Patents

Literature

81results about How to "With retarding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

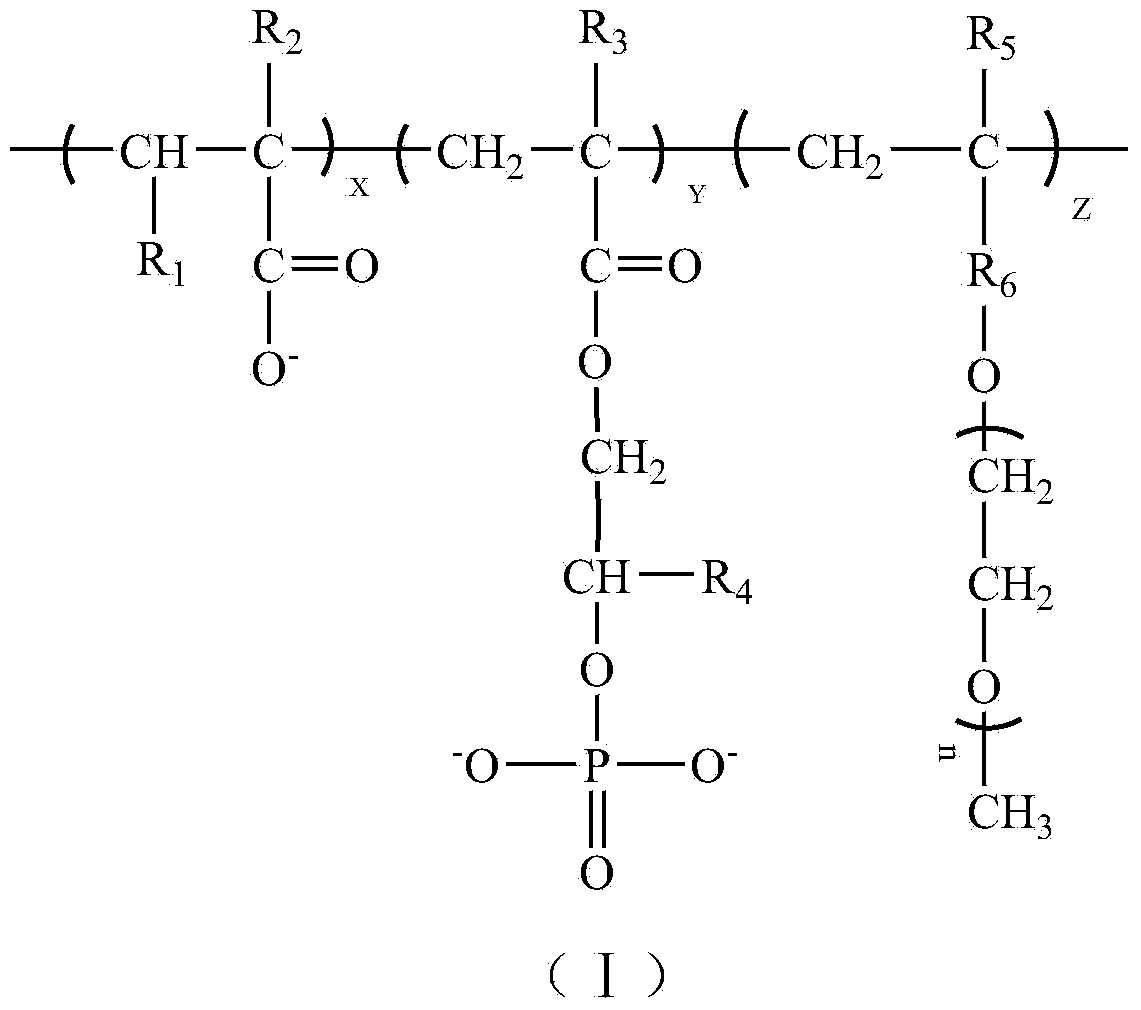

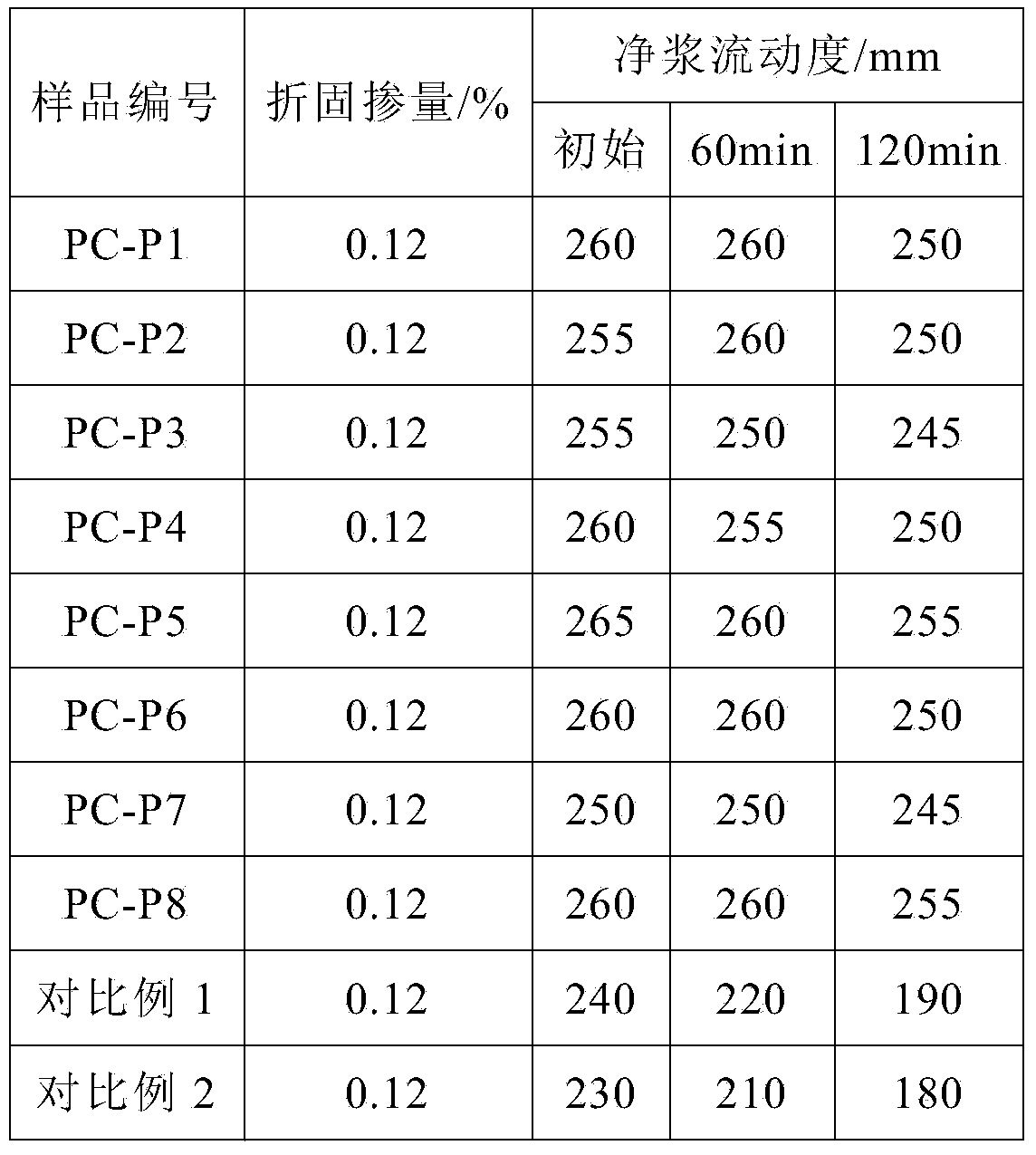

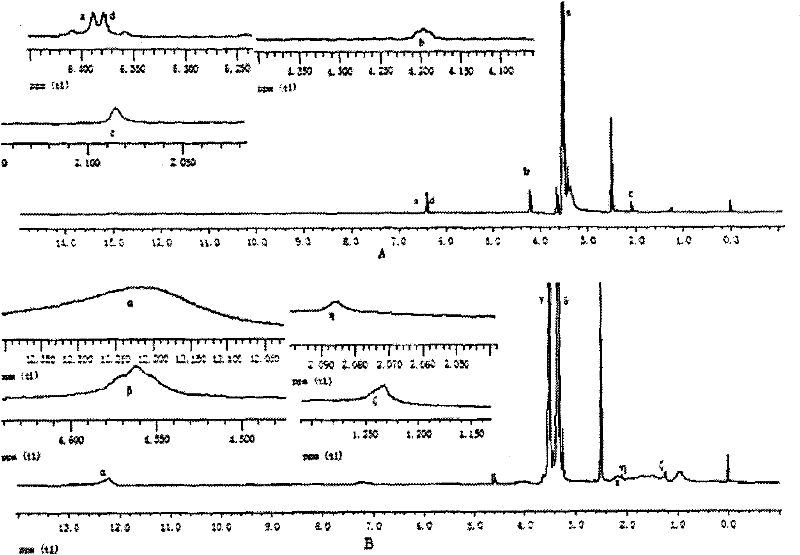

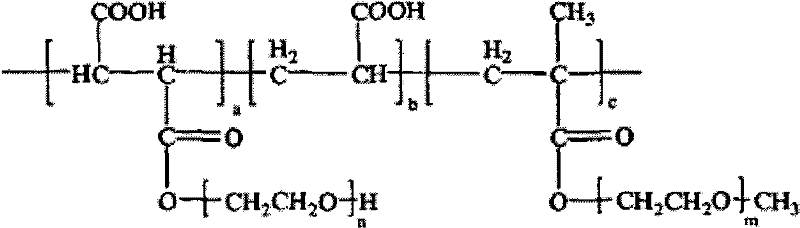

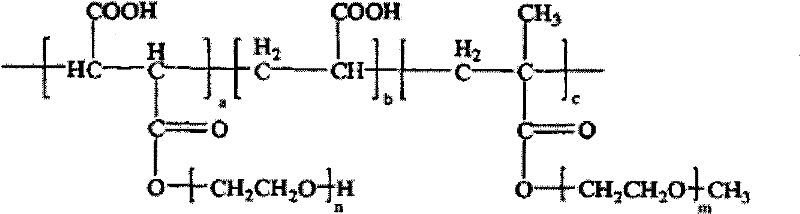

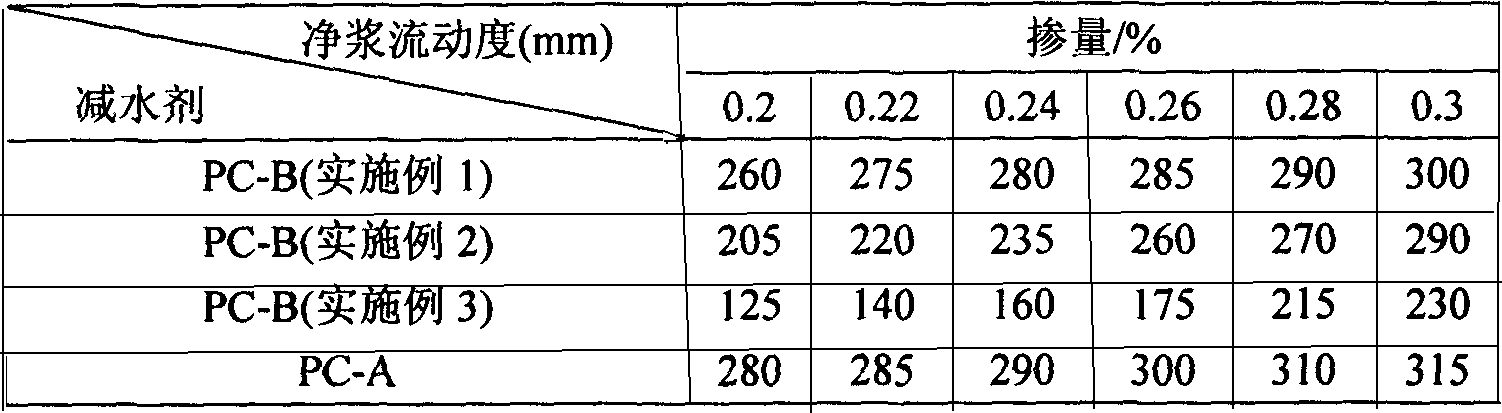

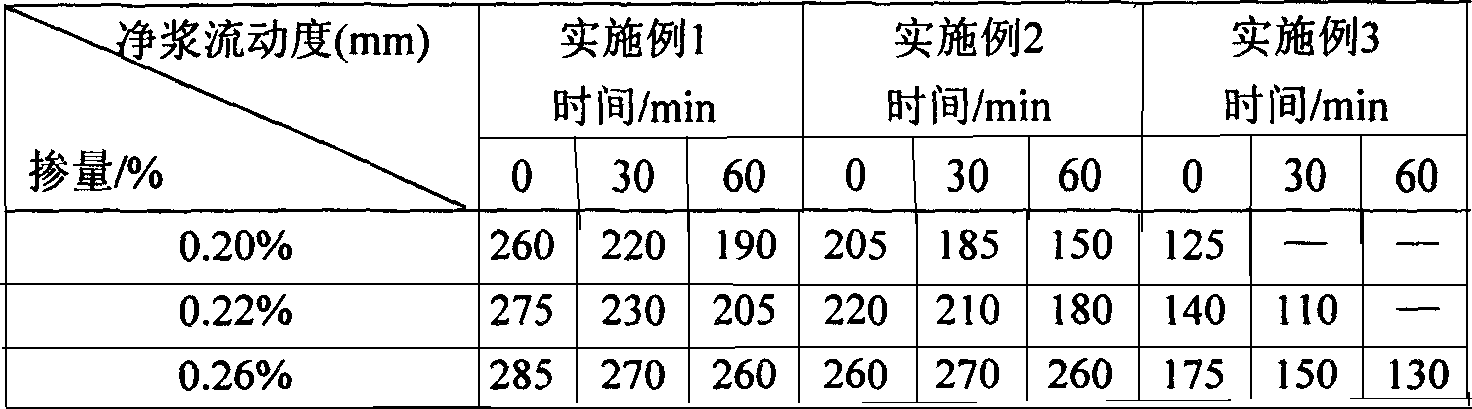

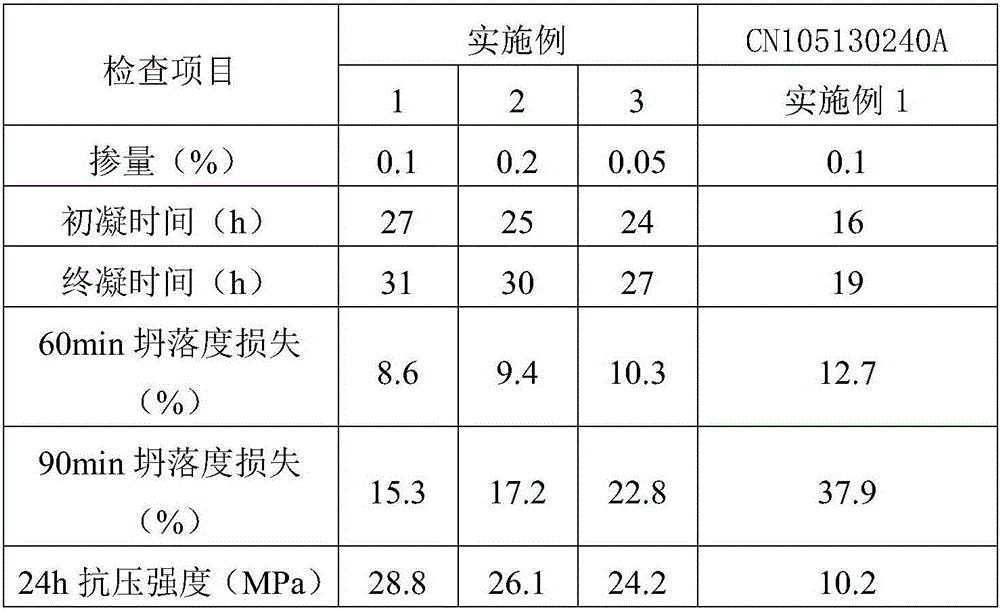

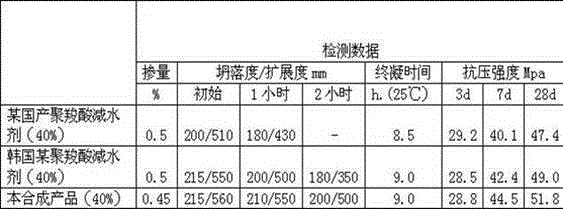

High-performance polycarboxylate water reducing agent and preparation method thereof

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

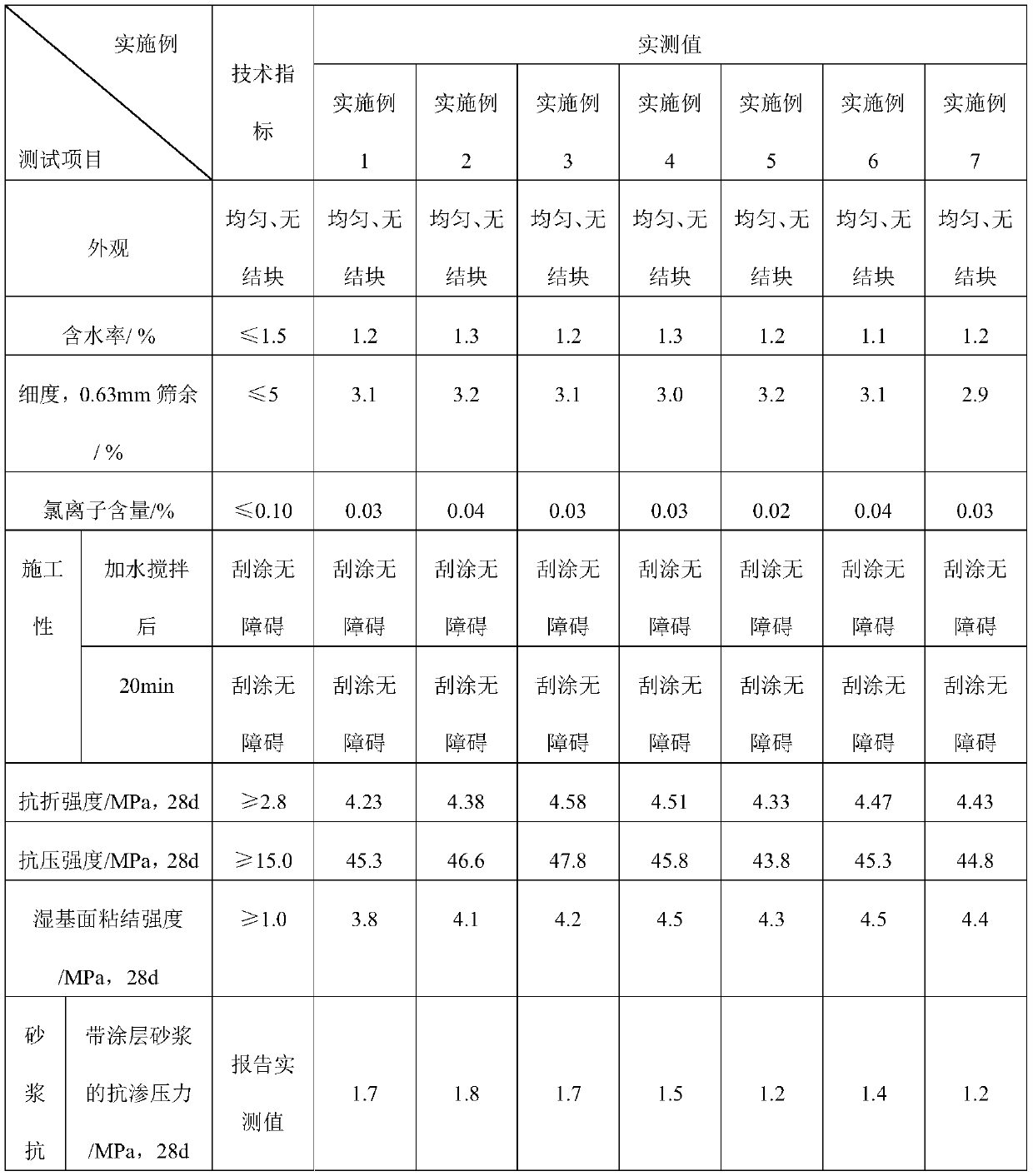

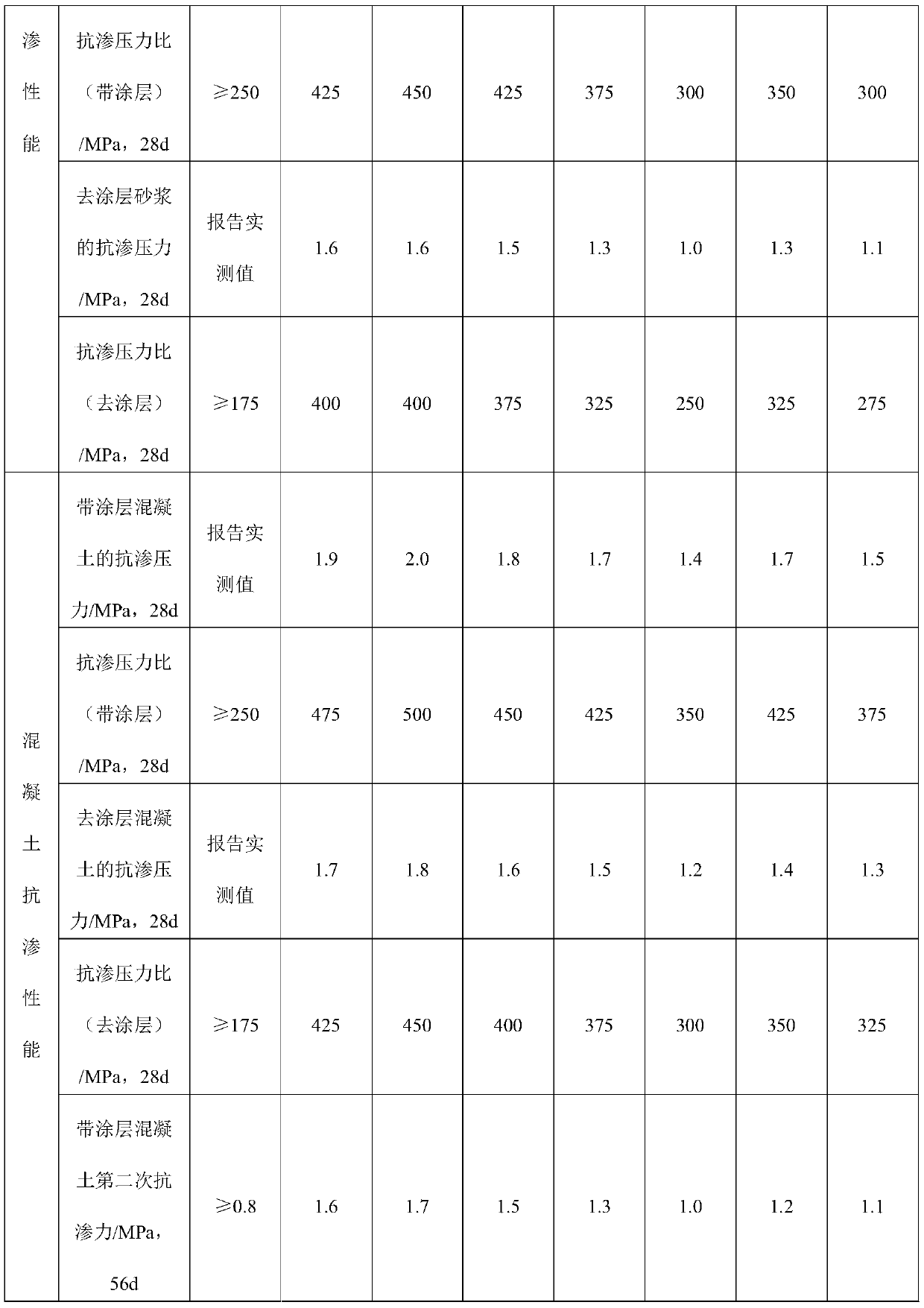

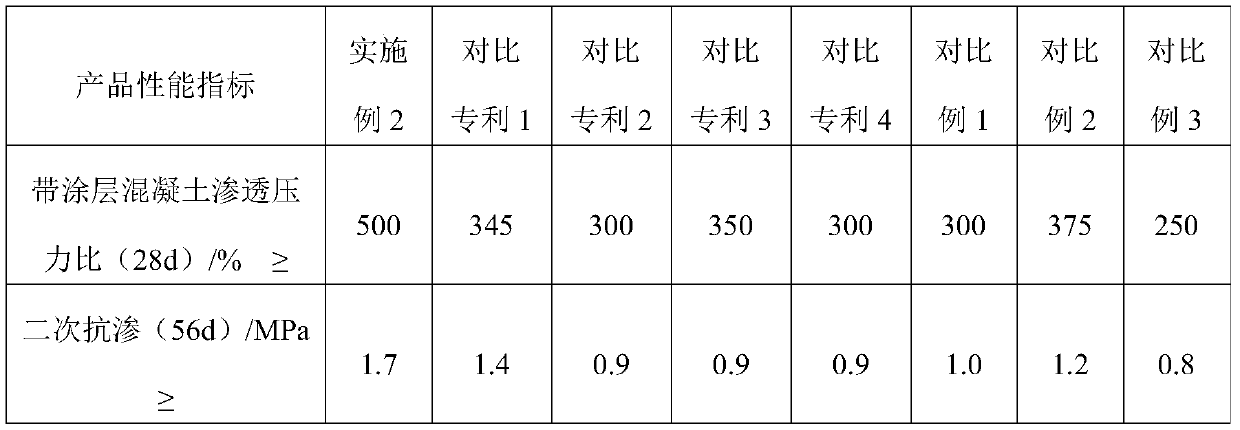

Cement-based capillary crystalline waterproof material based on nanosilicon-based material and preparation method and application thereof

The invention relates to a cement-based capillary crystalline waterproof material based on a nanosilicon-based material and a preparation method and application thereof. The waterproof material is prepared from, by weight, 45-65 parts of cement, 14-32 parts of quartz sand, 5-10 parts of a retarder, 0.1-0.4 part of the nanosilicon-based material, 2-9 parts of a crystal precipitant, 0.5-5 parts of asurfactant, 0.5-2 parts of a complexing agent, 1-5 parts of a calcium ion compensation agent, 0.5-2 parts of a water reducing agent and 0.2-2 parts of cellulose ether. Compared with the prior art, the cement-based capillary crystalline waterproof material is suitable for repairing pores and cracks inside cement, when a cement-based material has the cracks of which the diameters are small than 0.4mm, insoluble sediment is generated in the cracks of the cement-based material in the presence of water to fill and seal the cracks of the cement-based material, and thus self-repairing of the cracksof the cement-based material is achieved.

Owner:上海凯顿百森建筑工程有限公司

Synthetic method for maleic polycarboxylic water reducer

The invention discloses a synthetic method for maleic polycarboxylic water reducer. The method is characterized in that: maleic anhydride (MA) and polyethylene glycol (PEG) / methoxy polyethylene glycol (MPEG) are used as the raw materials to synthesize polyethylene glycol maleate monoester (PEG-MA) / methoxy polyethylene glycol maleate monoester (MPEG-MA); and PEG-MA / MPEG-MA, AA / AANa and methoxy polyethylene glycol metacrylic acid ester (MPEG-MAA) are used as the raw materials to synthesize a maleic polycarboxylic water reducer containing carboxyl and a polyoxyethylene (PEO) side chain structure. According to the invention, the molecular structure of the polycarboxylic water reducer introduces carboxyl and PEO with a long side chain, which enables electrostatic repulsion among cement particles to be increased, dispersibility, i.e. retentivity of dispersion of cement to be improved, and steric hindrance among cement particles is realized, thereby realizing low slump loss. Simultaneously, the preparation method provided in the invention has the advantages of a simple process, mild reaction and wide sources of cheap raw materials.

Owner:赵争艳

Preparation method of oxidation-etherification starch used as concrete water reducer

The invention relates to a preparation method of oxidation-etherification starch used as concrete water reducer. The preparation method is characterized by comprising the following steps: adding water into starch to prepare starch milk with moisture content of 20-40 percent; adjusting the pH value to 9-11; adding sodium hypochlorite as an oxidant the weight of which is 6-10 percent of the weight of the starch, mixing and reacting for 3-4h at the temperature of 35-40 DEG C under stirring; neutralizing until the pH value is 7-8; adding sodium bisulfite the weight of which is 5-15 percent of the weight of the oxidant to stop the reaction; filtering, washing and drying to obtain oxidized starch; dispersing the oxidized starch into absolute alcohol to prepare suspension with the concentration of 30-40 percent; adjusting the pH to 9-11; adding a mixed solution of oxacyclopropane and absolute alcohol and mixing; placing the mixture in an airtight reactor and reacting for 16-24h at the temperature of 40-45 EDG C under the protection nitrogen; neutralizing until the pH value is 7-8; and filtering, washing the solid with the absolute alcohol and drying to obtained the oxidation-etherification starch product. The preparation process is environmental-friendly and innocuous and has excellent performance when used as the water reducer.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

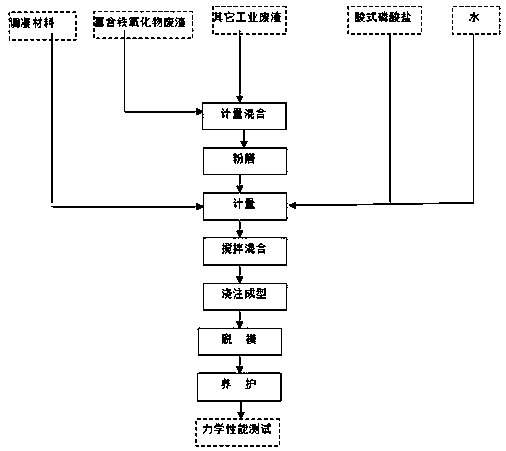

Iron phosphate cement

The invention discloses an iron phosphate cement, belonging to the technical field of building materials. The cementing material is prepared by uniformly mixing the following raw materials with the particle size of 1-100 mu m in parts by weight: 100 parts of acid phosphate, 400-800 parts of waste residue containing rich iron oxides, 3-6 parts of coagulation regulating material, 10-30 parts of other industrial waste residues and 15-200 parts of water. The iron phosphate cement has the advantages of adjustable setting time (several minutes to several hours), quick hardening, high strength, high binding property, no reduction of later strength, and the like, and can be quick hardened at normal temperature. The iron phosphate cement is simple in preparation technique, has high constructability, is suitable for quick emergency repair of defects of roads, airport pavements, bridges, tunnels, cooking ranges, dams, ditches and other engineering structures, and has wide application prospects in curing of high-risk waste residues containing rich radioelements, heavy metal elements, arsenic and the like.

Owner:KUNMING UNIV OF SCI & TECH

Phosphor slag power concrete mortar

InactiveCN101269942AReduce cement consumptionProlong clotting timeSolid waste managementSlagSilicate Cement

The present invention discloses phosphorous ground slag cement mortar, and comprises ordinary silicate cement, phosphorous ground slag, sand and water. On the one hand, the phosphorous ground slag used in the present invention is used as mixed material to substitute the cement in equal weight to be mixed into the pre-mixing commodity mortar, thus reducing the consumption volume of the cement; on the other hand, the retardation property of the phosphorous slag is used to obviously prolong the condensation time, thereby overcoming the weakness that the retardation agent must be added into the traditional pre-mixing commodity mortar, and can realize the effect similar to the adding of the retardation agent. Therefore, the present invention makes full use of the effect of the phosphorous to improve the workability of the mortar, thereby greatly reducing the production cost, and reducing the environmental pollution.

Owner:GUIZHOU UNIV

Poly carboxylic acid series super plasticizer and its preparing method

The present invention is serial polycarboxylic acid super plasticizers and their preparation process, and belongs to the field of concrete admixture technology. The super plasticizer is prepared with acrylic acid, methoxy polyglycol-1000 and sodium vinyl sulfonate, and through the esterification of acrylic acid and methoxy polyglycol-1000 in water bath to prepare intermediate polyglycol acrylate, and the subsequent free radical polymerization of polyglycol acrylate, sodium vinyl sulfonate and acrylic acid under the action of initiator in water solution. The preparation process has easily controlled condition, simple operation, no pollution, low cost and other features. The product of the present invention may be used as concrete super plasticizer suitable for different kinds of cement.

Owner:CHONGQING UNIV

Concrete retarder

The invention discloses a concrete retarder which is prepared from the following components in parts by weight: 4-6 parts of ammonium phosphate, 5-7 parts of ammonium sulfate, 6-8 parts of sodium tripolyphosphate, 10-15 parts of amino trimethylene phosphonic acid, 3-7 parts of gelatin, 1-3 parts of glycerol, 2-4 parts of sodium citrate, 10-15 parts of zeolite powder, 10-15 parts of pumice powder, 3-5 parts of water reducer, 1-3 parts of dispersant and 0.4-0.6 part of surfactant. The concrete retarder has the advantages of good retarding effect, high strength, no pollution and the like, and is a concrete additive with developing future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

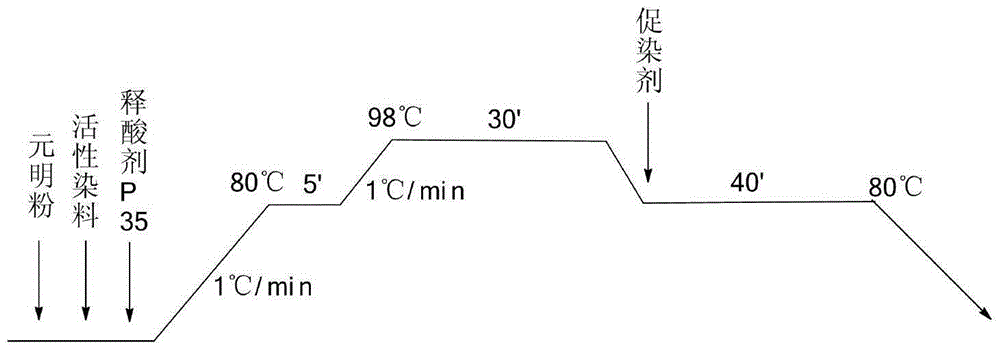

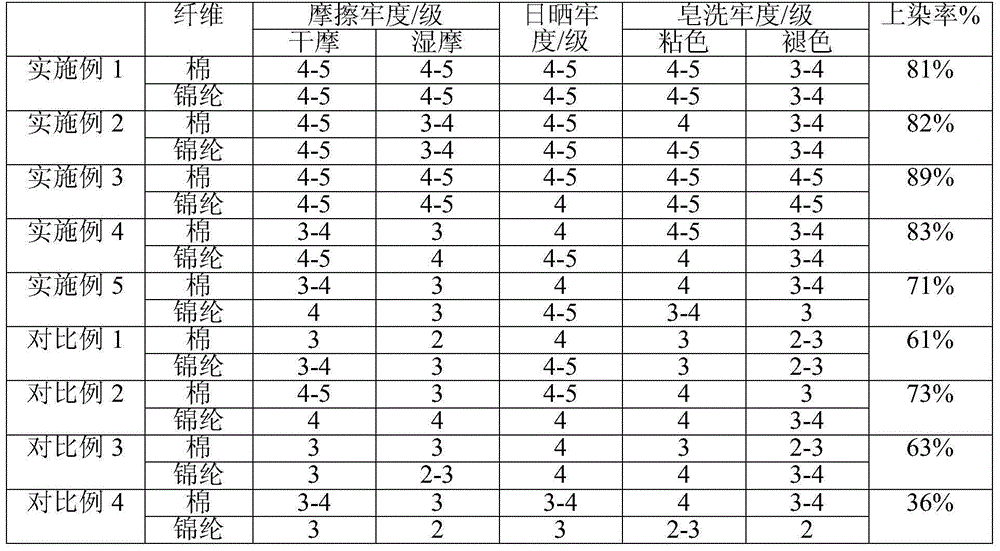

One-bath dyeing method for brocade cotton through reactive dyes

The invention discloses a one-bath dyeing method for brocade cotton through reactive dyes. The method comprises steps as follows: step (1), brocade cotton cloth is pretreated, dye liquor is added, and the bath ratio of the brocade cotton cloth to the dye liquor is 1: (4-6); step (2), the dye liquor is gradiently heated to 95-100 DEG C, the cloth is kept at the temperature to be dyed for 30-40 min, the dye liquor is cooled to 80-85 DEG C, a dyeing accelerant solution is added, and color fixation is performed for 40-50 min; step (3), the dyed brocade cotton is obtained through aftertreatment after dyeing in the step (2) is completed. One-bath dyeing of the brocade cotton is realized through coordination of the temperature, an acid-releasing agent, anhydrous sodium sulphate and the reactive dyes, a process is simple, energy is saved, and the prepared dyed brocade cotton has high washing fastness and small chromatic aberration.

Owner:浙江劲光纺织科技有限公司

Concrete retarder

The invention discloses concrete retarder. The concrete retarder comprises, by weight, 2-4 parts of sodium borate, 3-7 parts of monopotassium phosphate, 4-8 parts of calcium sulfate, 6-8 parts of etidronic acid, 3-5 parts of ethylene diamine tetraacetic acid, 1-4 parts of sorbitol, 25-30 parts of bentonite, 10-15 parts of vermiculite powder, 4-6 parts of a water reducing agent, 1-3 parts of a dispersing agent and 0.4-0,8 part of a surface active agent. The concrete retarder has the advantages of good retarding effect, high strength, free of pollution and the like, and is a concrete additive which is quite promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Super-long super slow release type polycarboxylic acid slump-retaining agent master batch

The invention discloses a super-long super slow release type polycarboxylic acid slump-retaining agent master batch suitable for projects such as hydraulic tunnels, railway tunnels, metros and underground oil and gas delivery adopting concrete having the capability of retaining slump for 4-6 hours under the conditions of hot weather and long distance. Limited by 40% of the mass percent of mother liquid, the total mass of synthesized raw materials is 1000 parts, the usage amount proportion is that the usage amount of polyether macromonomer accounts for 325-335 parts, the usage amount of unsaturated carboxylic acid micro-monomer accounts for 10.0-18.0 parts, the usage amount of acrylic hydroxyalkanoate accounts for 35.0-45.0 parts, the usage amount of crosslinking monomer accounts for 5.0-10.0 parts, the usage amount of sulfonic acid type chain transfer agent accounts for 2.0-5.0 parts, the usage amount of hydrogen peroxide accounts for 2.0-3.5 parts, the usage amount of vitamin C accounts for 0.60-0.90 part, the usage amount of caustic soda liquid accounts for 7-10 parts, and the balance is water. The polycarboxylic acid slump-retaining agent is moderate in molecular weight, can be independently used or compounded with other polycarboxylic acid water reducing agents for usage, can remarkably improve the indexes such as slump-retaining property, cohesiveness and flowing retention ability of newly mixed concrete in 6 hours.

Owner:HUBEI UNIV OF TECH

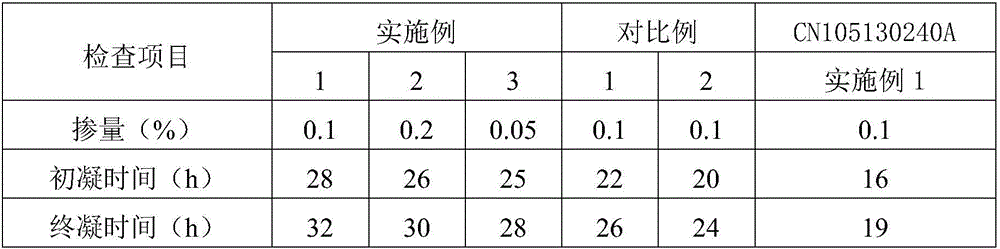

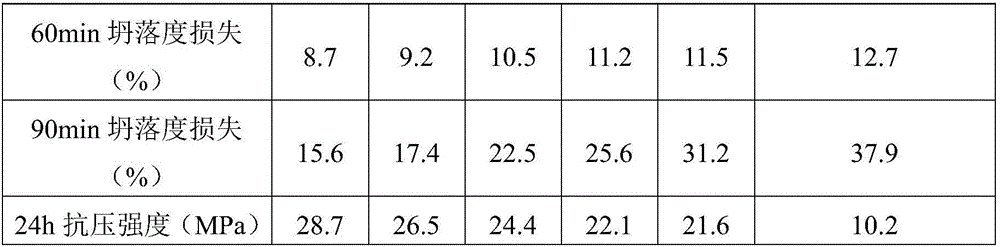

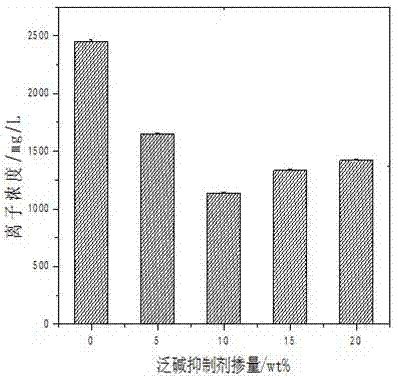

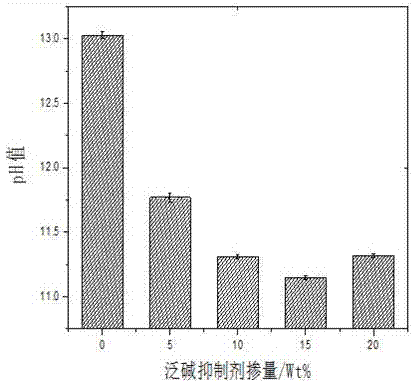

Alkali-activated slag cement efflorescence inhibitor and preparation method thereof

The invention relates to the technical field of building materials, in particular to an inhibitor capable of inhibiting efflorescence of alkali-activated slag cement and adjusting the performance of the alkali-activated slag cement, and a preparation method of the inhibitor. The alkali-activated slag cement efflorescence inhibitor is characterized by being prepared from the following raw materials by mass percent: 10-30% of zeolite, 10-20% of silica fume, 20-30% of pulverized fuel ash, 5-15% of boric acid and 5-55% of superfine slag powder. The alkali-activated slag cement efflorescence inhibitor provided by the invention is simple to prepare and use, and has a certain retarding effect; after the efflorescence inhibitor is added into alkali-activated slag cement concrete and mortar, the working performance of the alkali-activated slag cement concrete and mortar can be improved, the engineering quality is improved after construction, the early strength and later strength of the alkali-activated slag cement concrete can be increased by 15-20%, the efflorescence probability of the alkali-activated slag cement concrete is greatly reduced, and the reduction magnitude reaches up to 80%; the alkali-activated slag cement efflorescence inhibitor can inhibit the efflorescence phenomenon of the alkali-activated slag cement after construction, and has an inhibiting effect on the efflorescence phenomenon of the building materials after construction.

Owner:UNIV OF JINAN

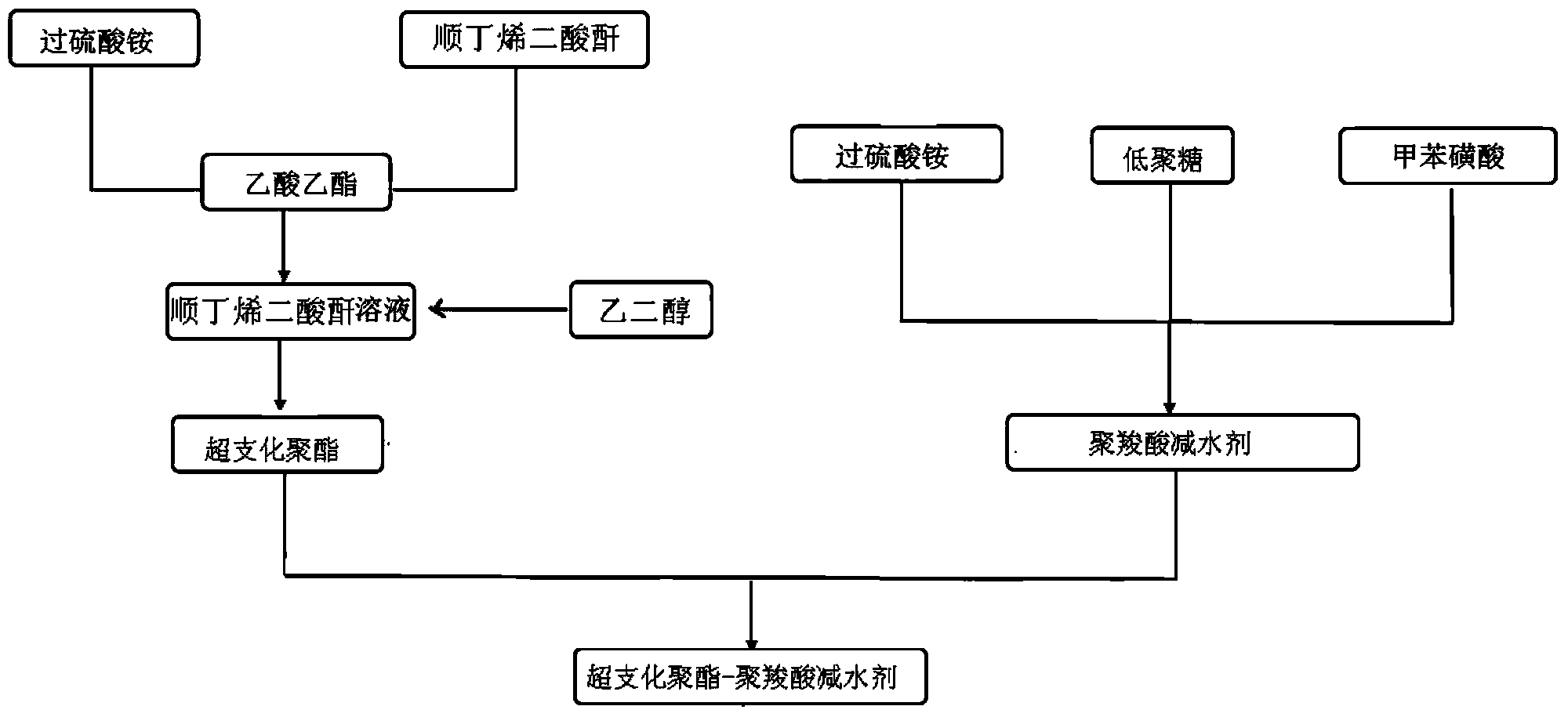

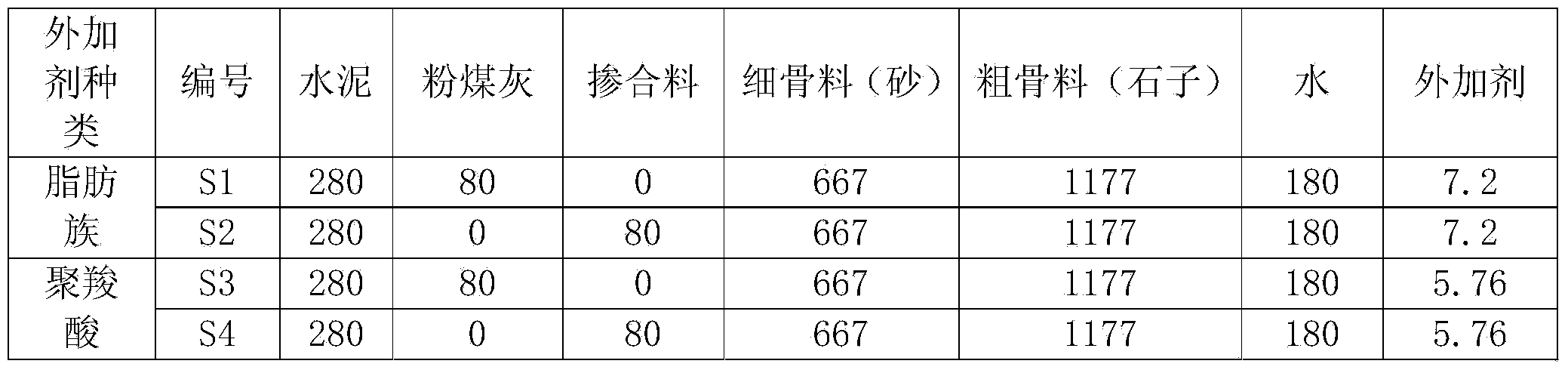

Hyperbranched polyester-polycarboxylate water reducing agent and preparation method for same

The invention discloses a hyperbranched polyester-polycarboxylate water reducing agent and a preparation method for the same. The method comprises the following steps: synthesizing hyperbranched polyester, adding oligosaccharide, ammonium persulfate, a polycarboxylate water reducing agent and a catalyst, performing end group modification on the hyperbranched polyester under the action of the catalyst, and synthesizing the hyperbranched polyester-polycarboxylate water reducing agent. According to the hyperbranched polyester-polycarboxylate water reducing agent and the preparation method for the same, a synthesis process is researched from the designability and controllability of branching degree and molecular weight during the synthesis of the hyperbranched polyester to further prepare a novel polycarboxylate water reducing agent product with high performance and adaptability, an experimental basis is provided for industrial application and popularization, and meanwhile, important theoretical value and economic benefits are created.

Owner:SHANDONG HONGYI TECH

Retarding composite limestone powder admixture

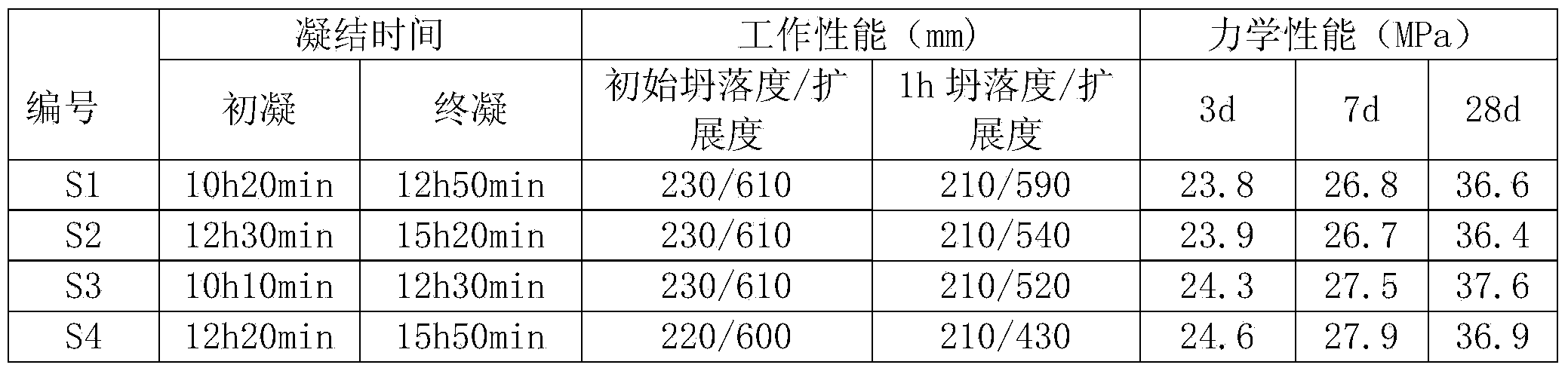

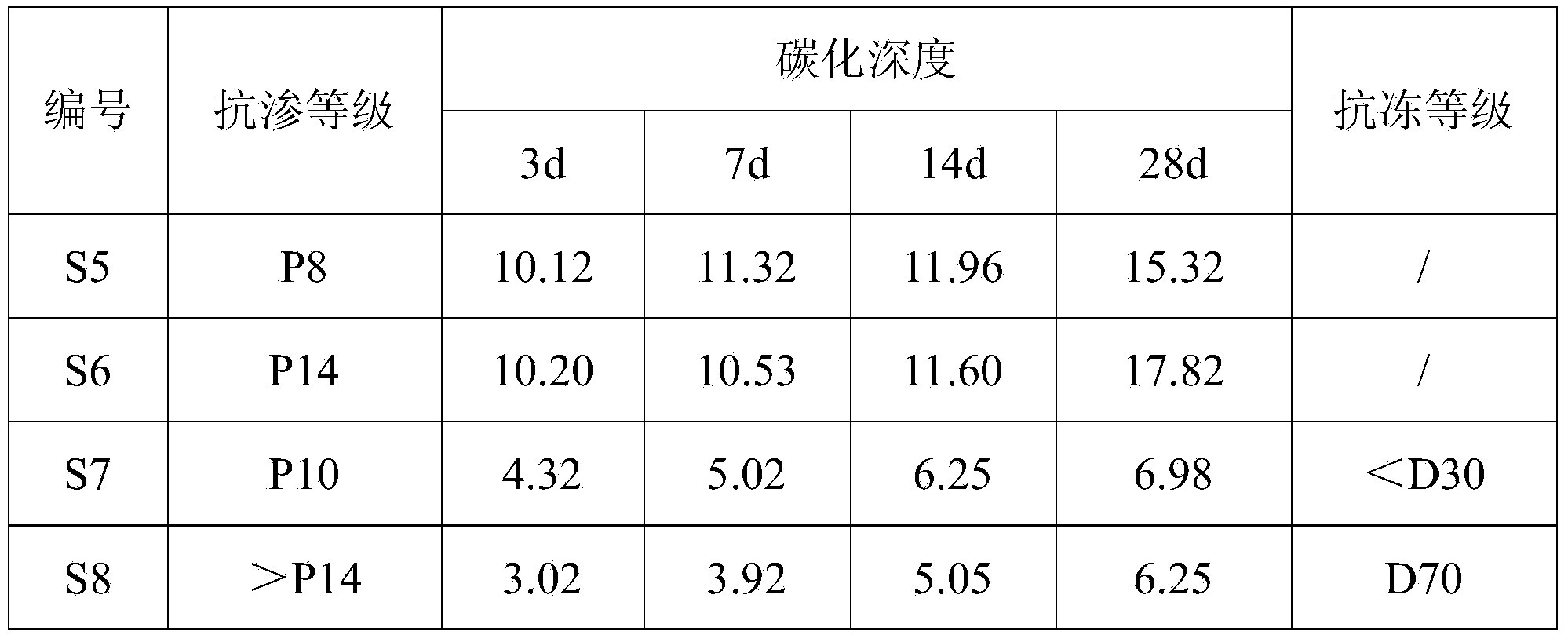

InactiveCN103833242ASmall loss over timeImprove mechanical propertiesCement productionWork performanceSlag

The invention relates to a retarding composite limestone powder admixture which comprises the following components by weight: 75-90% of limestone powder; 15-20% of steel slag; 3-8% of phosphorus slag; 0.3-2% of grinding aid. The components are well mixed according to the ratios, and then grinded into fine powder with a fineness specific surface area of not less than 350 m2 / kg to obtain the admixture. The admixture has retarding effect, reduces gradual loss in slump of concrete, facilitates smooth construction, and meets requirements of working performance, mechanical properties, and durability of concrete during construction; the admixture adopts limestone powder instead of cement or fly ash, thereby preventing resource waste; concrete prepared by the admixture of the invention is suitable for various building constructions.

Owner:CHONGQING XINCAI CONCRETE GRP

Novel concrete retarder

The invention disclsoes a novel concrete retarder. The novel concrete retarder is prepared from the following components in parts by weight: 2 to 5 parts of ammonium borate, 3 to 8 parts of sodium pyrophosphate, 4 to 9 parts of magnesium sulfate, 6 to 9 parts of diethylenetriaminepenta(methylenephosphonic) acid, 3 to 6 parts of sodium carboxymethyl cellulose, 1 to 4 parts of maltodextrin, 1 to 3 parts of sodium tartrate, 15 to 20 parts of palygorskite powder, 4 to 7 parts of a water reducing agent, 1 to 3 parts of a dispersant and 0.5 to 0.8 part of a surfactant. The novel concrete retarder provided by the invention has the advantages of excellent retarding effect, high strength, no pollution and the like, and is a concrete additive which has a very good development future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Polyphosphonic acid type water reducing agents and synthesis method thereof

The invention discloses polyphosphonic acid type water reducing agents. The polyphosphonic acid type water reducing agents are prepared from raw materials as follows: a, methyl allyl polyethenoxy ether; b, acrylic acid or methylacrylic acid; c, vinylphosphonic acid; d, ammonium persulfate; e, mercaptoacetic acid or mercaptopropionic acid; f, trisodium phosphate. The mole ratio of a to b to c to f is 1:(3-4):(0.2-1):(2-3); the material d accounts for 0.2%-0.5% of the total weight of all the materials; the material e accounts for 0.1%-0.3% of the total weight of all the materials. Besides, the invention further discloses a synthesis method of the polyphosphonic acid type water reducing agents. Compared with common polycarboxylate superplasticizers, the phosphonic acid and carboxylic acid copolymerized water reducing agent has a better water reducing effect and a slump keeping effect and has a certain delayed coagulation function on concrete.

Owner:吉林众鑫化工集团有限公司

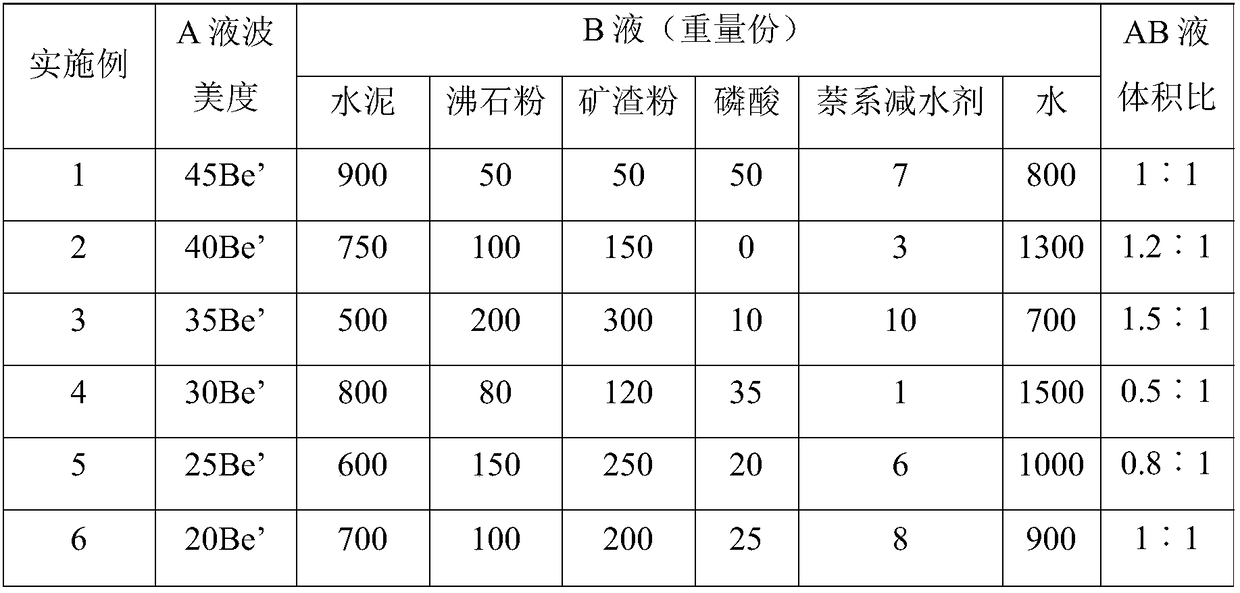

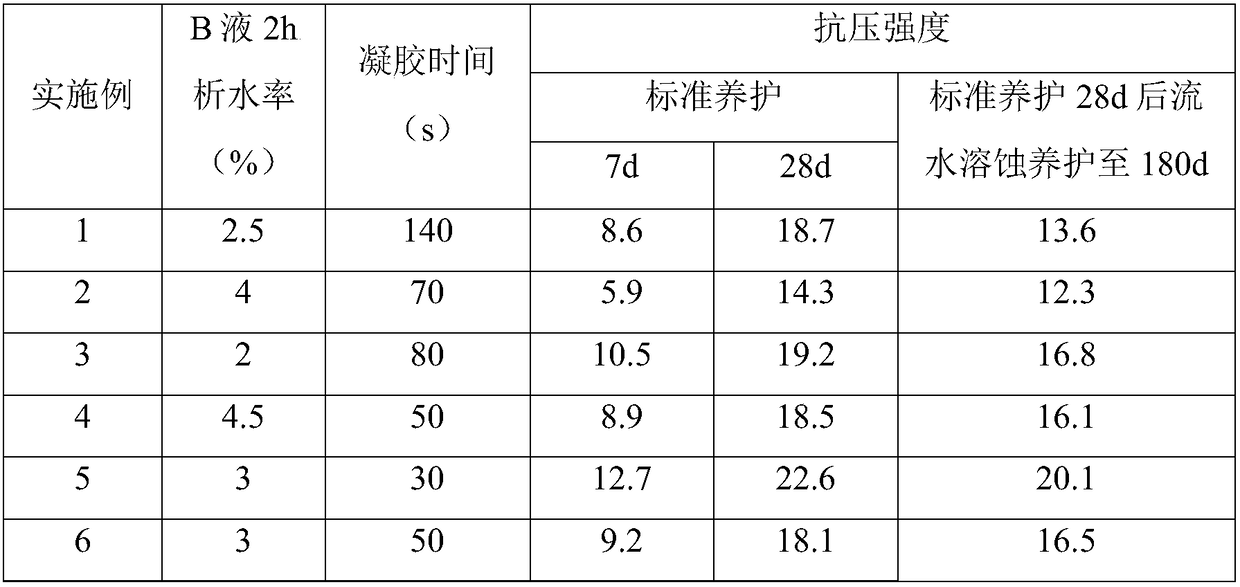

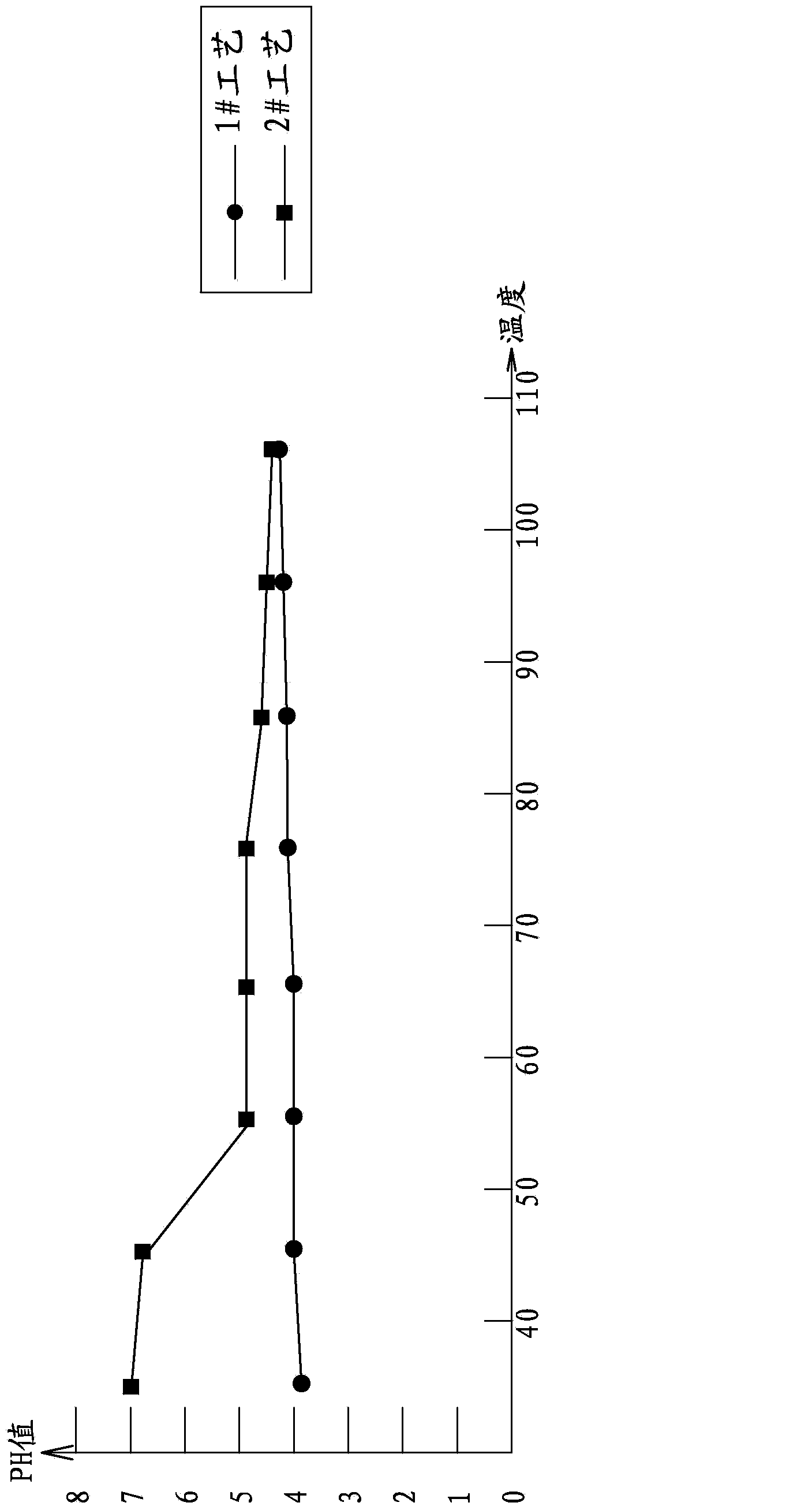

Modified double-liquid paste injection material

The invention discloses a modified double-liquid paste injection material and relates to soft stratum reinforcement of underground construction and anti-seepage water plugging paste injection. The modified double-liquid paste injection material comprises a liquid A and a liquid B, wherein the liquid A is sodium silicate which has a modus of 2.0-3.5 and a baume degree of 20-45Be'; the liquid B is modified cement slurry which consists of the following components in parts by weight: 500-900 parts of cement, 50-200 parts of zeolite powder, 50-300 parts of ore slag powder, 0-50 parts of phosphoricacid, 1-10 parts of a naphthalene water reducer and 700-1500 parts of water; when being used, the liquid A and the liquid B are uniformly mixed in a volume ratio of (0.5-1.5):1, and the modified double-liquid paste injection material is prepared. As a part of cement is replaced by the zeolite powder and the ore slag powder to react with the sodium silicate, the zeolite powder is of a micro porousstructure and is capable of improving the peaceability and the stability of the cement slurry, water energy adsorbed into pores of the zeolite powder can be released at a later hydration reaction stage, then a solid can be sufficiently hydrated, and the compactness and the strength can be improved.

Owner:建发合诚工程咨询股份有限公司

Quick repairing material and preparation method

InactiveCN107540321AHigh compressive strengthSatisfied with fast hardening and high strengthFiberChemical admixture

The invention discloses a quick repairing material and a preparation method. The quick repairing material is prepared from sulphoaluminate cement, fly ash, intermediate sand, polyvinyl alcohol fiber,water and a chemical admixture, and comprises the following specific components: 100 parts of sulphoaluminate cement, 0-30 parts of fly ash, 80-100 parts of intermediate sand, 0.8-1.2 parts of a naphthalene water reducing agent, 0-0.5 part of borax, 0-0.12 part of sodium gluconate, 0-0.15 part of citric acid, 0-1.5 parts of lithium carbonate, 0-2.0 parts of aluminum sulfate, 0-1.5 parts of aluminum chloride, 0-1.5 parts of calcium nitrate, 0-2.0 parts of sodium chloride and 0-2.0 parts of polyvinyl alcohol fiber. Firstly, the repairing material can be constructed under the temperature condition of 10 DEG C below zero to 40 DEG C, the initial setting time is 15-25 minutes, and the final setting time is 25-35 minutes; secondly, the repairing material achieves excellent compressive strength,the 2h compressive strength is 15-45MPa, and the 7d compressive strength is 45-80MPa; finally, the polyvinyl alcohol fiber is selected for reinforcing the sulphoaluminate cement, so that the quick repairing material has the 1d folding strength of 10-12MPa, the 7d folding strength of 12-14MPa and the 7d bending strength of 5-7MPa, and is free of dry shrinkage, therefore, requirements on quick hardening, high strength and toughness of a repairing project can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Nylon rapid-dyeing color-homogenizing agent

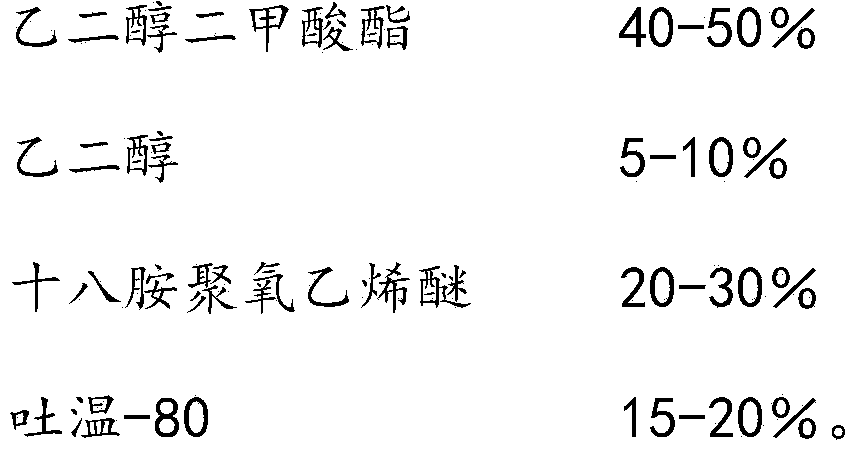

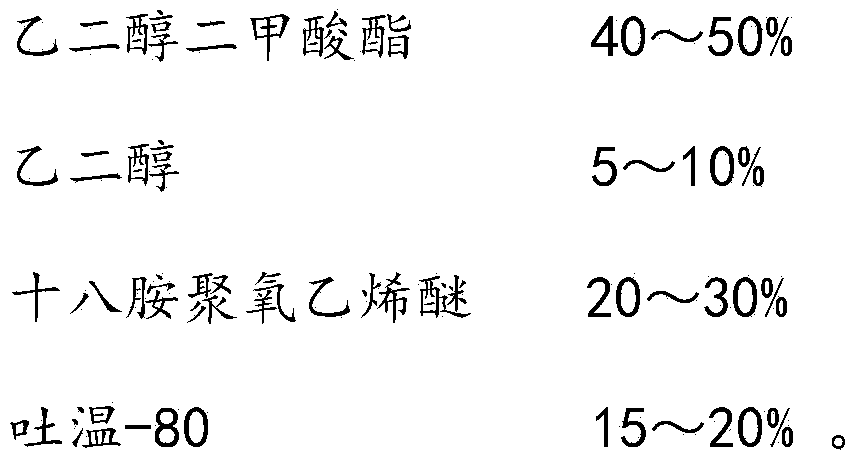

The invention discloses a nylon rapid-dyeing color-homogenizing agent. The nylon rapid-dyeing color-homogenizing agent is prepared from the following raw materials in weight percentage: 40-50% of ethylene glycol diformate, 5-10% of ethylene glycol, 20-30% of octadecylamine polyoxyethylene ether and 15-20% of tween-80. The nylon rapid-dyeing color-homogenizing agent can keep the dye liquid to have high pH value at below 70 DEG C in use, can effectively prevent weak acid dyes from dyeing at low temperature, is beneficial to slowly dyeing of the weak acid dyes, can greatly reduce the whole dyeing process time, has excellent acid-release effect when the dye liquid is at above 70 DEG C, can enable the weak acid dyes and polyarmide fiber to be combined firmly, has excellent slowly-dyeing effect, solves the problem of dyeing defect caused by instant dyeing in the traditional nylon dyeing technique process, and can improve the dyeing rate of dyes; all components are environment-friendly products and meet the requirements of Okeo-Tex Standard 100 of the European union and the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations.

Owner:JINJIANG NANXING PRINTING & DYEING MATERIAL

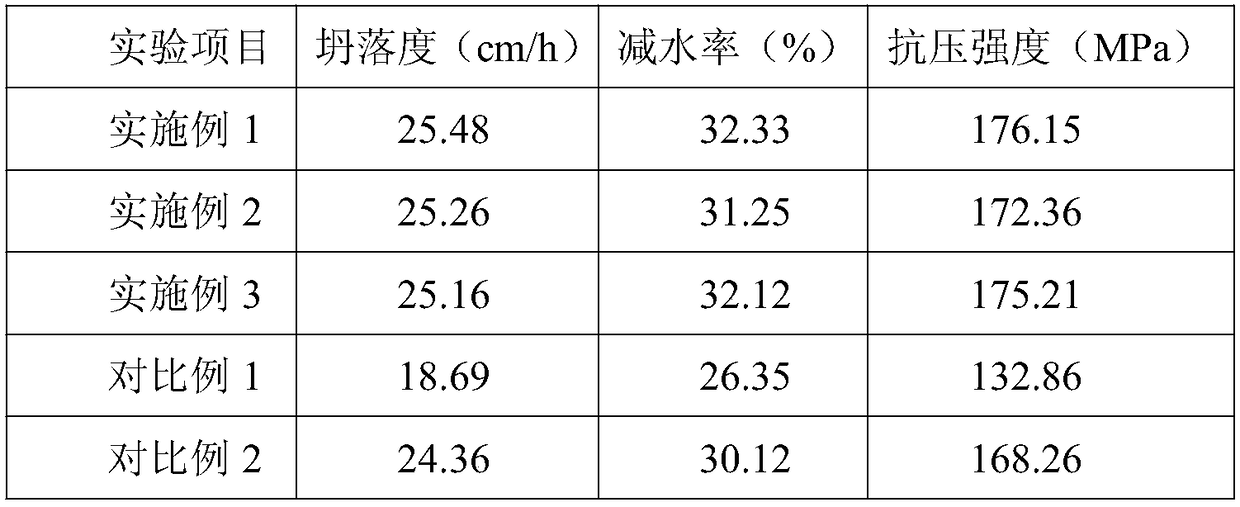

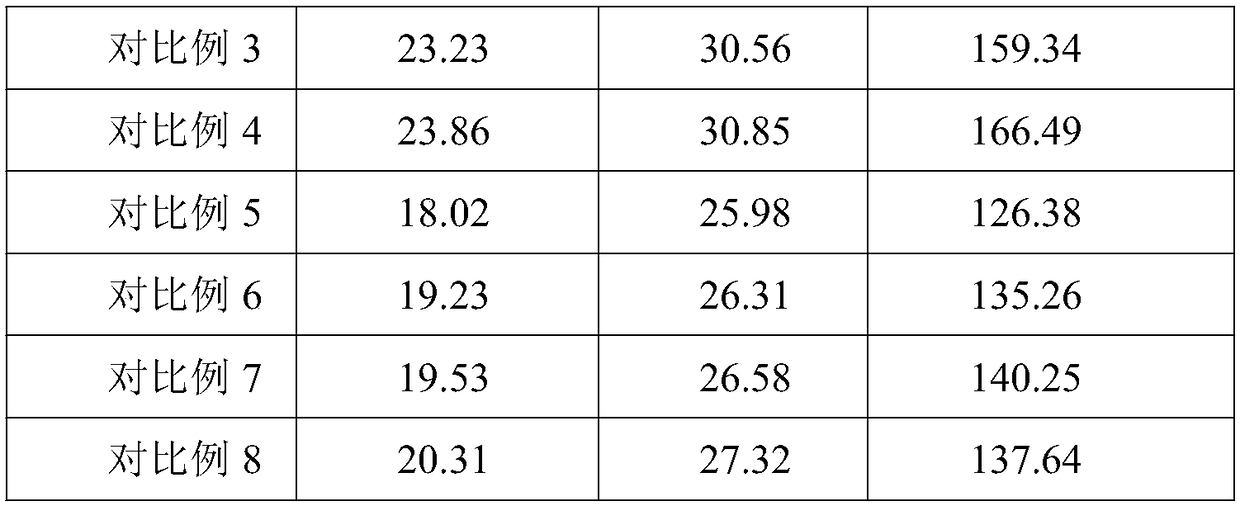

Polycarboxylate type water reducing agent for concrete and preparation method thereof

The invention discloses a polycarboxylic acid type water reducing agent for concrete and belongs to the technical field of concrete additives. The water reducing agent is prepared from the following raw materials: methyl vinyl polyoxyethylene ether, methoxy polyethylene glycol methacrylate, fumaric acid, acrylic acid, sodium methallylsulphonate, mercaptoethanol, potassium peroxydisulfate, 2,2'-azobisisobutyronitrile, polyethylene glycol sodium stearate, sodium rosinate and phenol. According to the polycarboxylic acid type water reducing agent, a reinforcing system is formed by utilizing the polyethylene glycol sodium stearate, sodium rosinate and phenol and cooperatively improves the slump degree, water reduction rate and compressive strength of the concrete.

Owner:长沙小新新能源科技有限公司

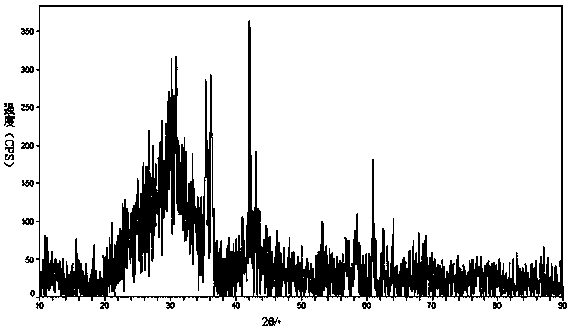

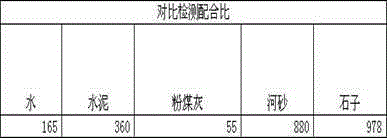

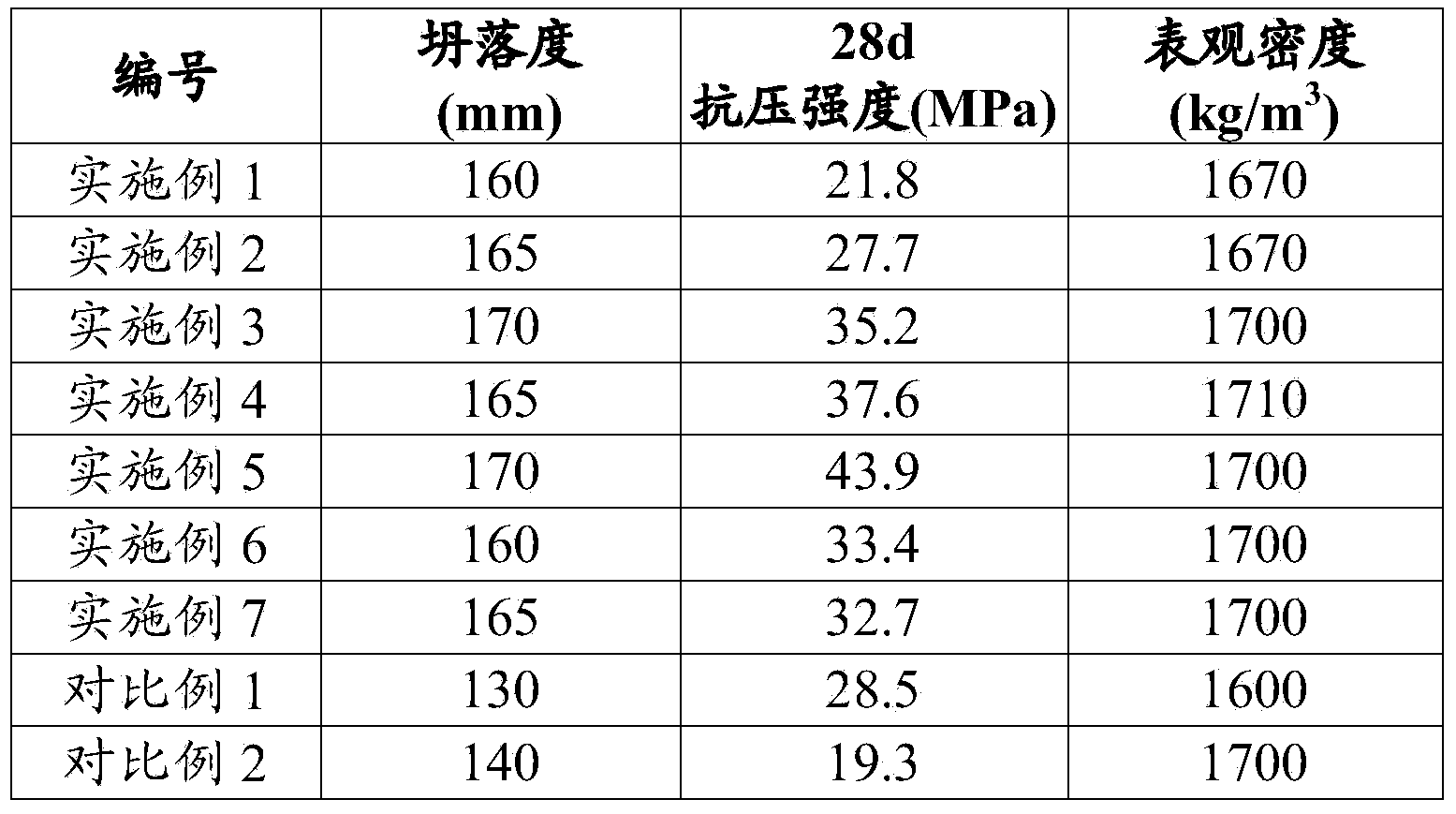

Lightweight aggregate concrete containing low-quality recycled aggregate and preparing method thereof

ActiveCN104058673AWith retarding effectHigh strengthSolid waste managementStable stateSaturated-surface-dry

The invention discloses lightweight aggregate concrete containing low-quality recycled aggregate. The raw materials of the lightweight aggregate concrete are comprised of cement, coal ash, mineral powder, water, low-quality recycled light-fine aggregate, low-quality recycled light-coarse aggregate, inorganic salt and polrvinyl benzene sulphonate. The raw materials of the lightweight aggregate concrete further comprise additional water consumption. The additional water consumption is represented through the formula of delta W=msr*wsr + mgr*wgr, wherein the msr means consumption of the low-quality recycled light-fine aggregate, the wsr means the saturated-surface-dried water absorption rate of the low-quality recycled light-fine aggregate, the mgr means consumption of the low-quality recycled light-coarse aggregate and wgr means the 1h water absorption rate of the low-quality recycled light-coarse aggregate. According to the lightweight aggregate concrete and the preparing method of the lightweight aggregate concrete, when the low-quality recycled aggregate is applied to preparing of the lightweight aggregate concrete, through adjustment to the raw materials and matching with specific additionally added agents, the additional water consumption targeted to the low-quality recycled aggregate is adopted, so that the mixture state can meet the use requirements, the stable state of the mixture is maintained, cement slurry can be helped to be evenly coated around the aggregate, workability of the concrete mixture is good, and no bleeding and segregation phenomena exist.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Autoclaved fly-ash brick and making technology thereof

The invention discloses an autoclaved fly-ash brick and a making technology thereof. The autoclaved fly-ash brick is prepared from, by mass, 40-50 parts of fly ash, 5-7 parts of stone chips, 20-25 parts of aeolian sand, 4-6 parts of furnace slag, 10-12 parts of calcium oxide and 1-2 parts of desulphurization gypsum. The making technology includes the steps of mixing, stirring, dispelling, grinding, pressing and molding and high-pressure oxygen steaming, and the finished product is obtained. According to the autoclaved fly-ash brick and the making technology thereof, the calcium oxide and the desulphurization gypsum are put into the mixture, the plasticity of mixture slurry is improved, and the certain delayed coagulation effect is achieved; as the stone chips, the furnace slag are mixed into the made ingredients, the vibration resistance and the compaction performance of the autoclaved fly-ash brick are effectively increased, the heat conductivity coefficient is low, and the heat preservation effect is good.

Owner:安徽中城新型建材有限公司

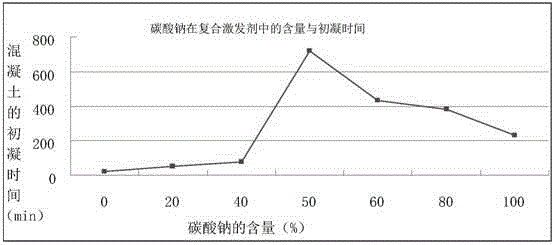

Alkali slag concrete composite activator and preparation method of concrete mixture

The invention relates to an alkali slag concrete composite activator and a preparation method of a concrete mixture. The composite activator in alkali slag concrete is made by mixing solid sodium hydroxide with a composition of one or two of solid alkali metal carbonate and alkali metal bicarbonate; the preparation method of the mixture includes the following steps: first, preparing activated powdery material, the composite activator and mixing water material; second, mixing materials of solid components; third, after adding all the solid components, adding mixing water and stirring; by using the composite activator and the preparation method thereof according to the technical scheme, it is possible to overcome the technical defect that sodium hydroxide in alkali slag concrete is currently dissolved sodium hydroxide so that the production process has a complex flow; the solid activator need not be dissolved and cooled first, the production process is simplified, production cost is reduced, the applicable range is wide, and there is no need for additive retarders.

Owner:张彭成

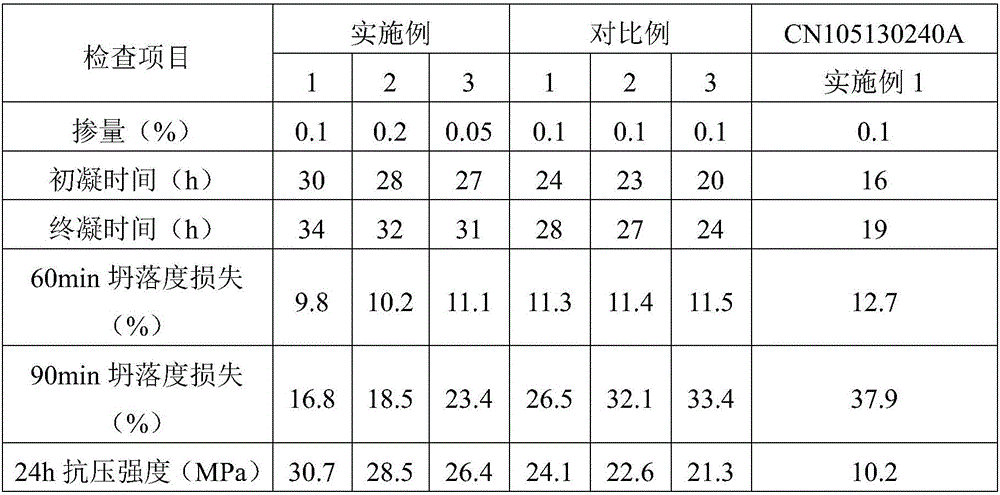

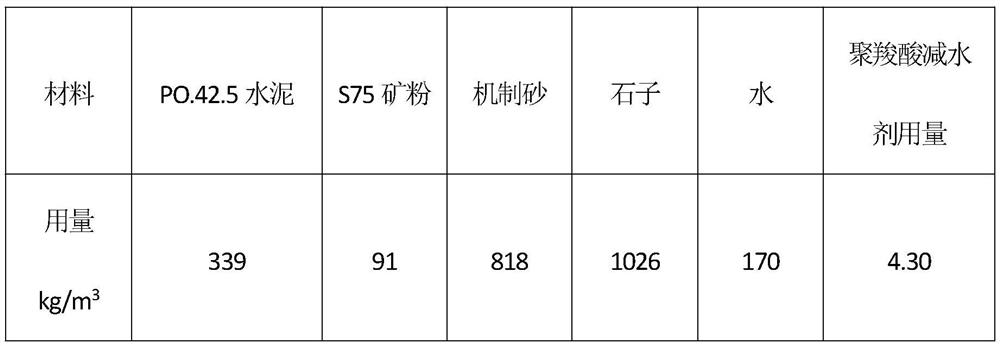

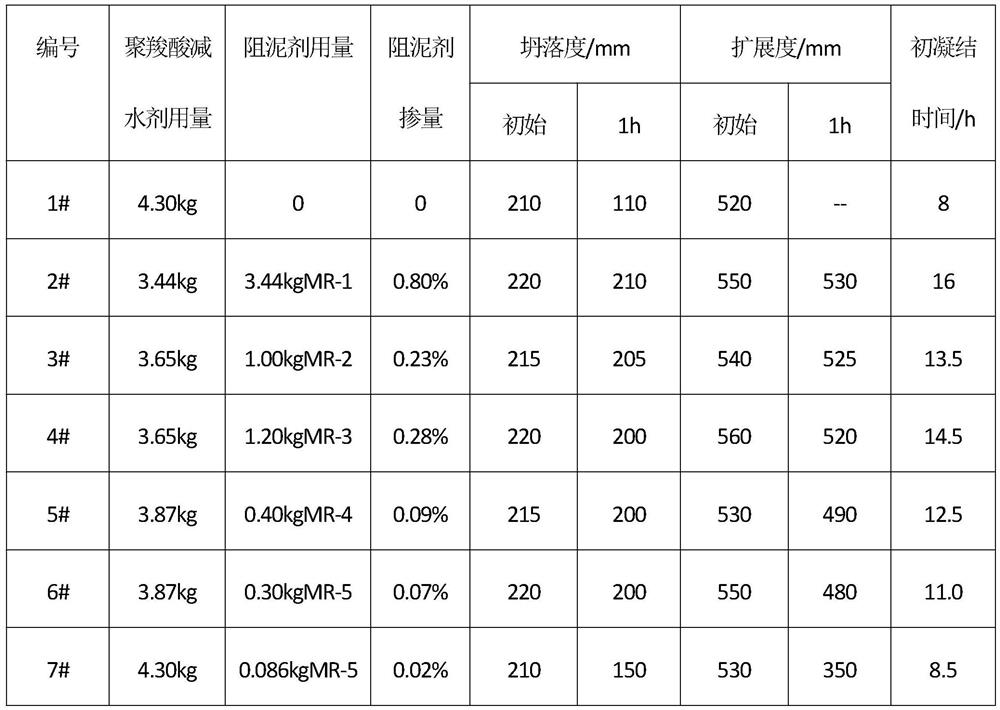

Mud concrete retarder composition and application thereof

The invention belongs to the technical field of building admixtures, and discloses a mud concrete retarder composition and application thereof. The mud retarder composition is composed of 10-60% of organic phosphonic acid compounds, 10-60% of A quaternary ammonium salt cationic lignosulfonate copolymer and 0-80% of water. The mud concrete retarder disclosed by the invention can effectively reducethe consumption of a polycarboxylate superplasticizer in concrete with high mud content of sandstone materials, improves the initial fluidity and slump retention capacity of the concrete, and can be compounded with the polycarboxylate superplasticizer for use.

Owner:EAST CHINA UNIV OF SCI & TECH

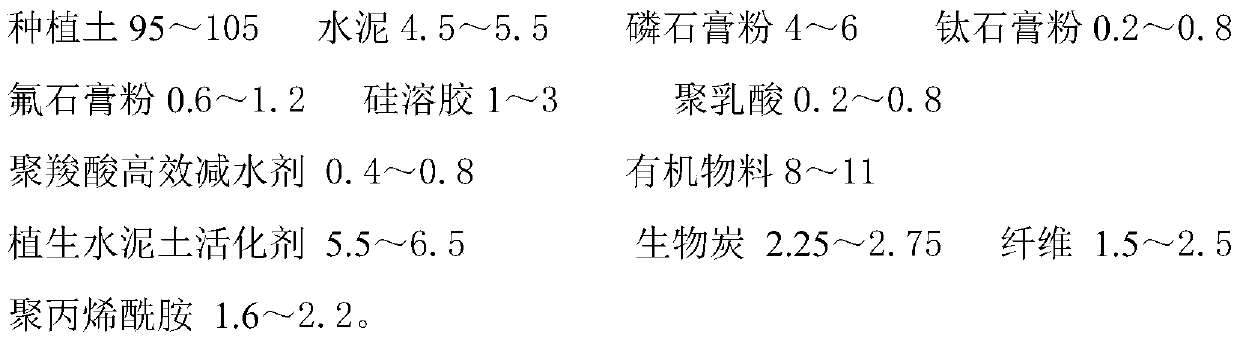

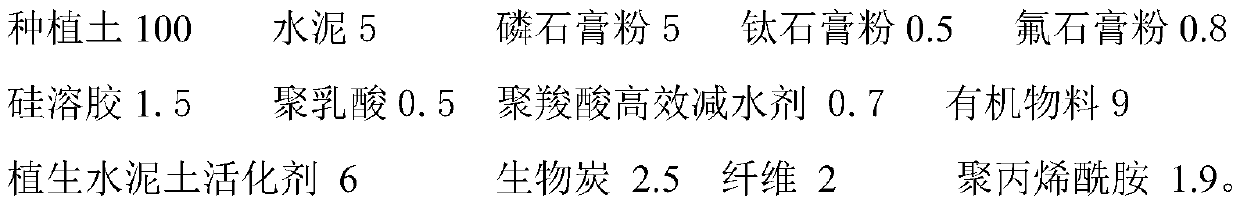

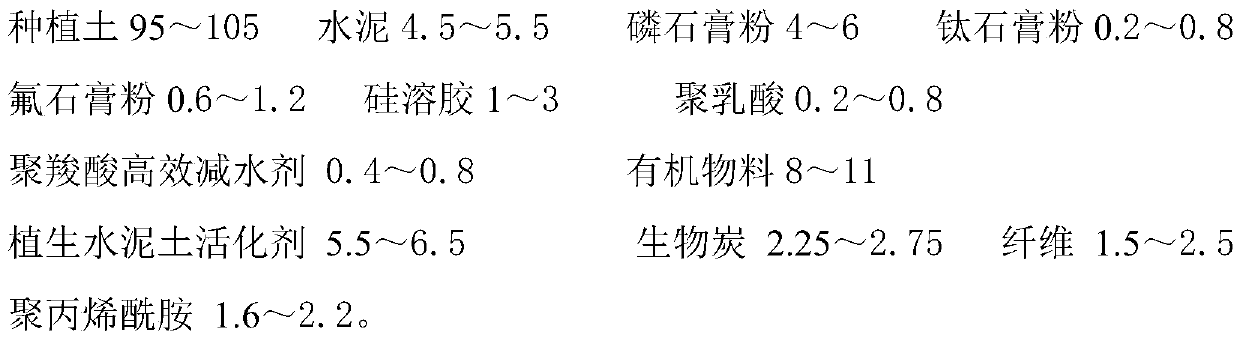

Plant-growing cement soil ecological restoration substrate and preparation method thereof

InactiveCN110372273AImproves compressive strength and frost resistanceReduce cement consumptionExcavationsIndustrial wastePolyacrylamide

The invention discloses a plant-growing cement soil ecological restoration substrate. The plant-growing cement soil ecological restoration substrate is prepared from the following components in partsby weight: 95-105 parts of planting soil, 4.5-5.5 parts of cement, 4-6 parts of phosphogypsum powder, 0.2-0.8 part of titanium gypsum powder, 0.6-1.2 parts of fluorogypsum powder, 1-3 parts of silicasol, 0.2-0.8 part of polylactic acid, 0.4-0.8 part of a polycarboxylic acid efficient water reducing agent, 8-11 parts of an organic material, 5.5-6.5 parts of a plant-growing cement soil activator, 2.25-2.75 parts of biochar, 1.5-2.5 parts of fibers and 1.6-2.2 parts of polyacrylamide. According to the plant-growing cement soil ecological restoration substrate and a preparation method thereof, the problems that the material utilization rate is low and industrial waste residue cannot be effectively utilized, the physical and chemical properties between various industrial by-products or industrial waste are utilized, a large amount of the industrial waste such as phosphogypsum can be consumed, the use amount of cement in a product can also be decreased, and the production cost is lowered.

Owner:CHINA THREE GORGES UNIV +2

Antifreeze cement

The invention relates to antifreeze cement, which is prepared by processes of crushing raw material and drying, burdening, grinding, calcining, stirring and grinding. The invention is characterized in that a proper proportion of the antifreeze component can be filled in cement raw material for calcining, the antifreeze component is added in calcinied clinker, placed in a stirring device for fully stirring and grinding to prepare the cement finished product.

Owner:大连市铭源全科技开发有限公司

Method for preparing mortar thickener

The invention discloses a method for preparing a mortar thickener and belongs to the field of construction. Corn starch is taken as a raw material to improve the substitution effect of carboxymethyl starch, which can prevent mortar from being separated and bleeding and can prevent water from evaporating too quickly in the early stage of curing or being absorbed too quickly by a base material, so that cement can be well hydrated; sugarcane black liquid is taken as a raw material for amination, positive ion groups are introduced in the molecular structure of lignin, so that the air-entraining performance is achieved, and the anti-cracking, anti-seepage and retarding effects are improved; propylene-based polyoxyethylene ether and maleic anhydride and the like are adopted as raw materials, anair-entraining delayed coagulation thickener additive is synthesized, and the mortar thickener has excellent performances such as good water reducing effect, good delayed coagulation effect and low air entrainment and the like. The peaceability of a mixture can be effectively improved, the water-reducing rate is high, the plasticity is strong, the slump loss is small, the amount of cement used canbe greatly reduced, and the cost performance of mortar is effectively improved.

Owner:广西御华混凝土有限责任公司

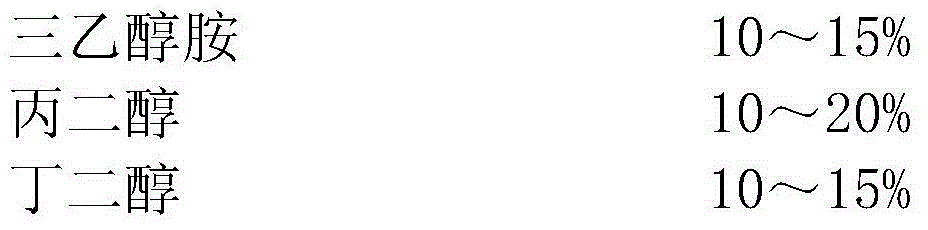

Efficient cement grinding aid

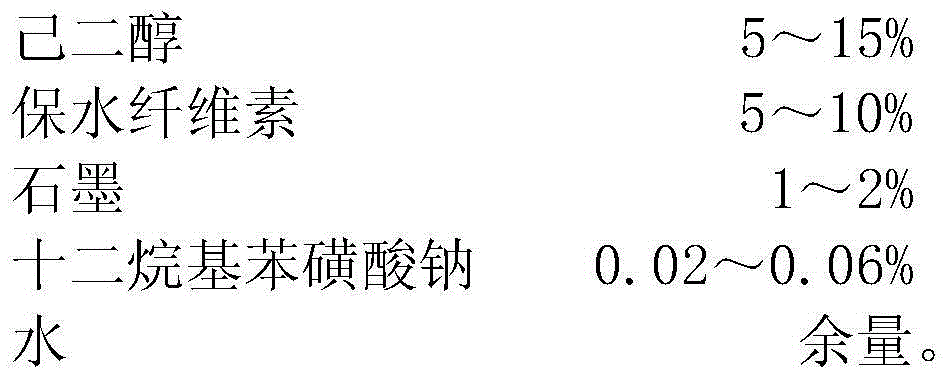

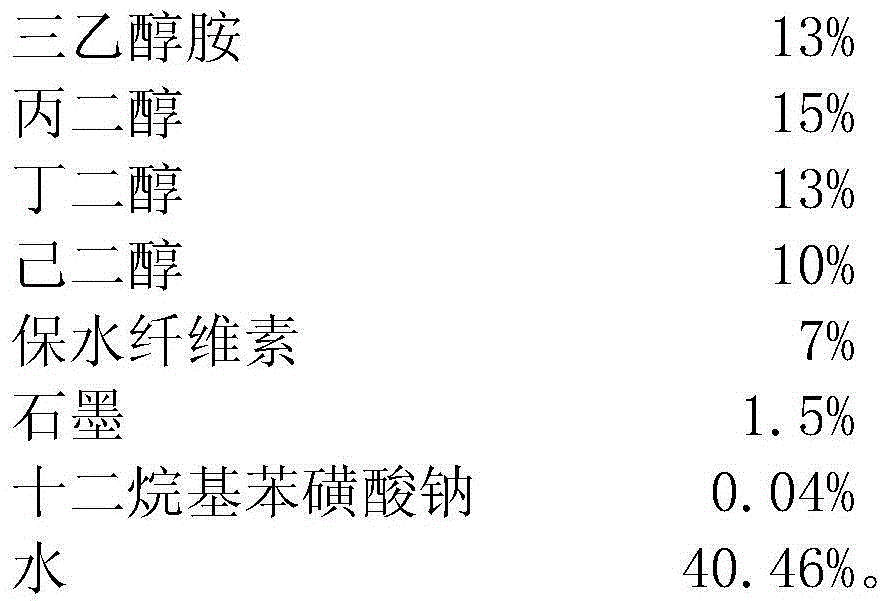

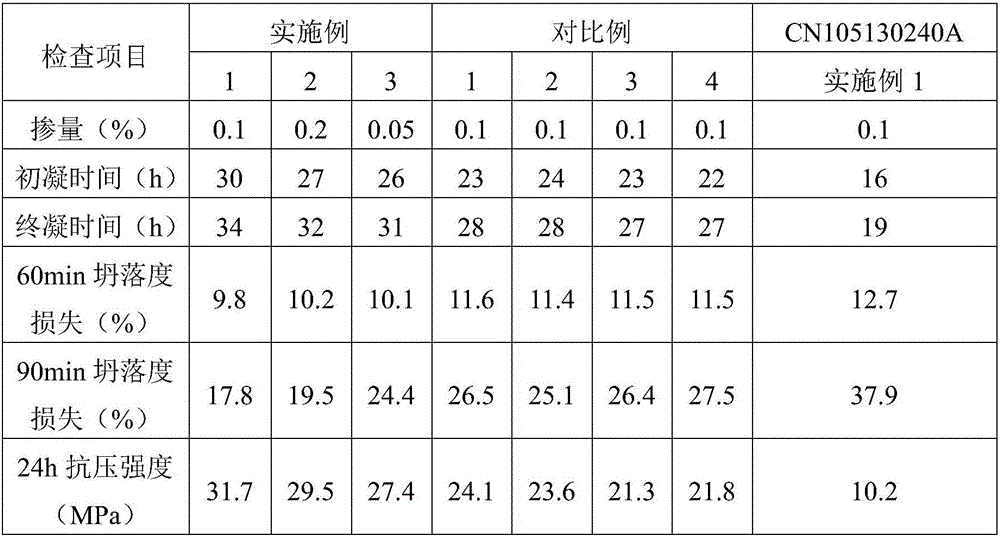

The invention relates to the technical field of cement additives, in particular to an efficient cement grinding aid which is prepared from the following raw materials in weight percentage: 10-15% of triethanolamine, 10-20% of propylene glycol, 10-15% of butanediol, 5-15% of hexanediol, 5-10% of water holding cellulose, 1-2% of graphite, 0.02-0.06% of sodium dodecyl benzene sulfonate and the balance of water. The efficient cement grinding aid is applicable to the field of cement grinding assistance. When cement is ground and the efficient cement grinding aid is added, the cement grinding efficiency can be greatly improved, and the cement strength can be improved; the efficient cement grinding aid has certain delayed coagulation function, and triethanolamine is replaced by part of alcohol, so that the cost is reduced.

Owner:天瑞集团南召水泥有限公司

Composite concrete retarder

The invention discloses a composite concrete retarder, made from, by weight, 2-6 parts of sodium fluorosilicate, 3-9 parts of sodium dihydrogen phosphate, 4-8 parts of ammonium bicarbonate, 4-6 parts of ammonium persulfate, 7-9 parts of glycine, 2-6 parts of sodium carboxymethyl cellulose, 2-4 parts of shell-lac, 1-3 parts of ammonium oxalate, 10-15 parts of halloysite, 15-20 parts of Al2O3-ZrO2 porous ceramic powder, 2-5 parts of a water-reducing agent, 1-3 parts of a dispersant, and 0.3-0.6 part of a surfactant. The composite concrete retarder has the advantages of good retarding effect, high strength, zero pollution and the like, and is a concrete admixture that is promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com