Door frame type seepage-proof earthwork cloth spreading machine for tunnel

A technology of anti-seepage geotextile and spreading machine, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., to achieve the effect of good laying quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

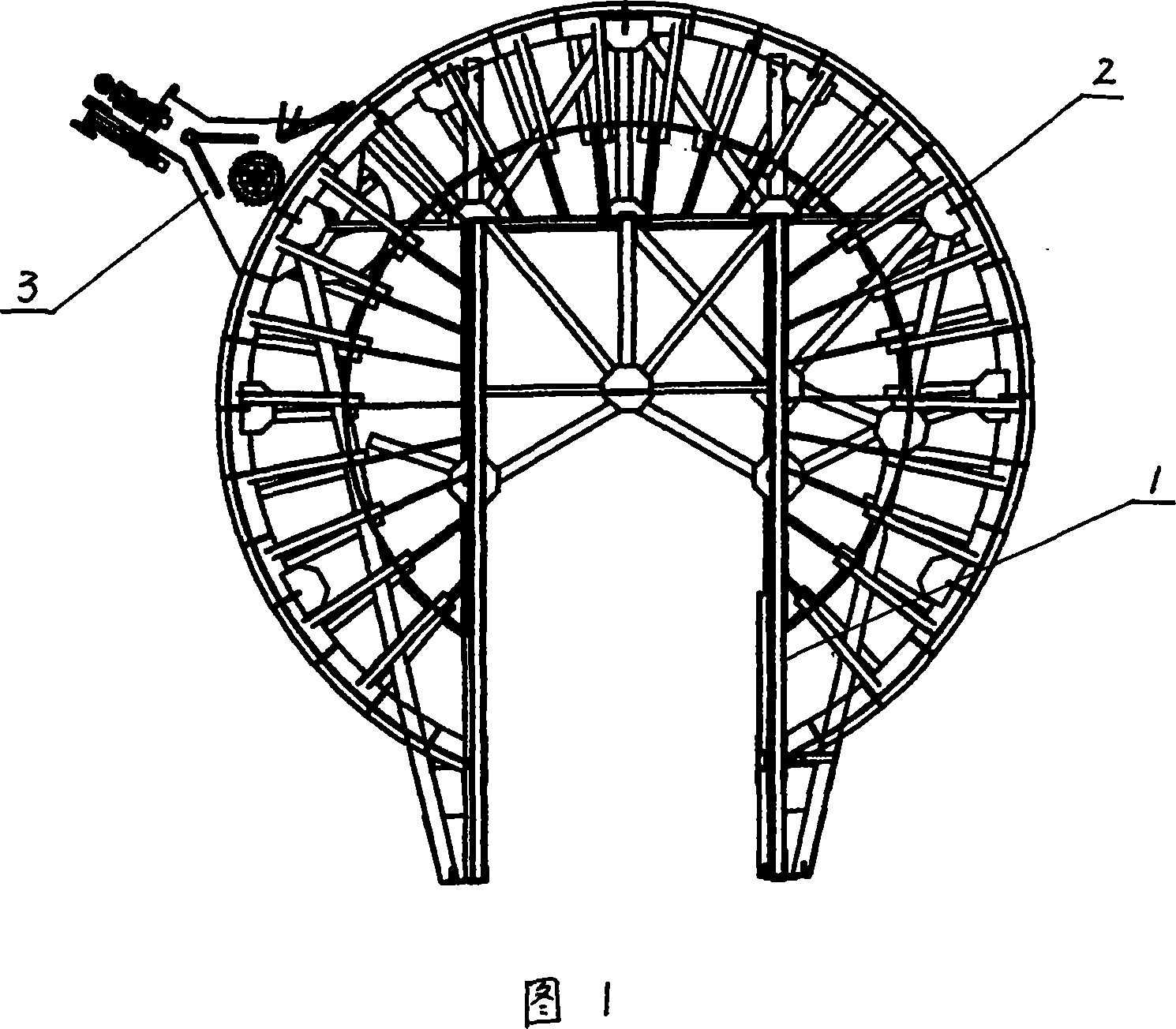

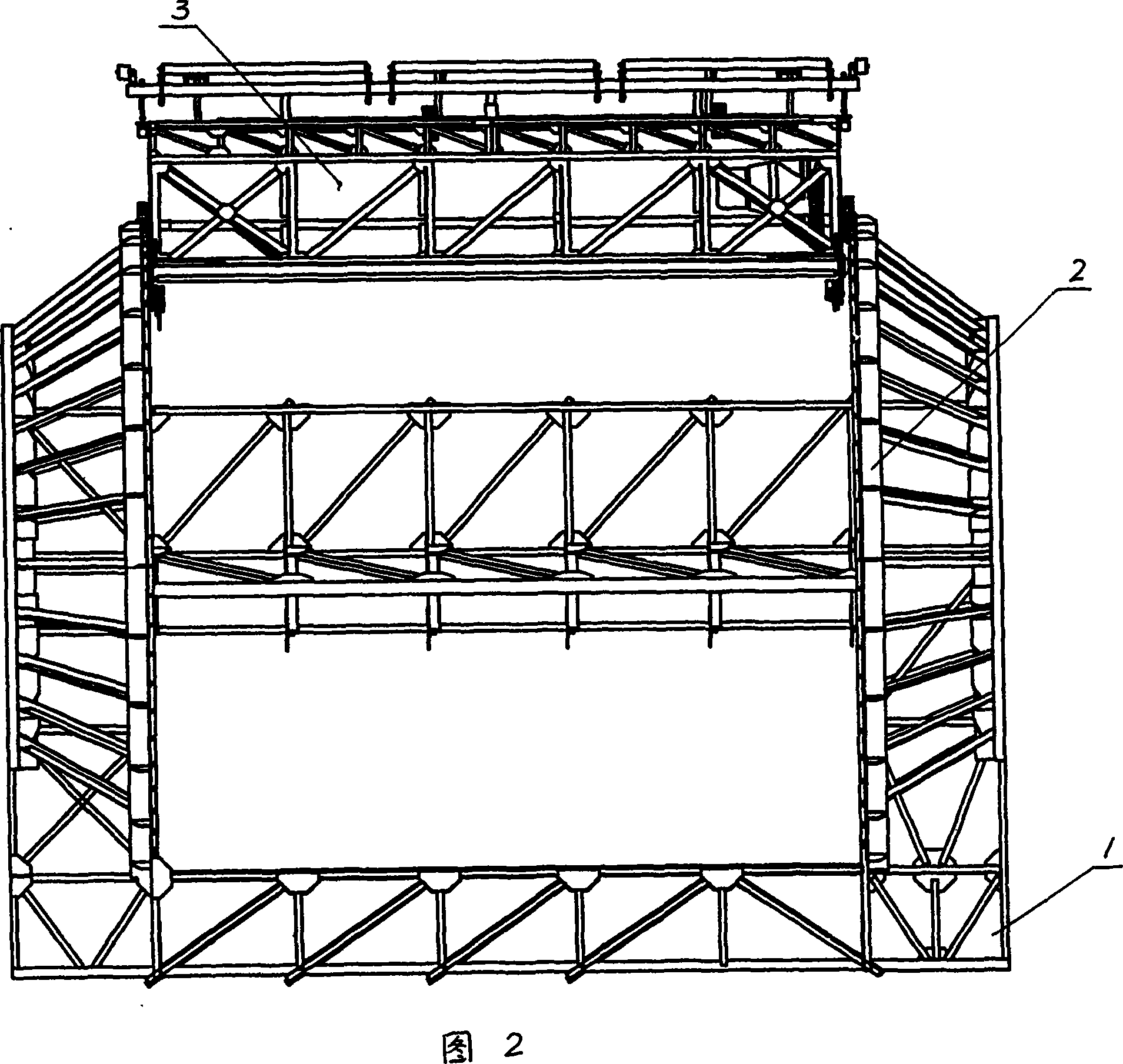

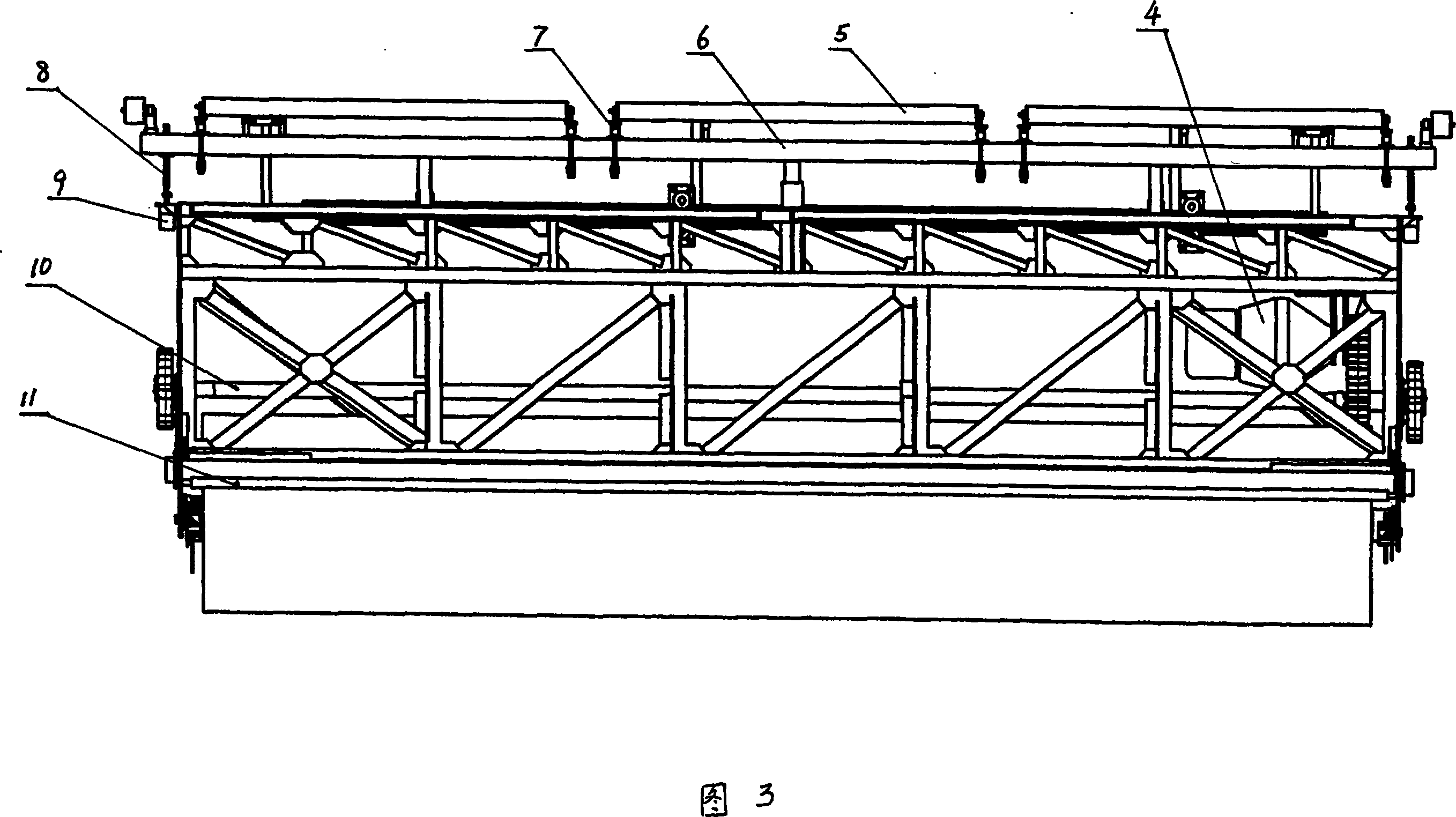

[0014] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, a gantry-type tunnel anti-seepage geotextile spreading machine includes a base 1, a guide rail 2 and a spreading trolley 3, and the spreading trolley 3 consists of a main Composed of motor 4, spreading roller 5, geotextile roll 12, traveling wheel 13 and glue spraying device 14, main motor 4 is provided with a speed control circuit, spreading trolley 3 is placed along the axial direction of the tunnel, and straddles two arc guide rails 2 Between them, the trolley walks along a track similar to the shape of the tunnel section. The two traveling wheels 13 of the trolley are connected to the same drive shaft 10. The main motor 4 is installed on the drive shaft 10. The geotextile roll 12 is located below the drive shaft 10. Each of the traveling wheels 13 above Another motor 9 is provided, the motor 9 is connected to one end of the driving screw 8, the other end of the driving screw 8 is connected to the support beam 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com