Efficient cement grinding aid

A cement grinding aid and high-efficiency technology, applied in the field of high-efficiency cement grinding aid, can solve the problems of affecting the quality of cement, increasing the grinding cost, and increasing the amount of mixing, so as to improve the cement grinding efficiency, improve the grinding efficiency, expand the The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

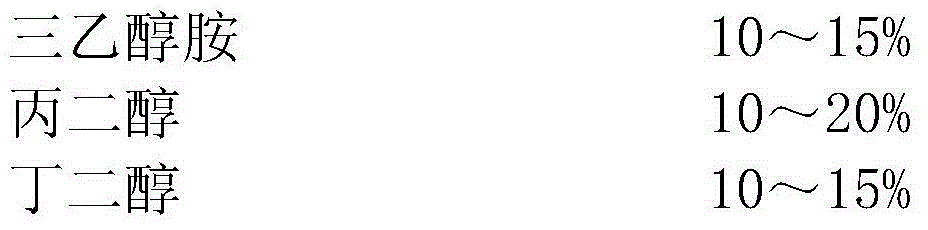

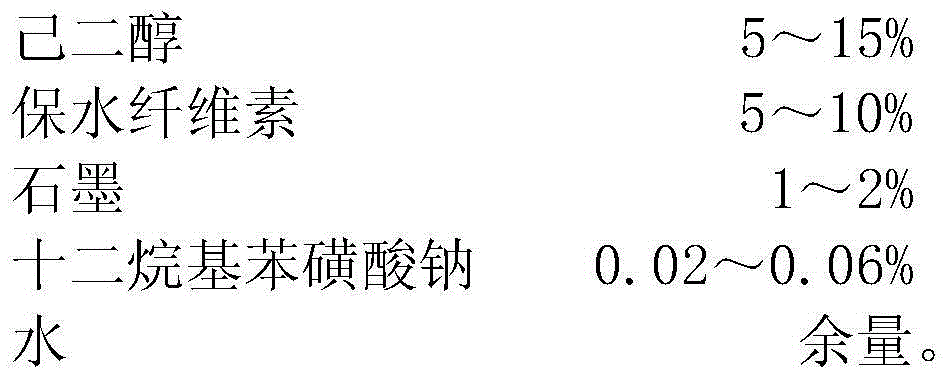

Method used

Image

Examples

Embodiment 1

[0020] Weigh the following raw materials by weight percentage: 10% triethanolamine, 20% propylene glycol, 10% butanediol, 15% hexanediol, 5% hydroxypropyl methylcellulose, 1% graphite with a particle size of 1 μm, twelve Sodium alkylbenzene sulfonate 0.02%, water 38.98%, mixed, forced mechanical stirring to get the product.

Embodiment 2

[0022] Weigh the following raw materials by weight percentage: 12% triethanolamine, 18% propylene glycol, 12% butanediol, 8% hexanediol, 9% methyl cellulose, 1.8% graphite with a particle size of 2 μm, dodecylbenzene Sodium sulfonate 0.03%, water 39.17%, mixed, forced mechanical stirring to get the product.

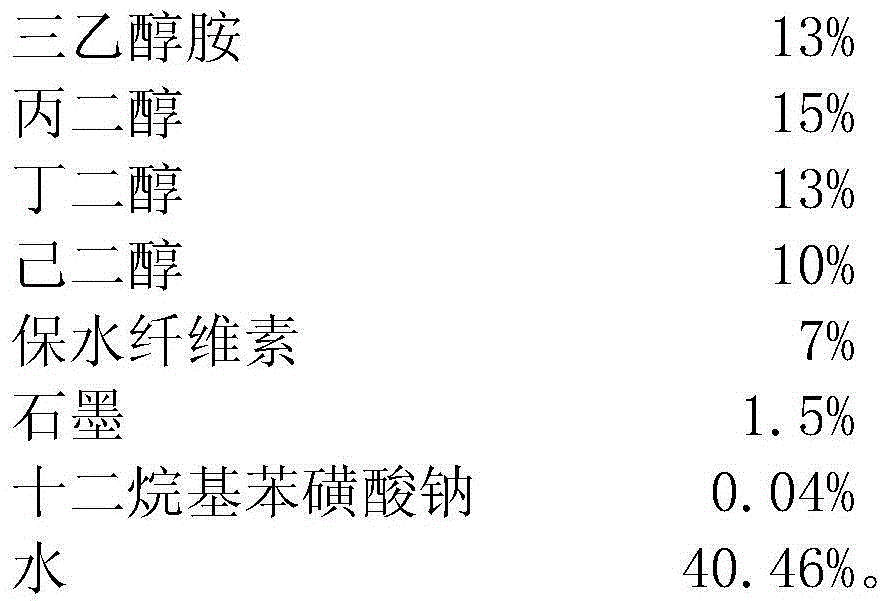

Embodiment 3

[0024] Weigh the following raw materials by weight percentage: 13% triethanolamine, 15% propylene glycol, 13% butanediol, 10% hexanediol, 7% hydroxypropyl methylcellulose, 1.5% graphite with a particle size of 3 μm, twelve Sodium alkylbenzene sulfonate 0.04%, water 40.46%, mixed, forced mechanical stirring to get the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com