Modified phosphate cement-based fireproof coating material and preparation method thereof

A fire retardant coating, cement-based technology, applied in the field of fire retardant coatings, can solve problems such as weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

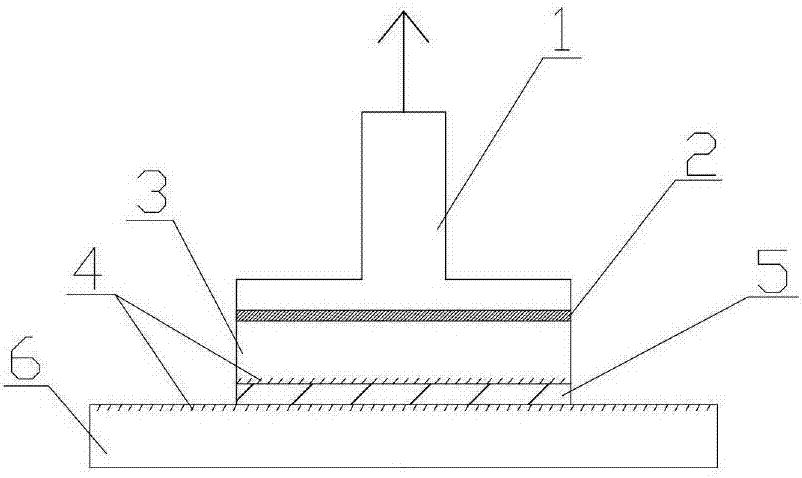

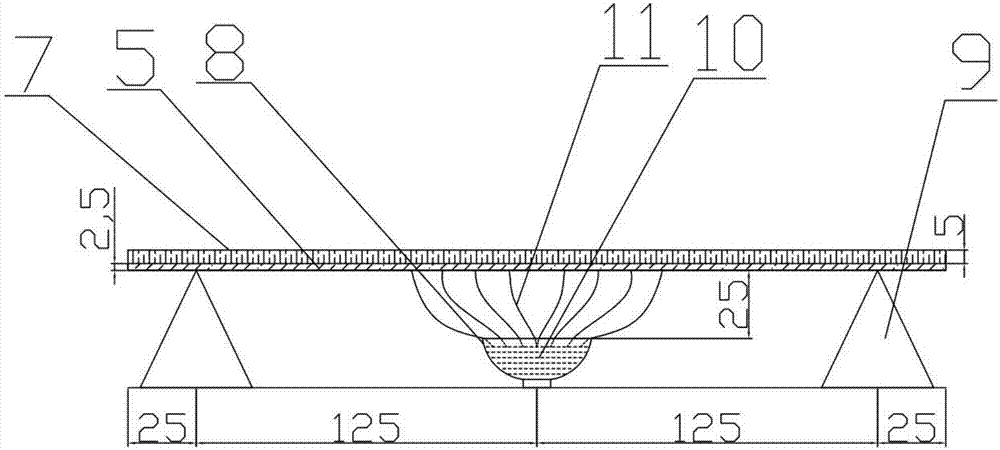

Method used

Image

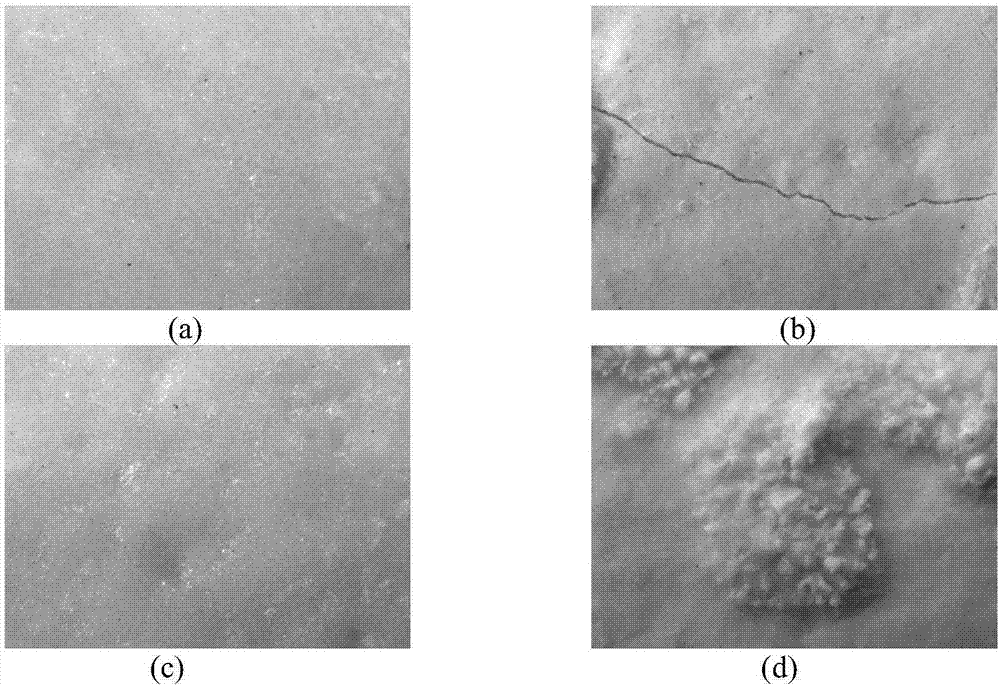

Examples

preparation example Construction

[0040] The present invention does not have any special requirements for the preparation method of the modified phosphate cement-based fireproof coating, and all raw material components can be directly mixed evenly. In the present invention, the preparation method of the phosphate cement fireproof coating preferably comprises the following steps:

[0041] Dispersing the fibers with water to obtain a fiber water mixture;

[0042] mixing dihydrogen phosphate, magnesium source and composite retarder to obtain cement base material;

[0043] The fiber water mixture is mixed with the cement base material to obtain the modified phosphate cement-based fireproof coating.

[0044]The invention disperses the fiber with water to obtain the water mixture of the fiber. In the present invention, the fiber is dispersed in water preferably by ultrasonic dispersion; the ultrasonic frequency of the ultrasonic dispersion is preferably 35000-45000 Hz, more preferably 38000-42000 Hz, most preferab...

Embodiment 1

[0063] According to the ratio of 3mm glass fiber, potassium dihydrogen phosphate, burnt magnesia, composite retarder and water in Table 4, prepare phosphate cement fireproof coating.

[0064] The fibers were ultrasonically dispersed with water, the ultrasonic frequency was 40,000 Hz, the ultrasonic power was 120 W, and the ultrasonic dispersion time was 5 minutes to obtain a fiber water mixture.

[0065] Potassium dihydrogen phosphate, magnesium source and composite retarder were stirred and mixed at a stirring speed of 140 r / min, and the stirring and mixing time was 1 min to obtain a cement paste base material.

[0066] The fiber water mixture and the cement slurry base material are sequentially mixed at low speed and high speed to obtain the phosphate cement fireproof coating. The stirring rate of the low-speed mixing is 140r / min; the time of the low-speed mixing is 30s. The stirring rate of the high-speed mixing is preferably 285r / min; the time of the high-speed mixing is ...

Embodiment 2

[0071] According to the ratio of 6mm glass fiber, sodium dihydrogen phosphate, overfired magnesia, composite retarder and water in Table 5, prepare phosphate cement fireproof coating.

[0072] The fibers were ultrasonically dispersed with water, the ultrasonic frequency was 40,000 Hz, the ultrasonic power was 120 W, and the ultrasonic dispersion time was 5 minutes to obtain a fiber water mixture.

[0073] The sodium dihydrogen phosphate, the magnesium source and the composite retarder were stirred and mixed at a stirring rate of 140 r / min, and the stirring and mixing time was 1 min to obtain a cement paste base material.

[0074] The fiber water mixture and the cement slurry base material are sequentially mixed at low speed and high speed to obtain the phosphate cement fireproof coating. The stirring rate of the low-speed mixing is 140r / min; the time of the low-speed mixing is 30s. The stirring rate of the high-speed mixing is preferably 285r / min; the time of the high-speed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com