Gluing device for electronic product protective film production

A technology for electronic products and protective films, which is applied in the field of gluing devices for the production of electronic product protective films. It can solve problems affecting the gluing process, lack of cleaning devices, and affecting gluing efficiency, and achieve uniform distribution and slow down the coagulation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

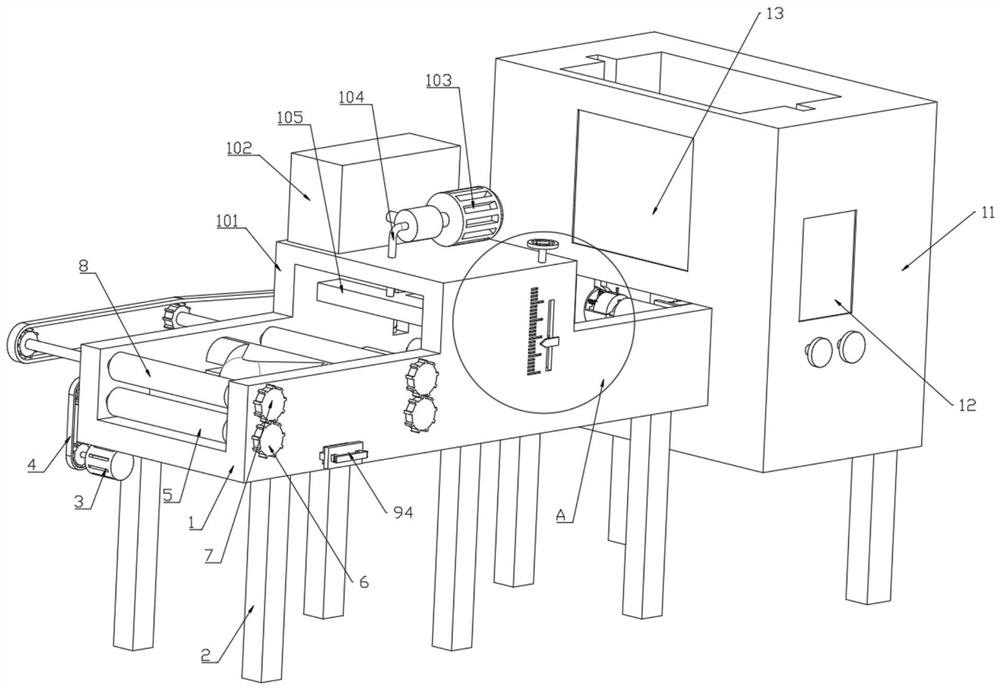

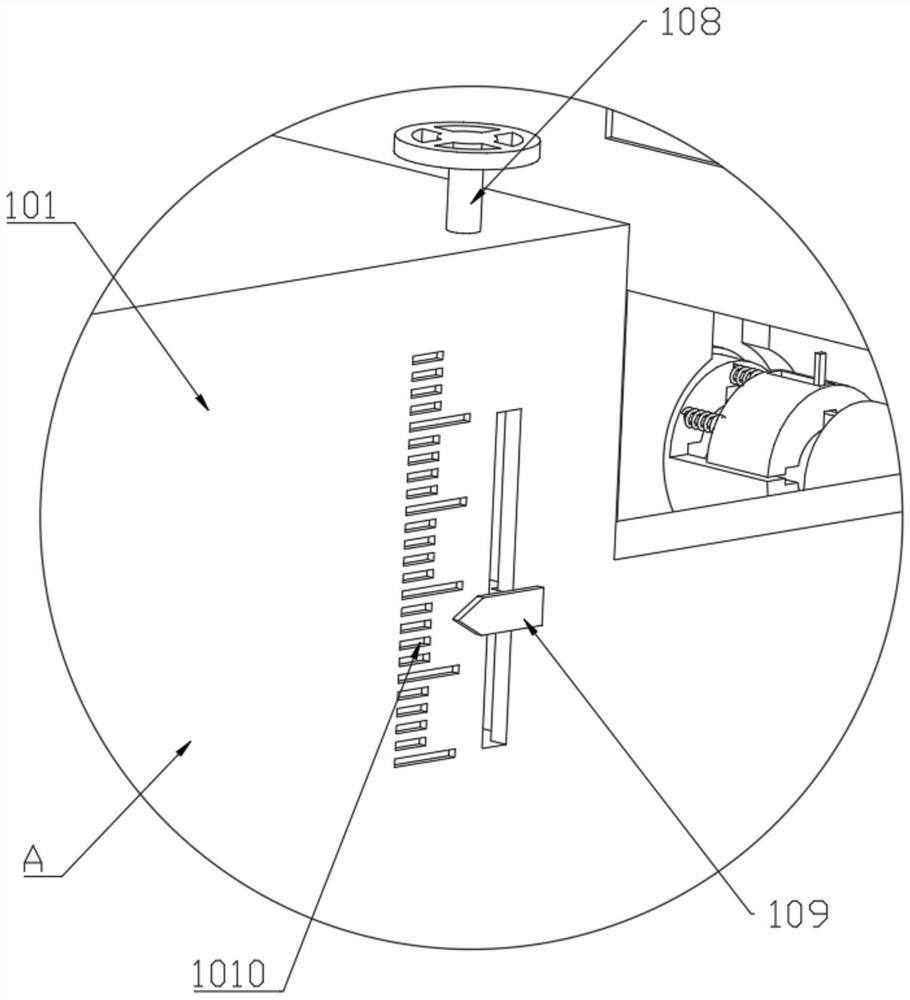

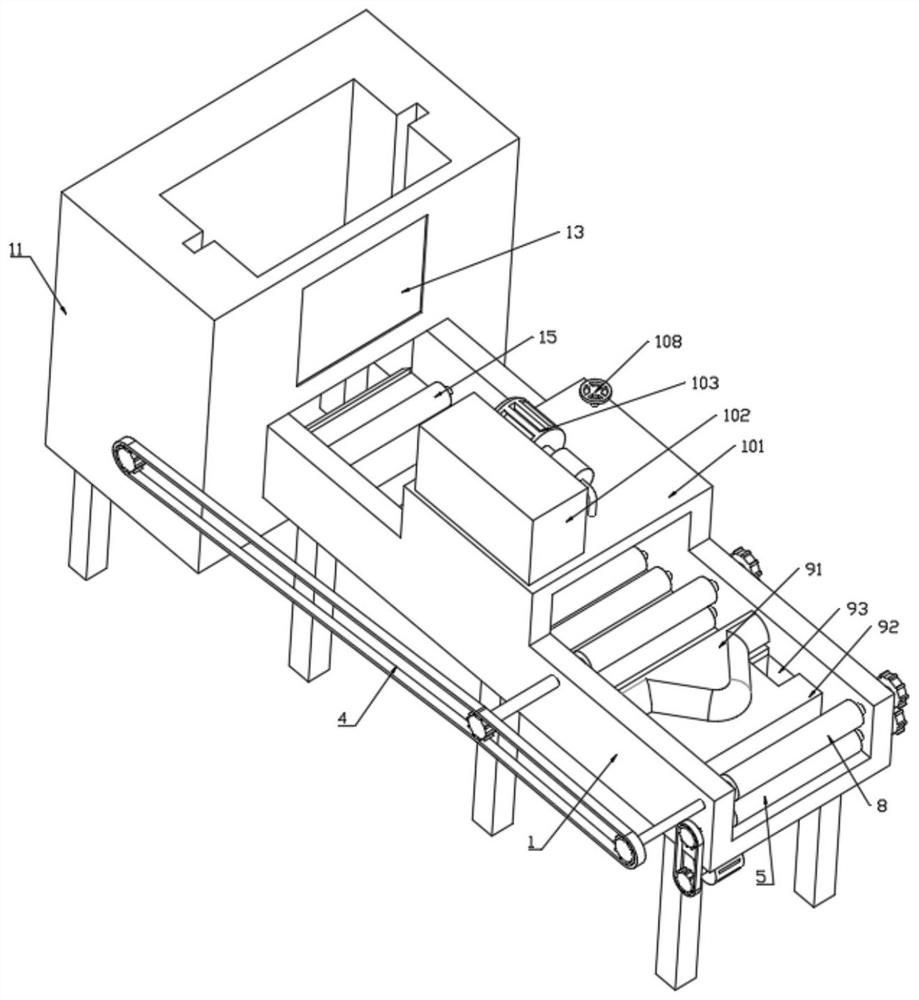

[0029]Embodiment 1: A gluing device for the production of protective films of electronic products, including a support frame 1, a support column 2 is fixedly connected to the lower end surface of the support frame 1, a driving motor 3 is fixedly connected to the left part of the lower end surface of the support frame 1, and the driving motor 3 The output end is rotatably connected to the first transmission roller 5 through the transmission device 4, and one end of the first transmission roller 5 is meshed with the second gear 7 through the first gear 6, and one side of the second gear 7 is fixedly connected to the second transmission roller 8, and the support frame 1. A cleaning mechanism 9 is provided on the left side of the upper end surface. A uniform glue coating mechanism 10 is provided on the middle part of the upper end surface of the support frame 1. A feeding box 11 is fixedly connected to the right end of the support frame 1. The inner cavity of the feeding box 11 is p...

Embodiment 2

[0030] Embodiment two: the difference between this embodiment and embodiment one is that, wherein, the blanking mechanism 14 includes an arc-shaped plate 141, a first rack 142, a first transmission gear 143, a second transmission gear 144, and a second rack 145 , transmission cylinder 146, first spring 147, sliding plate 148, limit plate 149, winding cylinder 1410, cutting knife 1411, torsion spring 1412, supporting plate 1413, second spring 1414, cross block 1415, one side of arc plate 141 The first transmission gear 143 is engaged with the first rack 142, and the first transmission gear 143 is slidably connected with the second transmission gear 145 through the engagement with the second transmission gear 144. One side of the second rack 145 is rotatably connected with the transmission cylinder through the connecting plate. 146, the outer surface of the transmission cylinder 146 is slidably connected with a sliding plate 148 through the first spring 147, and the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com