Mud concrete retarder composition and application thereof

A composition and concrete technology, which is applied in the field of construction admixtures, can solve the problems of waste of raw materials, reduce polycarboxylate superplasticizers, increase the distance between clay layers, etc., and achieve the effects of reducing particle aggregation, reducing dosage, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

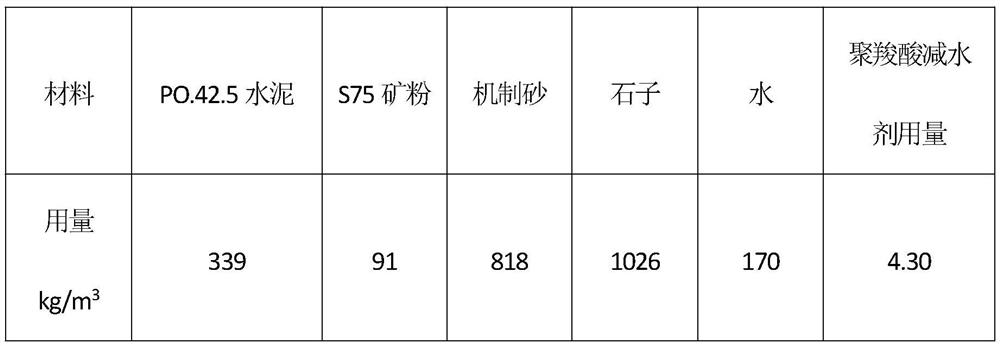

Method used

Image

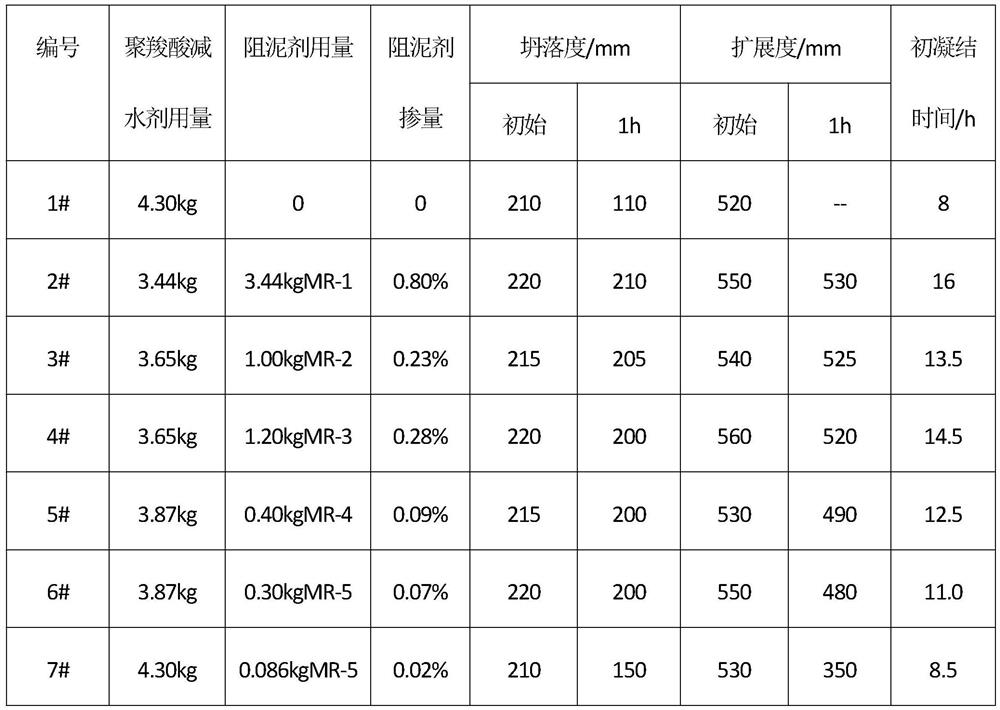

Examples

Embodiment 1

[0020] Weigh 800g of water into a beaker, add 100g of ethylenediamine tetramethylene phosphonic acid under stirring, and add 100g of chloro-2-hydroxyl-3-(trimethylamino)propylpolyethylene oxide lignin after stirring for 10 minutes Sodium sulfonate, continue to stir for 20 minutes, after dissolving completely, the mud inhibitor composition MR-1 is obtained.

Embodiment 2

[0022] Weigh 500g of water into a beaker, add 200g of hydroxyethylidene diphosphonic acid under stirring, and add 300g of chloro-2-hydroxyl-3-(trimethylamino)propylpolyethylene oxide lignosulfonic acid after stirring for 10 minutes Sodium, continue to stir for 20 minutes, after the dissolution is complete, the anti-sludging agent composition MR-2 is obtained.

Embodiment 3

[0024] Weigh 550g of water and place it in a beaker, add 150g of aminotrimethylene phosphonic acid under stirring, and add 300g of calcium chloride-2-hydroxy-3-(trimethylamino)propylpolyethylene oxide lignosulfonate after stirring for 10 minutes , continue to stir for 20 minutes, and after the dissolution is complete, the mud-repelling agent composition MR-3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com