Patents

Literature

44 results about "Zinc Phosphate Cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A material used for cementation of inlays, crowns, bridges, and orthodontic appliances and occasionally as a temporary restoration. It is prepared by mixing zinc oxide and magnesium oxide powders with a liquid consisting principally of phosphoric acid, water, and buffers. (From Bouchers' Clinical Dental Terminology, 3d ed)

Phosphate cement based patching material and preparation method thereof

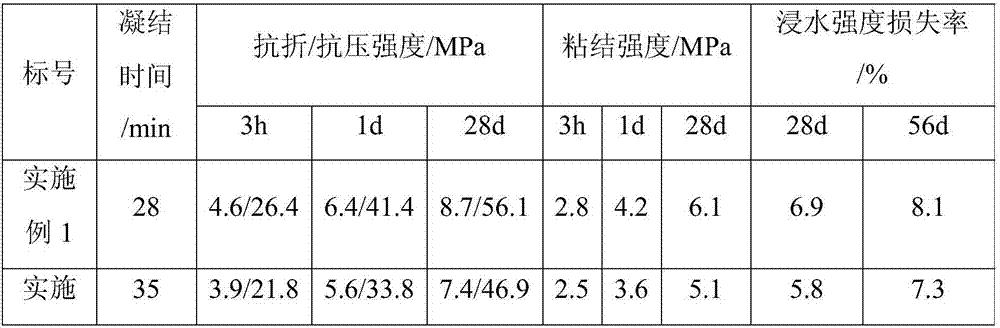

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

Method for preparing calcium phosphate cement/chitosan-gelatine composite porous holder

InactiveCN101125223APromote enhancementImprove bindingBone implantZinc Phosphate CementPhosphoric acid

The present invention discloses a preparing method of the calcium phosphate cement / chitosan-gelatin composite scaffold, the process is as follows: mixing the alpha- tricalcium phosphate, monohydrate calcium biphosphate, hydroxyapatite and calcium carbonate according to the mass ration and rubbing, then obtaining the calcium carbonate cement solid powder; mixing the disodium hydrogen phosphate solution and the cement solid powder in the mass ratio and stirring to a mash, then filling into a mould, vacuum solidifying and mold releasing, after that, solidifying again and obtaining the calcium phosphate cement scaffold; subsequently, dissolving the chitosan and the gelatin into the acetic acid water solution, configuring the chitosan-gelatin solution and adding the glutaraldehyde water solution; putting the calcium phosphate cement scaffold into the chitosan-gelatin solution, in vacuum condition, filling chitosan-gelatin solution into the calcium phosphate cement scaffold, after that cooling and drying, obtaining the calcium phosphate cement / chitosan-gelatin composite scaffold. The prepared calcium phosphate cement / chitosan-gelatin composite scaffold has a perfect mechanical property and biological property.

Owner:TIANJIN UNIV

Aqueous, pourable, foamable, pumpable and settable dispersions and use thereof to produce porous, mineral lightweight construction materials

An aqueous, pourable, foamable, pumpable and settable dispersion, its use to produce a porous, mineral lightweight construction material, and a process for producing the dispersion, are described. The dispersion contains cement and / or zinc phosphate cement or a mixture of cement and / or zinc phosphate cement and a Silicate and / or an aluminosilicate with an alkaline or acidic activator for producing a geopolymer and / or a geopolymer, containing a Surfactant, 0.01 to 5 wt %, relative to the dry mass of the dispersion, of modified and / or unmodified natural potato starch, rice starch, corn starch, and wheat starch and of cooked and / or raw, comminuted pieces of grains, potatoes and rice, and water having a hardness of >3.2 mmol / 1. Also described herein are the porous, mineral lightweight construction material and its use. The construction material contains, relative to a given lightweight construction material, 50 wt % to 95 wt % of a cement and / or a zinc phosphate cement or a mixture of a Silicate and / or of an aluminosilicate with an alkaline or acidic activator for producing a geopolymer and / or a geopolymer with cement and / or zinc phosphate cement, 0.001 wt % to 3 wt % of a Surfactant, and 0.01 wt % to <10 wt % of potato starch, rice starch, corn starch and / or wheat starch of cooked and / or raw, comminuted pieces of grains, potatoes and rice.

Owner:WINDPLUSSONNE

X-ray developing calcium phosphate cement and preparation method and application thereof

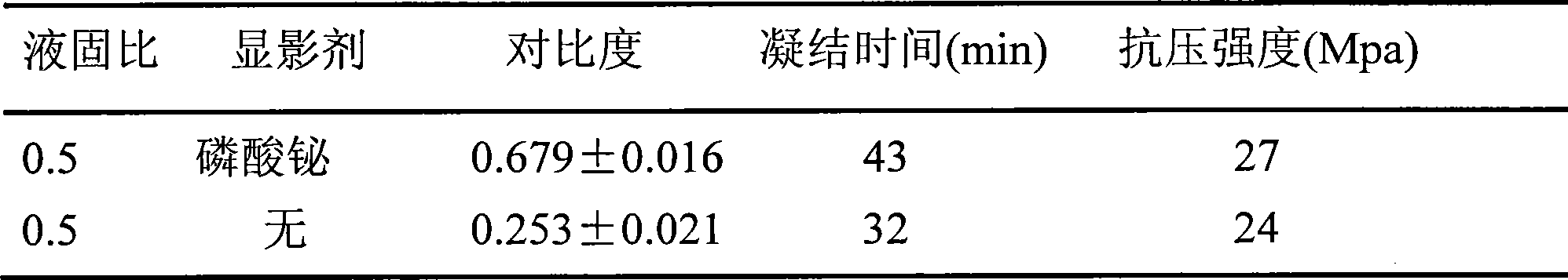

The invention discloses X-ray developing calcium phosphate cement and a preparation method and application thereof. The method comprises the following steps: (1) adding a developer in calcium phosphate cement powder and carrying out dry mixing or wet mixing by adding organic dispersant for 0.5-5h, drying and sifting out to obtain the X-ray developing calcium phosphate cement powder; (2) evenly mixing hardening liquid and the X-ray developing calcium phosphate cement powder based on liquid-solid ratio of 0.3-0.6mL / g to obtain X-ray developing calcium phosphate cement paste. In the method, bismuth compound and iodide are successfully applied to the calcium phosphate cement as the developers for the first time, thus remarkably enhancing the developing property of the calcium phosphate cement while keeping intrinsic curing characteristic of the calcium phosphate cement, effectively improving the success ratios of operations and broadening the application prospect of the calcium phosphate cement.

Owner:SOUTH CHINA UNIV OF TECH

Calcium phosphate cement

ActiveUS20060225620A1Quick SetupLong-term shelf lifeSurgical adhesivesOther chemical processesCalcium biphosphateZinc Phosphate Cement

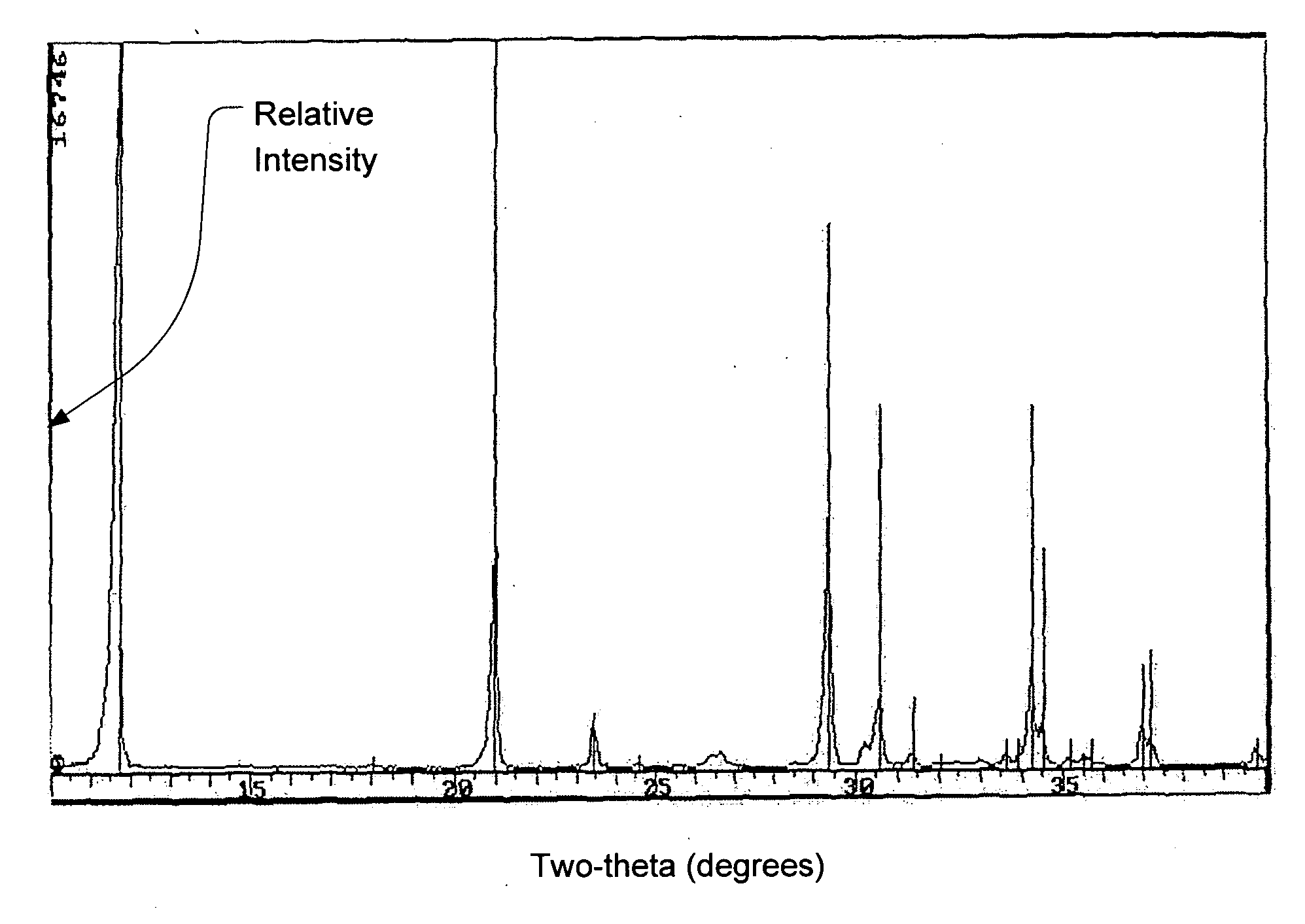

The invention is related to a rapid setting calcium phosphate cement comprising a powdered first component comprising stabilized dicalcium phosphate dihydrous containing from about 10 ppm to about 60 ppm of magnesium, a powdered second component comprising a calcium phosphate mineral other than said stabilized dicalcium phosphate dihydrous, and a liquid third component comprising water.

Owner:HOWMEDICA OSTEONICS CORP

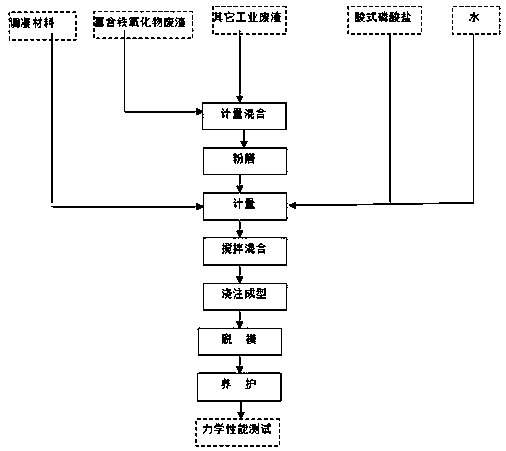

Iron phosphate cement

The invention discloses an iron phosphate cement, belonging to the technical field of building materials. The cementing material is prepared by uniformly mixing the following raw materials with the particle size of 1-100 mu m in parts by weight: 100 parts of acid phosphate, 400-800 parts of waste residue containing rich iron oxides, 3-6 parts of coagulation regulating material, 10-30 parts of other industrial waste residues and 15-200 parts of water. The iron phosphate cement has the advantages of adjustable setting time (several minutes to several hours), quick hardening, high strength, high binding property, no reduction of later strength, and the like, and can be quick hardened at normal temperature. The iron phosphate cement is simple in preparation technique, has high constructability, is suitable for quick emergency repair of defects of roads, airport pavements, bridges, tunnels, cooking ranges, dams, ditches and other engineering structures, and has wide application prospects in curing of high-risk waste residues containing rich radioelements, heavy metal elements, arsenic and the like.

Owner:KUNMING UNIV OF SCI & TECH

Piezoelectric calcium phosphate cement composite material

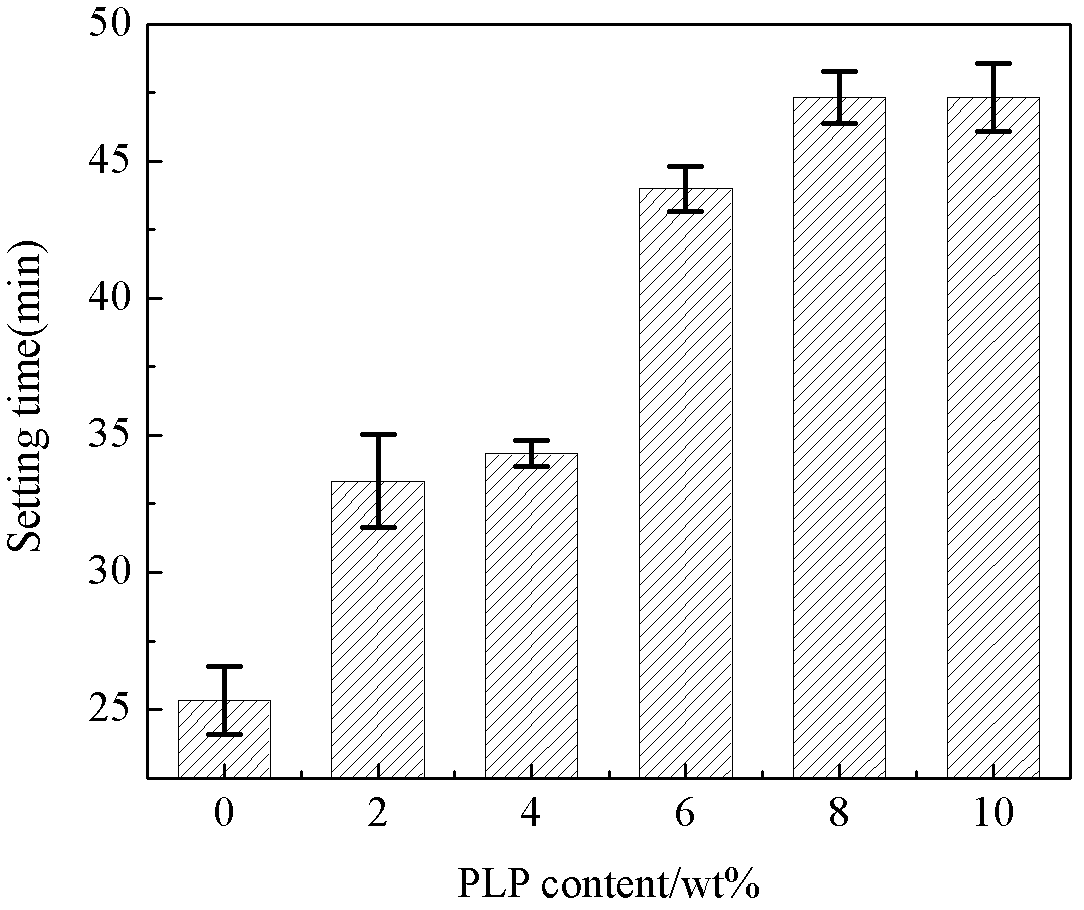

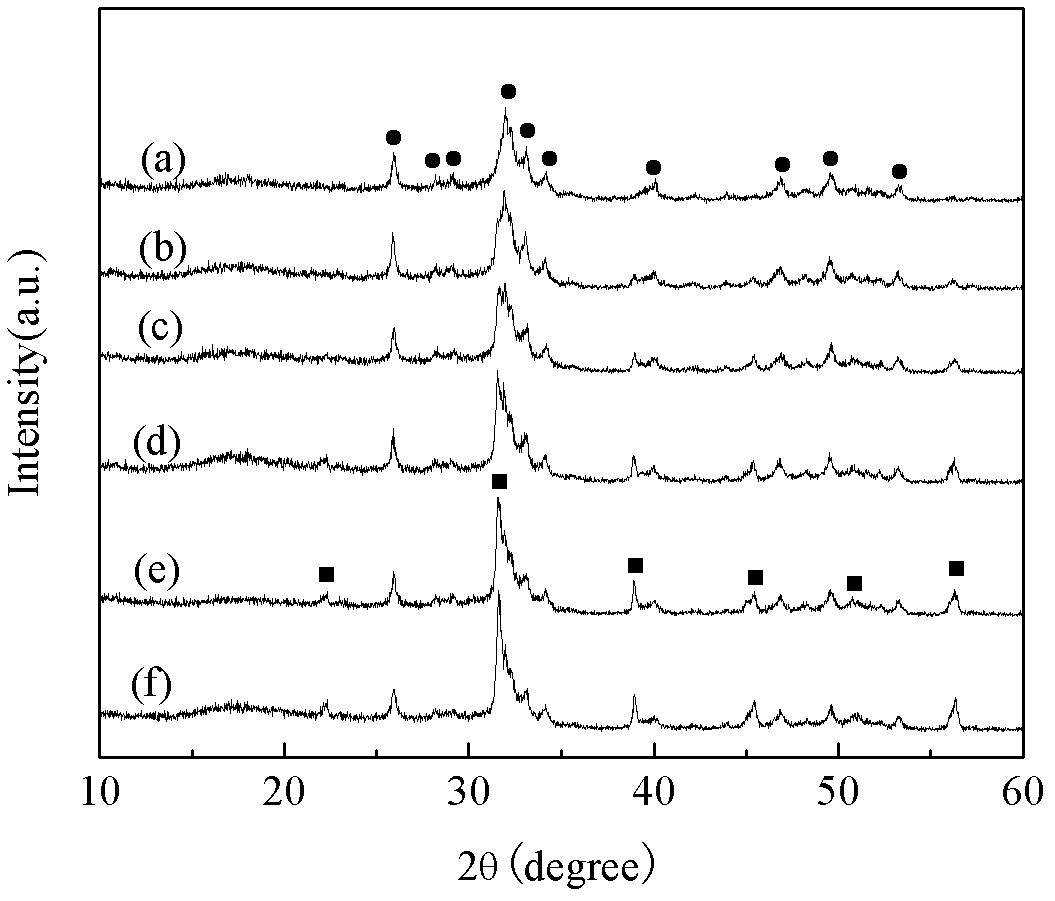

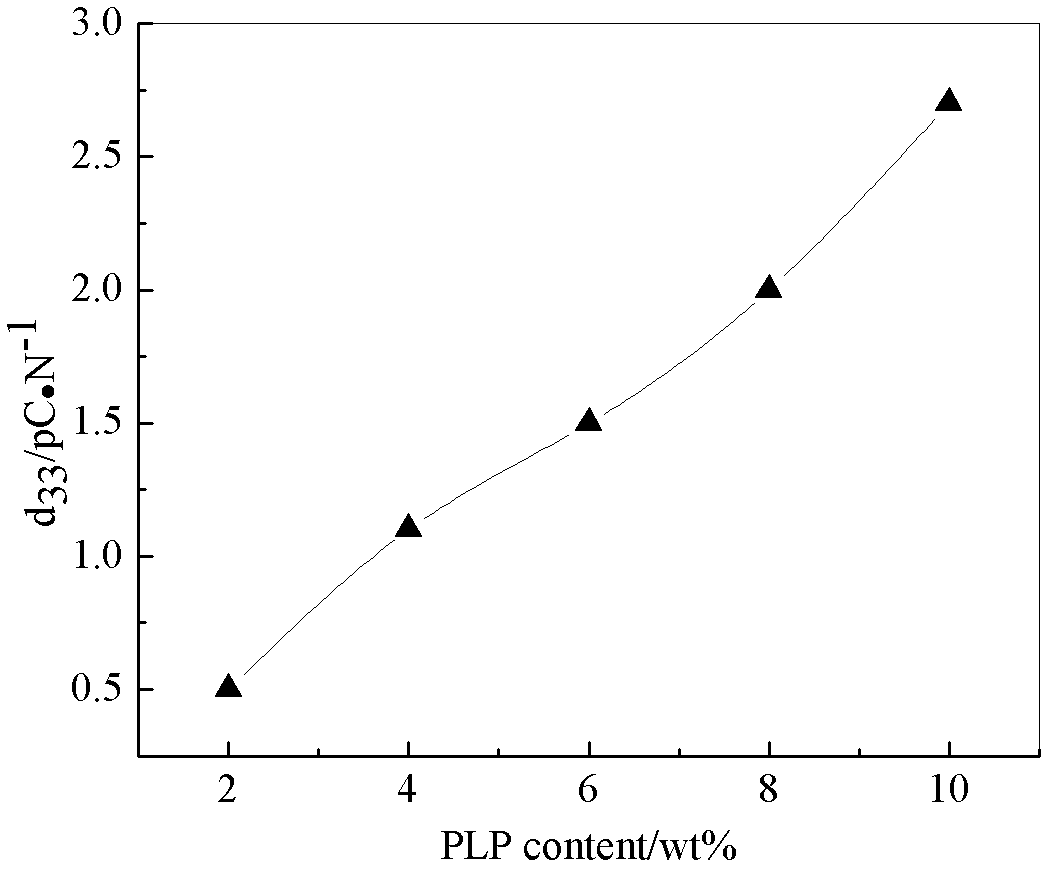

The invention discloses cement solid-phase powder which comprises calcium phosphate cement (CPC) powder and nano piezoelectric (PLP) powder, wherein the PLP powder accounts for 0.5-20% of the total mass of the cement solid-phase powder, and the CPC powder accounts for 80-99.5% of the total mass of the cement solid-phase powder. The invention also provides a piezoelectric calcium phosphate cement composite material which is characterized by being prepared by uniformly mixing the cement solid-phase powder and a setting liquid according to a solid-liquid ratio of 1.0-4.0g / ml, putting the obtained paste into a steel mold, defoaming while pressurizing, and curing for 1-7 days. The prepared piezoelectric calcium phosphate cement composite material has the advantages of adjustable setting time, high compression strength and certain piezoelectricity, and can be used for the reconstruction and repair of human bone tissues.

Owner:NANJING UNIV OF TECH

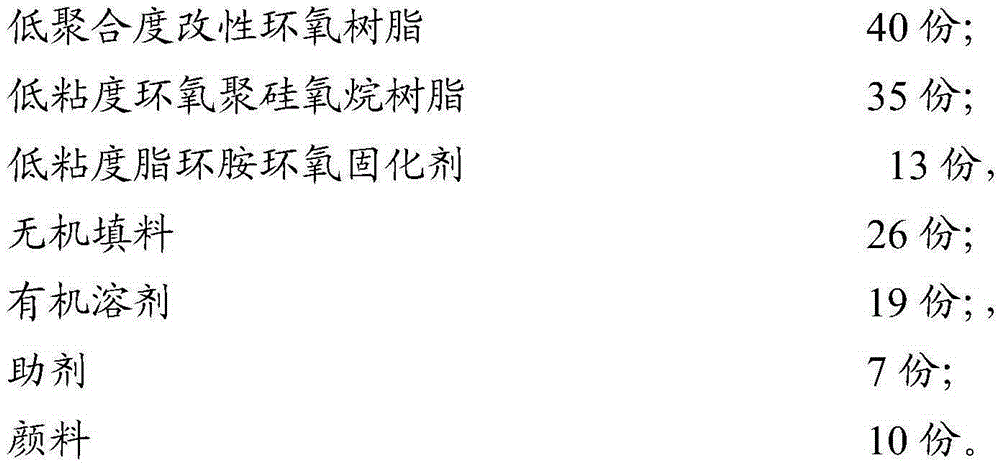

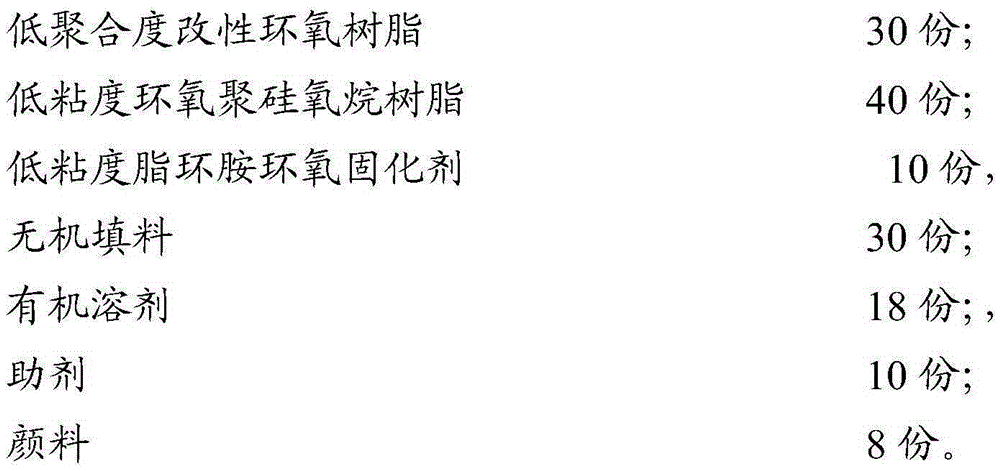

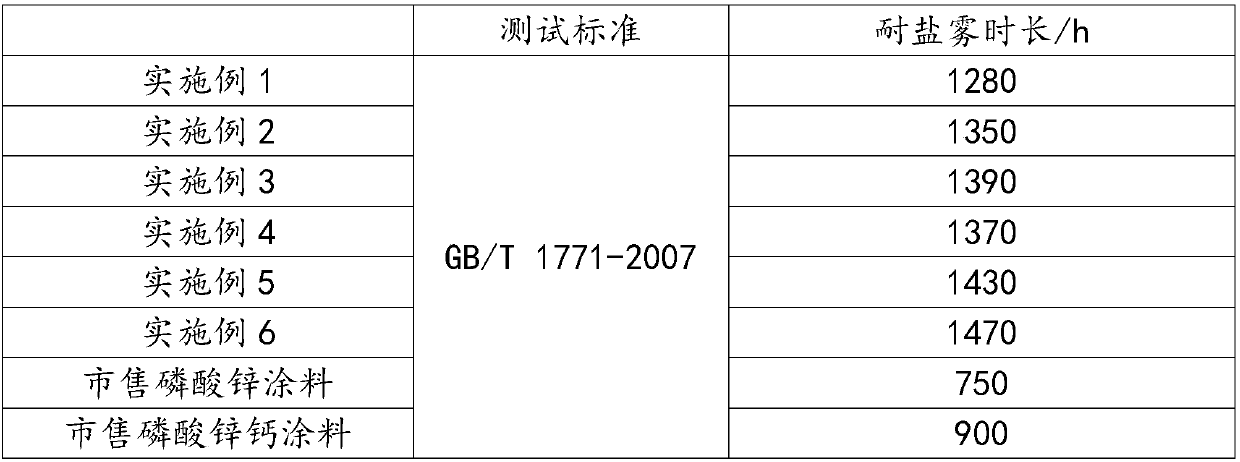

High-solid epoxy zinc phosphate primer paint and preparation method of high-solid epoxy zinc phosphate primer paint

InactiveCN105255315AReduce dosageEmission reductionAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc Phosphate Cement

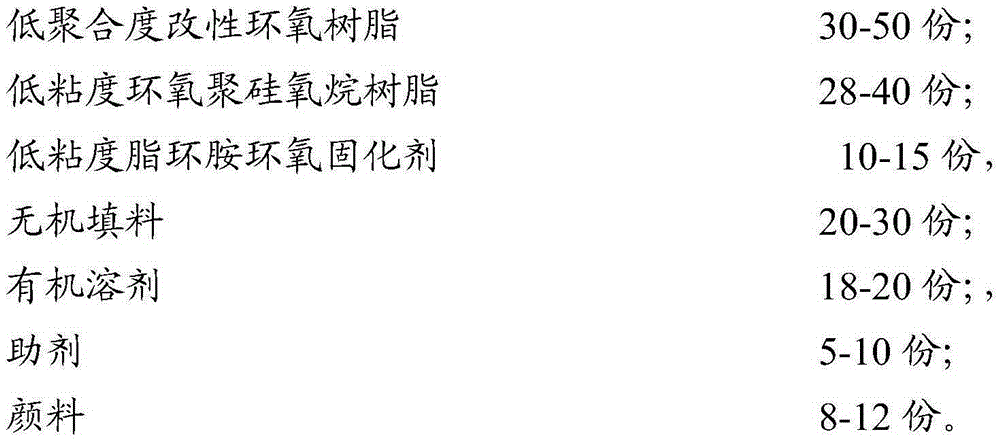

The invention relates to a high-solid epoxy zinc phosphate primer paint formula and a preparation method of high-solid epoxy zinc phosphate primer paint. The high-solid epoxy zinc phosphate primer paint is mainly applied to the protection of metal materials of containers, ships, automobiles, hardware, engineering machinery, bridges, sea engineering and the like, and comprises polymers (including low-polymerization-degree modified epoxy resin, low-viscosity epoxy polysiloxane resin and the like), low-viscosity cycloaliphatic amine epoxy solidifying agents, coloring pigment, zinc phosphate anti-rust pigment, inorganic fillers, organic solvents, dispersing agents, thickening agents, defoaming agents and flatting agents. The preparation method of the high-solid epoxy zinc phosphate primer paint formula is also provided. The paint rformula has the advantages that in the production of the high-solid epoxy zinc phosphate primer paint according to the formula, the size solid content are not less than 80 percent; the airless spraying diluent consumption is less than 5 percent; the solvent consumption is reduced by more than 60 percent through being compared with that of the conventional epoxy zinc phosphate paint; the discharge of the organic solvents is greatly reduced; other performance is identical to that of the conventional epoxy zinc phosphate paint.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

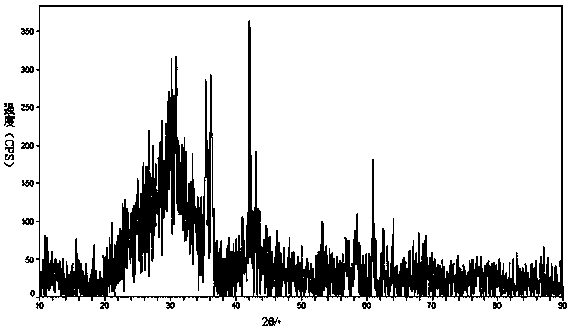

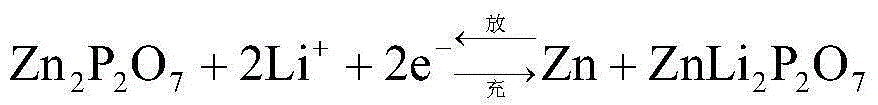

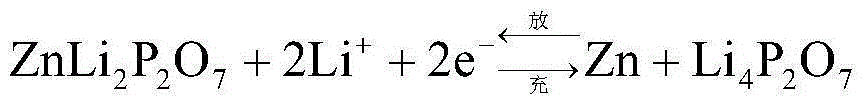

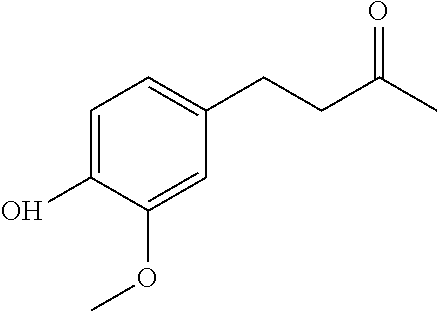

Sintering preparation method for zinc anode material

ActiveCN105206832ALow costSuppression of redistribution and other issuesAlkaline accumulatorsCell electrodesZinc Phosphate CementPower grid

The invention relates to a sintering preparation method for a zinc anode material. The method comprises the steps that the temperature of a mixture including zinc sources and phosphorus sources is increased to 550 DEG C-850 DEG C under protection of protective gas at the temperature increasing speed of 0.1-20 DEG C / min, a thermostatic reaction is performed for 0.5-48 h, after the reaction is finished, cooling and smashing are performed, and then zinc phosphate or zinc pyrophosphate or zinc tripolyphosphate or a mixture of the zinc phosphate and the zinc pyrophosphate and the zinc tripolyphosphate, namely, the zinc anode material is obtained. The method for preparing the zinc anode material has the advantages of being simple in technology, low in cost and little in pollution. The zinc anode material prepared by adopting the method can be applied to a battery system with an alkaline and neutral aqueous solution, is a suitable electrode active material, is low in cost and high in activity and has the wide application prospect in energy storage aspects of electric tools, electric vehicles, power grids and the like.

Owner:中国人民解放军军事科学院防化研究院

Oral Care Compositions

ActiveUS20190110965A1Improved demineralizationHigh antibacterial activityCosmetic preparationsToilet preparationsOrganic acidZinc Phosphate Cement

An oral care composition comprising zinc phosphate, sodium fluoride, stannous pyrophosphate, and an organic acid buffer system, as well as methods of using the same.

Owner:COLGATE PALMOLIVE CO

Modified phosphate cement-based fireproof coating material and preparation method thereof

The invention provides a modified phosphate cement-based fireproof coating material and a preparation method thereof. The modified phosphate cement-based fireproof coating material is prepared from the following raw materials in parts by mass: 10 to 20 parts of dihydric phosphate, 5 to 15 parts of a magnesium source, 0.5 to 1.5 parts of a composite retarder, 0.1 to 2 parts of fiber and 1 to 10 parts of water. The modified phosphate cement-based fireproof coating material provided by the invention has good working performance, the setting rate is appropriate, the longest initial setting time can be up to 62 minutes, the fluidity is 150 to 210 mm, and film formation is easy; the modified phosphate cement-based fireproof coating material has a higher adhesion force with a substrate after film formation and hardening of the modified phosphate cement-based fireproof coating material.

Owner:SHENZHEN UNIV

Tooth filling material and preparation method thereof

InactiveCN105902398AImprove mechanical propertiesImprove polishing effectImpression capsDentistry preparationsThermal dilatationPolymer science

The invention relates to a tooth filling material and a preparation method thereof. The tooth filling material includes, by mass, 15-35 parts of glycidyl methacrylate, 10-25 parts of Arabic gum, 5-20 parts of glass powder, 5-15 parts of silicon dioxide, 3-12 parts of nano montmorillonite, 1-6 parts of calcium carbonate, 0.5-3 parts of 1,6-hexanediol diacrylate, 0.8-3.5 parts of dicumyl peroxide, 0.3-1.5 parts of triethylene diamine, 0.2-1 part of EDTA, 0.2-1.2 parts of an organic tin stabilizer, 3-10 parts of zinc phosphate cement, and 0.1-0.5 parts of resorcinol monobenzoate. The tooth filling material has excellent mechanical performance and polishing performance, has the similar gloss and the similar coefficient of thermal expansion of a tooth, can effectively prevent edge micro-leakage and heat conductivity, has a good hole filling effect and is long in service life.

Owner:SUZHOU COSMETIC MATERIALS

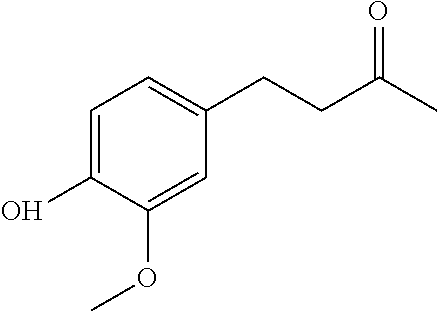

Calcium zinc phosphate/bagasse composite anti-corrosion pigment and preparation method thereof

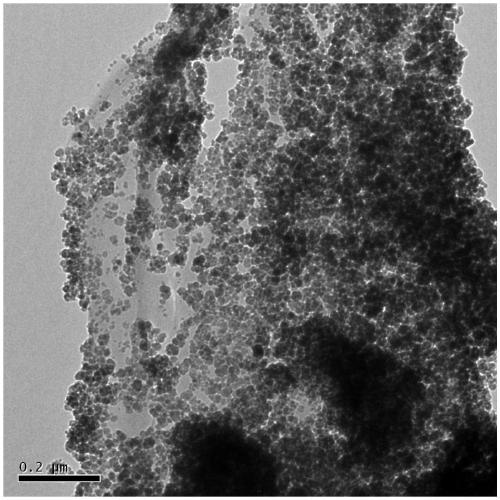

ActiveCN109627827AEfficient synthesisHigh reactivityAnti-corrosive paintsMicro nanoZinc Phosphate Cement

The invention provides calcium zinc phosphate / bagasse composite anti-corrosion pigment and a preparation method thereof. The preparation method comprises the steps of mixing a zinc salt solution and acalcium salt solution to form a mixed raw material solution; putting bagasse into the mixed raw material solution for soaking, and dropwise adding a phosphoric acid solution to a bagasse soaking solution for a reaction in an ultrasonic stirring state; after the reaction is completed, conducting filtering to obtain a solid substance, and washing and drying the solid substance to obtain the calciumzinc phosphate / bagasse composite anticorrosive pigment. Prepared calcium zinc phosphate has a micro-nano size and is uniformly distributed on the bagasse, and the reactivity of zinc phosphate is improved after calcium particles are modified; meanwhile, calcium zinc phosphate is compounded with the bagasse, the problems of easy aggregation and difficult dispersion of calcium zinc phosphate with the small particle size are solved, and the anti-corrosion performance of calcium zinc phosphate is fully exerted. The preparation process is simple and high in synthesis efficiency and has broad marketapplication prospects.

Owner:XIAMEN SUNRUI SHIP COATING

Oral Care Compositions

ActiveUS20180168978A1Improve protectionEnhanced stannous stabilityCosmetic preparationsToilet preparationsOrganic acidZinc Phosphate Cement

Owner:COLGATE PALMOLIVE CO

Oral Care Compositions

ActiveUS20180168977A1Improve protectionEnhanced stannous stabilityCosmetic preparationsToilet preparationsOrganic acidZinc Phosphate Cement

Owner:COLGATE PALMOLIVE CO

Preparation method of water battery zinc cathode material

InactiveCN109326775ALow costSuppression of redistribution and other issuesFuel and secondary cellsCell electrodesZinc Phosphate CementAqueous solution

The invention relates to a preparation method of a water battery zinc cathode material. By controlling solution reaction, one or a mixture of zinc phosphate, zinc pyrophosphate and zinc tripolyphosphate, namely the zinc cathode material, is obtained. The method for preparing the zinc cathode material has the characters of being simple in process, low in cost and little in pollution. The zinc cathode material prepared by adopting the method can be used in battery systems of alkaline and neutral aqueous solutions, is a proper electrode active material, is low in cost and high in activity, and has wide application prospects in the energy-storage aspects of electric tools, electrocars, power grids and the like.

Owner:ZHEJIANG WELLY ENERGY CORP

Oral care compositions

ActiveUS10285919B2Improved demineralizationHigh antibacterial activityCosmetic preparationsToilet preparationsZinc Phosphate CementMedicine

An oral care composition comprising high water oral care compositions comprising an orally acceptable carrier, zinc phosphate, a first stannous ion source (i.e., stannous fluoride), and a second stannous ion source (i.e., stannous chloride). Methods and uses for this composition are also described throughout.

Owner:COLGATE PALMOLIVE CO

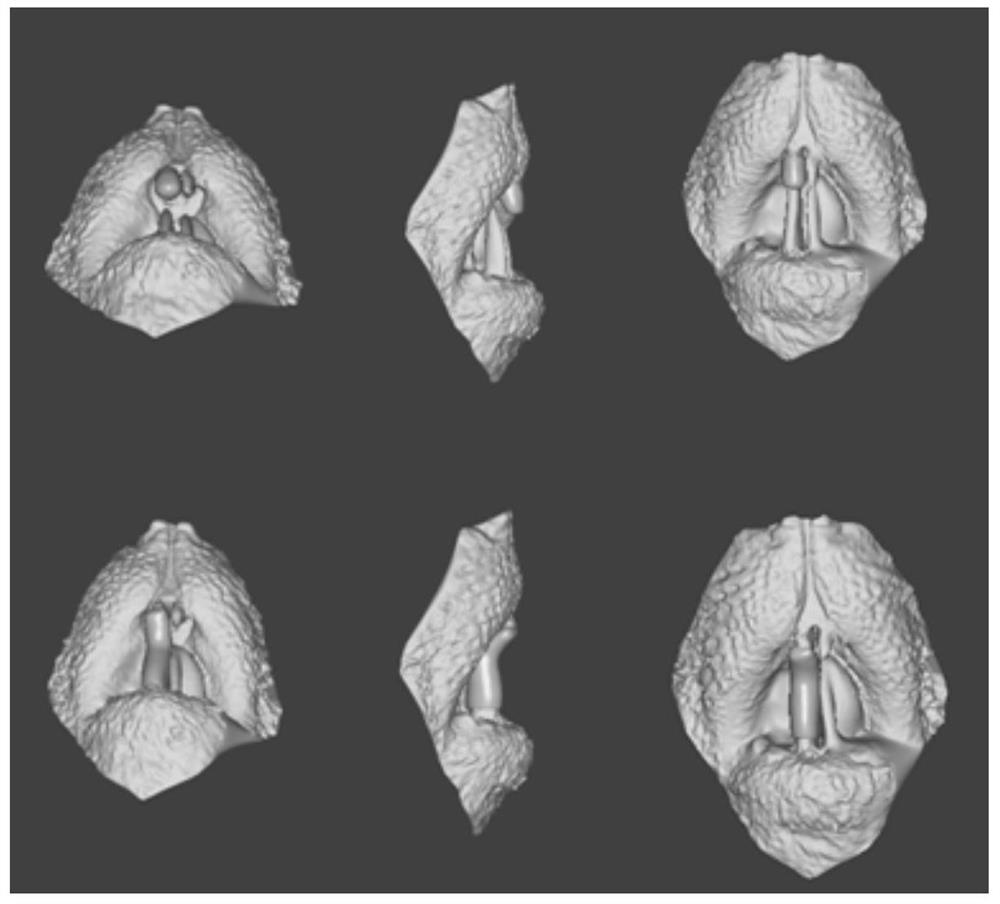

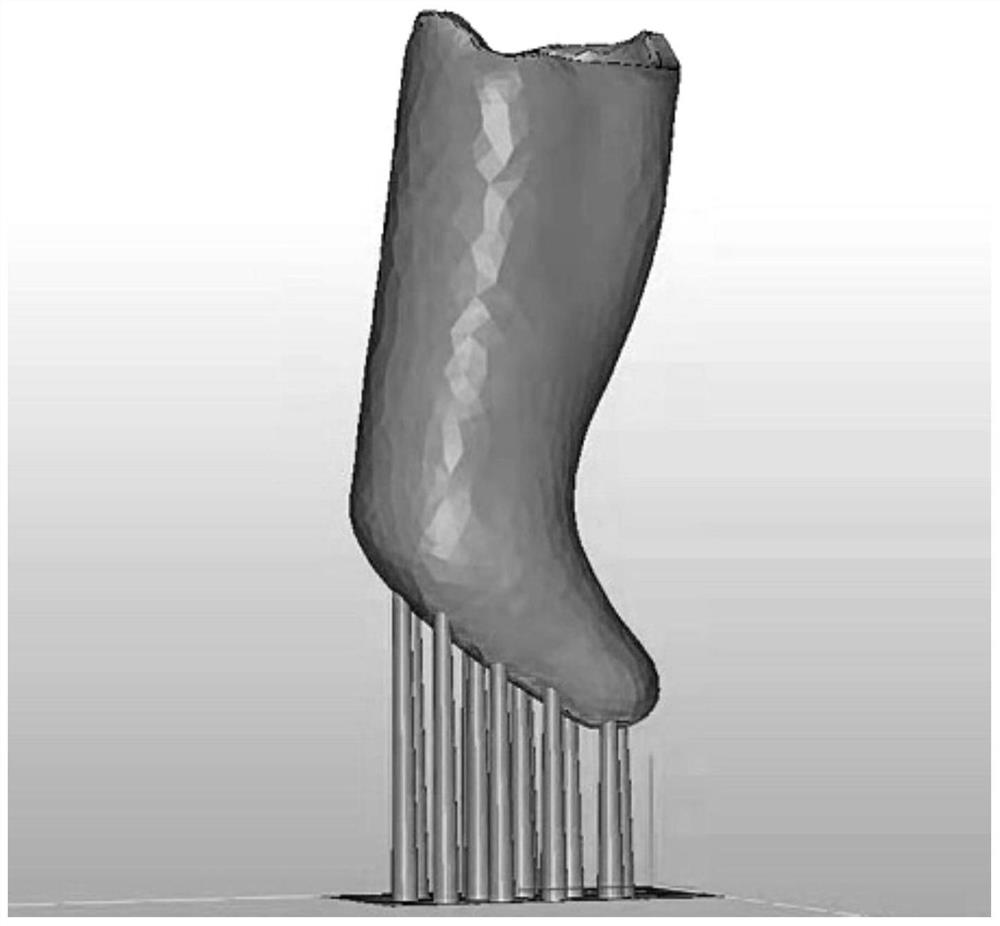

Method for constructing temporomandibular joint osteoarthritis animal model by applying digital technology

InactiveCN113440254AAvoid heterogeneityAvoid disadvantagesComputer-aided planning/modellingModel sampleZinc Phosphate Cement

The invention discloses a method for constructing a temporomandibular joint osteoarthritis animal model by applying a digital technology, relates to the technical field of medicine and animal models, and solves the problem that an existing animal model construction method is poor in intuition, poor in precision and poor in expected controllability, resulting in that a model sample is easy to generate heterogeneity. The method for constructing the temporomandibular joint osteoarthritis animal model by applying the digital technology comprises the steps of: selecting an SD rat, anesthetizing, and digitally scanning animal teeth; selecting a 6-week-old female SD rat with the weight of 160-180 g, feeding the rat in a clean environment, adaptively feeding the rat for one week, injecting 10% chloral hydrate into the abdominal cavity of the SD rat, and anesthetizing the rat; producing a telescopic crown; establishing the temporomandibular joint osteoarthritis animal model; and under the anesthesia of chloral hydrate, adhering by zinc phosphate cement. The method applies the digital technology, is simple in production process, more visual in 3D scanning and high in precision, has predictability, and avoids heterogeneity of samples.

Owner:JIAMUSI UNIVERSITY

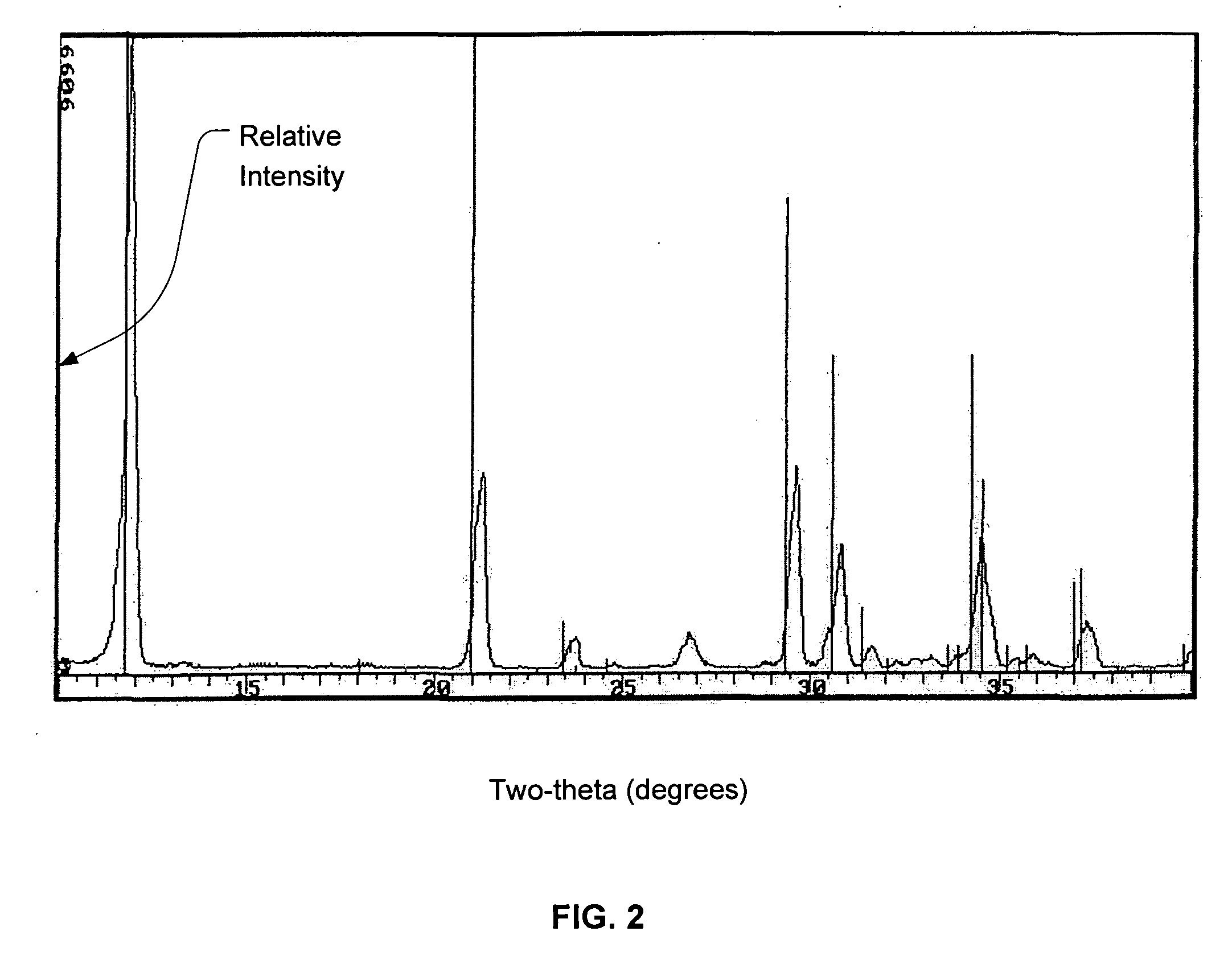

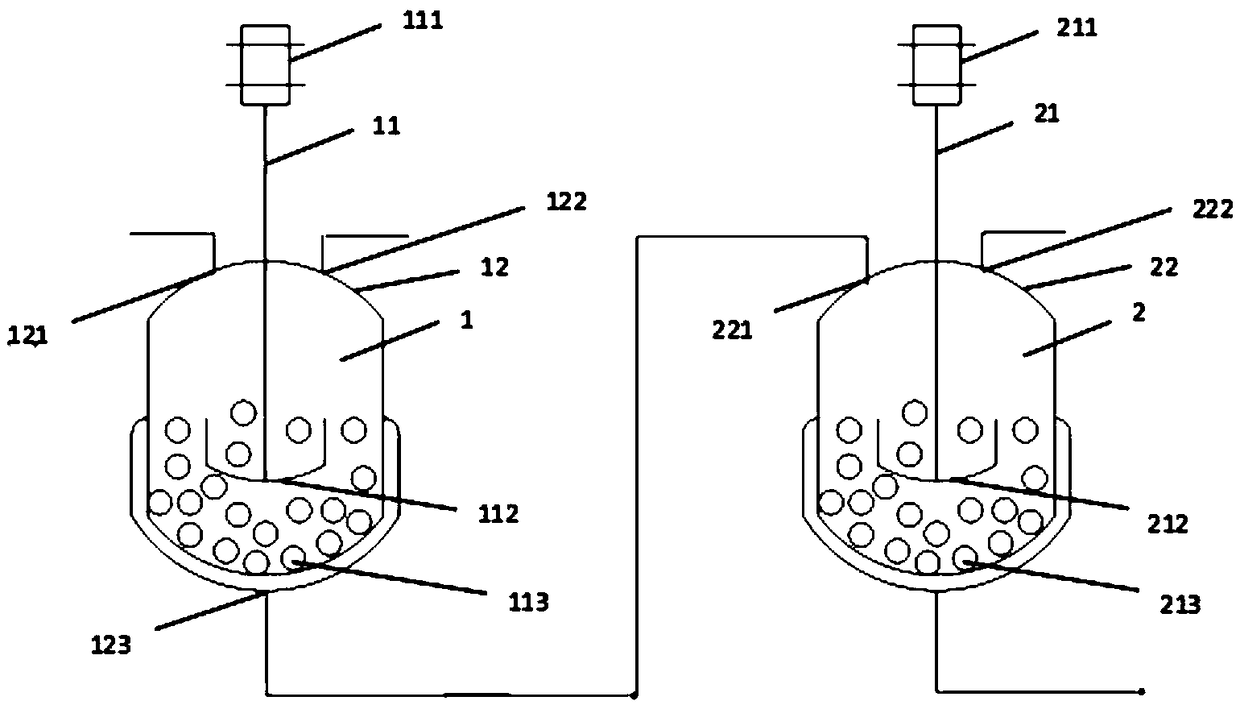

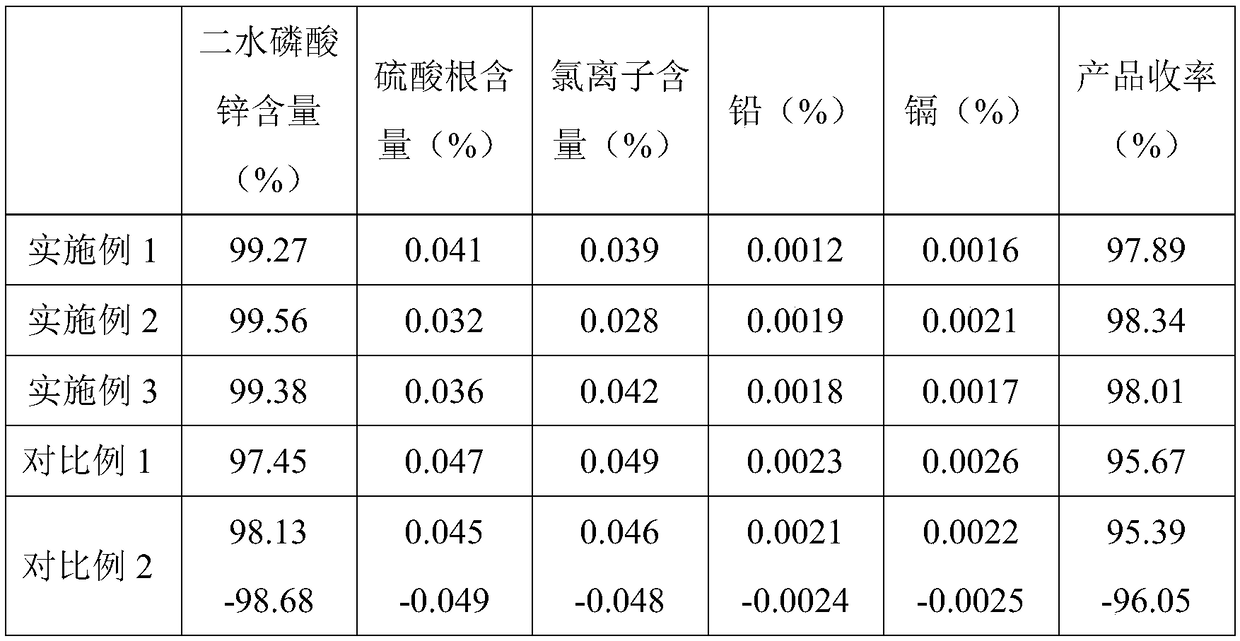

Method of preparing high purity zinc phosphate by mechanical activation continuous reaction

ActiveCN108946693ASemi-continuous processSimple production processPhosphorus compoundsSulfate radicalsZinc Phosphate Cement

The invention discloses a method of preparing high purity zinc phosphate by a mechanical activation continuous reaction. The method comprises the following steps: S1, dissolving soluble carbonate or hydrogen carbonate and soluble zinc salt in water, separately to prepare a carbonate or hydrogen carbonate solution and a zinc salt solution; S2, mechanically activating the zinc salt solution and thecarbonate or hydrogen carbonate solution in a first reaction kettle synergically in a wet process for a reaction to prepare a precipitate; S3, conveying the precipitate and a solution to a second reaction kettle, adding a phosphoric acid solution, and carrying out a reaction in a mechanical activating condition in a synergic wet process to prepare zinc phosphate. The yield of the obtained productreaches 97.89-98.34%, the content of zinc phosphate dehydrate is 99.27-99.56%, the content of sulfate radicals is 0.032-0.041%, the content of chlorine ions is 0.028-0.042% and the content of lead is0.0012-0.0019%. Compared with the prior art, the output and quality of the product are superior.

Owner:广西科立方新材料有限公司 +2

Preparation method of medical ceramic simulating coating

InactiveCN107227055AKeep dryStrong adhesionAnti-corrosive paintsZinc Phosphate CementPolymer science

The invention discloses a preparation method of a medical ceramic simulating coating. The preparation method utilizes epoxy polyurethane, zinc phosphate, calcium carbide, nanometer titanium dioxide, zinc oxide, methyl ethyl ketone peroxide, ash-calcium powder, aluminum oxide, ammonium persulfate, xylene, butyl acrylate, tributyl phosphate, nano-calcium carbonate, polytetrafluoroethylene, octanol and a thickener as raw materials. The medical ceramic simulating coating has viscosity of 40-60s, fineness of 10-30 micrometers, flexibility of 0.6-1mm, adhesion of 1-2 level, impact strength of 60-80 kg / cm, salt water resistance of preventing foaming for 1-3d, boiling water resistance of preventing falling-off for 8-12h, no change after soaking in 40% sodium hydroxide for 6-10h, has hardness of 0.8-1, surface drying time of 1-3h, solid drying time of 18-20h and glossiness of 94-98%.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Oral care compositions

ActiveUS10195128B2Improved demineralizationImprove stabilityCosmetic preparationsToilet preparationsOrganic acidZinc Phosphate Cement

Owner:COLGATE PALMOLIVE CO

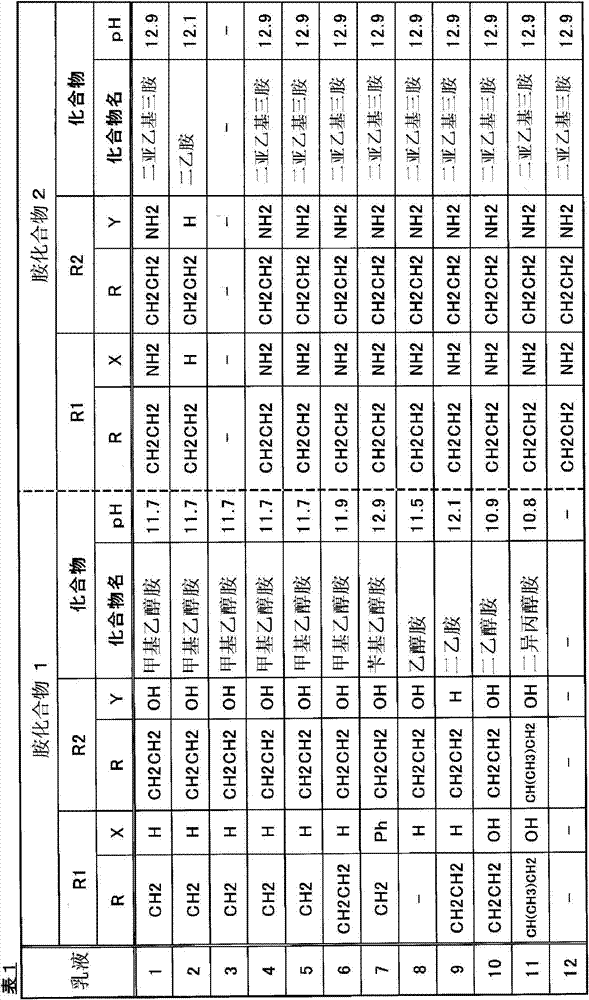

Composition for metal surface treatment

InactiveCN103339210BPrevent precipitationControlling the Z-potentialElectrophoretic coatingsAnti-corrosive paintsZeta potentialEmulsion

[Problem] To provide a means for forming on a metal material a film for imparting sufficient corrosion resistance without pretreatment such as zinc phosphate-based conversion coatings. [Solution] A metal surface treatment composition which is used in an energization method having multiple stages in the same bath and which contains Bi ions and a resin emulsion in which at least one type of cationic resin is dispersed in water, wherein the zeta potential of the aforementioned resin emulsion in a pH5-pH9 aqueous medium is +40mV to +100mV.

Owner:NIHON PARKERIZING

Zinc phosphate cement binding material for dental department

ActiveCN102302413BReduce acidityResolve stimulusImpression capsDentistry preparationsFine structureZinc Phosphate Cement

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

Zinc phosphate cement binding material for dental department

ActiveCN102302413AReduce acidityResolve stimulusImpression capsDentistry preparationsFine structureZinc Phosphate Cement

The invention discloses an improved zinc phosphate cement binding material for dental department. The binding material comprises powder and liquid. The powder comprises the following components: 100 parts of zinc oxide, 10 to 15 parts of magnesium oxide, 3 to 5 parts of silicon dioxide, 1 to 2 parts of bismuth oxide, and 3 to 5 parts of sodium carbonate. The liquid comprises the following components: 100 parts of orthophosphoric acid, 4 to 20 parts of aluminum oxide, 4 to 20 parts of zinc oxide, and 40 to 60 parts of water. The powder and the liquid are blended in a ratio of every 2 grams of powder to 1 milliliter of liquid. The prepared oral binding material is paste with certain flowability before solidification, and can penetrate fine structures on the surfaces of teeth and a recovered body so as to play a binding role. The binding material has good mechanical property, greatly weakens the acidity, and does not bring obvious stimulating sense to a patient.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

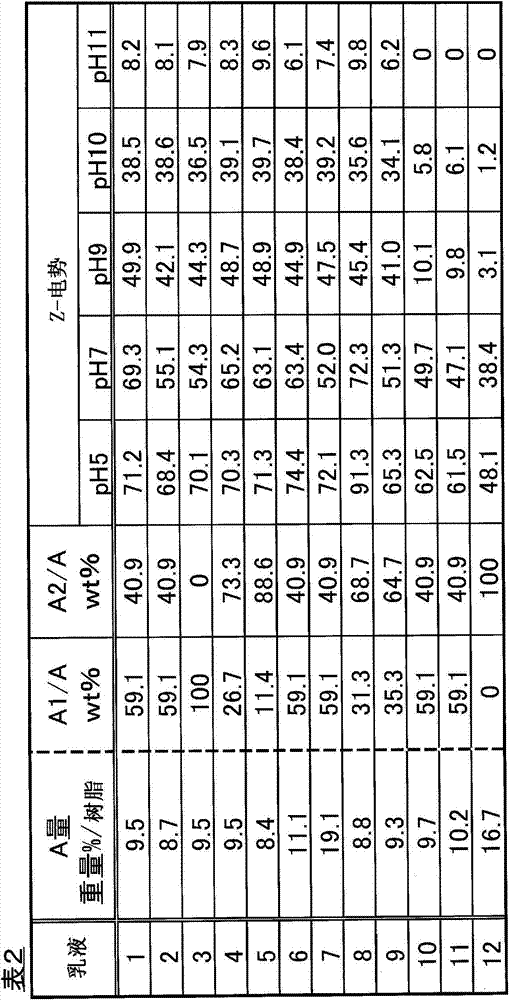

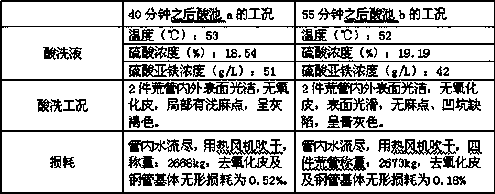

Acid pickling process of carbon structural steel tube

The invention discloses a pickling process for carbon steel pipes. During pickling of steel pipes, a composite corrosion inhibitor is added to the pickling solution, and the composite corrosion inhibitor is prepared from the following components in mass percentage of: benzalkonium bromide 70~80%, zinc phosphide 8~12% and zinc carbonate 8~12%. The present invention adds a composite corrosion inhibitor to the pickling solution, which can form a layer of precipitation protective film on the surface of the steel pipe, which does not reduce the peeling speed of the oxide scale, but also reduces the corrosion of the steel matrix and the generation of hydrogen, and reduces the amount of hydrogen The generation of brittleness.

Owner:常熟市异型钢管有限公司

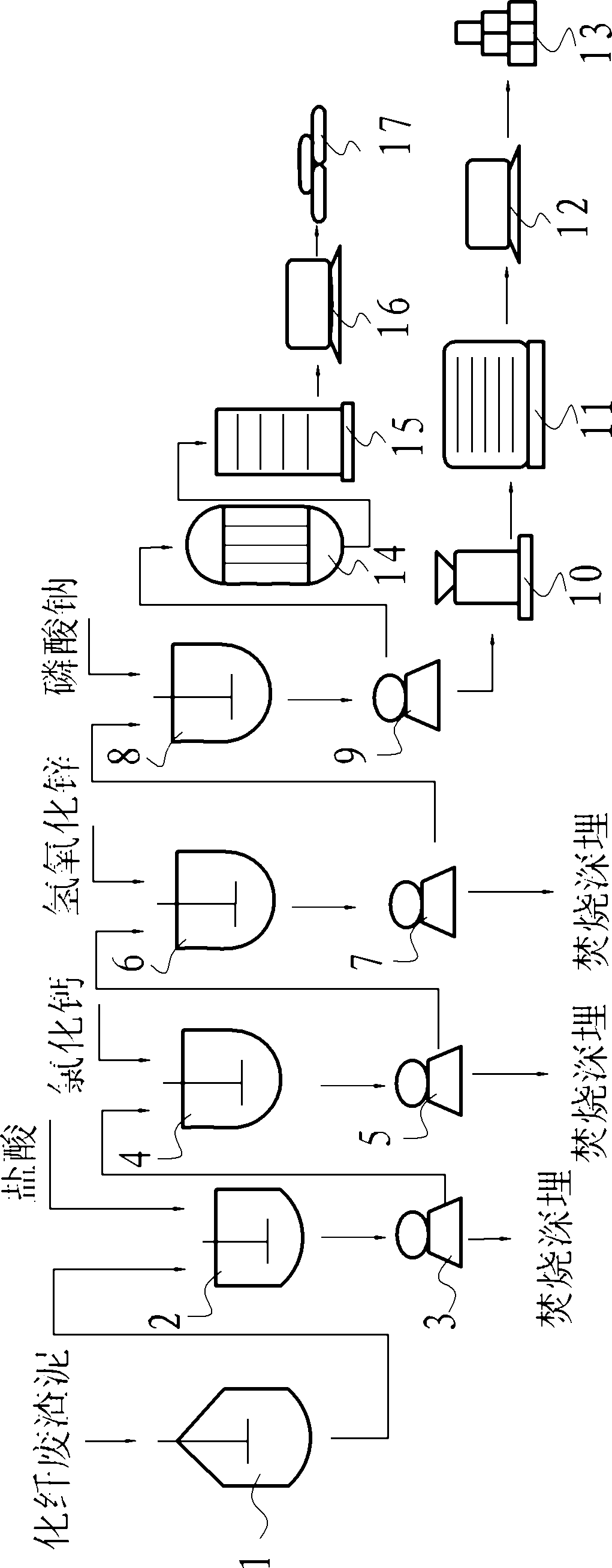

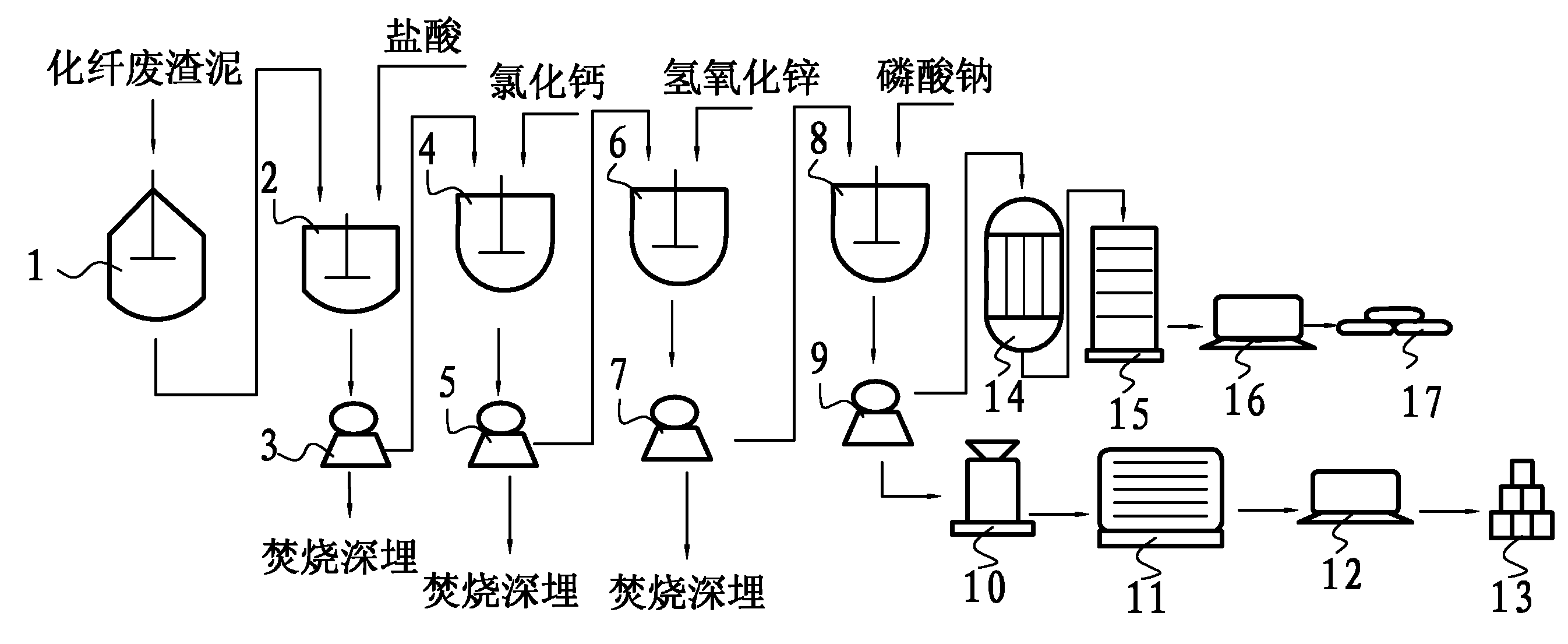

Method for simultaneously preparing zinc phosphate and sodium chloride by chemical fiber waste residue mud

The invention belongs to the technical field of chemical industry three-waste treatment and utilization, and in particular relates to a method for simultaneously preparing zinc phosphate and sodium chloride by chemical fiber waste residue mud. The main technical scheme comprises washing chemical fiber waste residue mud, preparing into diluted emulsion, reacting with hydrochloric acid, and recycling the gas generated during reaction through absorption; adding a small amount of calcium chloride and zinc hydroxide sequentially in the mixed liquid generated after reaction, and filtering after reaction; then carrying out reaction on filtrate and sodium phosphate to produce the mixed solution of zinc phosphate and sodium chloride, and filtering; washing filter cake, drying, crushing, checking weight, and packaging to obtain zinc phosphate powder product; and distilling the sodium chloride solution, cooling and crystallizing, crushing and packaging to obtain the sodium chloride crystal product. According to the method provided by the invention, not only is waste mud generated by the chemical fiber production industry treated effectively, the chemical industry pollution is eliminated, but also the chemical fiber waste mud can be changed into zinc phosphate and sodium chloride products with economic value, the production process and the device thereof are simple, and the cost is low.

Owner:冯若愚

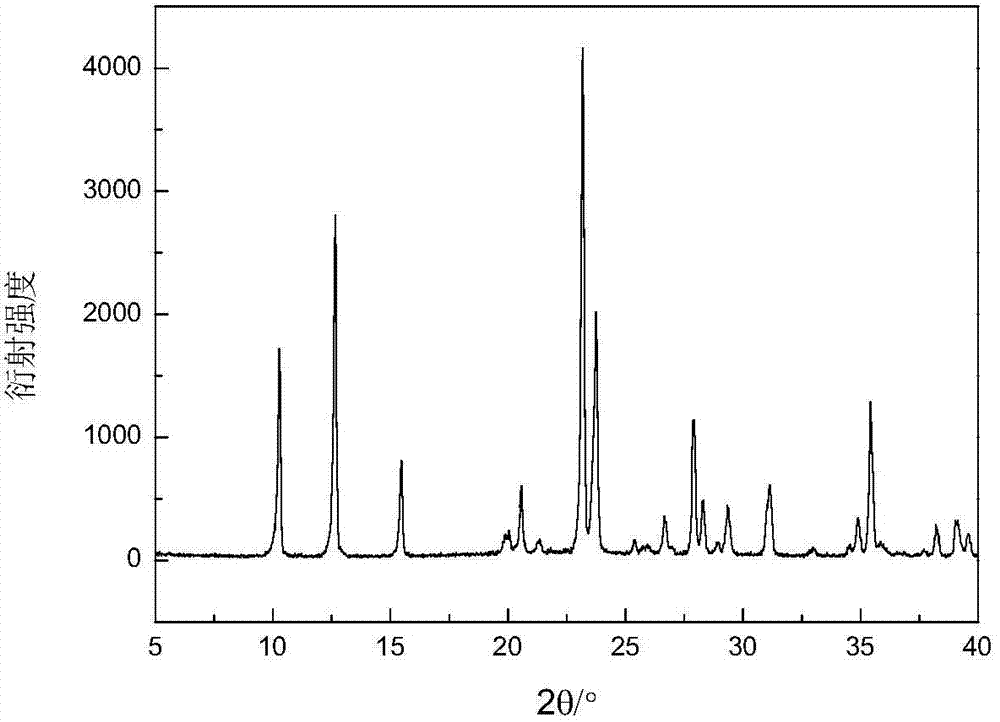

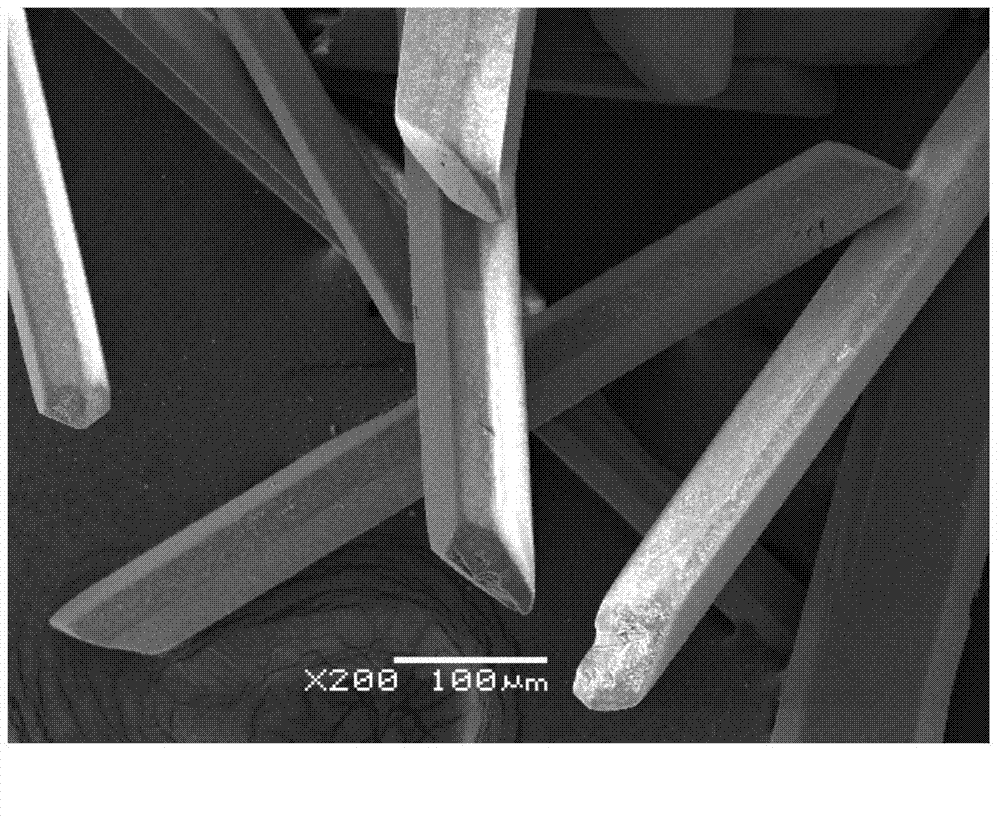

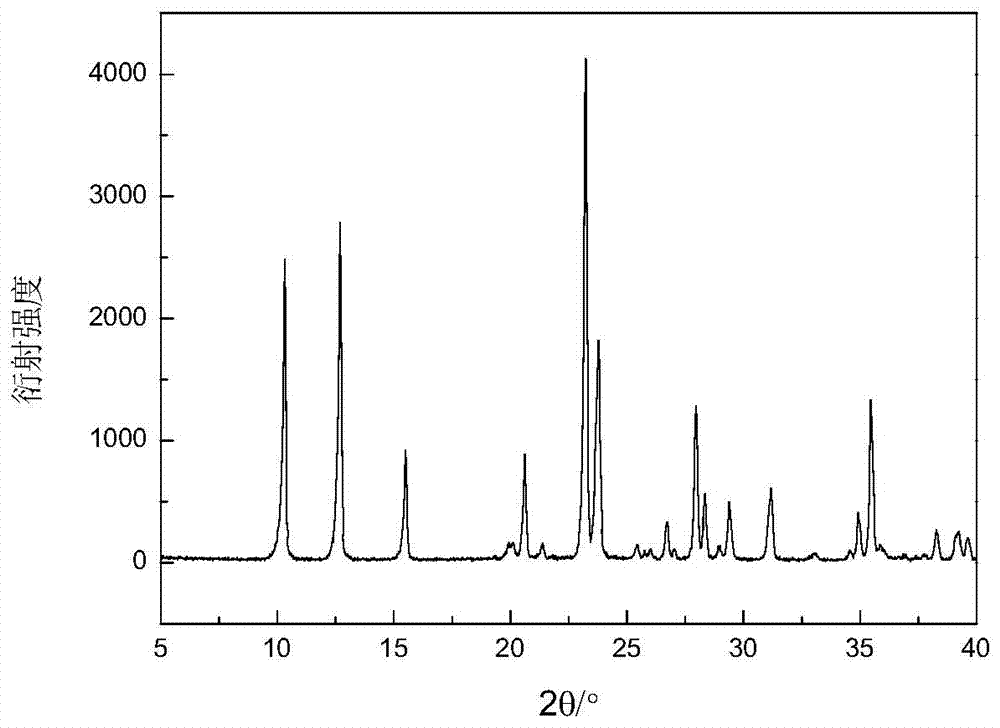

Method for preparing zinc phosphate compounds Zn(C3N2H4)HPO4 and Zn4P3O11(OH).3C3N2H4

InactiveCN104774181AUniform shapeLarge specific surface areaOrganic chemistryPhosphorus compoundsZinc Phosphate CementMicrowave

The invention discloses a method for preparing zinc phosphate compounds Zn(C3N2H4)HPO4 and Zn4P3O11(OH).3C3N2H4, which comprises the following steps: (1) sequentially adding zinc acetate, iminazole and phosphoric acid into deionized water, and magnetically stirring to obtain an initial mixed solution; and (2) putting the initial mixed solution obtained in the step (1) into a special microwave reaction kettle prepared from polytetrafluoroethylene, crystallizing, naturally cooling to room temperature to obtain a crystallization product, washing the crystallization product with deionized water, and drying to obtain the zinc phosphate compounds Zn(C3N2H4)HPO4 and Zn4P3O11(OH).3C3N2H4. A microwave heating process is utilized to respectively prepare the zinc phosphate compounds Zn(C3N2H4)HPO4 and Zn4P3O11(OH).3C3N2H4 in one reaction system by changing the reaction conditions.

Owner:DALIAN POLYTECHNIC UNIVERSITY

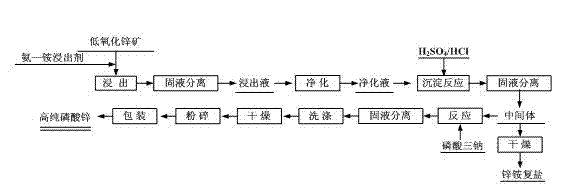

Method for preparing zinc phosphate by using low-grade zinc oxide ores

InactiveCN102887494BPromote development and utilizationRich sourcesPhosphorus compoundsAmmonium compoundsZinc Phosphate Cement

The invention relates to a method for preparing zinc phosphate by using low-grade zinc oxide ores, and belongs to the technical field of inorganic chemical industry. The method comprises the following steps of: by using the low-grade zinc oxide ores as raw materials, leaching and purifying the low-grade zinc oxide ores by using ammonia-ammonium salt to obtain an ammonia leaching purified solution, adding a precipitator for reaction to generate a zinc-ammonium compound salt intermediate precipitation, then completely dissolving the intermediate so that the intermediate solution and a trisodium phosphate solution are subjected to liquid-liquid reaction to generate a zinc phosphate solid precipitation, and obtaining a high-purify powdery zinc phosphate dehydrate product after drying the zinc phosphate solid precipitation, wherein the high-purify powdery zinc phosphate dehydrate product has larger than or equal to 45% of PO4<3->, larger than or equal to 45% of Zn<+> and more than 98% of zinc phosphate and can be used as a raw material for a high-grade anticorrosive paint. The method has the advantages that the technology is simple, the raw materials are abundant in source and low in cost, the liquid-liquid reaction mode is adopted, the reaction speed of the raw materials is fast, and the encapsulation phenomenon is avoided. The product is easy to wash and has fine particle size (+45mum is less than or equal to 0.5%); and the yield of the product is more than 92%. The method not only can be used for promoting the development and utilization of the low-grade zinc oxide ores and but also greatly reducing the production cost of the zinc phosphate product.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

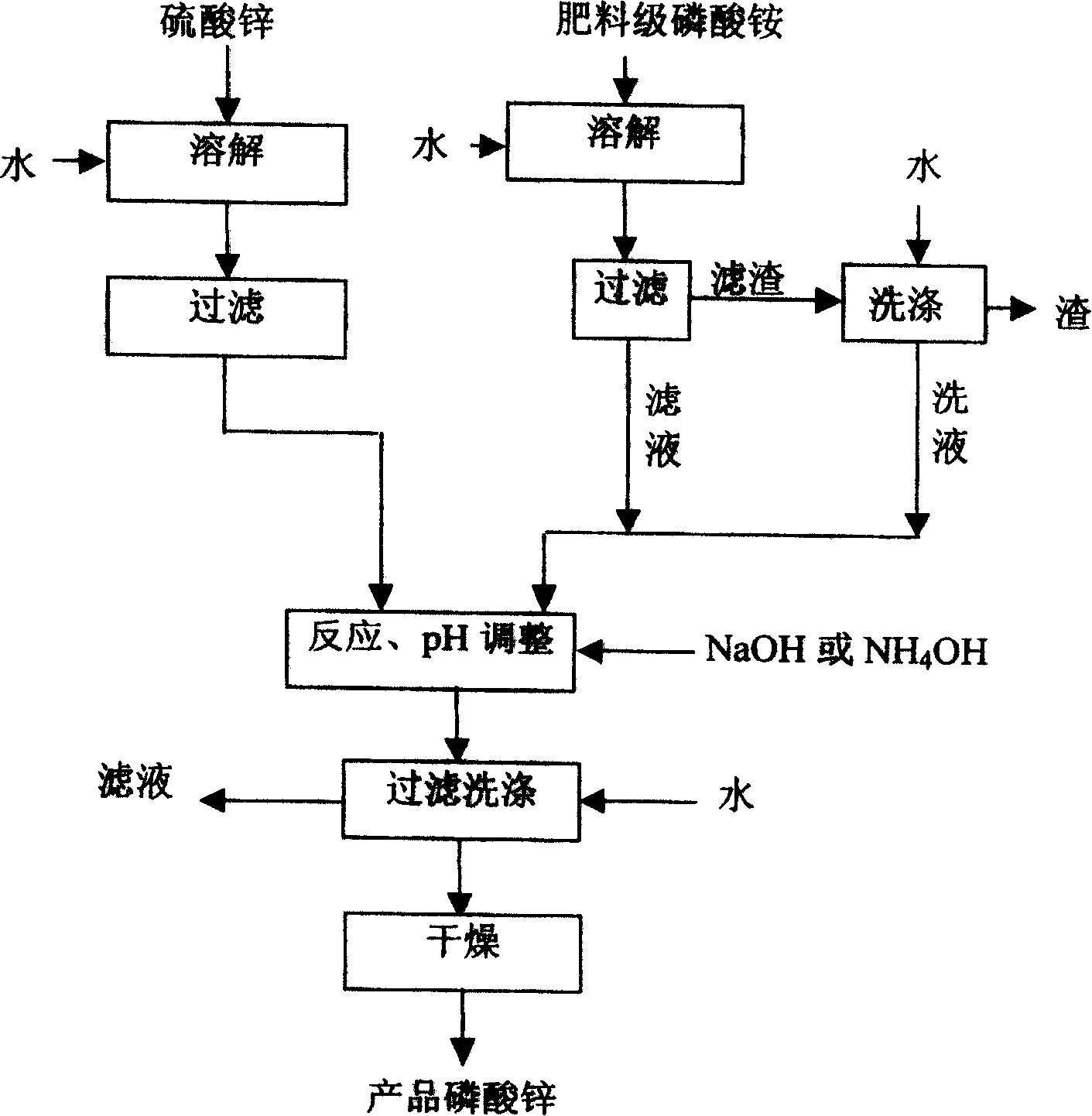

Method of producing zinc phosphate using phosphorus fertilizer

InactiveCN100395178CWide variety of sourcesReduce manufacturing costPhosphatesZinc Phosphate CementPhosphate ion

A process for preparing zinc phosphate from P fertilizer includes such steps as respectively dissolving fertilizer-class ammonium phosphate and soluble Zn salt in hot water, proportionally adding them to a container with stirrer, keeping the temp to 50-80 deg.C, regulating pH=6.5-8.5, ageing reaction, filtering, washing the filtered cake with hot water to obtain wet zinc phosphate, and drying.

Owner:KUNMING UNIV OF SCI & TECH

No.4 main shaft oil and production method thereof

The invention discloses a No.4 main shaft oil. The No.4 main shaft oil comprises 35-50wt% of 25# transformer oil, 15-40wt% of degreased paraffin oil, 7-15wt% of an antioxidant, 4-14wt% of dodecencylsuccinic acid, 10-25wt% of zinc phosphate and 3-12wt% of polyisobutylene. A production method of the No.4 main shaft oil comprises the following steps: adding 25# transformer oil and degreased paraffin oil to a container at normal temperature under normal pressure, heating to 80-90DEG C, stirring until complete mutual dissolution, sequentially adding the antioxidant, dodecencylsuccinic acid, polyisobutylene and zinc phosphate, stirring, stopping stirring after complete mutual dissolution, cooling to below 40DEG C, sampling, detecting, and packaging.

Owner:DALIAN KELINER CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com