Poly carboxylic acid series super plasticizer and its preparing method

A polycarboxylic acid-based, superplasticizer technology, applied in the field of concrete admixtures, can solve the problems of fluctuations in performance and performance stability of superplasticizers, cumbersome synthesis process, small acid and alcohol, etc., and achieves easy control of synthesis conditions, Simple production process and low alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

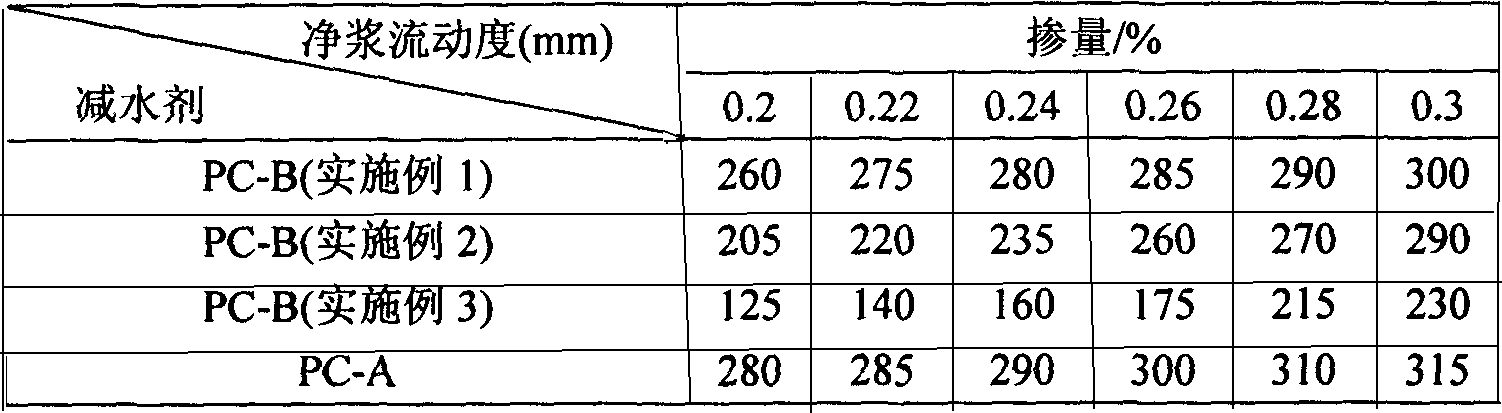

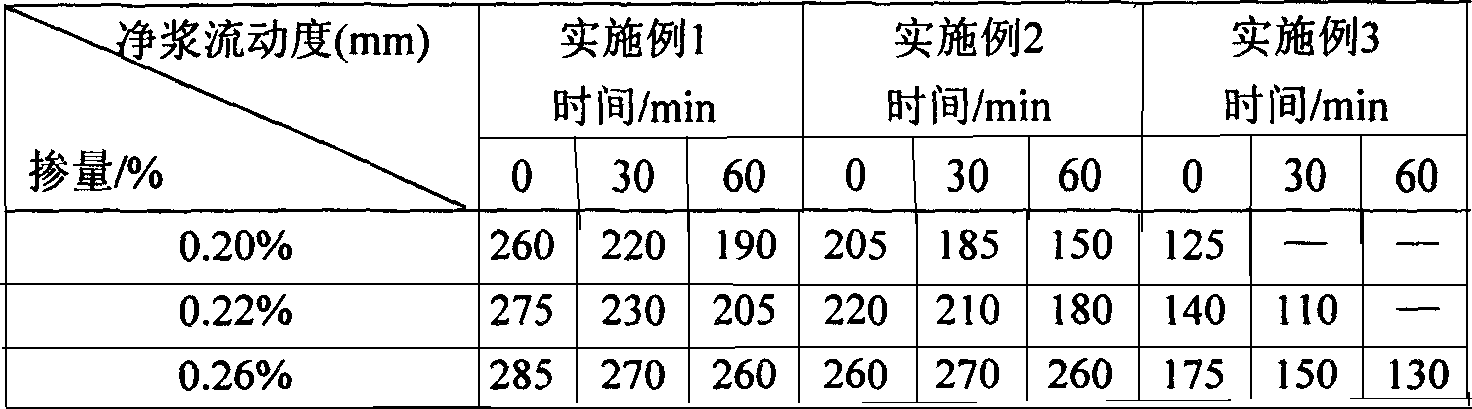

specific Embodiment approach 1

[0022] A polycarboxylic acid superplasticizer mainly comprises methoxy polyethylene glycol-1000, acrylic acid and sodium vinyl sulfonate. Wherein: methoxypolyethylene glycol-1000: acrylic acid: the molar ratio of vinyl sulfonate sodium is 1: 7 / 3: 2 / 3, namely the molar percentage of methoxypolyethylene glycol-1000 is: 25% , The mole percentage of acrylic acid: 58.3%, the mole percentage of sodium vinyl sulfonate: 16.7%.

[0023] A kind of concrete method step of the preparation method of polycarboxylate superplasticizer is as follows:

[0024] (1) material preparation

[0025] First prepare the materials according to the following components and ratios: the molar ratio of methoxypolyethylene glycol-1000:acrylic acid:sodium vinyl sulfonate is 1:7 / 3:2 / 3, that is, methoxypolyethylene glycol- The molar percentage of 1000 is: 25%, the molar percentage of acrylic acid: 58.3%, the molar percentage of sodium vinyl sulfonate: 16.7%;

[0026] The consumption of catalyzer p-toluenesulf...

specific Embodiment approach 2

[0033] A polycarboxylic acid superplasticizer mainly comprises methoxy polyethylene glycol-1000, acrylic acid and sodium vinyl sulfonate. Wherein: the molar ratio of methoxypolyethylene glycol-1000:acrylic acid:sodium vinyl sulfonate is 1:2:5 / 2, that is, the molar percentage of methoxypolyethylene glycol-1000 is: 18.1%, acrylic acid The mole percentage of sodium vinylsulfonate is 36.4%, and the mole percentage of sodium vinyl sulfonate is 45.5%.

[0034] A kind of concrete method step of the preparation method of polycarboxylate superplasticizer is as follows:

[0035] (1) material preparation

[0036] First prepare the materials according to the following components and ratios: the molar ratio of methoxypolyethylene glycol-1000: acrylic acid: sodium vinylsulfonate is 1: 2: 5 / 2, that is, the ratio of methoxypolyethylene glycol-1000 Mole percentage: 18.2%, mole percentage of acrylic acid: 36.3%, mole percentage of sodium vinyl sulfonate: 45.5%.

[0037] The consumption of ca...

specific Embodiment approach 3

[0044] A polycarboxylic acid superplasticizer mainly comprises methoxy polyethylene glycol-1000, acrylic acid and sodium vinyl sulfonate. Wherein: the molar ratio of methoxypolyethylene glycol-1000:acrylic acid:sodium vinyl sulfonate is 1:6:1 / 2, that is, the molar percentage of methoxypolyethylene glycol-1000 is: 13.3%, acrylic acid The mole percentage of sodium vinyl sulfonate is 6.7%.

[0045] A kind of concrete method step of the preparation method of polycarboxylate superplasticizer is as follows:

[0046] (1) material preparation

[0047] First prepare the raw materials according to the following components and ratios: the molar ratio of methoxypolyethylene glycol-1000: acrylic acid: sodium vinylsulfonate is 1: 6: 1 / 2, that is, the ratio of methoxypolyethylene glycol-1000 Mole percentage: 13.3%, mole percentage of acrylic acid: 80%, mole percentage of sodium vinyl sulfonate: 6.7%.

[0048] The consumption of catalyzer p-toluenesulfonic acid is 3.75wt% of the methoxypol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com