Patents

Literature

187 results about "Phorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phorate is an organophosphate used as an insecticide and acaricide.

Selenium-rich rice cultivating process

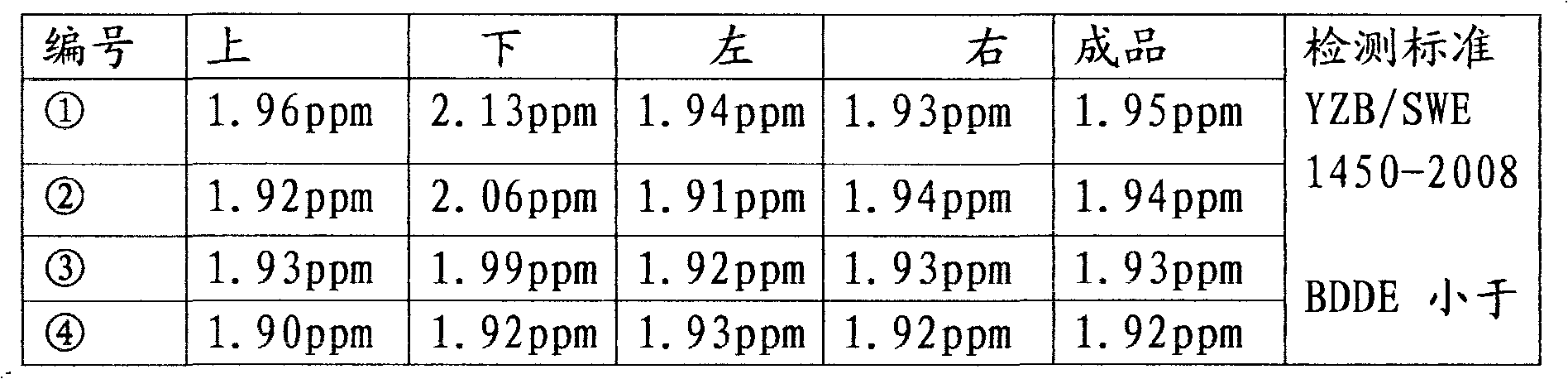

InactiveCN1608435AIncrease selenium contentLess componentsBiocideAnimal repellantsCommon coldPhosphate

The selenium-rich rice cultivating process includes conventional cultivation and features that the selenium-rich agent is sprayed once during the earing up and flowering period of rice. The selenium-rich agent comprising selenium-containing inorganic compound and phosphate is dissolved in water of 50-90 times and sprayed to leaf of rice during the earing up and flowering period of rice. In case of rainy day after spraying, replenished selenium-rich agent is sprayed timely. The sprayed inorganic selenium will be converted completely into natural organic selenium, and the produced selenium-rich rice is non-toxic, and has the health functions of preventing common cold, preventing and treating hypertension and myocardial pathological changes, etc.

Owner:杨容甫

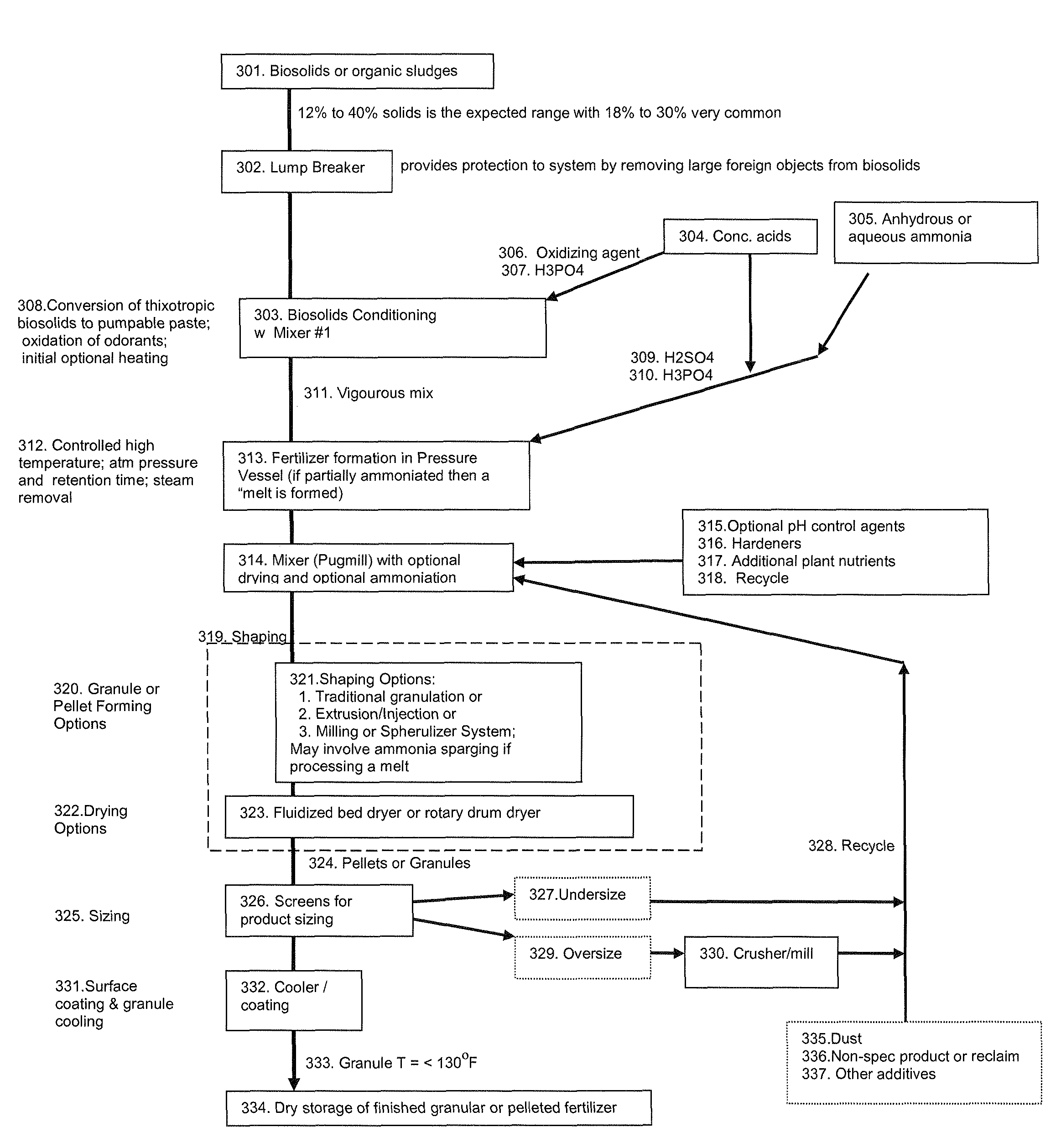

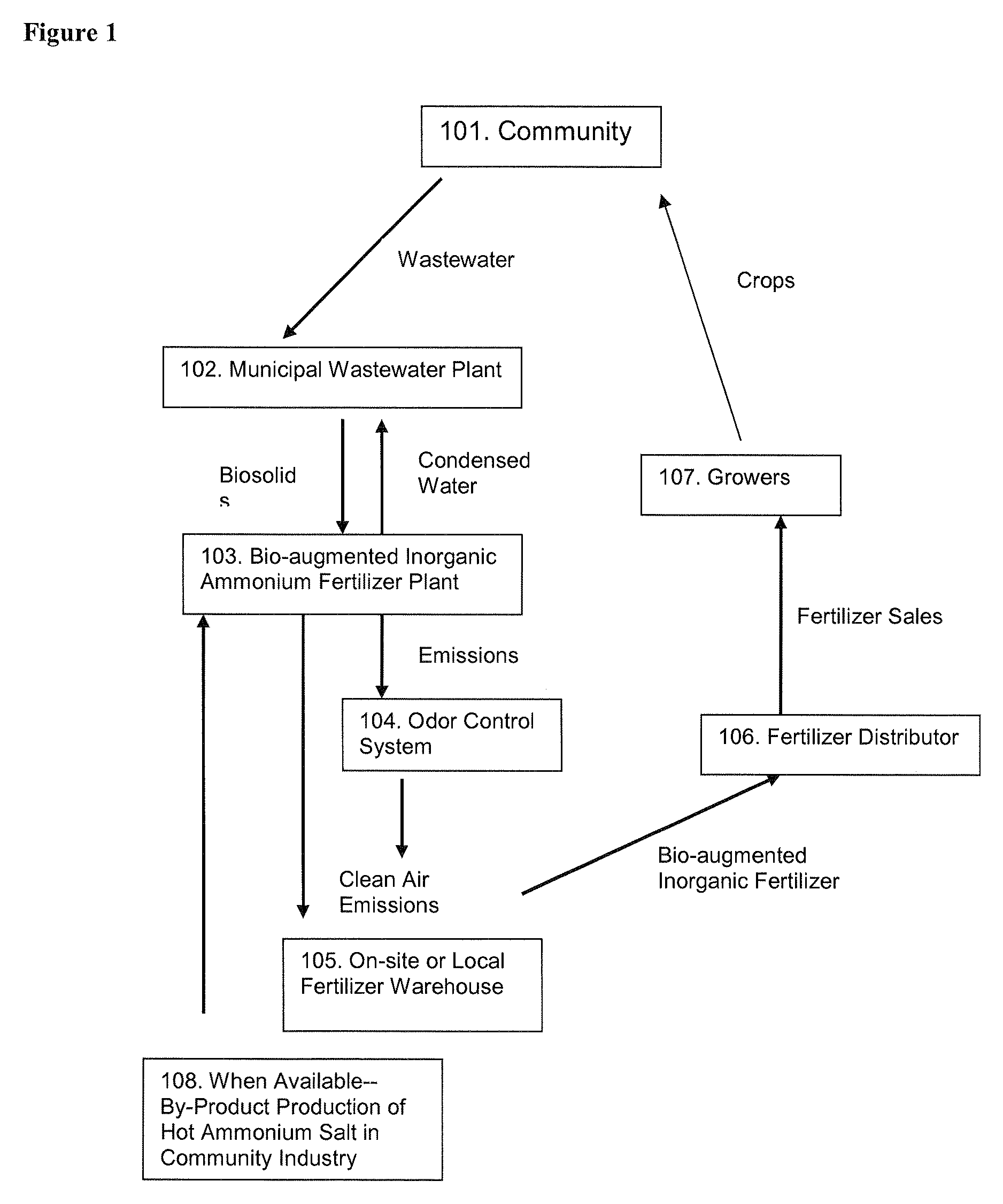

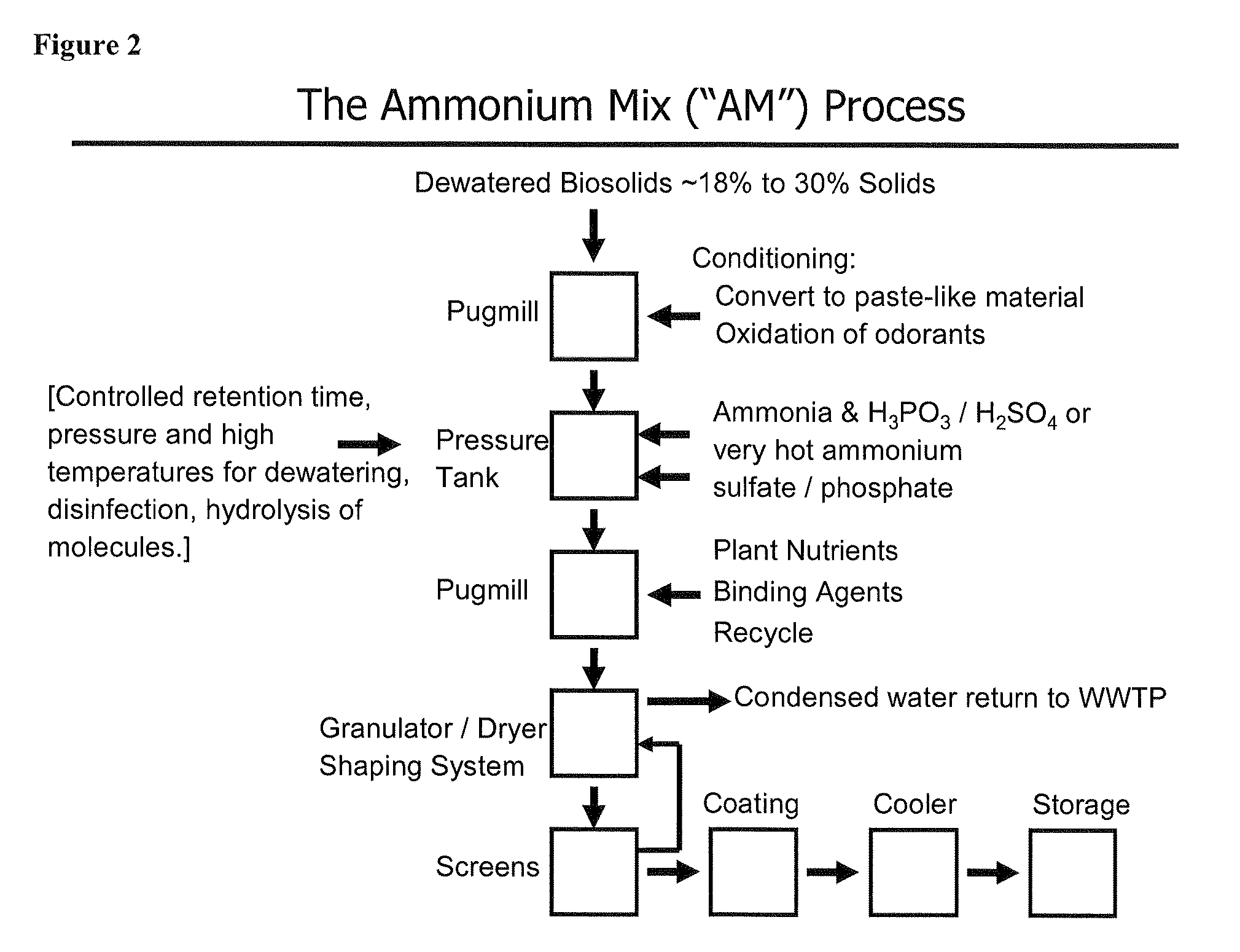

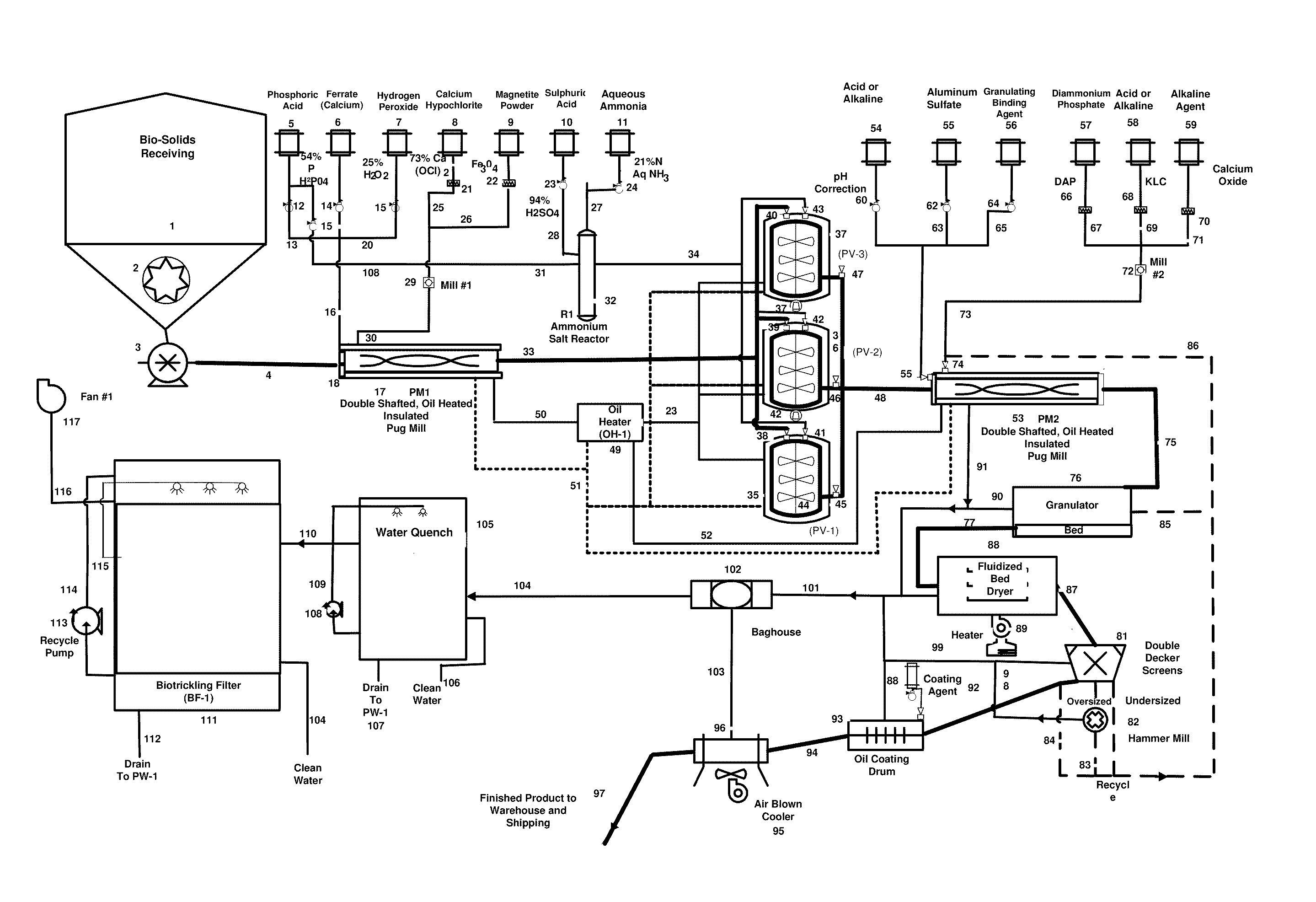

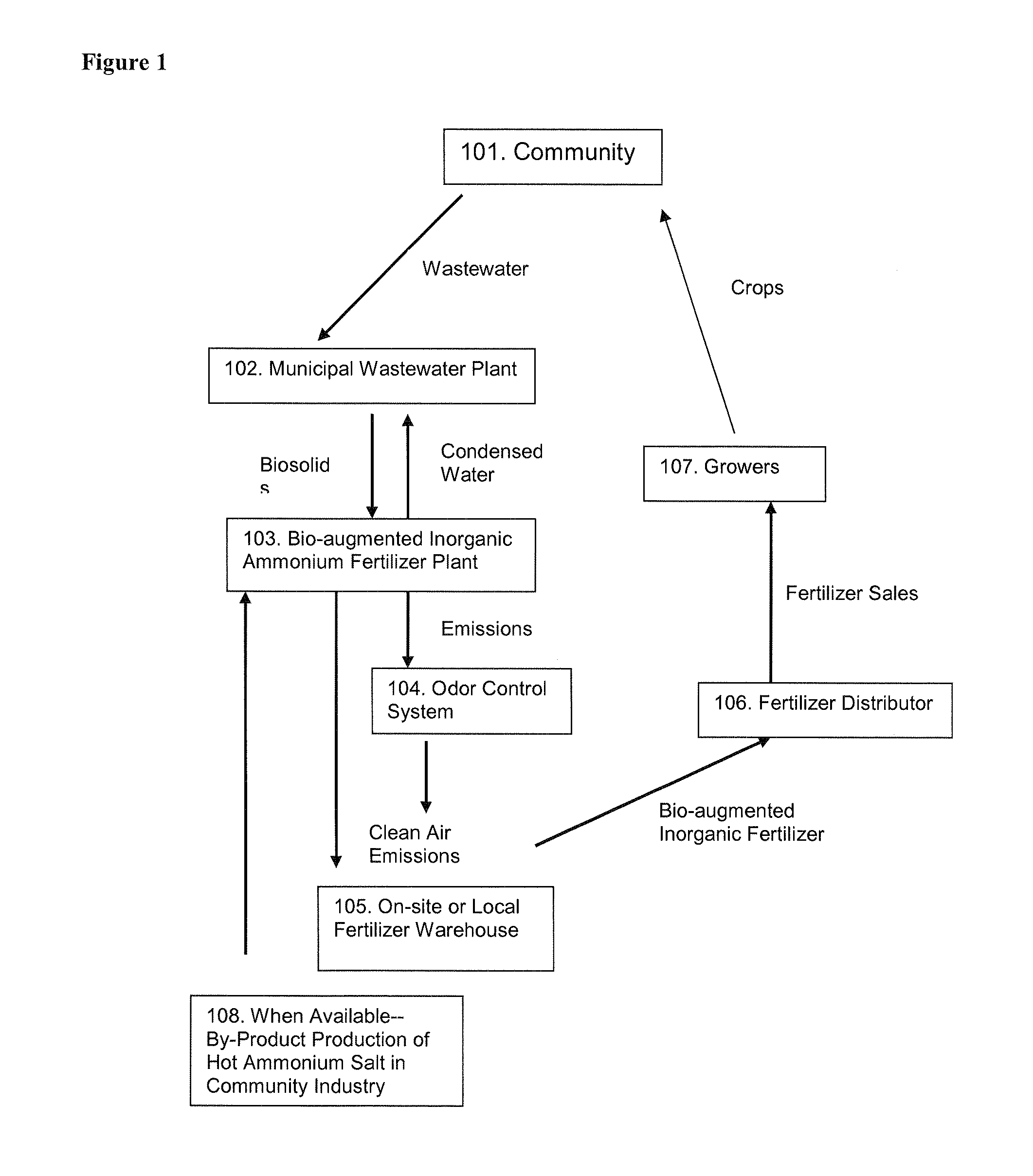

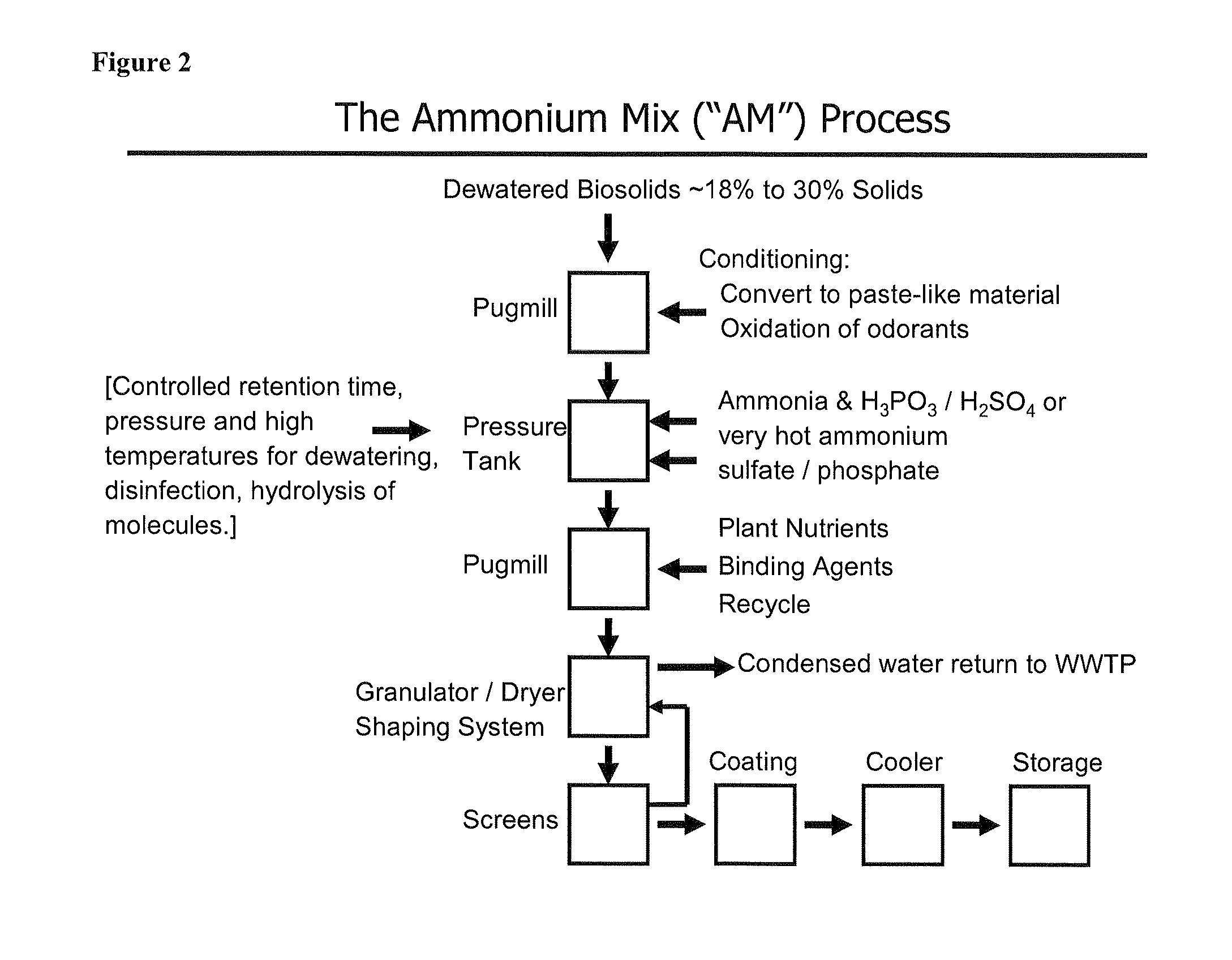

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS7947104B2Reduce responsibilityEliminate needByproduct vaporizationExcrement fertilisersRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

High-yield and high-efficiency planting technology for Daba Shan buckwheat

InactiveCN102771274AAchieve high productivity and high efficiencyEnsure high production density requirementsHorticultureWarm waterPhorate

The invention relates to a high-yield and high-efficiency technology for Daba Shan buckwheat. The Daba Shan buckwheat is produced by the following steps of selecting lands for beans, potatoes, maize and vegetables as main planting stubbles of land for planting Daba Shan buckwheat; and by adopting a mode of row planting on high ridges, sowing Daba Shan buckwheat seeds from April 5th to April 15th in spring and sowing the Daba Shan buckwheat seeds from July 10th to July 15th in autumn. Drying the seeds for 1-2 days before sowing; soaking the selected seeds with warm water of 35-40DEG C for 10-15 minutes; mixing the seeds with phorate creme which accounts for 0.5 percent of the amount of the seeds; after mixing, stacking the seeds for 3-4 hours and spreading for drying water on the surfaces of the seeds; and sowing on furrow ridges of 160-180cm according to the sowing width of 15cm and a blank row of about 18cm. By using comprehensive technical measures of selecting high-yield excellent seeds, optimally stubbles and finely preparing land, carrying out row planting on high ridges, fully applying base fertilizer and early fertilizing, promoting control and artificially supplementing for pollinating during flowering phase, timely harvesting and the like, the area, space and sunshine and heat resources are utilized to the maximum extent and further high yield and high efficiency in unit area are achieved.

Owner:高义富

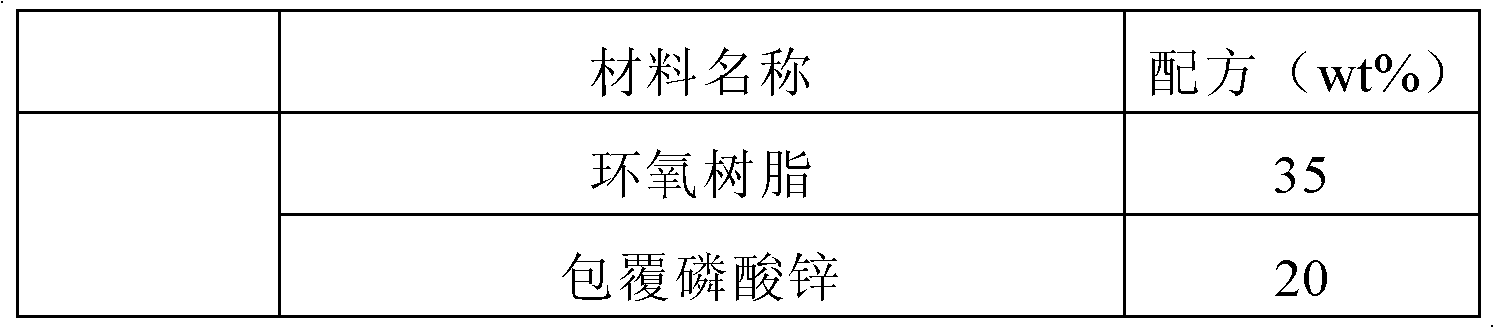

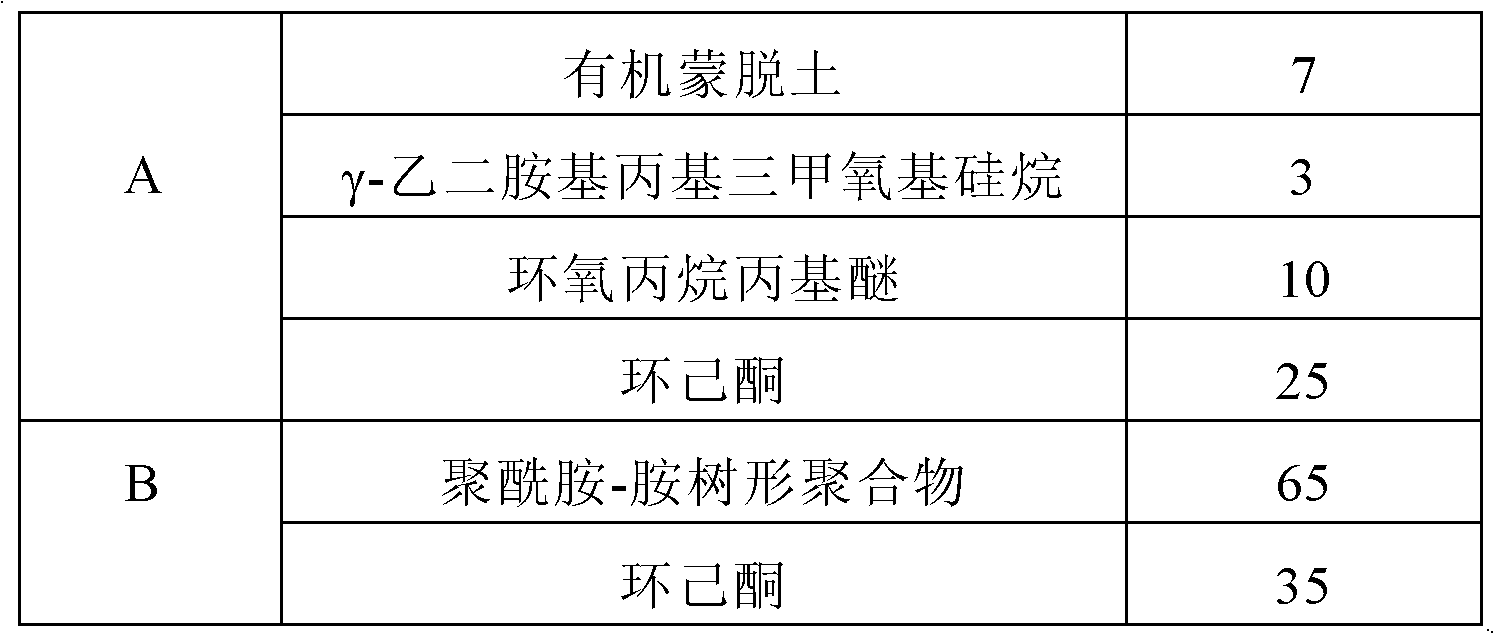

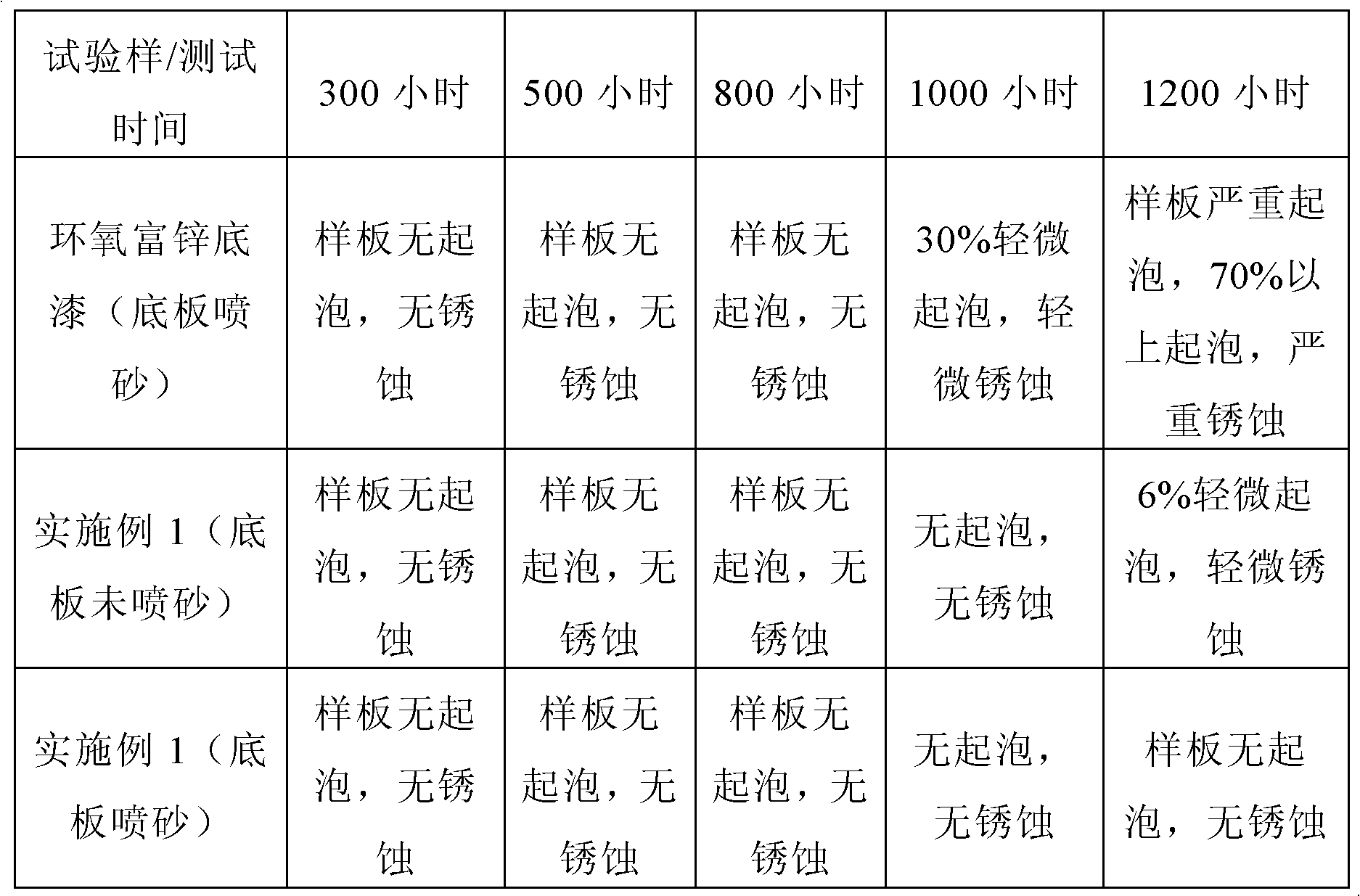

Durable fresh-maintained preservative primer

InactiveCN102643594AImprove adhesionStrong recoatability between layersAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention relates to a durable fresh-maintained preservative primer. Raw materials of the primer comprises a component A and a component B, wherein the consumption of the component B is 5-15 percent by weight that of the component A; the component A comprises the following components in percentage by weight: 20-50 percent of epoxy resin, 10-30 percent of phosphate, 1-10 percent of additive, 5-20 percent of diluting agent and 15-35 percent of solvent; and the component B comprises the following components in percentage by weight: 50-80 percent of curing agent and 20-50 percent of solvent. Compared with the prior art, the durable fresh-maintained preservative primer disclosed by the invention has the advantages of favorable adhesive force, strong laminated coating property, tough and tensile paint film, impact resistance, convenience in construction, long preservative effect cycle, favorable construction matching property and particularly excellent salt spray resistance.

Owner:项妙祥

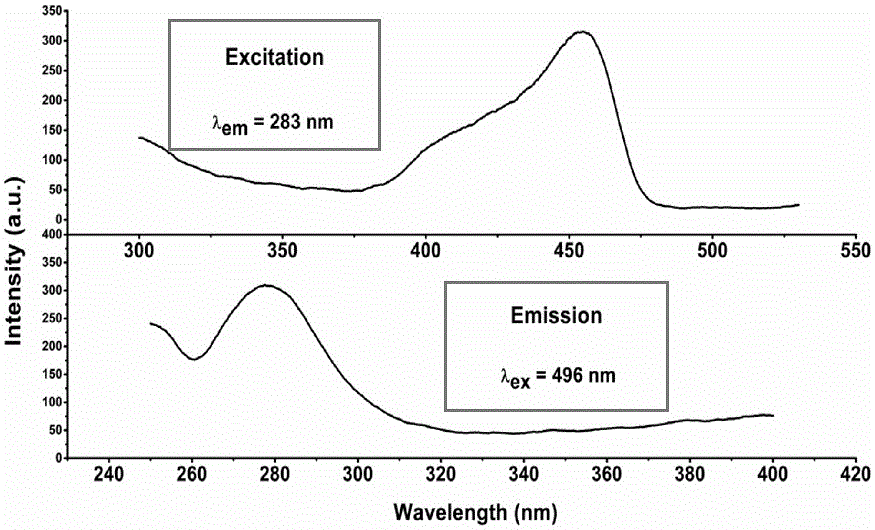

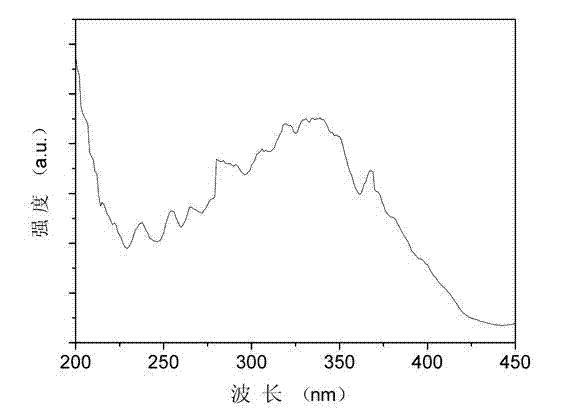

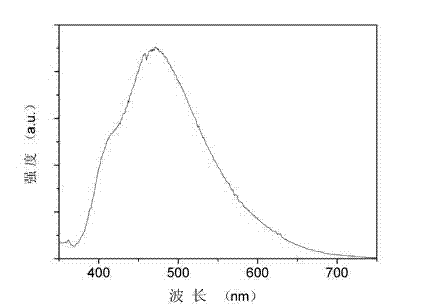

Phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, and preparation method and application thereof

InactiveCN105018089ASimple processEasy to operateFood preservationLuminescent compositionsUltraviolet lightsLED lamp

The present invention discloses a phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, wherein phosphate or metaphosphate serves as a substrate, and the substrate material is doped with Pr<3+>; a molar ratio of phosphate or metaphosphate to Pr<3+> is (0.9-3):(0.01-0.1). The present invention further provides a preparation process of the material, comprising: (a) according to the chemical formula, weighing oxide materials of corresponding elements and ammonium dihydrogen phosphate according to a stoichiometric ratio; and (b) grinding the weighed materials, burning the ground materials at the temperature of 850 to 950 DEG C for 2.5-4 h, cooling the materials to the room temperature, and grinding the materials to obtain a powder-like up-conversion luminescence material. It is experimentally proved that when excited by a common light source (such as an incandescent lamp, an xenon lamp, a fluorescent lamp and an LED lamp), especially by sunlight, the material can emit ultraviolet light UVC that can effectively kill bacteria; and the material has a broad application prospect in the fields of food safety and environmental protection.

Owner:HEBEI UNIVERSITY

Solid glyphosphate-formulation and manufacturing process

Disclosed is a solid formulation of the herbicidal active agent glyphosate [N-(phosphonomethyl)glycine] compressed into tablet form. It is applied in the agricultural and horticultural sectors to destroy unwanted vegetation. The solid formulation according to the invention consists essentially of free glyphosate acid, salifying agents (alkali or ammonium hydrogencarbonate or carbonate in conjunction with solid organic acids), biological activating agents and diluents. A suitably sized tablet can consequently be adapted to supply an appropriate dose of spray mixture per surface unit for small-scale users. Submerging in water causes the glyphosate to convert into a soluble salt. The resulting carbon dioxide facilitates rapid disintegration of the tablet.

Owner:SCHIRM AG

Special liquid fertilizer for cultivating poplar and preparation method thereof

InactiveCN101941871AGuaranteed interactivityEfficient decompositionFertilizer mixturesPlant rootsPhosphate

The invention discloses a special liquid fertilizer for cultivating poplar. The liquid fertilizer is used for fertilizing poplar in alkaline land. The liquid fertilizer comprises the following components in percentage by weight: 6-10% of inorganic nutrient, 10-15% of organic substance, and additives containing microbes and amino acid. After the special liquid fertilizer for cultivating poplar is mixed into soil, the microbes in the liquid fertilizer generate various organic acids under the activating action of amino acid in the poplar growth process so as to maintain the interaction between catalyst and ferment, so that the organic acids and enzymes can effectively decompose indissoluble phosphates and potassium formates in alkaline land soil and nucleic acid to supply nutrients for plant roots, thereby lowering the application amount of inorganic phosphorus and inorganic potassium and reducing the environmental pollution. The invention also provides a method for preparing the special liquid fertilizer for cultivating poplar.

Owner:GREEN ORGANIC ANMAO BIOTECH

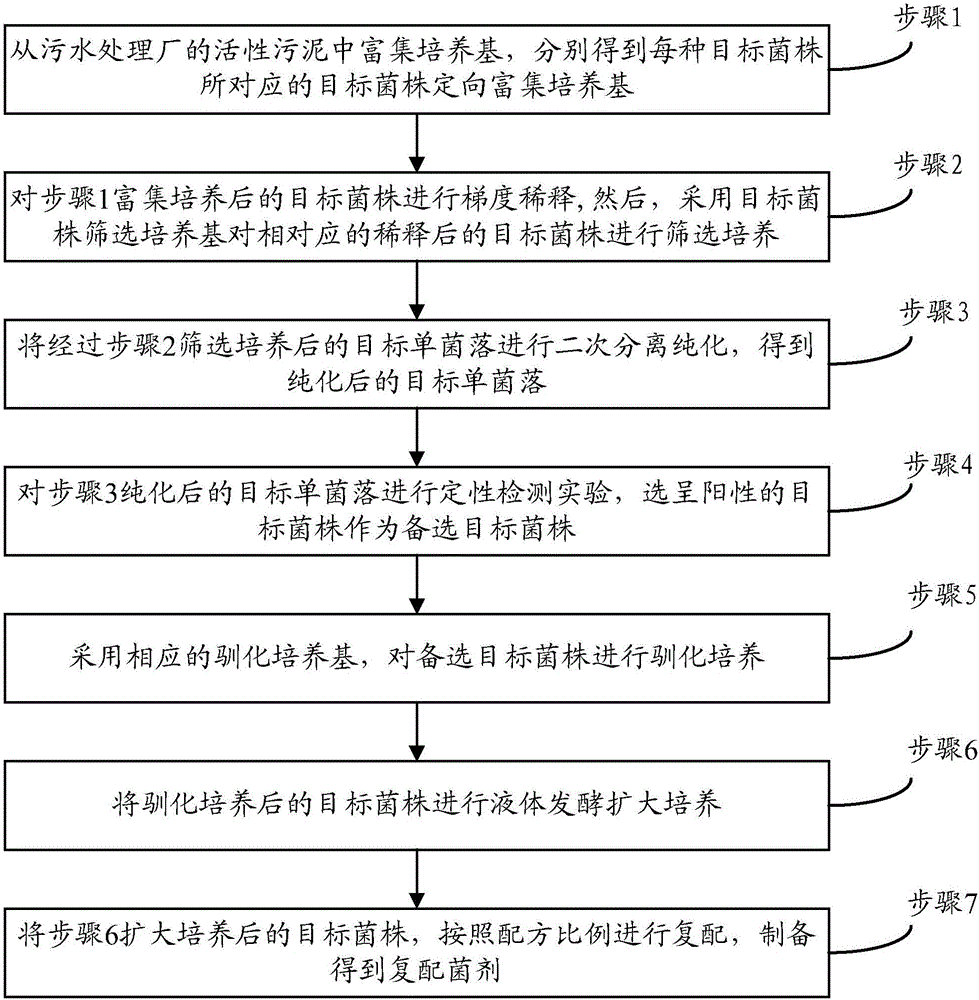

Compound bacterial agent for purifying black and odorous water body and preparation method thereof

ActiveCN106148246ADegraded ammonia nitrogen contentDegradation of phosphate contentFungiBacteriaNitrifying bacteriaBacillus subtilis

The invention provides a compound bacterial agent for purifying a black and odorous water body and a preparation method thereof. The compound bacterial agent comprises the following components: actinomycetes, bacillus subtilis, nitrifying bacteria, lactic acid bacteria, candida utilis and pseudomonas aeruginosa in a weight ratio of 2:2:2:1:1:1. The invention has the following advantages: the COD content, ammonia nitrogen content and phosphate salt in the black and odorous water body can be effectively reduced, and the odor of the black and odorous water body can be eliminated; and meanwhile, by adding the ammonia nitrogen removal strain, the transparency of the water body can be gradually improved.

Owner:BIOLAND ENVIRONMENTAL TECH GRP CORP

Process for Treating Sludge and Manufacturing Bioorganically-Augmented High Nitrogen-Containing Inorganic Fertilizer

ActiveUS20110265532A1Reduce logisticsReduces liabilityCalcareous fertilisersClimate change adaptationRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC

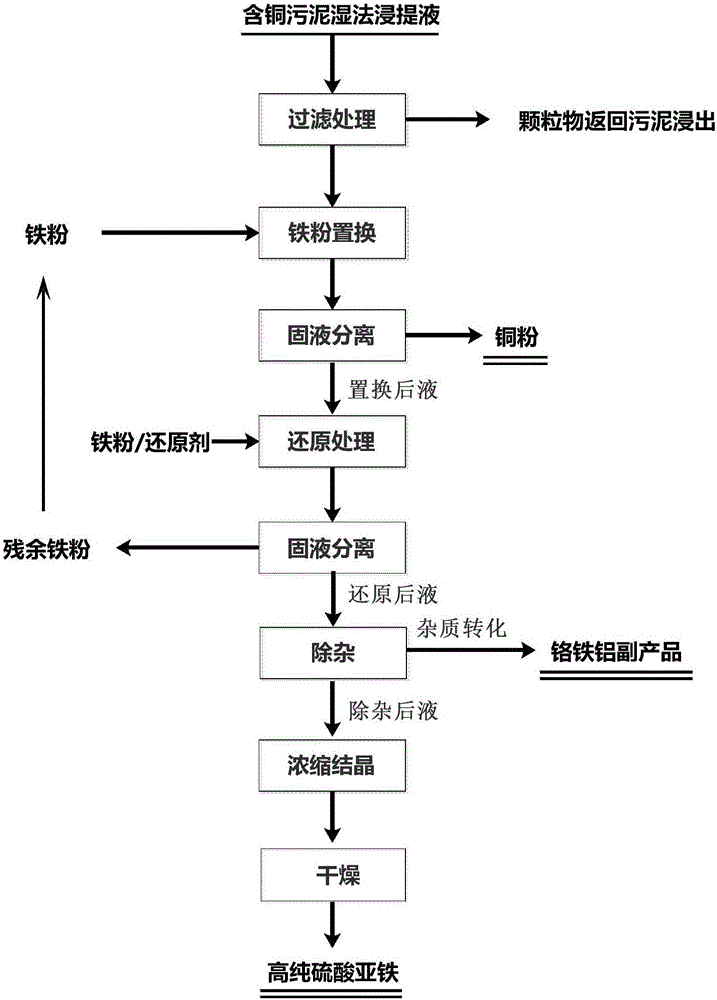

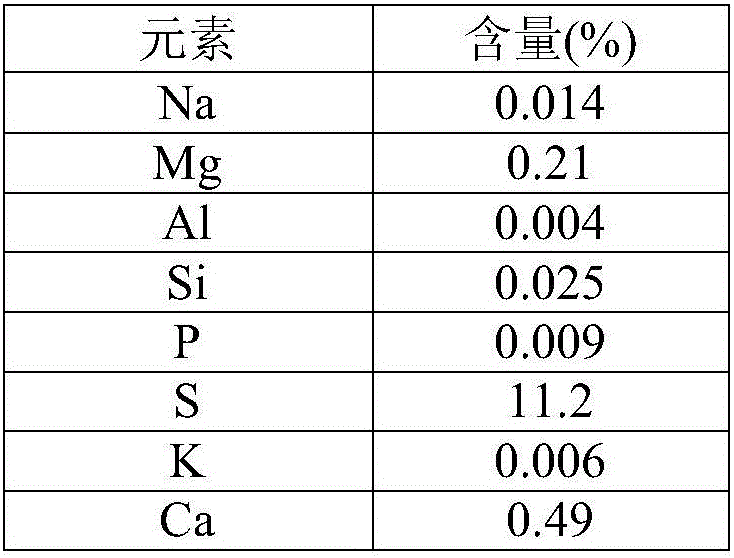

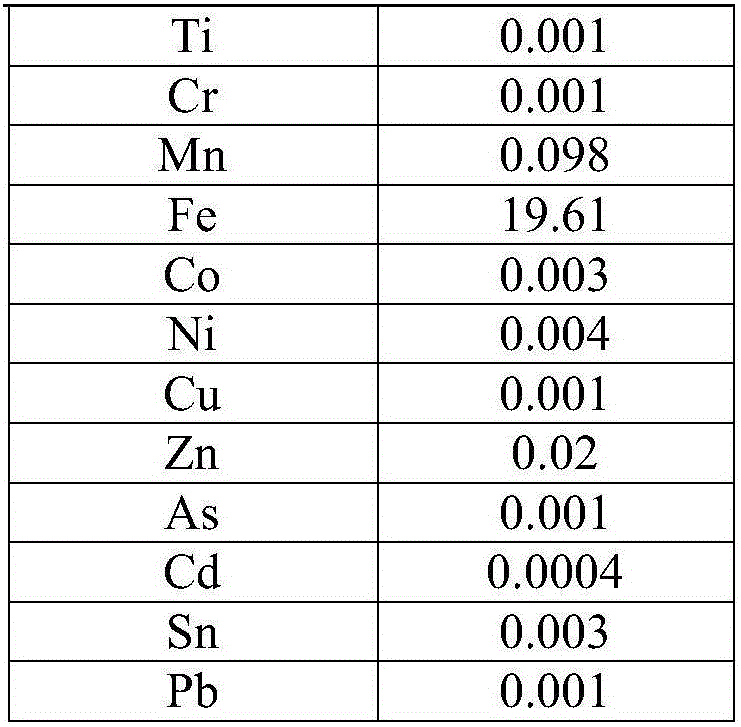

Method for preparing copper powder and ferrous sulfate by using solution leached through sludge containing copper wet method

ActiveCN106521166AHigh economic valueNo emissionsIron sulfatesProcess efficiency improvementPhosphateResource utilization

A method for preparing copper powder and ferrous sulfate by using a solution leached through a sludge containing copper wet method comprises the following steps that firstly, the solution is leached through the sludge containing copper wet method and filtered; the filtered leaching agent is transferred into a reactor, iron powder is added for a replacement reaction, the concentration of Cu2+ in the leaching agent is reduced to be less than 0.5 g / L after the reaction is complete, solid-liquid separation is conducted, and the copper powder and the replaced solution are obtained; a reducing agent is added to the replaced solution, and the redox potential in the replaced solution is controlled to be reduced to be less than 400 mV; the replaced solution is transferred to an impurity removal reaction tank, heating is conducted, an inorganic solution containing phosphate radical is slowly added, solid-liquid separation is conducted, and phosphate precipitate and impurity-removed liquid are obtained; and the concentration of Fe2+ ions in the impurity-removed liquid is increased to be greater than 300 g / L after evaporation and concentration, transferring to a cooling system is conducted for crystallization, and a ferrous sulfate heptahydrate product is obtained after washing. By the adoption of the method, the cost is low, environmental protection is achieved, the added value of products is high, and resource utilization of waste resources can be achieved.

Owner:厦门资生环保科技有限公司

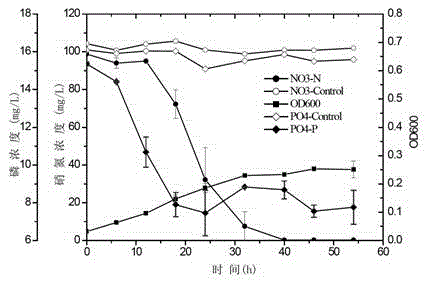

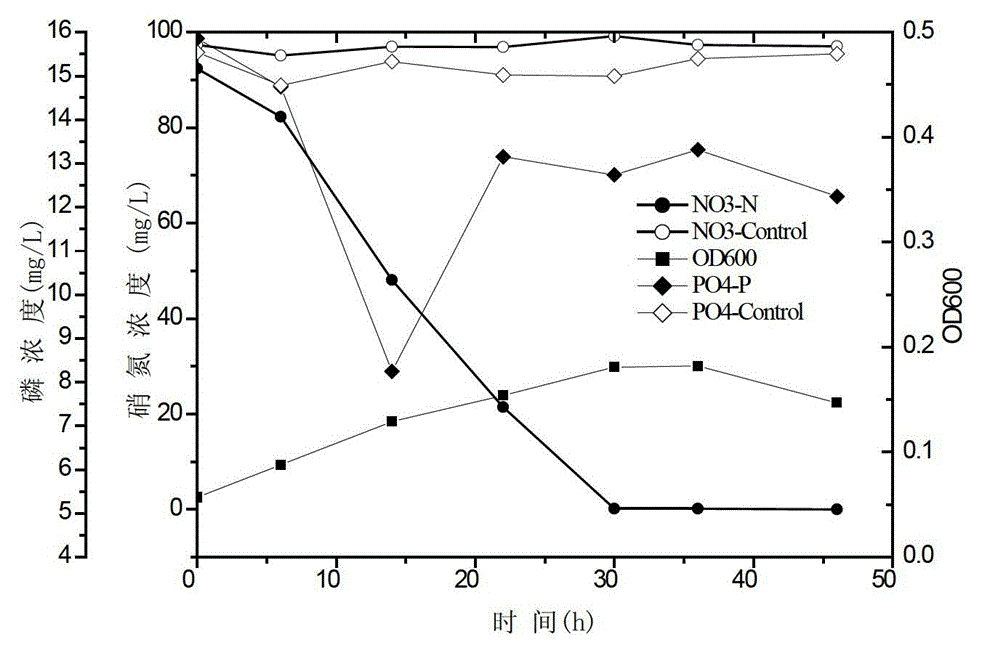

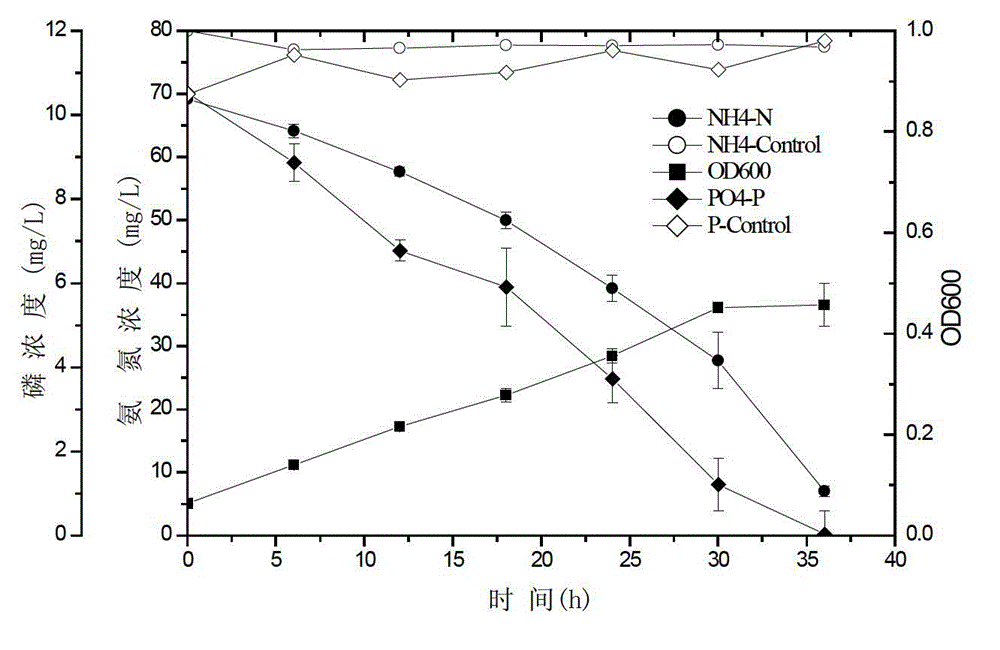

Pseudomonas aeruginosa for denitrification and phosphorous removal under different dissolved oxygen conditions and application of pseudomonas aeruginosa

ActiveCN102876616AResolution timeSolve space problemsBacteriaMicroorganism based processesPhosphateBacterial strain

The invention relates to a pseudomonas aeruginosa with heterotrophic nitrification-aerobic denitrification and dephosphorization functions under different dissolved oxygen conditions and application of the pseudomonas aeruginosa. The bacterial strain can carry out growth metabolism by using organic carbon as a unique carbon source and ammonia nitrogen as a unique nitrogen source, the ammonia nitrogen can be respectively converted into gas products through the heterotrophic nitrification-aerobic denitrification effect under different dissolved oxygen conditions such as the oxygen deficit condition, the microaerobic condition and the aerobiotic condition, and the goal of denitrification is reached. The bacterial strain can also carry out growth metabolism by using nitrate nitrogen as a unique nitrogen source, the nitrate nitrogen can be converted into gaseous products through the dephosphorization effect under the oxygen deficit, microaerobic and aerobiotic conditions, and the goal of denitrification is reached. Meanwhile, the bacterial strain can also reach the goal of removing phosphate in water through converting inorganic phosphorus into self components under different dissolvedoxygen conditions. Therefore, the bacterial strain can be used for synchronously removing elements such as carbon, nitrogen and phosphorus in the water under different dissolved oxygen conditions, and wide application prospects are realized in the wastewater treatment.

Owner:PEKING UNIV

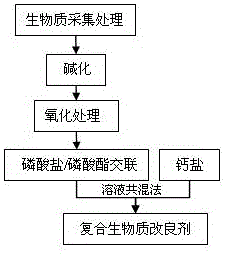

Preparation method of composite biomass improver for remedying heavy metal-polluted soil

ActiveCN106701091ARaw materials are widely availableSolve storage problemsAgriculture tools and machinesOrganic fertilisersPhosphorylationPhosphate

The invention discloses a preparation method of a composite biomass improver for remedying heavy metal-polluted soil. The method comprises the following steps: with agricultural waste as a raw material, washing, drying, grinding and screening; soaking in an alkaline solution; after the soaking, washing with dilute acid or water to neutrality; oxidizing with an oxidizing agent such as ozone, hydrogen peroxide or potassium permanganate; with phosphate or phosphate ester as a crosslinking agent and distilled water as a dispersing agent, performing a phosphorylation addition reaction; filtering after complete phosphorylation addition reaction; compounding the phosphorylated biomass with calcium salt by a solution blending method; heating and stirring till complete reaction; filtering and separating out solid materials; washing with a sodium chloride solution and deionized water to neutrality; and drying to obtain a composite biomass improver. The invention has the characteristics of simple preparation method, low cost, no secondary pollution and the like and also solves two major problems of agricultural waste stacking and farmland heavy metal pollution.

Owner:INST OF BIOLOGICAL RESOURCES JIANGXI ACAD OF SCI

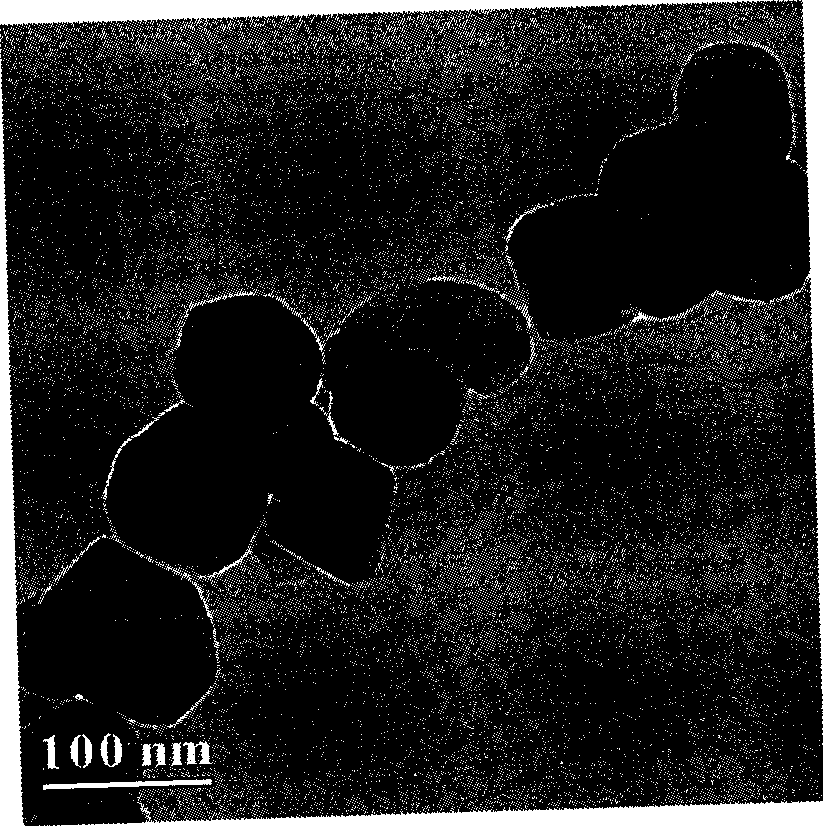

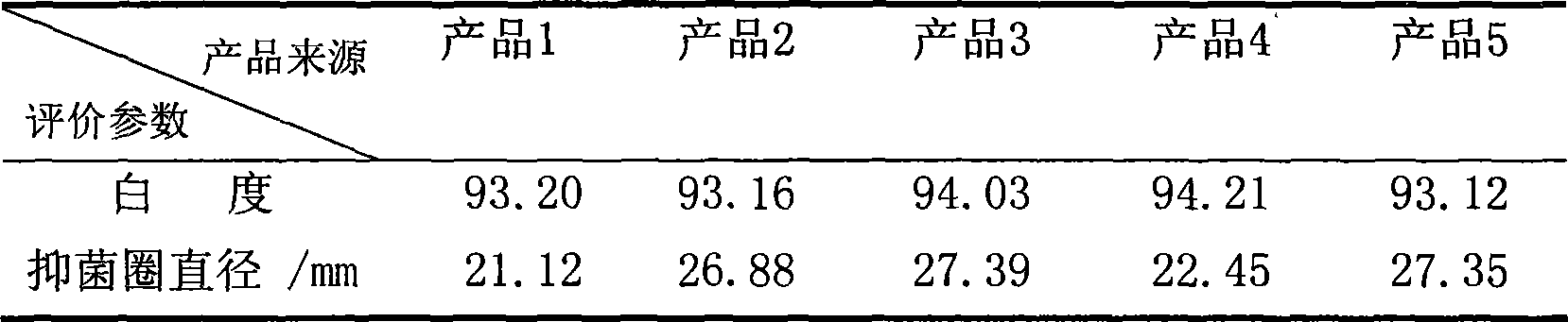

Method for preparing antimicrobial material using nano calcium carbonate as substrate

InactiveCN101480194AImprove antibacterial propertiesHigh antibacterial materialBiocideFungicidesPhosphatePhosphoric acid

The invention relates to a method for preparing an antibacterial material by using nanometer calcium carbonate as a basal boy, which belongs to the field of biocide containing inorganic compounds. The method comprises the following steps: a dispersant is added to Ca(OH)2 slurry and is carbonized by pumping CO2 to prepare the slurry of the nanometer calcium carbonate basal body; titanium salt or / and zinc salt, silver salt and phosphate or phosphoric acid are mainly added to the slurry, or silicate is also added to the slurry; after 1 to 4 hours of reaction of the slurry, the slurry is sucked, filtered and dried so as to obtain the antibacterial material using the nanometer calcium carbonate as the basal boy. The method has lower cost, simple technology and low energy consumption, and the prepared antibacterial material product has higher antibacterial performance, higher whiteness and wide range of application.

Owner:HEBEI UNIV OF TECH

Medicated chicken meatball and preparation method thereof

The invention relates to a medicated chicken meatball and a preparation method thereof. The medicated chicken meatball is processed and made according to the following raw materials in parts and mix proportion by weight: 50-70 parts of chicken breast meat, 20-30 parts of chicken skin, 5-10 parts of yam flour, 5-10 parts of hawthorn powder, 60-80 parts of starch, 3-6 parts of salt, 1.5-3 parts of white sugar, 0.1-0.3 part of monosodium glutamate, 1-1.5 parts of phosphate, 0.04-0.1 part of carrageeenen, 0.01-0.04 part of ball gelatin, 0.2-0.4 part of shallot powder, 0.1-0.2 part of ginger powder, 1-3 parts of soy sauce, 100-120 parts of ice water and 1-3 parts of sesame oil. Since the food materials of hawthorn and yam which belong to the homology of medicine and food contained in the product, lipid dissolution, blood-lipid lowering, blood vessel extension, blood pressure lowering, suppression of blood-glucose elevation after meal and promotion of gastric and intestinal digestion can be effectively realized, and the efficacies of invigorating the spleen and nourishing the stomach are provided. The nutritional ingredients of the product is guaranteed to the maximum extent due to the adoption of the cooking approaches of steaming and boiling, and the product has the characteristics of unique mouthfeel, simpleness in processing, convenience for eating, nutrition, wholesomeness and the like, thereby being convenient for industrialized production and popularization.

Owner:天津宝迪农业科技股份有限公司

Pesticide wastewater dephosphorizing agent

ActiveCN104098166AReduce phosphorus contentEasy to handleWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSorbentPhosphate

Owner:临安天川环保科技有限公司

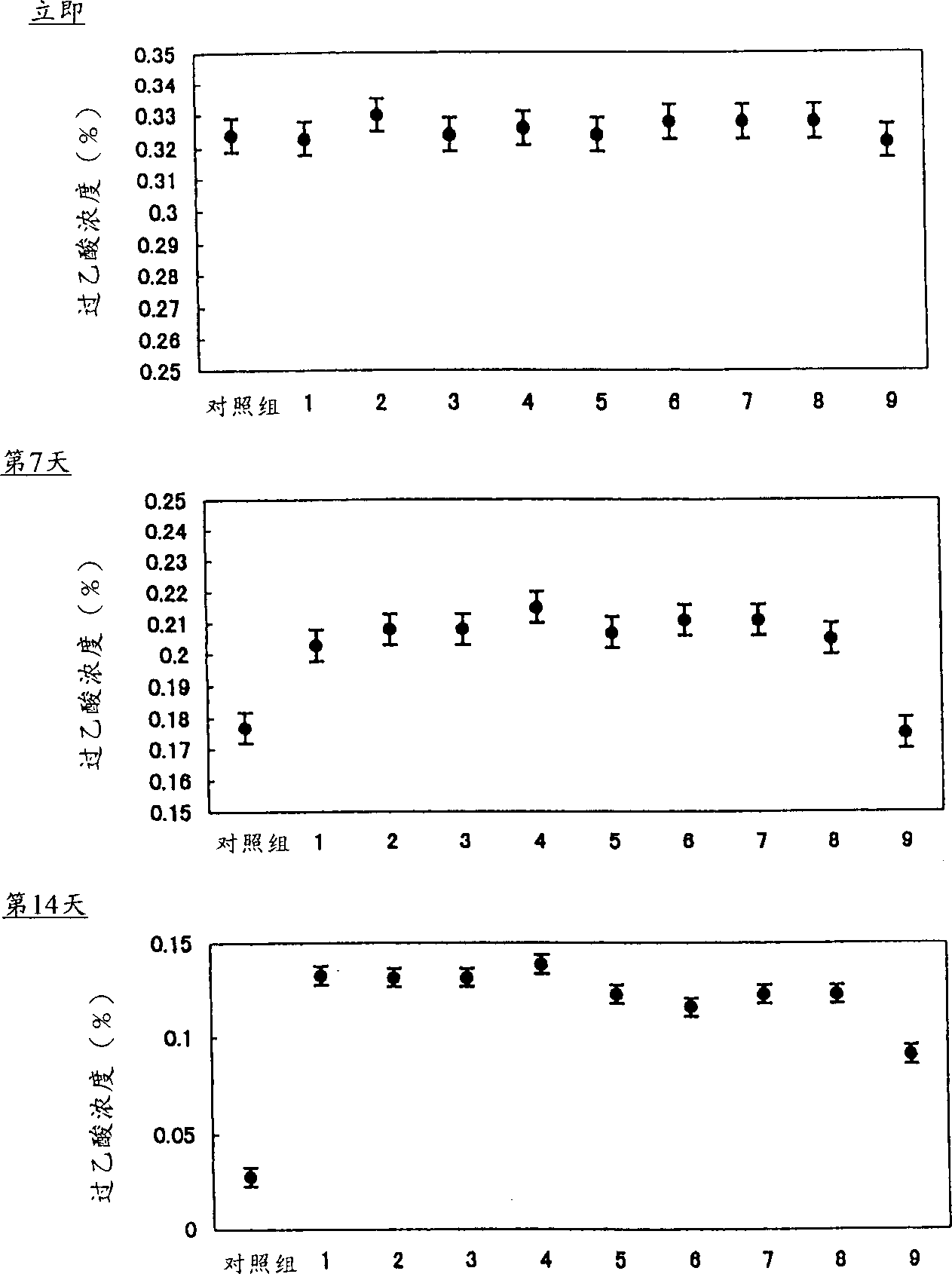

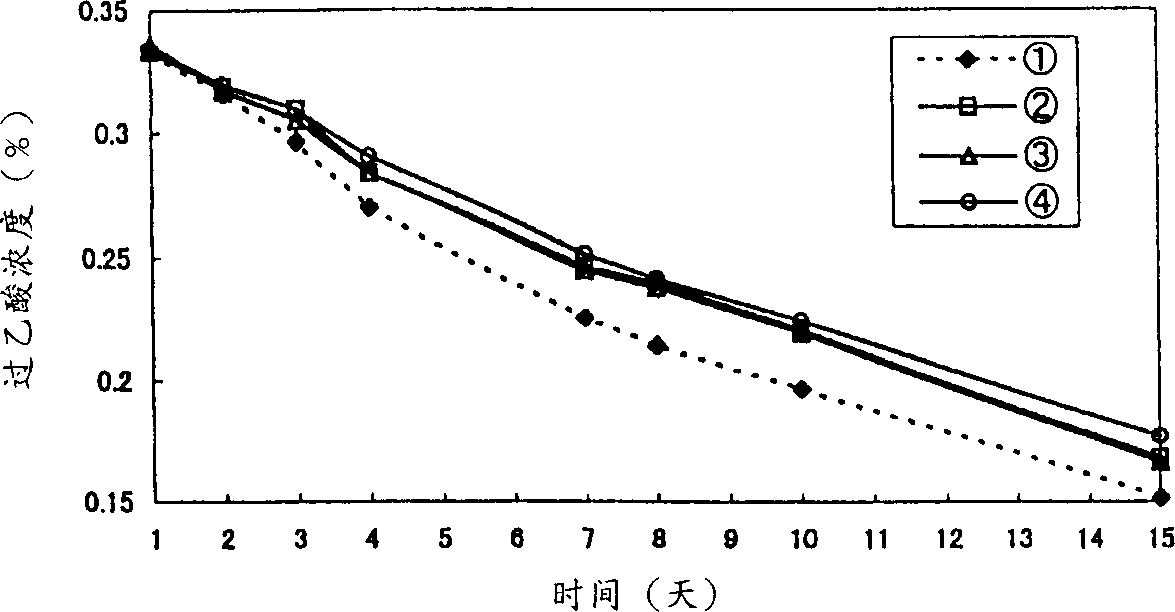

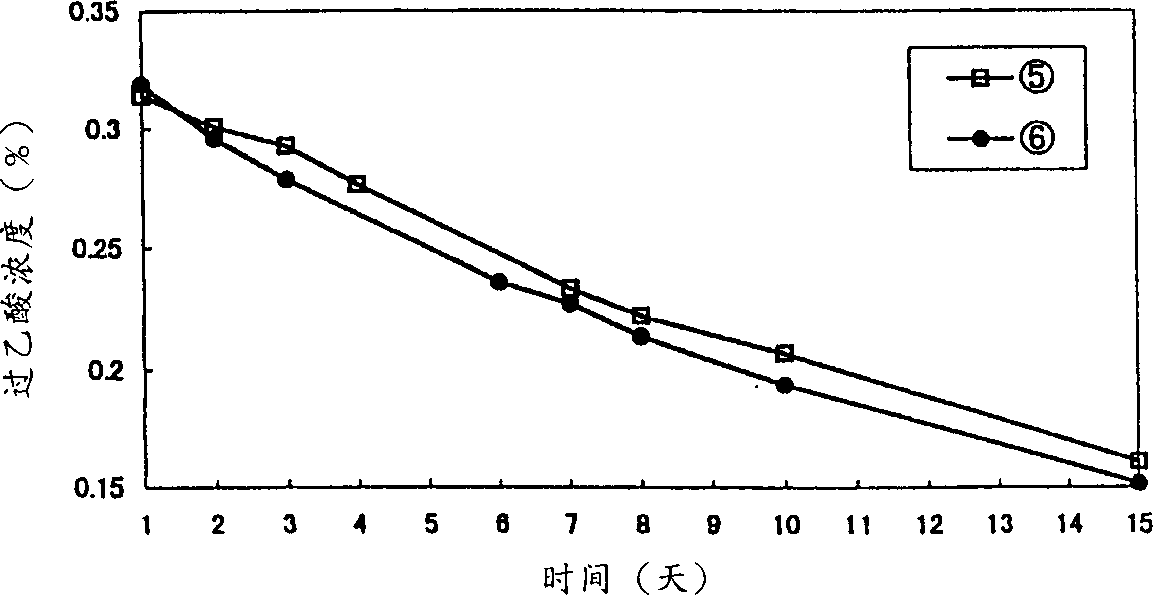

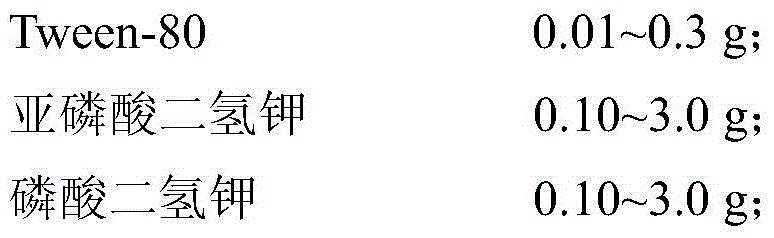

Bactericidal/disinfectant peracetic composition

A bacterial preparation including peracetic acid as a main component and including peracetic acid, at least one phosphate, and at least one nonionic surfactant. The preparation is diluted to provide a practical solution including peracetic acid in a concentration capable of destroying bacterial spores and acid-fast bacteria while maintaining the concentration of the practical solution for at least seven days.

Owner:更家株式会社

Flavored morchella raw fish and preparation method thereof

The invention discloses a flavored morchella raw fish which is prepared from the following raw materials in parts by weight: 90-110 parts of frozen tuna, 15-16 parts of lyophilized royal jelly powder, 22-24 parts of grape pulp, 8-9 parts of morchella, 5-7 parts of steamed bun, 9-11 parts of mango juice, 17-18 parts of walnut kernel, 7-8 parts of honey, 0.5-1 part of a mulberry root, 0.4-1 part of penthorum Chinese pursh, 1.8-2 parts of wax gourd seeds, 0.2-0.3 part of sodium glutamate, 0.1-0.3 part of ethyl maltol, 0.1-0.2 part of phosphate, 1-2 parts of lactic acid bacteria, 300mmol / L of CaCl2 solution, refined salt and a proper amount of sugar. The flavored morchella raw fish has the advantages of unique taste, long shelf life and good health effect; the flavored morchella raw fish is unfrozen by a pickling method and is pickled by an injection method; the technology is unique and novel; the value-added space and the extension benefits of the raw fish product are increased; and due to the addition of traditional Chinese medicine components such as mulberry root and penthorum Chinese pursh, walnut kernel is endowed with the health effects of moistening the lung for removing phlegm and clearing away heat and toxic materials.

Owner:合肥市韩林家庭农场有限公司

Delay-released inorganic nano antiseptic with high whiteness and its prepn

The antiseptic has nano level hydroxyapatite as carrier and added antiseptic metal salt accounting for 1-8 wt%. The crystal is granular and the antiseptic metal ions enter to the crystal lattice of hydroxyapatite. The preparation process includes the steps of dropping calcium nitrate solution into phosphate solution of pH value of 11-12 for reaction to produce hydroxyapatite, washing with water and deposition, stoving, crushing, high-temperature calcination, superfine crushing, etc. The product has high whiteness, fine grain size and delay released antiseptic effect. It may be used as the functional additive for fiber product, plastic, white household appliance, antiseptic building material, water treating agent, ship protecting agent, etc.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Phosphorus-solubilizing and potassium-solubilizing and nitrogen fixing organic functional fertilizer obtained by means of straw fermentation

InactiveCN104086336APossess the functions of phosphorus, potassium, nitrogen fixation, etc.The fermentation process is simpleFertilizer mixturesSodium BentonitePhosphate

The invention relates to a phosphorus-solubilizing and potassium-solubilizing and nitrogen fixing organic functional fertilizer obtained by means of straw fermentation. The fertilizer is prepared from the following components in parts by weight: 100 parts of straw chips, 0.03-0.04 part of a compound microbial agent for soil improvement, 05-2.0 parts of phosphate, 6-12 parts of coal ash, 5-10 parts of sepiolite, 5-15 parts of peat and 5-12 parts of bentonite. The fertilizer provided by the invention has the technical effects that (1) the straw raw material is pre-treated by using alkaline substances, so that the straw raw material is easier to ferment subsequently, and the fermentation efficiency is improved; and (2) a special microbial flora is adopted for compatibility, so that the fermentation efficiency is improved; the overall fermentation process can be completed by primary fermentation without conventional secondary or even third fermentation, so that the unexpected technical benefits and remarkable progress are gained. Therefore, the time and cost are greatly saved, the craft process is simplified, and the fertilizer is convenient to popularize and use, so that the economic benefit is improved.

Owner:JINGMEN FENGSHOU FERTILIZER IND

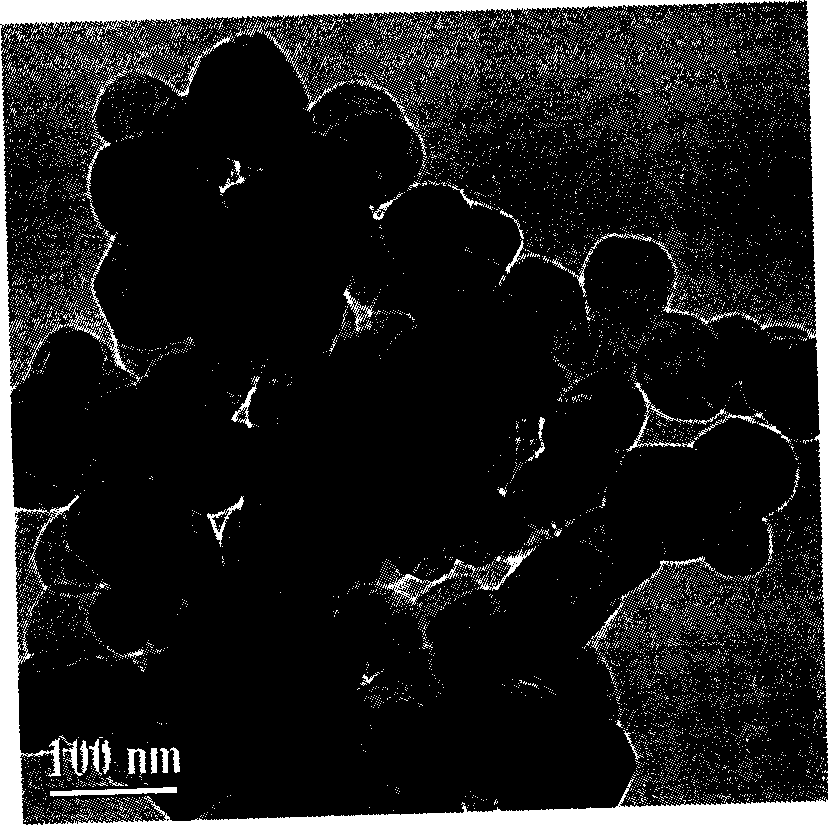

Method for preparing superfine composite inorganic antimicrobial agent

InactiveCN1653908AUniform particle sizeImprove the bactericidal effectBiocideAnimal repellantsPhosphateAntibiotic Y

The present invention is preparation process of superfine compound inorganic antibiotic. Technologically, the present invention is that silver ion as depositing crystal nucleus is coated with titanium or other metal ion obtained with urea as precipitant and phosphate as secondary coating, and re-compounded with surfactant, and through dewatering, drying, calcining at 700-1100 for 2-10 hr, superfine antibiotic powder is prepared. The prepared antibiotic powder has relatively high bacteria and fungi killing effect, is superior to available silver antibiotic and titanium antibiotic, and may be used widely in fabric, plastic, paint, enamel, water processing and other fields.

Owner:NORTHWEST UNIV

Preparation method of liquid fertilizer with humic acid-urea complex as matrix

InactiveCN102249814AAbundant resourcesEase of continuous industrial operationFertilizer mixturesPhosphatePeat

The invention provides a preparation method of a liquid fertilizer with a humic acid-urea complex as the matrix. According to the preparation method, a humic acid-urea complex aqueous solution is firstly prepared by using phosphate as an activator and using humic acid raw material coals and urea as the main raw materials, and then the humic acid-urea complex aqueous solution undergoes a reaction with other raw materials to prepare the humic acid-urea complex liquid fertilizer. The invention has the following advantages: the used humic acid raw material coals (weathered coal, brown coal and peat) are rich in resources, cheap and easily available; the preparation method provided by the invention has characteristics of short production process flow, simple equipment operation, no discharge of pollutants during the production process, no environmental pollution and low production cost, and is suitable for large-scale industrial production; the product provided by the invention has comprehensive nutrient elements and high content of water-soluble humic acid, is easy for crops to absorb, has conspicuous fertilizer effects, can be used to improve the soil structure, stimulate crops to absorb nutrients, promote the growth of crops, raise the drought resistance and stress resistance of crops, increase the output and enhance the crop quality.

Owner:谭钧

ELISA reagent kit for detecting two oxyethyl group thiophosphate organophosphorus pesticide

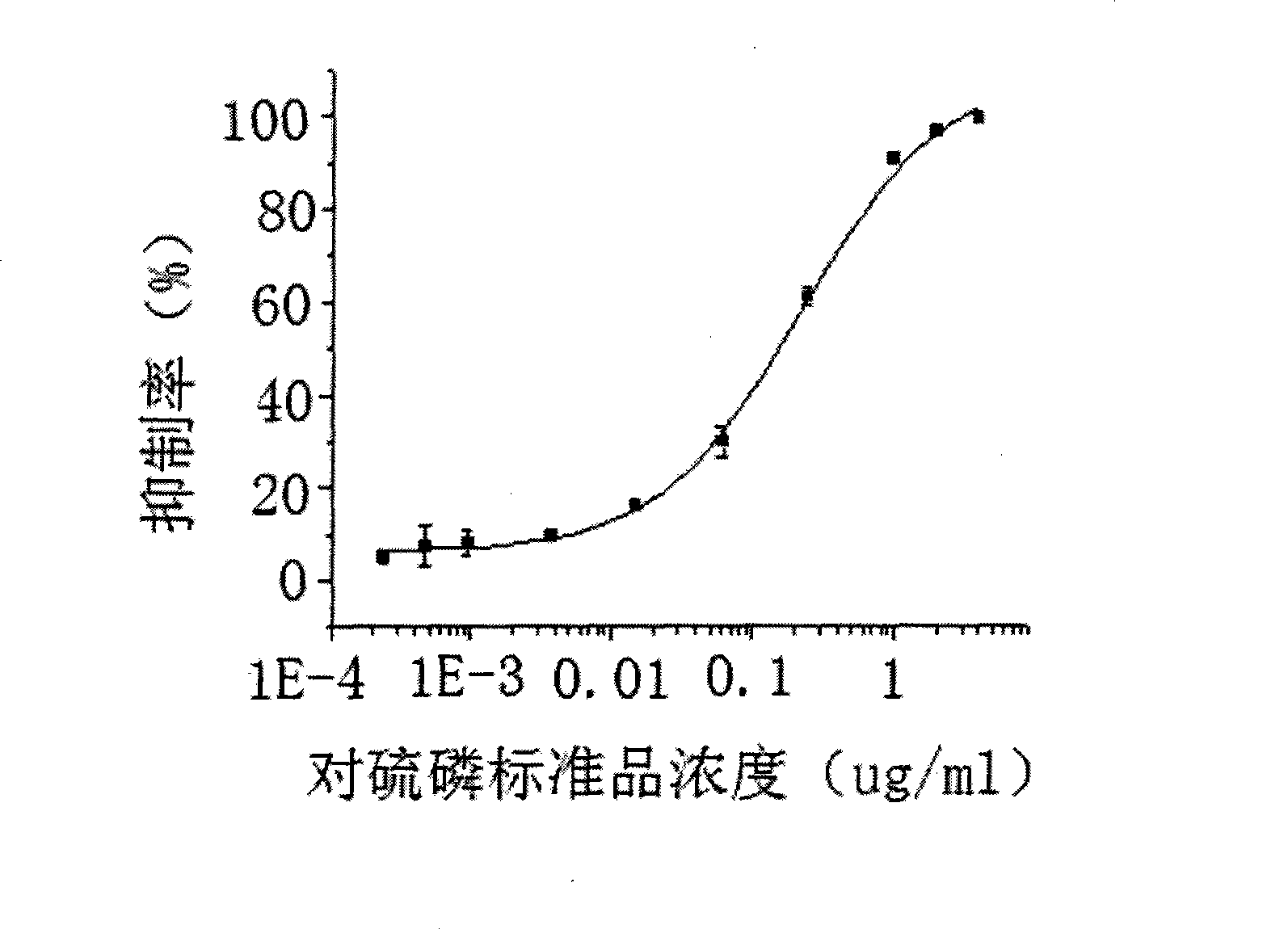

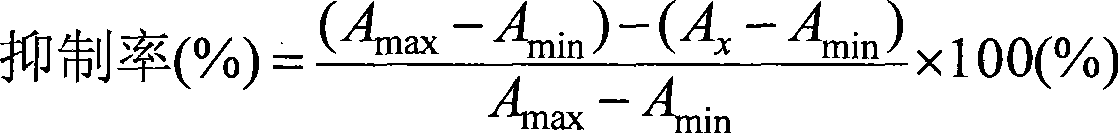

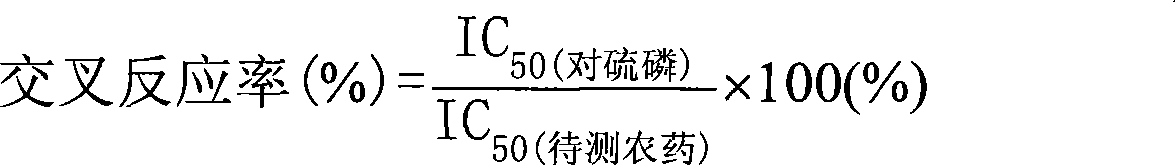

ActiveCN101477123AWeakened color reactionEnhanced color reactionMaterial analysisAntigenChlorpyrifos

The invention discloses an enzyme-linked immunosorbent assay kit for detecting diethoxy phosphorothioate organic phosphorus pesticide, which comprises a kit body, an ELISA plate coated with the antigen of the diethoxy phosphorothioate organic phosphorus pesticide, an antibody solution against diethoxy phosphorothioate organic phosphorus pesticide, a second anti-solution, a standard solution, a concentrated extracting solution, a substrate solution, a buffer solution of the substrate, a concentrated washing liquid and a stopping liquid. The organic phosphorus pesticide refers to the organic phosphorus pesticide containing the common structure of diethoxy phosphorothioate, in particular parathion, coumaphos, quinalphos, triazophos, phoxim, dichlofenthion, phorate, chlorpyrifos, bromophos ethyl, isazofos, diazinon, sulfotep and a mixture thereof. The enzyme-linked immunosorbent assay kit can be used to detect the organic phosphorus residues in fruits, vegetables, soil and water, and isconvenient in operation, high in sensitivity, low in price and is suitable for high-throughput screening monitored on spot.

Owner:SOUTH CHINA AGRI UNIV

Long after-glow phosphorescent material and preparation method thereof

InactiveCN102337127ALower crystallization temperatureImprove stabilityLuminescent compositionsAlkaline earth metalPhosphate

The invention discloses a long after-glow phosphorescent material and a preparation method thereof. The chemical formula of the long after-glow phosphorescent material is A3-x-y(PO4)2:xEu2+,yB, wherein A is one or more of alkaline earth metal ions of Ca2+, Sr2+ and Ba2+; B is one or more of Tb3+, Gd3+, Dy3+, Ce3+, Pr3+ and La3+; x is more than 0 and less than or equal to 0.3; and y is more than or equal to 0 and less than or equal to 0.3. The long after-glow phosphorescent material has stable performance, high waterproofness, moisture resistance and high-temperature resistance, and zero radioactivity and cannot harm human bodies and environment; moreover, the preparation method is simple, easy to implement, low in equipment requirement and environment-friendly.

Owner:佛山红狮陶瓷有限公司

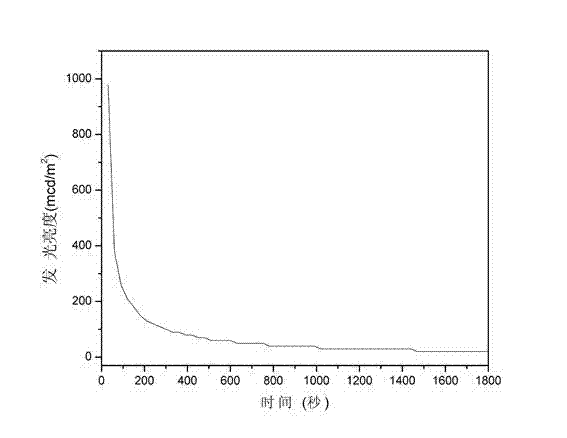

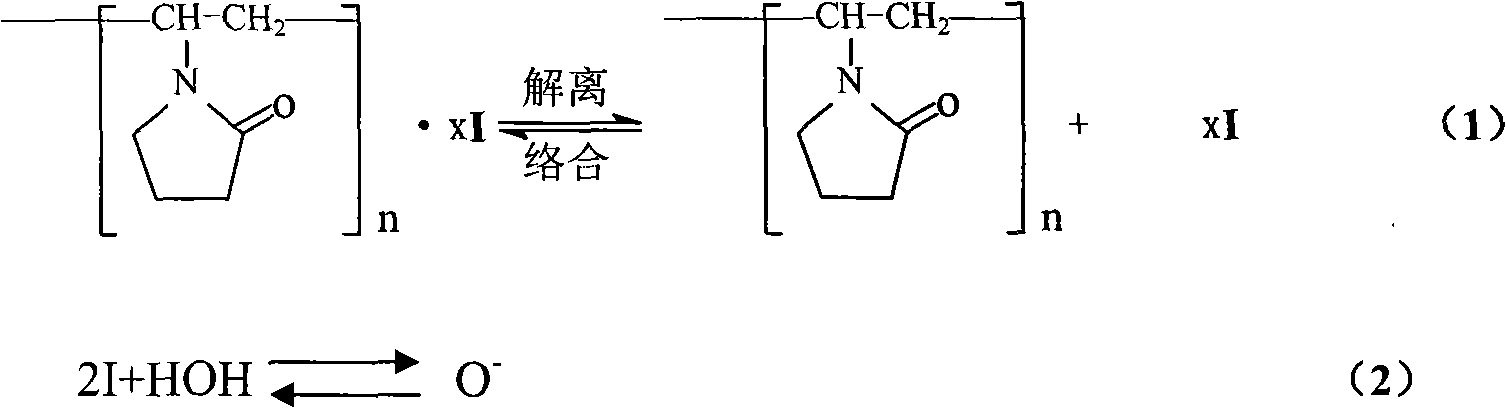

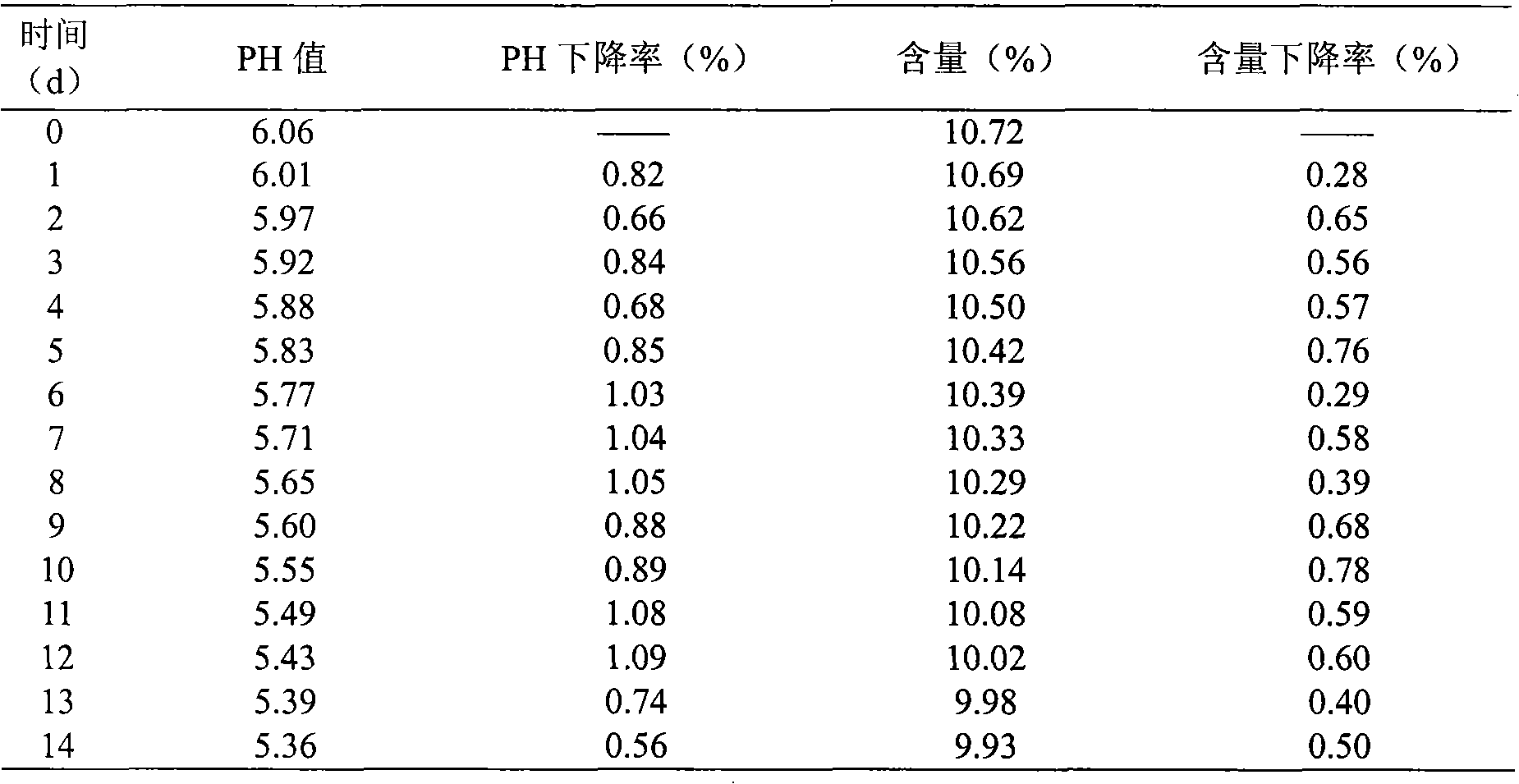

Stable type povidone iodine disinfectant and preparation method thereof

The invention relates to an iodine-containing disinfectant, in particular to a povidone iodine disinfectant and a preparation method thereof. The povidone iodine disinfectant is a stable type povidone iodine disinfectant which contains the following components according to percentage by weight (wt percent): 8.0 to 13.0 percent of the PVP-I, 0.5 to 1.0 percent of KIO3, 0.5 to 1.0 percent of KI,1.0 to 5.0 percent of glycerin, 5.0 to 15.0 percent of phosphate buffer and the margin is water. The preparation method of the stable type povidone iodine disinfectant comprises the steps as follows: a. the PVP-I and the KIO3 are dissolved in purified water; b. NaOH aqueous solution is used for adjusting pH to 6.0; c. the glycerin and the phosphate buffer are added into and stirred evenly; and d. the KI is added into and stirred evenly. The disinfectant can not only guarantee the stable iodine content of the povidone iodine disinfectant but also can guarantee the stable pH value of the iodine-containing disinfectant.

Owner:SHANGHAI LIKANG DISINFECTION HIGH TECH

Preparation method of sodium hyaluronate gel

InactiveCN102757570AReduce resistanceBiocompatibility effectsSurgeryProsthesisPhosphateBiocompatibility Testing

The invention discloses a preparation method of a sodium hyaluronate gel. The method comprises the steps that: (1) a cross linking agent is dissolved in an alkaline solution; a sodium hyaluronate raw material is added and dissolved; and the mixture is subjected to constant-temperature heating, such that a molded material is prepared; (2) the molded material is cut into blocks; the blocks are placed in a solution with physiological saline and phosphate with a certain ratio; and after 20-22h, a gel is prepared; (3) the obtained gel is subjected to particle grading by using a sieve, such that sodium hyaluronate gel particles are obtained; (4) a sodium hyaluronate raw material is added and dissolved in injection water, such that sodium hyaluronate hydrogel is obtained; (5) the sodium hyaluronate obtained in the steps (3) and (4) are mixed and cross-linked, such that a sodium hyaluronate gel is obtained; and (6) the obtained gel is sterilized under a temperature below 121 DEG C, such that the sodium hyaluronate gel is obtained. With the method, the prepared sodium hyaluronate gel is advantaged in relatively high thermal stability, relatively high degradation resistance, and good biocompatibility. The gel can swell in water, but cannot be dissolved. The gel has better rheological characteristic, and substantially improved mechanical strength.

Owner:颜先琴

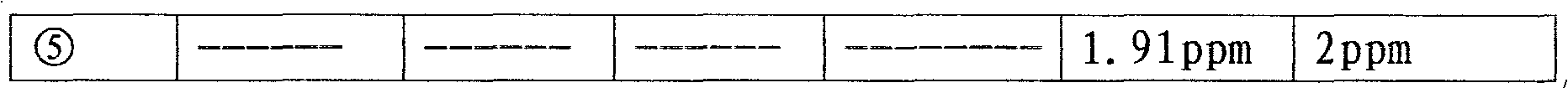

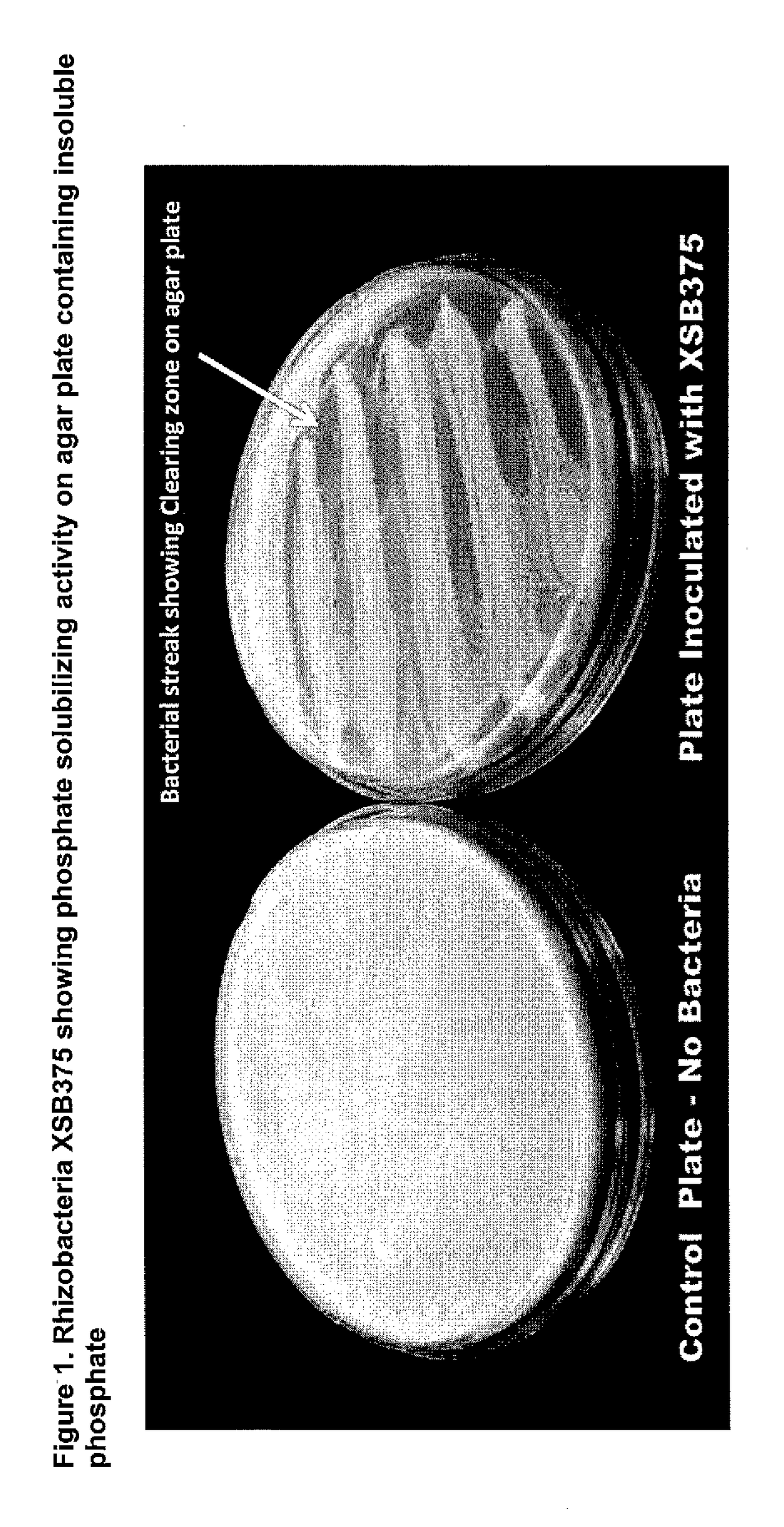

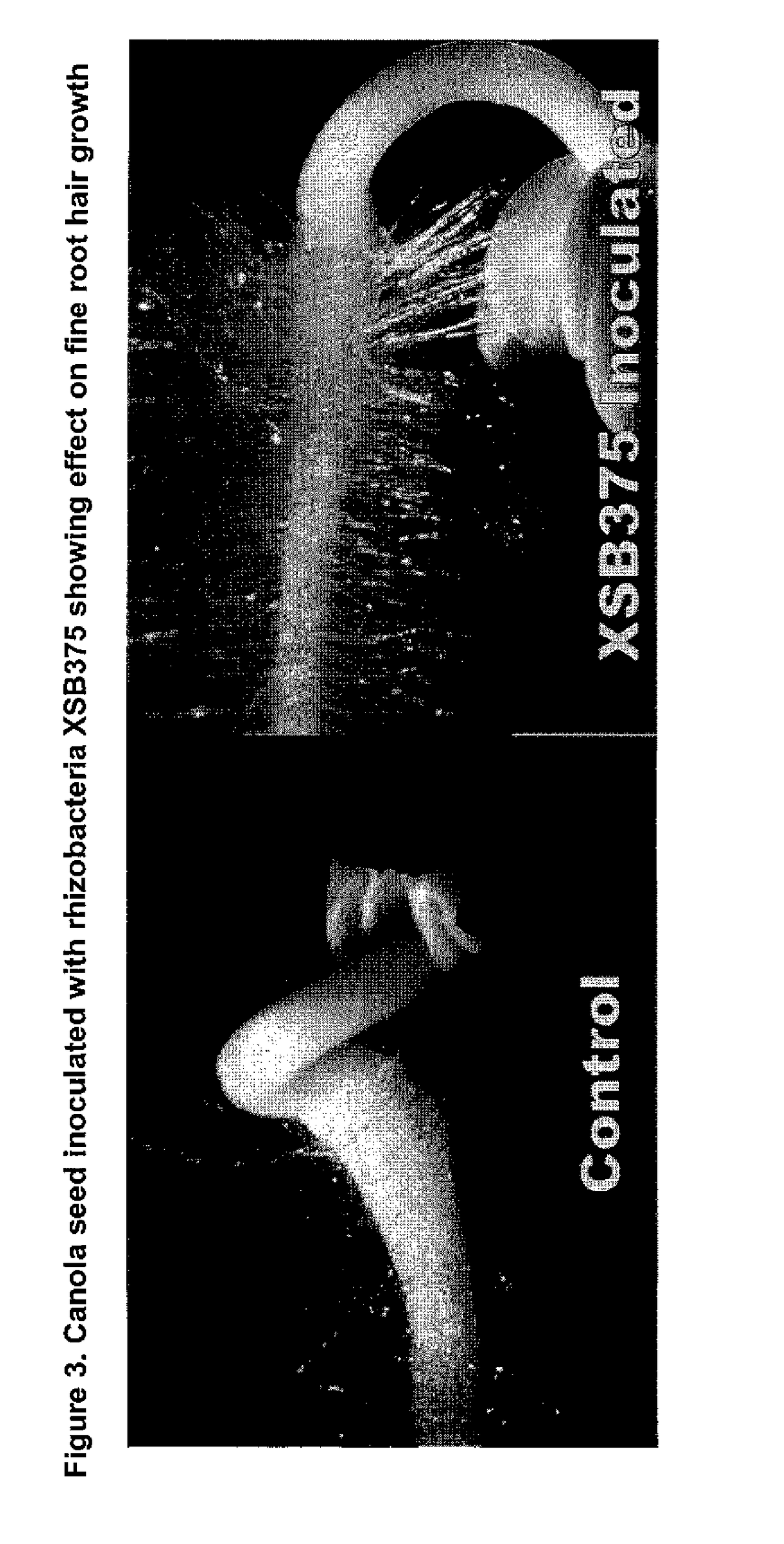

Phosphate Solubilizing Rhizobacteria Bacillus Firmus as Biofertilizer to Increase Canola Yield

A biologically pure phosphate solubilizing plant growth promoting rhizobacteria (PGPR) XSB375 was isolated from canola rhizosphere and identified as Bacillus firmus is provided herein. The PGPR is capable to solubilize phosphate that enhance plant available phosphorous. The PGPR XSB375 enhances seed germination, early emergence, plant vigor, root and shoot growth, and higher crop yield. This increased crop growth, development and yield is attributed from not only the greater phosphate solubilization making more available phosphorus to plant but also making other essential plant nutrients more available to the plant and the like. The application of this phosphate solubilizing PGPR can be done as liquid suspension or solid materials using onto soil, potting mix, seeds, seed pieces, seedlings, foliage, carrier materials, roots and planting soil.

Owner:XITEBIO TECH

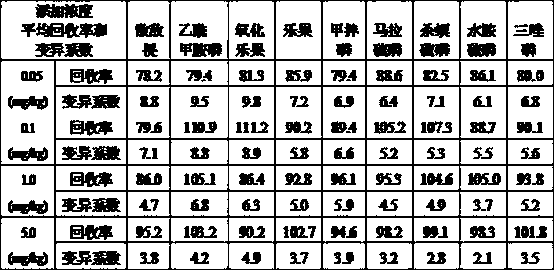

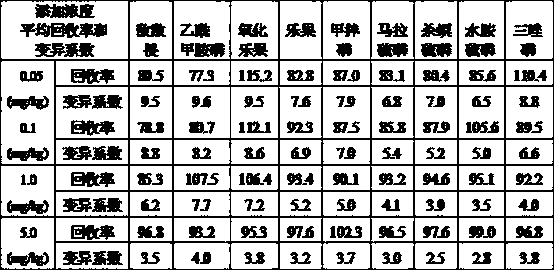

Gas chromatographic method for detecting residue amount of nine kinds of organophosphorus pesticide in rice

InactiveCN103472155AEasy to separateSimplified processing stepsComponent separationPesticide residueMalathion

The invention relates to a gas chromatographic method for detecting the residue amount of nine kinds of organophosphorus pesticide in rice. Qualitative and quantitative detection on the pesticide residues of dichlorphos, acephate, omethoate, dimethoate, phorate, malathion, fenitrothion, isocarbophos and triazophos is achieved. The gas chromatographic method is characterized in that acetonitrile is used as extractant, extracting solutions are concentrated through a gas blowing concentrator, and after volume metering is carried out through acetone, trace analysis is directly carried out on a gas chromatograph. The gas chromatographic method has the advantages that the separating effect of a chromatographic column on a target object is good, the detection result is high in accuracy, reproducibility is good, and method sensitivity meets the technical requirement of multi-pesticide-residue detection; compared with the method of GB / T5009.145-2003 national standards (the detection of multiple kinds of residues of organophosphorus and carbamates pesticide in plant food), the gas chromatographic method is simpler, simplifies the pre-processing processes of samples, shortens detection time, and saves cost.

Owner:邬金飞

Application of plant immune resistance inducer in prevention and control of damping-off and blight of cucumbers

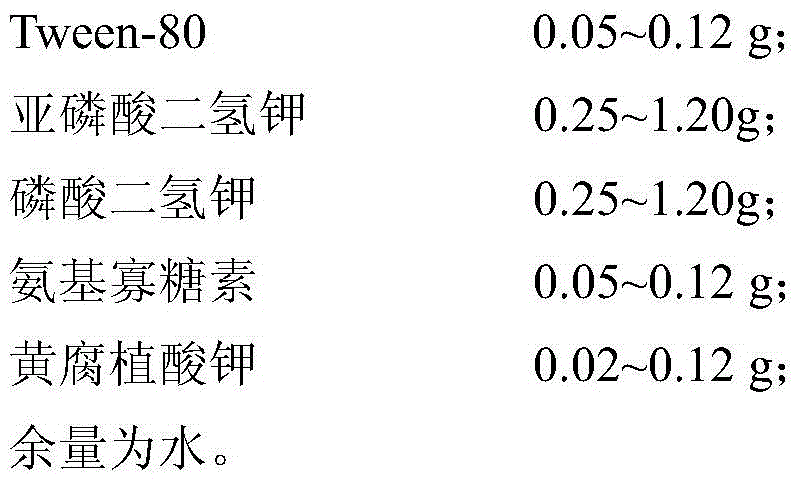

ActiveCN105660698AReasonable mix ratioGood control effectBiocidePlant growth regulatorsImmune resistancePhosphate

The invention discloses application of a plant immune resistance inducer in prevention and control of damping-off and blight of cucumbers. The plant immune resistance inducer is prepared from the following active ingredients in percentage by weight: 0.001 to 0.025 percent of amino-oligosaccharin, 0.01 to 0.25 percent of phosphite and 0.01 to 0.25 percent of phosphate. Each component of the immune resistance inducer obtained by combining the amino-oligosaccharin, the phosphite and the phosphate is mixed in a reasonable proportion, so that a good prevention and control effect on damping-off and blight of the cucumbers can be achieved, an emergence rate and a seedling rate of the cucumbers can be increased, and seedling quality of the cucumbers can be improved.

Owner:HANGZHOU ACAD OF AGRI SCI

Horseradish peroxidase magnetic nano flower and preparation method and application thereof

ActiveCN109234261AEasy to reuseIncrease contact areaWater contaminantsOxidoreductasesPhosphateMicrosphere

The invention belongs to the technical field of nanometer materials, in particular to a novel horseradish peroxidase magnetic nanometer flower and a preparation method and application thereof. The invention adds HRP into the configured phosphate buffer solution. And then the synthesized magnetic composite microsphere Fe3O4 + PMG + IDA-Cu<2+> is added into that reaction solution, the temperature ofthe thermostat is adjusted. And the reaction is continue for a certain time to obtain magnetic nano flowers; And was used to degrade bisphenol A pollutant. The enzyme activity and catalytic activityof the nano flower prepared by the invention are obviously improved. And the stability under different conditions is also obviously improved. And the enzyme activity can reach 183% of free enzyme; Degradation of more than 90% bisphenol A in 25 minutes is much better than that of free enzymes.

Owner:JIANGSU UNIV

Preparation method for gelatin/hydroxyapatite composite coating

InactiveCN106963984AImprove interface compatibilityImprove the disadvantage of poor affinityPharmaceutical delivery mechanismTissue regenerationPhosphateBiocompatibility Testing

The invention specifically relates to a preparation method for a gelatin / hydroxyapatite composite coating used for the surface of a bone tissue engineering scaffold. According to the invention, the composite coating is prepared through in-situ synthesis with a novel bone tissue engineering scaffold as a matrix material and gelatin, a calcium salt and phosphate as main raw materials; a calcium salt solution and a phosphate solution are added into a gelatin solution, and a composite coating solution is synthesized under the condition of heating; then the surface of the scaffold is subjected to amination and aldehydation modification; the gelatin / hydroxyapatite composite coating is finally loaded onto the surface of the scaffold; and since the surface of the scaffold is loaded with gelatin and nanometer hydroxyapatite, the defect of poor affinity between artificial synthetic high polymer materials and bone tissue is overcome, and the prepared scaffold can meet requirements of clinical medicine on cell affinity, biocompatibility and the like.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com