Plant-growing cement soil ecological restoration substrate and preparation method thereof

An ecological restoration, cement-soil technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of low material utilization rate and failure to effectively use industrial waste residue, etc., to reduce production costs, improve compressive strength and frost resistance. performance, the effect of reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

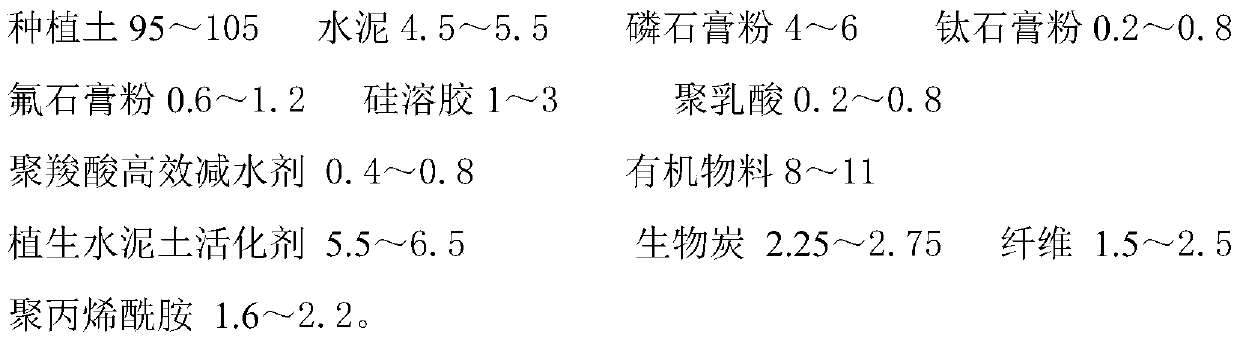

[0039] A planting cement-soil ecological restoration base material, said base material comprises the following components by weight:

[0040]

[0041] The preparation method of the above-mentioned planting cement-soil ecological restoration base material, the method comprises the following steps:

[0042] Step 1: Mix the phosphogypsum powder, titanium gypsum powder and fluorine gypsum powder in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare mixed gypsum material A;

[0043] Step 2: Mix the biochar, fiber and polyacrylamide in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare the mixed organic material B;

[0044] Step 3: Mix the mixed gypsum material A prepared in step 1, the mixed organic material B prepared in step 2, and the above-mentioned organic material in parts by weight with a mixer for 3-12 minutes and stir evenly to prepare the mixed material C;

[0045] Step 4: Mix the silica sol in the above pa...

Embodiment 2

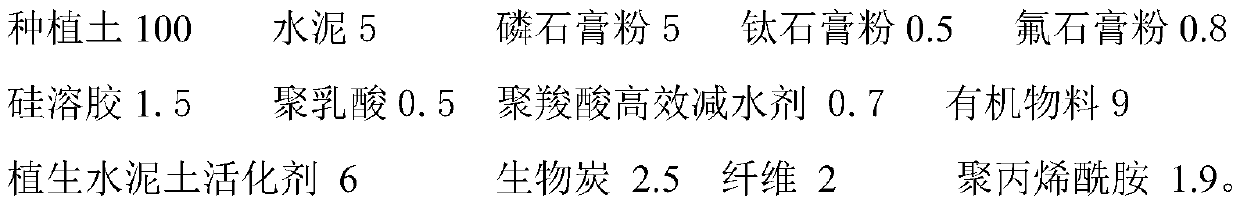

[0048] A planting cement-soil ecological restoration base material, said base material comprises the following components by weight:

[0049]

[0050]

[0051] The preparation method of the above-mentioned planting cement-soil ecological restoration base material, the method comprises the following steps:

[0052] Step 1: Mix the phosphogypsum powder, titanium gypsum powder and fluorine gypsum powder in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare mixed gypsum material A;

[0053] Step 2: Mix the biochar, fiber and polyacrylamide in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare the mixed organic material B;

[0054] Step 3: Mix the mixed gypsum material A prepared in step 1, the mixed organic material B prepared in step 2, and the above-mentioned organic material in parts by weight with a mixer for 3-12 minutes and stir evenly to prepare the mixed material C;

[0055] Step 4: Mix the silica sol in ...

Embodiment 3

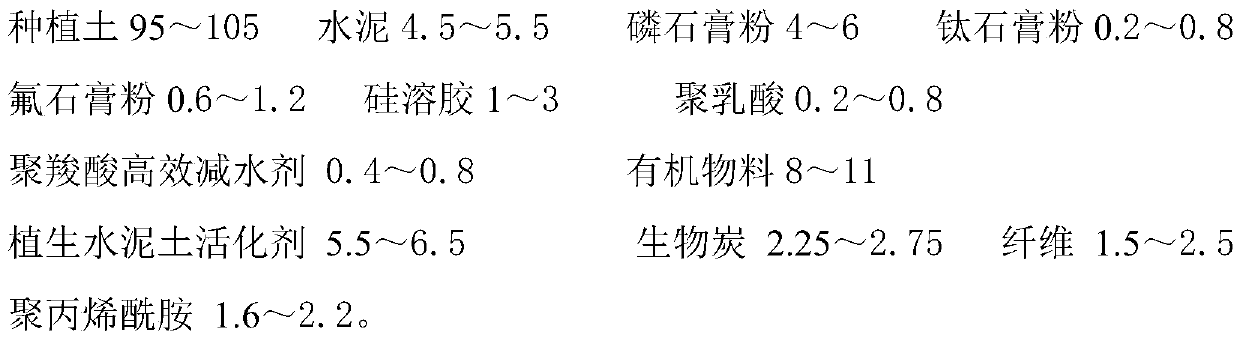

[0058] A planting cement-soil ecological restoration base material, said base material comprises the following components by weight:

[0059]

[0060] The preparation method of the above-mentioned planting cement-soil ecological restoration base material, the method comprises the following steps:

[0061] Step 1: Mix the phosphogypsum powder, titanium gypsum powder and fluorine gypsum powder in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare mixed gypsum material A;

[0062] Step 2: Mix the biochar, fiber and polyacrylamide in the above parts by weight with a mixer for 3-12 minutes and mix evenly to prepare the mixed organic material B;

[0063] Step 3: Mix the mixed gypsum material A prepared in step 1, the mixed organic material B prepared in step 2, and the above-mentioned organic material in parts by weight with a mixer for 3-12 minutes and stir evenly to prepare the mixed material C;

[0064] Step 4: Mix the silica sol in the above pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com