Highway roadbed cement and application method thereof

A high-speed roadbed and cement technology, applied in the field of high-speed roadbed cement, can solve the problems of uneven expressway roadbed, increased labor intensity of workers, and unfavorable roadbed cement paving and finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

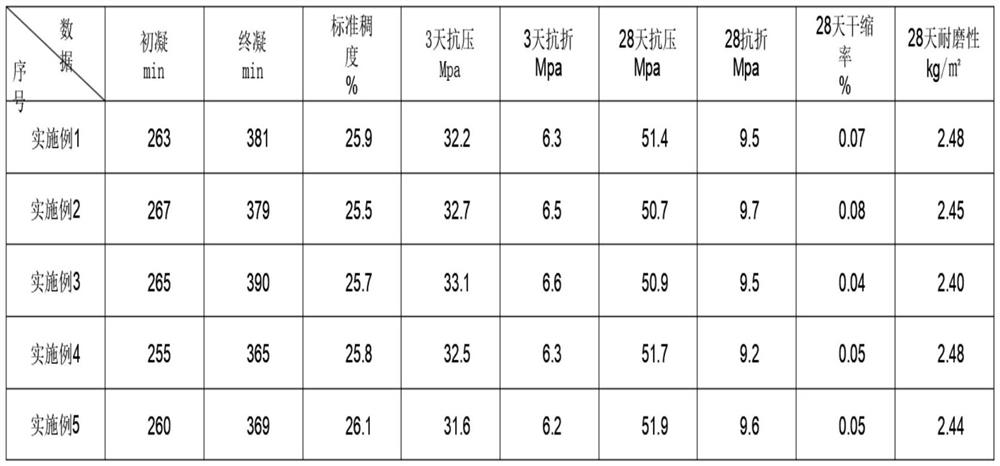

Embodiment 1

[0035] A high-speed roadbed cement, the high-speed roadbed cement comprising the following raw material components in parts by weight: 50-70 parts of cement clinker, 15-25 parts of blast furnace slag, 5-10 parts of modified phosphogypsum, 5 parts of dry fly ash ~ 7 parts, mixed retarder 5 ~ 8 parts and nanometer montmorillonite 2 ~ 4 parts. The mixed retarder includes the following raw material components in parts by weight: 4-8 parts of organic carboxylate, 5-7 parts of inorganic zinc salt, and the inorganic zinc salt includes 6-9 parts of zinc chloride, zinc sulfate 4-4.5 parts, 2-3 parts of zinc carbonate, the zinc chloride, zinc sulfate and zinc carbonate are in a mass content ratio of 3:2:1. The cement clinker comprises the following mass components: 80-95 parts of Portland cement clinker, 8-20 parts of mineral raw materials, 3-9 parts of iron raw materials and 1-3 parts of desulfurized gypsum. The mineral raw material includes the following mass components: 1-3 parts of...

Embodiment 2

[0043]A high-speed roadbed cement, which comprises the following raw material components in parts by weight: 80-90 parts of cement clinker, 17-28 parts of blast furnace slag, 3-8 parts of modified phosphogypsum, and 4 parts of dry fly ash ~8 parts, mixed retarder 6~9 parts and nano-montmorillonite 3~5 parts. The mixed retarder includes the following raw material components in parts by weight: 3 to 7 parts of organic carboxylate, 5 to 9 parts of inorganic zinc salt, and the inorganic zinc salt includes 5 to 9 parts of zinc chloride, zinc sulfate 4-6 parts and 3-7 parts of zinc carbonate, the zinc chloride, zinc sulfate and zinc carbonate are in a mass content ratio of 3:2.5:1. The cement clinker comprises the following mass components: 75-95 parts of portland cement clinker, 10-25 parts of mineral raw materials, 4-8 parts of iron raw materials and 1-2 parts of desulfurized gypsum. The mineral raw materials include the following mass components: 2 to 3 parts of tricalcium silic...

Embodiment 3

[0046] A high-speed roadbed cement, which comprises the following raw material components in parts by weight: 70-90 parts of cement clinker, 20-28 parts of blast furnace slag, 6-10 parts of modified phosphogypsum, 5 parts of dry fly ash ~9 parts, 8~10 parts of mixed retarder and 4~6 parts of nano-montmorillonite. The mixed retarder includes the following raw material components in parts by weight: 2 to 6 parts of organic carboxylate, 6 to 8 parts of inorganic zinc salt, and the inorganic zinc salt includes 4 to 9 parts of zinc chloride, zinc sulfate 5-8 parts and 4-9 parts of zinc carbonate, the zinc chloride, zinc sulfate and zinc carbonate are in a mass content ratio of 3:3:1. The cement clinker includes the following mass components: 70-95 parts of Portland cement clinker, 15-25 parts of mineral raw materials, 3-8 parts of iron raw materials and 1-5 parts of desulfurized gypsum. The mineral raw materials include the following mass components: 2 to 5 parts of tricalcium sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com