Synthetic method for maleic polycarboxylic water reducer

A technology of water reducing agent and polycarboxylic acid, applied in the field of synthesis of water reducing agent, can solve problems such as poor slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

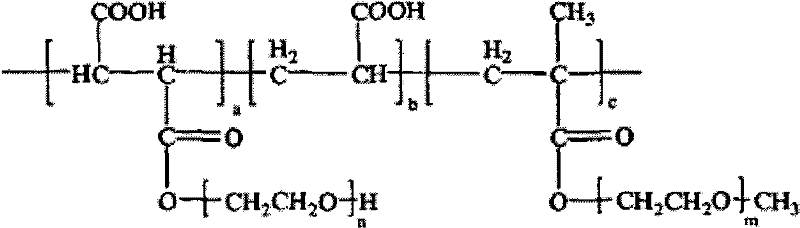

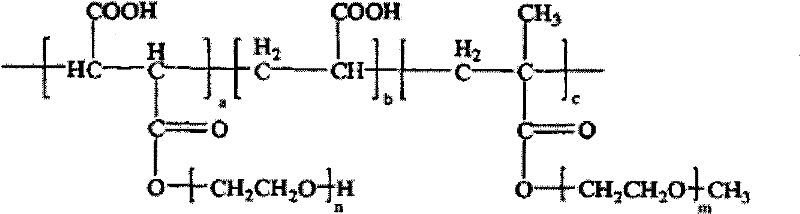

Method used

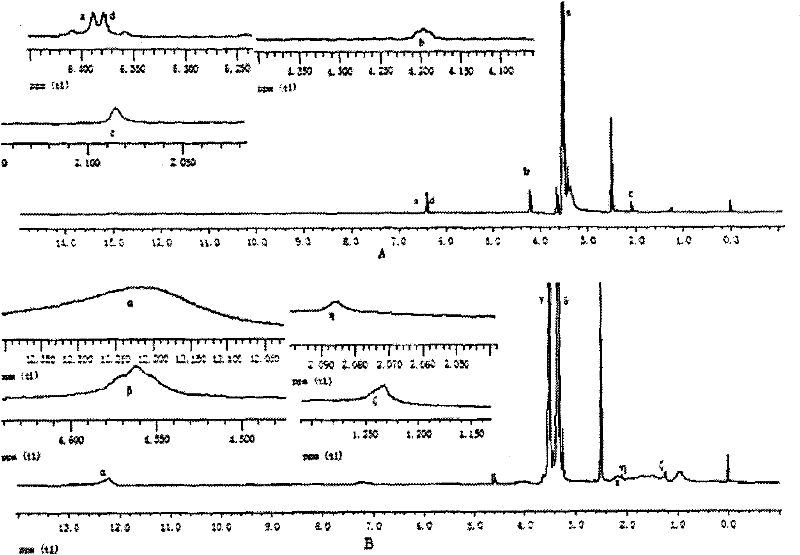

Image

Examples

Embodiment 1

[0020] Example 1: Weigh 50g polyethylene glycol (PEG) into a single-necked flask, add toluene (20% of the PEG mass), distill under reduced pressure with a water pump, and control the temperature of the water bath at 65°C until there are no bubbles in the flask. At a certain water bath temperature, add maleic anhydride (MA) and PEG (1000) or methoxy polyethylene glycol (MPEG (1000)) treated by toluene vacuum distillation at a molar ratio of 1:1 The esterification reaction in a single-neck flask was 5h. The synthetic macromonomer PEG-MA or MPEG-MA is formulated into an aqueous solution of ρ=50%. Acrylic acid (AA), styrene (ST) / sodium p-styrene benzene sulfonate (SSS), MPEG-MAA ρ=50% aqueous solution A according to the molar ratio of 8:0.02:1, prepare ρ=50% An aqueous solution of initiator. Put the prepared PEG-MA / MPEG-AA into a three-necked flask, and then add 10% solution A and 20% initiator solution. The temperature of the water bath was controlled at 80°C, and the reaction ...

Embodiment 2

[0021] Example 2: Weigh 50g polyethylene glycol (PEG) into a single-necked flask, add toluene (20% of the PEG mass), distill under reduced pressure with a water pump, and control the temperature of the water bath at 65°C until there are no bubbles in the flask. At a certain water bath temperature, add maleic anhydride (MA) and PEG (1000) or methoxy polyethylene glycol (MPEG (1000)) treated by toluene vacuum distillation at 1:1.1 into the single-necked flask. The reaction is 5h. The synthetic macromonomer PEG-MA or MPEG-MA is formulated into an aqueous solution of ρ=50%. Prepare acrylic acid (AA), styrene (ST) / sodium p-styrene benzene sulfonate (SSS) at a molar ratio of 5:0.02:1, MPEG-MAA ρ=50% aqueous solution A, prepare ρ=50% An aqueous solution of initiator. Put the prepared PEG-MA / MPEG-AA into a three-necked flask, and then add 10% solution A and 20% initiator solution. The temperature of the water bath was controlled at 80°C, and the reaction was carried out for 1 hour. ...

Embodiment 3

[0022] Example 3: Weigh 50g polyethylene glycol (PEG) into a single-necked flask, add toluene (20% of the PEG mass), distill under reduced pressure with a water pump, and control the temperature of the water bath at 65°C until there are no bubbles in the flask. At a certain water bath temperature, add maleic anhydride (MA) and PEG (1000) or methoxy polyethylene glycol (MPEG (1000)) treated by toluene vacuum distillation at 1:1.2 into the single-necked flask. The reaction is 5h. The synthetic macromonomer PEG-MA or MPEG-MA is formulated into an aqueous solution of ρ=50%. Prepare acrylic acid (AA), styrene (ST) / sodium p-styrene benzene sulfonate (SSS), MPEG-MAA ρ=50% aqueous solution A according to 3:0.02:1, prepare ρ=50% initiator Aqueous solution. Put the prepared PEG-MA / MPEG-AA into a three-necked flask, and then add 10% solution A and 20% initiator solution. The temperature of the water bath was controlled at 80°C, and the reaction was carried out for 1 hour. Mix the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com