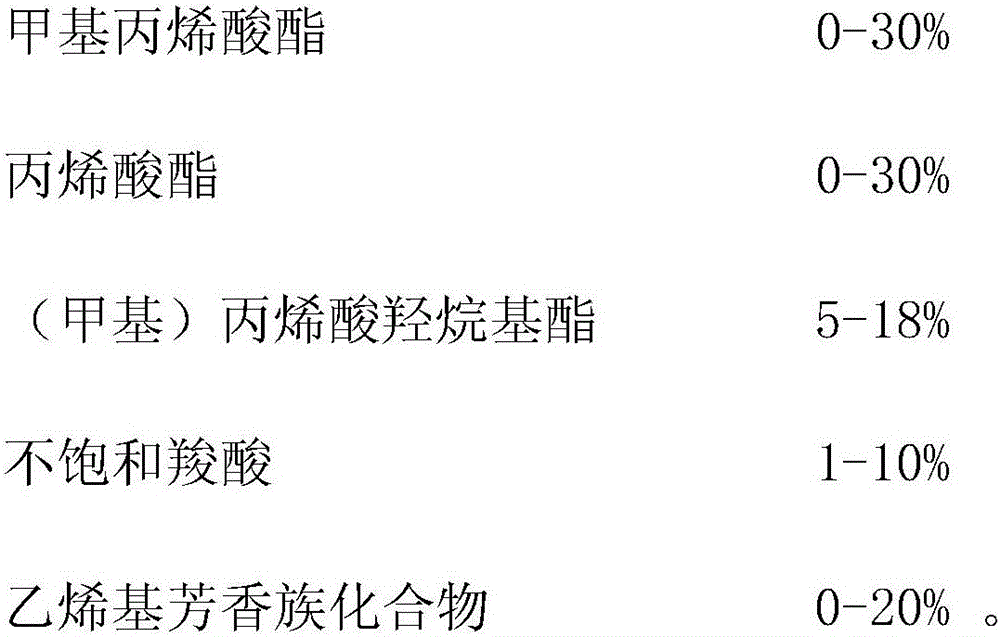

Method used

Image

Examples

preparation example Construction

[0043] The preparation method includes the following steps:

[0044] (1) Add alcohol ether solvent to a four-necked flask equipped with a stirring blade, thermometer and condenser, and raise the temperature to 80-200℃; the reaction temperature is 80-200℃, preferably 80-150℃. The specific temperature depends on the It depends on the type of initiator.

[0045] (2) Mix all reactive monomers and initiators, stir to make the mixture uniform;

[0046] (3) Divide the mixed solution in step (2) into two parts A and B, where the volume ratio of A:B is (1-9):1;

[0047] (4) Put part A into the dripping device, and finish the dripping at a constant rate within 2-5 hours. After the dripping of part A is finished, then drip part B, and add the silane coupling agent to the solution of part B , The dripping is completed within 0.5-2 hours; after the dripping is completed, increase the temperature by 5-10℃ and keep it for 2 hours;

[0048] (5) Reduce the temperature to 70°C or below, add organic ami...

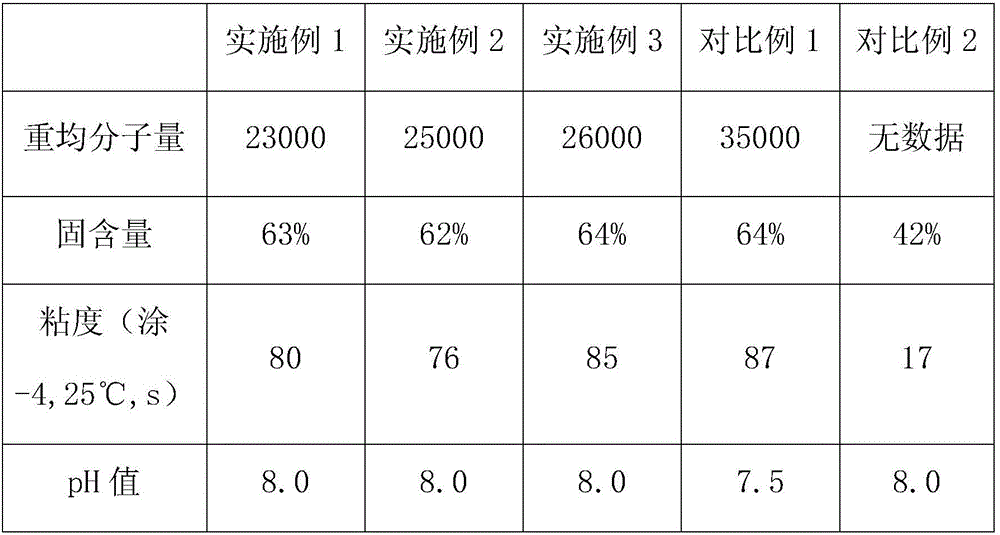

Embodiment 1

[0050] Add 20 g of ethanol and 40 g of propylene glycol butyl ether into a reaction device equipped with a stirring blade, a thermometer and a reflux condenser, and heat to 90°C. Mix 20 g of methyl methacrylate, 28 g of butyl acrylate, 20 g of isooctyl acrylate, 5 g of acrylic acid, 7 g of hydroxyethyl methacrylate, 20 g of E styrene, 3 g of initiator azobisisobutyronitrile, and divide them into A. , B is two components, the mass ratio of the two components is A:B=2:1, after the A component is dripped in 3 hours, add the silane coupling agent 5g vinyl trimethoxysilane to the B component within 1 hour After the dropwise addition is completed, after the reaction, the temperature is increased to 100°C and kept for 2 hours. After the temperature is lowered to 70°C, 4.5g of N,N-dimethylethanolamine is added to neutralize, and the material is discharged after stirring for 20 minutes to obtain the finished product.

Embodiment 2

[0052] Add 20 g of butanol and 40 g of propylene glycol butyl ether to a reaction device equipped with a stirring blade, a thermometer and a reflux condenser, and heat to 130°C. Combine 28 g of methyl methacrylate, 28 g of butyl acrylate, 9 g of acrylic acid, 15 g of hydroxyethyl methacrylate, 20 g of styrene, and 3 g of di-tert-butyl peroxide as the initiator. After mixing them, they are divided into two components A and B. The mass ratio of the components is A:B=3:1. After the A component has been dripped in 3 hours, add 3g of the silane coupling agent, 3-(2,3-epoxypropoxy)propyltrimethyl to the B component The oxysilane was added dropwise within 1 hour. After the reaction, the temperature was raised to 135°C and kept for 2 hours. After the temperature was lowered to 70°C, 9g of organic amine was added for neutralization. After stirring for 20 minutes, the material was discharged to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com