Preparation method of composite biomass improver for remedying heavy metal-polluted soil

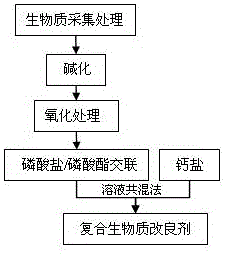

A technology for polluting soil and biomass, which is applied in the field of preparation of composite biomass modifiers, can solve problems such as weakened heavy metal fixation capacity, poor chemical stability, and huge biomass, and achieves strong heavy metal fixation capacity, low production cost, and high-quality preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take fresh rice straw, wash it with water, dry to constant weight, crush, sieve, and take 30-60 mesh rice straw for experiment. Mix a certain amount of rice straw with a sodium hydroxide solution with a concentration of 0.1 g / L, the amount of straw added is 20 g / L, fully react the mixed solution for 1 hour, filter it, and wash it with dilute hydrochloric acid and water until neutral. Mix and react with a solution of potassium permanganate concentration of 0.1g / L. After 2 hours of reaction, add 1.2 g / L sodium dihydrogen phosphate for cross-linking reaction. The temperature of the entire reaction system is 40°C. Rinse repeatedly until neutral. Composite with calcium salt by solution blending method, filter after the reaction is complete, rinse repeatedly with distilled water until neutral, and dry for later use. The prepared modified adsorbent and the prepared Cd-containing 2+ Solution mixing, Cd 2+ The concentration is 500mg / L, the pH value of the solution is 5.68, an...

Embodiment 2

[0022] Wash the corn stalks with water, dry them at 65°C to constant weight, crush them, sieve them, and take 30-60 mesh corn stalks for testing. Mix a certain amount of corn stalks with a sodium hydroxide solution with a concentration of 0.1 g / L. The amount of corn stalks added is 20 g / L. After fully reacting the mixed solution for 1 hour, filter it and wash it with dilute hydrochloric acid and water until neutral. Add 100mL of distilled water to the alkalized corn stalks, and then pass through ozone gas. After reacting for 15 minutes, add concentrated phosphoric acid in an amount of 0.15 mL of phosphoric acid / g corn stalks, and then place it in a water bath at 60°C for 1 hour and then filter. Rinse repeatedly with distilled water until neutral. Composite with calcium salt by solution blending method, filter after complete reaction, wash with distilled water repeatedly until neutral, dry for later use. Take the wastewater from the acidic reservoir effusion pool of a copper m...

Embodiment 3

[0024] Fresh rice straws were taken, rinsed, dried at 65°C to constant weight, crushed, sieved, and 30-60 mesh straws were taken for testing. Mix and soak a certain amount of rice straw and sodium hydroxide solution with a concentration of 0.1 g / L, the straw addition amount is 20 g / L, filter after soaking for 2 hours, wash with dilute hydrochloric acid and water until neutral. Then the alkalized rice straw was mixed with hydrogen peroxide solution, and the concentration of hydrogen peroxide was 2% (v / v). After 2 hours of reaction, 1.92 g / L disodium hydrogen phosphate was added for cross-linking reaction. After 2 hours of reaction at 25°C, the Composite with calcium salt by solution blending method, filter after complete reaction, rinse repeatedly with distilled water until neutral, dry for later use. A 16-week soil cadmium remediation test was carried out on the improver. The amount of the improver added was 5% (mass ratio). During the test period, the exchangeable Cd in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com